LIJIANG Glass Machine

The One-stop Solution, Professional Manufacturer and Vendor for Glass Processing Machine.

Automatic Insulating Glass Series Equipment

Who We Are

LIJIANG Glass manufactures professional glass processing equipment, including insulating glass machines, glass cutting machines, laminated glass cutting lines, IG production lines, washing machines, sealing robots, and tempering furnaces. Our equipment meets CE certification standards and our company is a Siemens Control Cabinet Authorized Partner, ensuring reliable automation and stable performance. Serving customers in 100+ countries, we provide efficient solutions that help glass factories improve productivity and competitiveness.

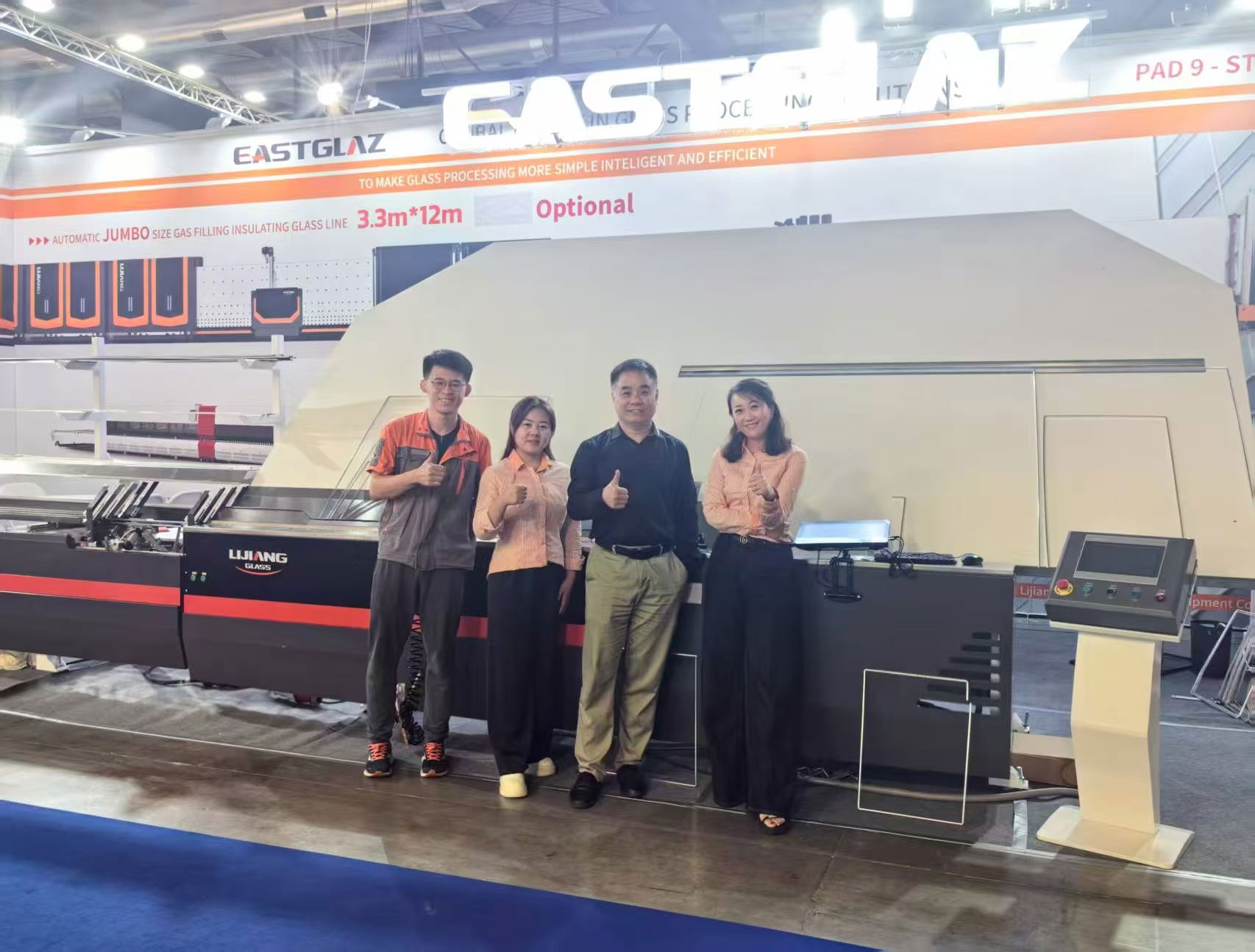

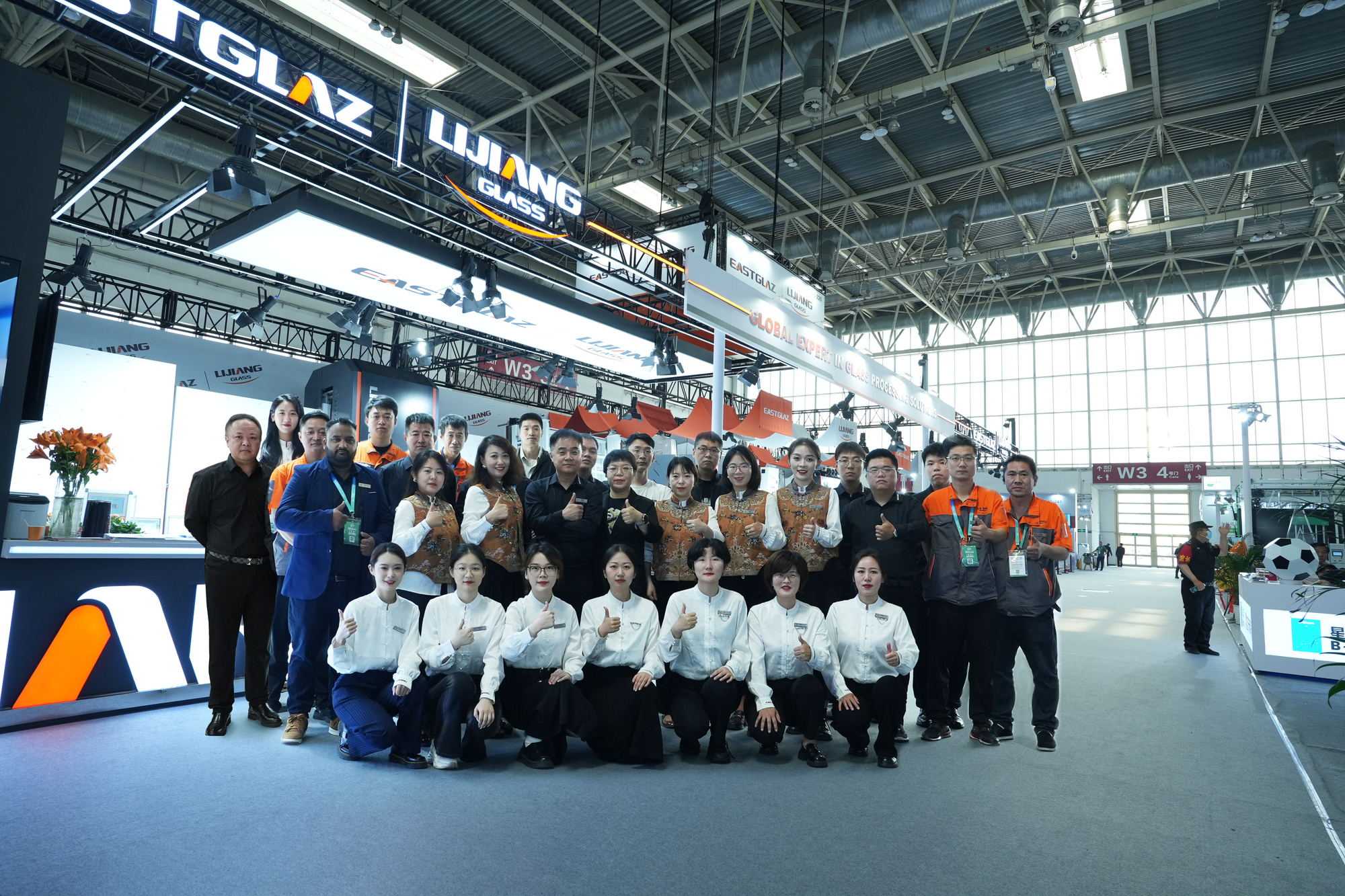

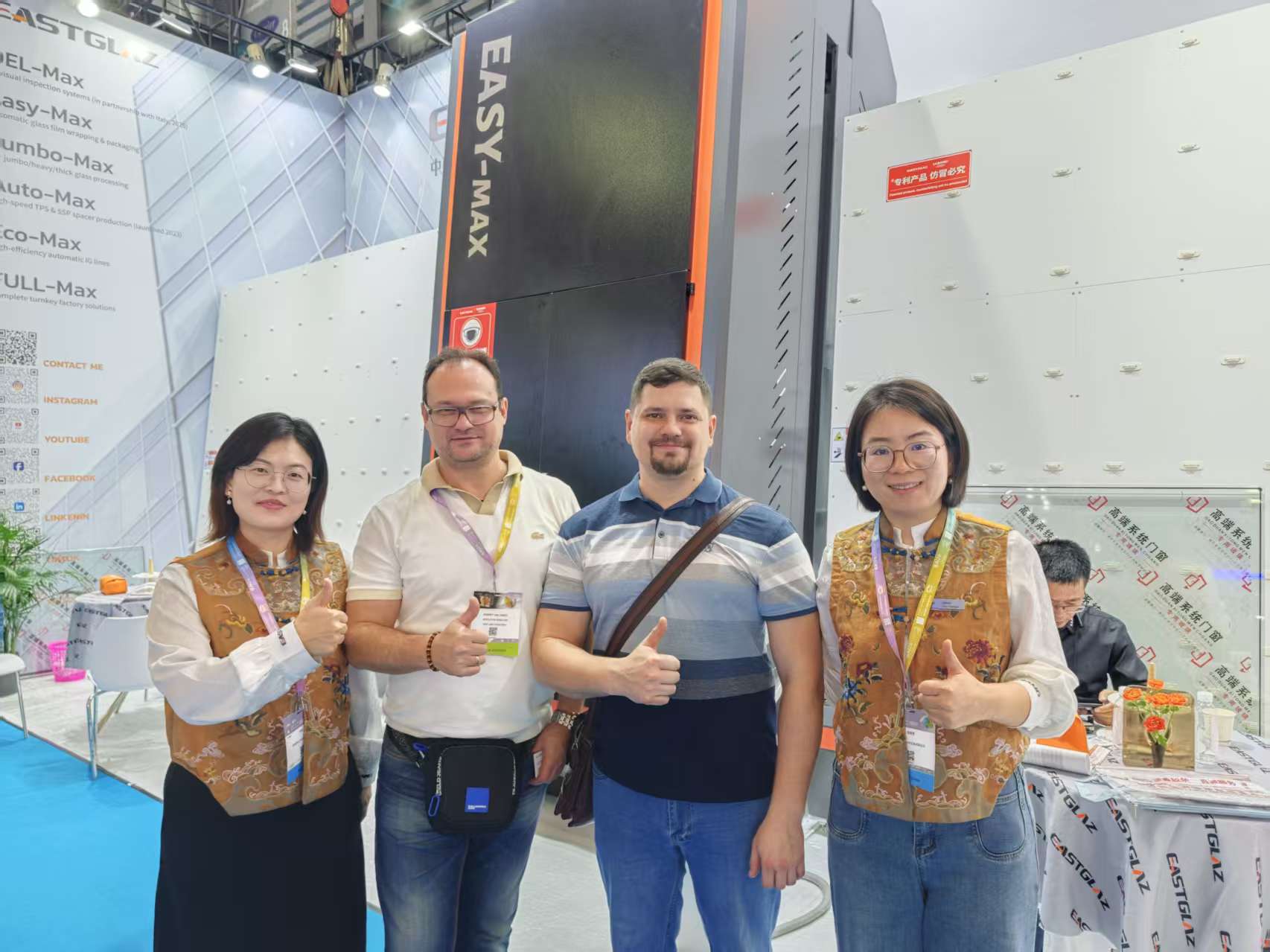

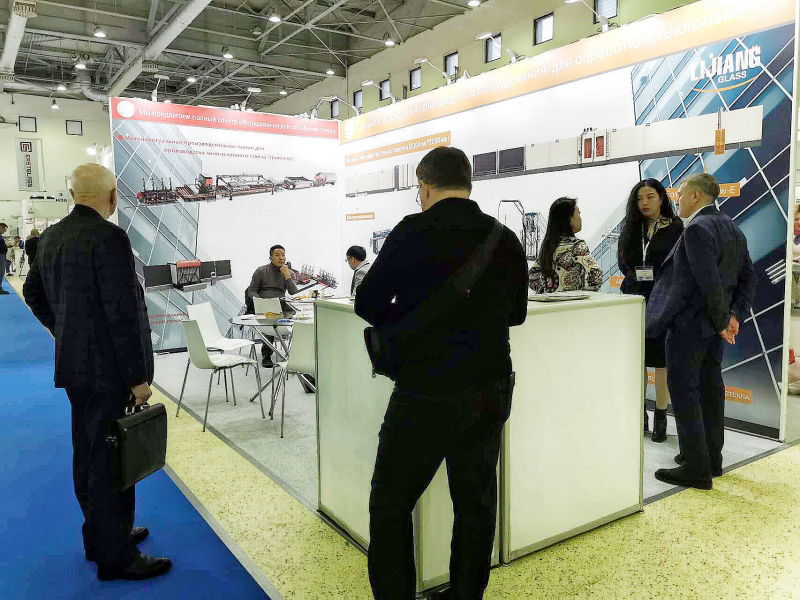

More Glass Process Fairs and Exhibitions

Feature Stories & Articles

LJ Glass Machinery completed the on-time shipment of high-quality glass processing machines, providing reliable and efficient solutions for glass factory production lines.

READ MOREHigh-Quality Automatic Glass Machinery Spare Parts & Accessories

LIJIANG Glass's growth is inseparable from the long-term support of our business partners, including spindles from motors from Japan Yaskawa, and inverters from Taiwan Best. All machine pumps are from Taiwan Delta Electronics, Electric accessories are from Germany Schneider, and controllers are from Germany Syntec technology...

Contact Us

- Greenland Central Plaza, Huaiyin District, Jinan City

- Room 1307, Block B, Greenland Central Plaza, Huaiyin District, Jinan City

- +86-18678875966 - www.LJGlassMachinery.com

- lijiangglass.cn@gmail.com

- Mon-Fri - 08:00-19:00

www.LJGlassmachinery.com is not only a professional glass machinery manufacturer and solution provider for the glass processing industry...