LJWQ-1600 Automatic Horizontal Glass Washing and Drying Machine

LJWQ-1600 Automatic Horizontal Glass Washing and Drying Machine used for washing and drying the upper and lower surfaces of ordinary plate glass and high quality Low-E glass, it is composed of incoming segment, washing air-drying segment and out going segment.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LJWQ-1600 Automatic Horizontal Glass Washing and Drying Machine

Structural Characteristics

The Imported Components

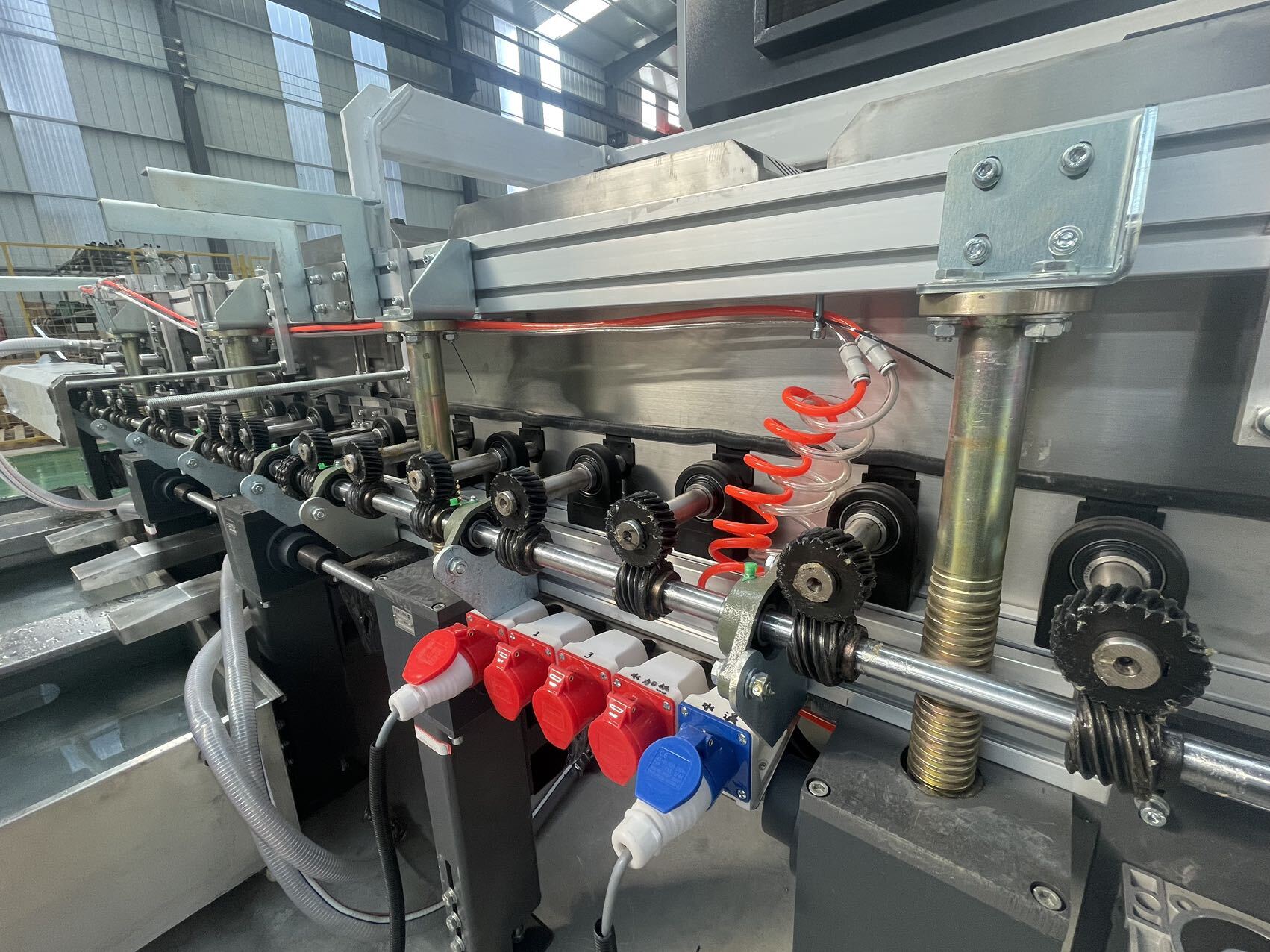

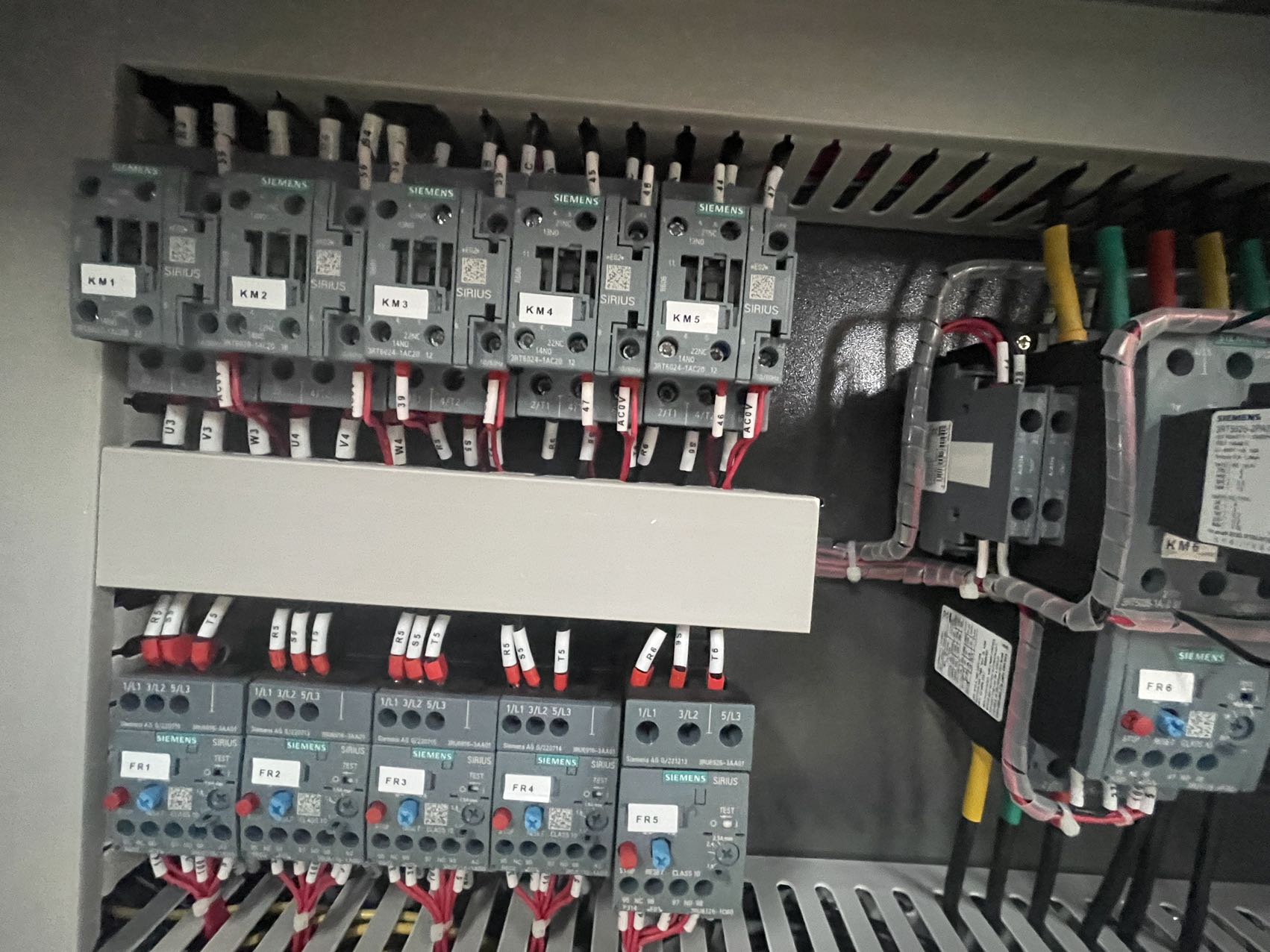

Figure 1 Using the imported components and PLC system of the LJWQ-1600 Horizontal Glass Washing Machine

Figure 1 Using the imported components and PLC system of the LJWQ-1600 Horizontal Glass Washing Machine

The 3 Pairs of Rubber Rollers

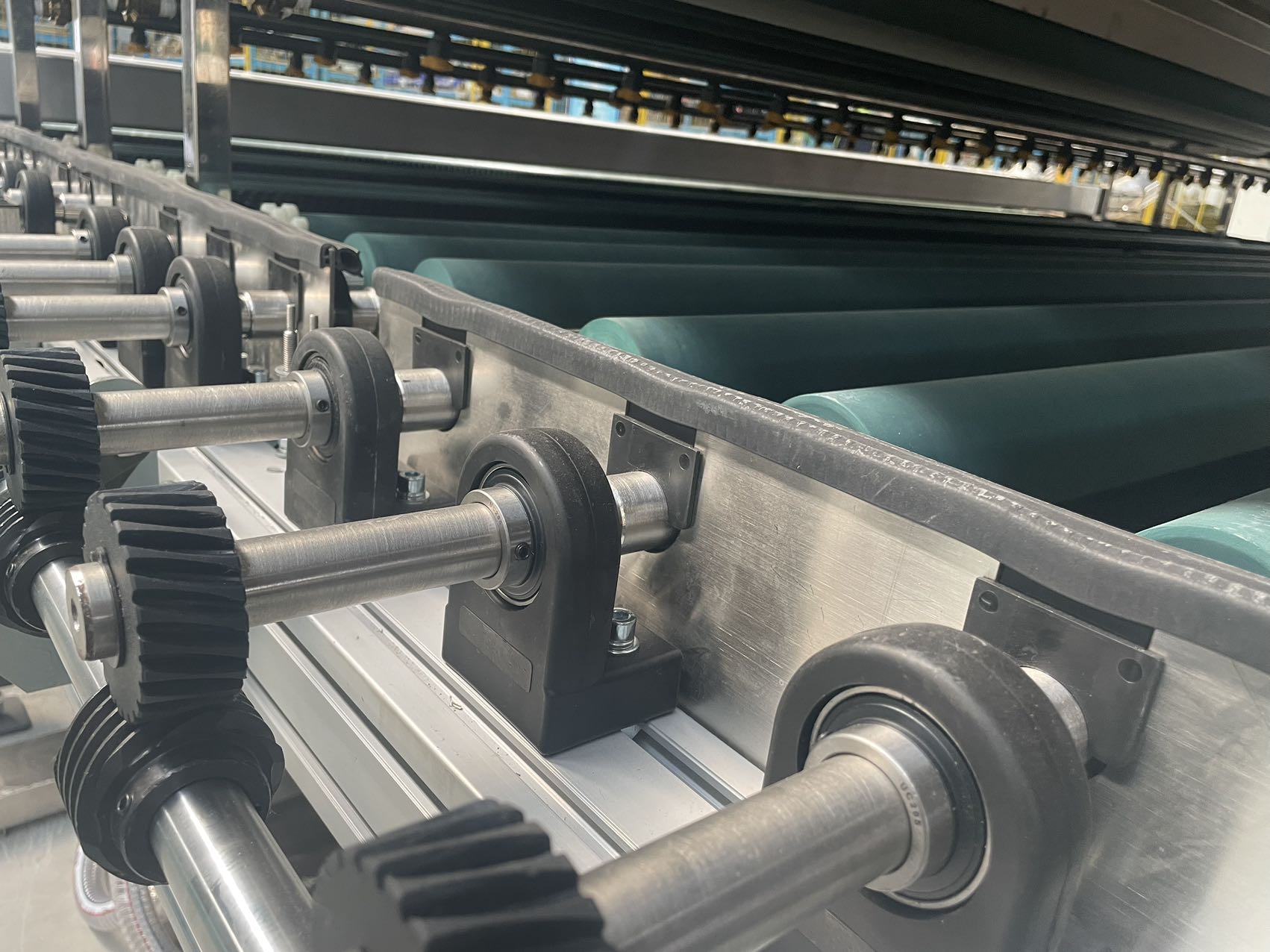

Figure 2 LJWQ-1600 Horizontal Glass Washing Machine equipped with 3 Pairs of Rubber Rollers

Figure 2 LJWQ-1600 Horizontal Glass Washing Machine equipped with 3 Pairs of Rubber Rollers

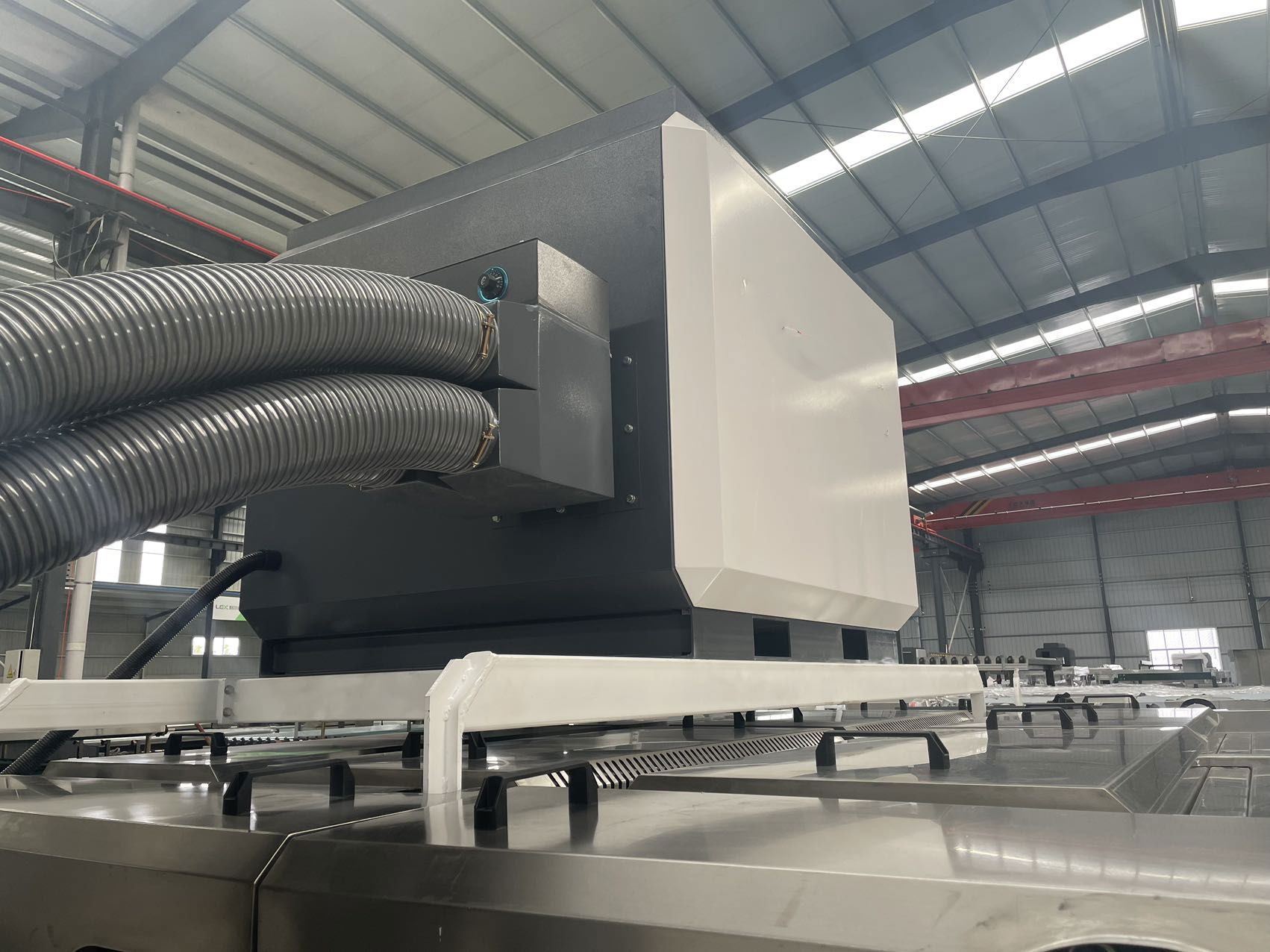

The High-power Fan

Figure 3 LJWQ-1600 Horizontal Glass Washing Machine equipped with a high-power fan

Figure 3 LJWQ-1600 Horizontal Glass Washing Machine equipped with a high-power fan

The Gradient Pressing Method

Figure 4 Using the Special Pressing Method of the LJWQ-1600 Horizontal Glass Washing Machine

Figure 4 Using the Special Pressing Method of the LJWQ-1600 Horizontal Glass Washing Machine

Main Technical Parameter

| Item. | Spec. |

| Maximum glass width | 2500mm (effective maximum: 2650mm) |

| Minimum glass specification | 400mm*400mm (limited to single row on left and right sides) |

| Glass thickness | 3mm-25mm (digital display) |

| Speed range | Glass thickness within 3-25mm Vmax=1-12m/min |

| Main drive, brush speed regulation method | Frequency control |

| Table height | 900±25mm |

| Total power | 42Kw(water-bearing wind heating: 15Kw) |

| Water source | Self-circulation, tap water (according to civil water standards) and deionized water water supplement deionized water equipment shall be provided by the buyer) |

| Power source | 380V 50Hz |

| Dimensions (length*width*height) | Approximately 6260mm*4800mm*3100mm |

| Weight | 3940kgs |

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

How to prevent the horizontal glass washing machines stuck to glass?

(1) Do not put glass exceeding the thickness limit of the washing and drying machine.

(2) When loading the film, the distance between the glasses should be large enough.

(3) Do not washing the area smaller than the minimum size specified by the equipment and the roller brush. If the glass is stuck or abnormal, stop the machine immediately to eliminate it.

(4) When washing narrow and long glass or glass with small sizes, the long side should be placed along the forward direction.

What are the defects that are prone to occur during the glass washing and drying?

(1) Edge burst: The transmission and clamping system problems cause the glass to collide in the washing machine.

(2) Scratches: There is broken glass under the washing machine and stacked sheets are stacked during operation.

(3) Unclean: the water tank is not changed in time, and the water quality is not clean; too much glass powder is stained on the brush; the air-drying section is not filtered or the filter is not clean, and the dust content is large.

(4) Blowing is not dry: the air volume and air pressure are not enough, and the air knife or blowing angle is not suitable.