Automatic Glass Cutting Machine

Affordable Automatic Glass Cutting Machines for Every Budget in 2025

LIJIANG Glass supplies automatic glass cutting machines with loading table systems, offering reliable performance, flexible configurations, and cost-effective solutions for glass factories of all sizes.

Lijiang Glass offers high-quality, budget-friendly glass cutting machines for commercial, industrial, and architectural glass processing. Our 2025 automatic CNC glass cutting machines are trusted by glass factories, manufacturers, and workshops worldwide, including the USA, UK, UAE, Canada, Australia, Russia, South Africa, China, and India, as well as Asia, Europe, North America, South America, Africa, and Oceania. We provide custom glass cutting, washing & drying, loading & unloading, tempering, and insulated glass production lines to maximize efficiency and precision in every glass project.

Automatic Glass Cutting Machine Buying Guide

The LIJIANG Glass Buying Guide are here for you -- there are our go-to recommendations for ultimate question: What kinds of automatic glass cutting machine or glass cutting line should you buy? There is a collection of buying guides by category.

The correct operation steps of the glass cutting machine

When we use a automatic glass cutting machine, we must check the glass to be cut in advance. As for the appearance of the glass, we cannot have the appearance of white spots and scratches. Only after the most basic conditions are qualified can mass production be carried out. When measuring, the front row should be the measurement object, and a full inspection should be done if necessary.

Know More

What is the performance characteristics of automatic glass cutting machine

How many features and advantages does the automatic glass cutting machine have, as should know as a senior practitioner in the glass processing industry, simply disassemble the entire glass cutting equipment, and analyze the performance characteristics of the glass cutting machinery from the perspective of mechanical, electrical and PLC control systems...

Know More

How to choose the automatic glass cutting machine equipment?

With the development of the glass market in some developing countries, automated glass machinery and equipment have also developed. Among them, glass cutting machines have gradually matured, and there are countless manufacturers. As a glass production enterprise, how should we choose the glass cutting equipment that suits us?

Know More

One article unlocks! Various application scenarios of architectural glass cutting table

Don't miss it! This article comprehensively shows how building glass cutting machines display their extraordinary capabilities and complete exquisite cutting in various building scenarios.

Know More

Automatic Glass Cutting Table | An Efficient Solution for Straight and Shaped Cutting of Float Glass

The automatic glass cutting table is a high-efficiency machine for straight and shaped float glass cutting. Its compact design fits workshops and production lines of any size. Equipped with CNC control and precision cutting technology, it handles glass from 2–19 mm thick with ±0.15 mm accuracy, ensuring smooth edges and precise dimensions. With automatic loading, layout optimization software, and fracture detection, it boosts production, lowers labor costs, and reduces waste. Ideal for architectural, appliance, curtain wall, or decorative glass, it offers a stable, efficient, and low-maintenance cutting solution.

Automatic Glass Cutting Equipment

Choosing the right automatic glass cutting machine is one of the most important decisions for any glass manufacturer. With so many options on the market—each promising precision, speed, and performance—it can be difficult to identify which equipment truly meets your production needs. In this guide, we’ll walk you through the key factors and four proven steps to help you purchase the best glass cutting equipment for your workshop or industrial plant.

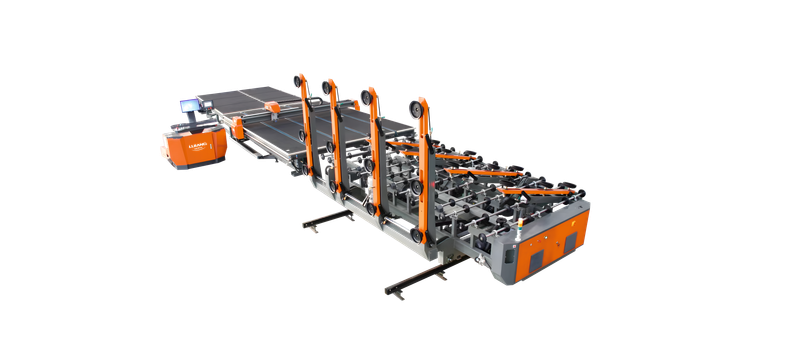

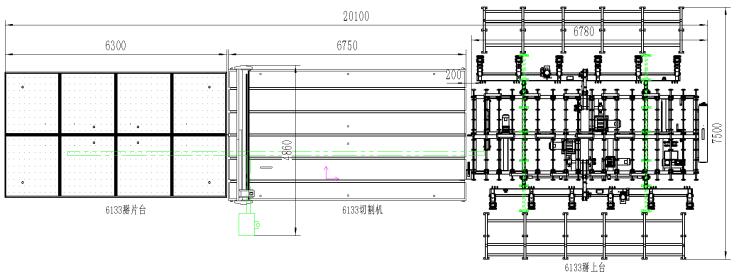

Fully automatic glass feeding, cutting and breaking connection line

Fully automatic glass feeding, cutting and breaking connection line Each action can be completed independently or can be used for normal work.After giving the loading signal (manual and automatic), the arm turns upward about 95 degrees through the overturning mechanism, and the whole machine starts to move forward.

When the induction device on the arm touches the glass, the whole machine stops walking.The vacuum system works, the glass is sucked by the sucker through vacuum systems. When the vacuum pressure reaches the set pressure, the vacuum pump stops. The sucker's telescopic connecting rod mechanism lifts the glass back and up 80 mm through the arm-lifting motor.

Stopping for about 1.5 seconds to make sure the glass is sucked up, the big arm driven by a motor to reverse the glass to the transmission roller. The suction cup under the glass begins to blow, and the telescopic connecting rod mechanism makes the suction cup and the glass fall at the same time.

When the glass falls on the conveyor roller, the small arm continues to fall, the glass is separated from the suction cup, and the conveyor starts to send the glass sheet to the front end of the loading machine and stop at the signal point.Then the whole frame moves automatically to find the zero position and stops.

Waiting for the signal from the cutting table, the glass can be sent to the cutting table at the same speed as the conveyor belt on the cutting machine. After the glass is sent out,automatically repeat the work cycle. The machine can select any position according to the required glass thickness.

- Sheet size: Min size: 2400*1500 mm (Single Side loading)

- Max loading size: 6100* 3300 mm

- Glass sheet thickness: 3 ~ 19 mm

- Working absorption depth: 700 mm

- X-axis walking speed: 5-25 m/min (adjustable)

- Y-axis walking speed: 8-12 m/min (adjustable)

- Conveying speed: 5-25 m/min (adjustable)

- Number of flip arms: 12 arms (double side loading)

- Number of single arm suckers: Three

- Loading type: Double side loading

- Working cycle: 60 S (30 S for each additional position)

- Installation power supply: AC 380V/50Hz (special circumstances can be adjusted according to customer requirements)

- Installation total power: 8-17 kw

- Compressed air: 0.6-0.8 Mpa;

- Vacuum: -50-99 Kpa (adjustable according to glass thickness)

- Working table height: 900 + 20 mm

- Machine size: 4650*2980*900 mm

- The alarm system: with reliable vacuum detection device, to appear abnormal situation can be automatic alarm and display, can be used to control when abnormal and confirmed The vacuum alarm when abnormal and guarantee under the glass in the vacuum state; When the emergency stop to ensure the vacuum suction cups in a glass in the vacuum state, avoid Avoid glass damage due to abnormal downtime;

- The operation pattern: the device has automatic mode and manual mode two functions for selection, operation convenient and intuitive;

- The operating interface: LCD touch-screen display, Chinese display, convenient operation;

- The main frame, and steel structure all use international quality rectangular pipe compound links and bolt assembly; Rectangular steel tube thickness: over 3-8 mm;

- The material of the machine has been aged, the surface has been rust-removing technology to remove rust spots and surface oxide layer, the bottom layer has been sprayed with high-grade epoxy primer, and the surface has been sprayed with high-gre automobile paint.

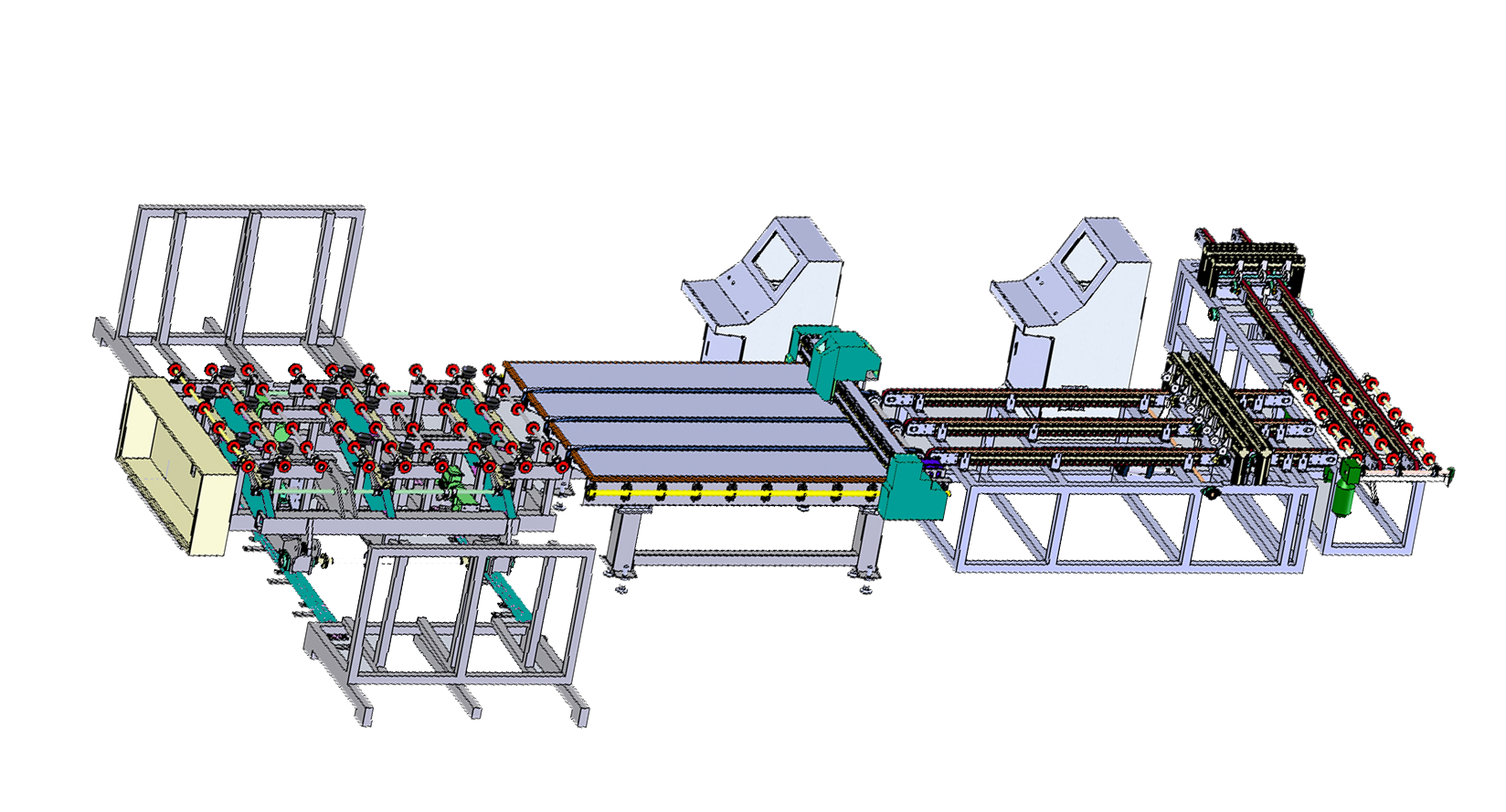

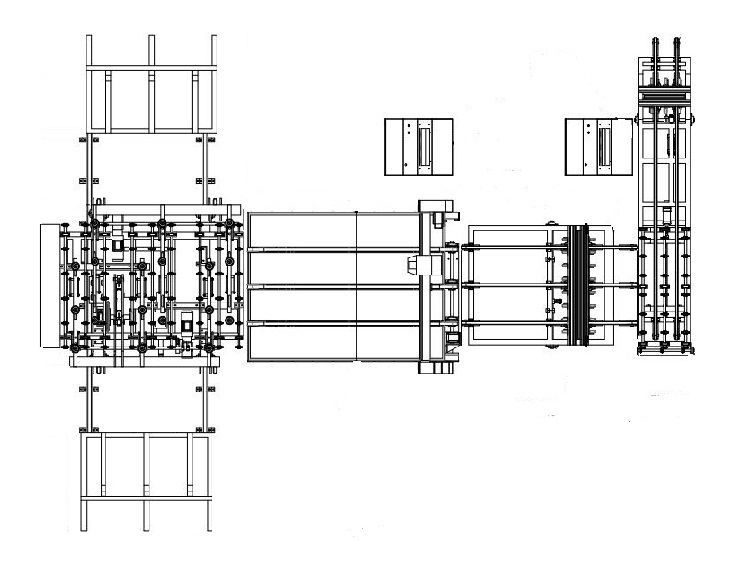

Fully automatic glass feeding, cutting and breaking connection line

Fully automatic glass feeding, cutting and breaking connection line - The chassis material is welded and formed by the national standard manganese-containing section bridge steel (Q345A) after aging treatment. The comprehensive mechanical properties, plasticity and welding properties of this kind of steel are good. The frame is processed as a whole, and the stability and accuracy of the equipment are greatly improved by tempering aging treatment to ensure the stability of the product. After special rust removal process, the surface rust spots and oxide layer are removed. The top coat is sprayed with high-grade epoxy primer and the top coat is sprayed with high-grade automobile paint.

- Through the analysis of professional structure software, the equipment ensures the stability, dynamic balance, mechanical strength to achieve the most perfect match, and ensures that the structure of the table is not deformed.

- The device has one key reset function. It can complete all the preparations before starting automatically by clicking on the touch screen, which greatly improves the work efficiency.

- Reasonable arrangement of integral cables and gas pipes and complete sealing

- High-speed silent linear guide is adopted for guide rail, which has high cutting accuracy and low noise.

- Advanced Japanese Ankawa servo motor is used in the driving part, which makes the equipment reliable, error small and efficient.

- Japanese SMC proportional solenoid valve is used for cutting rice. The pressure is automatically adjusted according to the glass thickness. The cutter head rotates 360 degrees, and the upper and lower buffering cutter cuts (any straight line and all kinds of special shaped glass can be cut accurately).

- The knife head is equipped with knife protection function. If the knife head falls outside the glass or the glass gap, the program stops automatically, effectively preventing damage to parts and glass.

- Double motor high speed drive (large inertia Yaskawa servo) ensures cutting speed and fluency;

- Conveyor device, synchronous automatic transmission device, convenient for glass upper and lower transmission, frequency conversion speed regulation, stable and easy to optimize the transmission speed;

- Positioning device, photoelectric scanning positioning system;

- Compensation function, tool eccentricity compensation, clearance compensation, pitch compensation.

- Max size: 6100×3300 mm

- Thickness: 3~19 mm

- Cutting accuracy: ±0.30

- Cutting accuracy of special-shaped glass: ±0.35

- Cutting speed: 0-200 m/min

- Conveying speed: 0-25 m/min

- Machine size:6800×4100×1500 mm

- Working table height: 900 mm±20 mm

- Weight: 2600 kg

- Total power of equipment:9-15 kw

Motion Controller:

- Fast running speed, smooth running, high control accuracy, modular controller structure;

- The man-machine interface is simple and generous, the parameter adjustment is simple, the parameters that need to be modified by operators are less, simple and intuitive, and the requirements for operators are low.

- Pipeline cutting mode, photoelectric positioning cutting mode and direct cutting mode are set freely through options. The automatic cutting mode and air operation mode can be switched at any time during the processing.

- Graphic library nesting programming, select special-shaped from the library, set relevant parameters, processing quantity, automatic nesting, generating processing trajectory;

- Complete storage of glass pressure stock, once the cutting pressure of each specification thickness is input and saved, it can be directly invoked;

- Real-time tracking and displaying of processing path, timely recording of motion coordinates, axis state, I/0 state, automatic recording of fault diagnosis and alarm;

- Receive a variety of processing documents, accept the standard G code of Optima, Super Package Software, AUTOCAD DXF file, the system has its own graphics editing software (exactly the same as Paul's editing method);

- Graphic library nesting programming, selecting abnormal shape from the library, setting relevant parameters, processing quantity, automatic nesting, generating processing trajectory;

- The sorting function of DXF class files, including the nearest point, entry point, or by graphics color clockwise, counterclockwise sorting and other options. Free the switch between single-phase cutting and bidirectional cutting is realized.

- Photoelectric positioning function, according to the actual position and deflection angle, automatically adjust cutting;

- Compensation function: tool eccentricity compensation, clearance compensation, pitch compensation;

- All kinds of protection: including soft and hard limit, cutter pressure limit, external emergency stop control and so on.

Optimization software:

- Importable optimization results done in the Office

- Cutting scheme can be manually created and edited

- With copy and mobile functions

- Manual editing of cutting sequence

- The cutting scheme can be quickly created by X, Y and Z modes.

- Simultaneous optimization of multiple original and small patches

- Optimized typesetting without size limitation

- Optimized Result Rotation, Mirror Management, etc.

- Priority management for small size cutting optimization

- Priority management of original glass sheet optimization

- Template Scanning Function and Scanning Graphics Processing

- Original glass sheet storage Management

- 20 efficient optimization algorithms

- Cutting graphics can be edited

- Label Design and Label Printing(Label-WAY)

- Clear Printing of Optimized Result Report

- Excel Data File Import

- Low-E Glass and Adhesive Glass Cutting Management

- A graphics library containing 350 parametric graphics, including all the commonly used graphics types (Geo-Way)

- Two-Dimensional CAD System with Abnormal Scanning Processing Function (Cad-Way)

- Automatically converting digital signals from CNC systems into graphical forming points

- There are many language choices for the software operation interface, including the Chinese interface.

- Follow up the latest international software development, provide upgraded versions in real time, and achieve the latest functional requirements for customers

、Contactors: Renmin/Zhengtai

、Circuit Breaker: Renmin/Zhengtai

、Button: Renmin/Zhengtai

、Main solenoid valve: Airtac

、Other Pneumatic Components: Deke/Shengguan

、Fan:Liyuan

Mechanical part;

、Working table: Waterproof High Density Plate

、Table: Imported industrial felt (black)

、Breaking bar: solid wood (natural color)

Note: Depending on the delivery date and technical improvement, the production company reserves the right to replace the purchased parts of the same brand.

- Pre-washing Function;

- Automatically accurate positioning for 3 side step DGUs or 4 side step IGUs;

- Automatic argon-gas filling could set gas value and display the process of filing online with high gas concentration.

- Breaking bar: 3+1 type

- Table Size: 6300*3500 mm

- Glass thickness:3-19 mm

- Power: 8 kw

- Table height: 900 + 20 mm

Automatic Air-floated Glass Breaking Table Connection Line

Automatic Air-floated Glass Breaking Table Connection Line Customized Demand & Service

Procurement of Other Glass Processing Machine

Most Popular- Purchase other automatic glass processing equipment(such as Tempering Glass Machine and Insulating Glass Machine)and export them together with the same containers. No purchase sourcing cost.

Equipment On-site Installation and Guidance

Most Popular- It is necessary to dispatch some years-experience after-sales services engineers with on-site automatic equipment installation and commissioning guidance 200usd per day with the those terminal users.

Care the Equipment's Full-life Cycle Maintenance

Most Popular- Provide a copy of spare parts and fragile parts commonly used in automatic glass equipment and purchase them together, takes responsible for the full life cycle maintenance of those glass equipment.

Re-plan Your Glass Factory Workshop Layout

Most Popular- Based on years+ of experience in glass processing, LIJIANG Glas will give customers reasonable suggestions on re-plan your glass factory workshop layout from the perspective of water, electricity, place, effectively improving...

Make an Appointment For Production

Sales Promotion & Discounts

LIJAING Glass After-Sales Department will help you if you have any questions or problems – the range of services at your disposal includes everything from start-up to product returns.

If necessary, a member of our staff will be on the site within a very short period to work together with you and to take care of your issues and interests. Our employees in after-sales service are not only glass experts—they are also qualified in many other specific areas. For example, our team includes experienced designers who are pleased to provide any additional glass cutting machine suggestions for any specific events.

$250

All About the Automatic Glass Cutting

When selecting and using a fully automatic glass cutting machine, attention should be paid to aspects such as equipment performance, ease of operation and after-sales service to ensure the production efficiency and product quality of glass processing enterprises.

Common Faults and Troubleshooting Methods of Automatic Glass Cutting Machines

- Glass cutting speed decreases or glass cutting diagonal changes

Troubleshooting method:

(1) Open the cover of both sides of the panel;

(2) Loosen the tension sleeves on both sides;

(3) Adjust the tightness of the timing belts on both sides to be consistent.

- After the cutting line is removed, the glass cannot be cut through and cannot be broken.

Troubleshooting methods:

(1) Adjust the angle of the cutter wheel;

(2) Replace the appropriate cutter wheel.

- Cutting line glass cutting edge exposed edge

Troubleshooting methods:

(1) Inject lubricating oil;

(2) Reduce the knife pressure.

- The set cutting size becomes larger or smaller than the actual machine operating size.

Troubleshooting method: Adjust the settings of the cutting machine driver.

- No floating function

Reason: The air path may be blocked, the fan is damaged or the air source triplex is blocked.

Troubleshooting methods:

(1) Clear the air path and triple components;

(2) Replace the fan.

- After the operation panel is set, the cutting head cannot automatically return to the mechanical origin.

Reason: It may be that the proximity switch for returning to the mechanical origin is damaged.

Troubleshooting method: Replace the origin switch.

- No positive or negative limit

Reason: The positive and negative limit switches are damaged.

Troubleshooting method: Replace the limit switch with a new one.

- The computer cannot find the board (hardware)

Reason: Usually caused by poor contact with the board.

Troubleshooting method: Remove the board card from the PCI slot and reinsert it tightly.

- Servo overvoltage alarm

It is caused by the wrong connection between the servo motor power supply and the ground wire. Just correct the wrong wire connection.

- Encoder communication protection

The encoder address book wire is weakly welded or broken, just re-solder the encoder wire.

- The servo motor vibrates too much

Reason: The fasteners are loose or the motor is too rigid.

Troubleshooting methods:

(1) Adjust the tightness of the rotating parts;

(2) Reduce the rigidity of the servo motor.

Know More

Which automatic glass cutting machine is more suitable for you?

The manual glass cutting machine is the most traditional glass cutting machine. The entire machine consists of two parts: a glass conveyor belt and a cutting table. By operating the conveyor belt manually, the glass to be cut is transported to the cutting table for cutting with a blade. The advantage of this cutting machine is that it can cut relatively small pieces of special-shaped glass and process the glass into different shapes. The disadvantage is that cutting the glass into a unique shape requires a special mold, and the manual operation itself is time-consuming and labor-intensive, making mass production impossible.Manual glass-cutting machine

This kind of glass cutting machine is roughly the same as a manual cutting machine, but a semi-automatic button operation device is added to the cutting machine. Although it is still mainly used to cut special-shaped glass, and special molds need to be made in advance according to the shape of the glass, the size of the glass that can be processed is larger than that of a manual cutting machine. And because it uses pneumatic plus motor kinetic energy during cutting, it saves a lot of manpower, so the production efficiency is much higher than that of manual cutting machines.Semi-automatic glass cutting machine

This glass cutting machine is a step further than semi-automatic glass cutting machines. It consists of a chassis mechanism, a beam mechanism, a glass processing tabletop, a cutter head mechanism, a conveying mechanism, a mechanical positioning mechanism, an electrical control system, etc., and has a complex structure.Fully automatic glass cutting machine

Its processing method is controlled by the computer software equipped with the machine, which directly draws and then performs the operation. In this way, you can set in advance whether to make square, round, or special-shaped glass through the computer, without making a mold in advance.

The most advanced form of this kind of cutting machine is the production line model. In addition to the film-loading table, computer cutting machine, and film-breaking machine, this model also has a film-unloading table. The whole process of the assembly line is computer-controlled, with a high degree of automation, and is suitable for long periods. It can handle large quantities of glass products and is easy to maintain.

When cutting with a fully automatic glass cutting machine, typesetting is required first, and then cutting, film removal, and other processes can be carried out. Not only is it required to discharge as many pieces as possible that meet the required shape on the original glass sheet to improve the utilization rate of raw materials, but it is also required that the typesetting operation is simple and easy to use. Mechanical interactive typesetting is the most commonly used and convenient way for operators to type and cut according to the work order on site.

This kind of glass cutting machine also operates fully automatically through computer control. But unlike traditional blade cutting, it uses high-pressure water cutting technology, mainly for thicker glass products. Various complex patterns are formed through computer numerical control. This cutting machine performs cold cutting without producing thermal deformation or thermal effects. It can ensure smooth incision and can be completed in one go without the need for secondary operations. Due to these advantages, it can also perform complex operations of drilling glass.Water jet glass cutting machine

What is the standard operating steps for Automatic Glass Cutting Machines?

2. Check that there are no white spots or scratches on the appearance of the glass to be cut.

3. Push the longitudinal beam, and then push the cross beam after returning to its position to prevent collision with each other.

4. Before starting the machine, check whether there is air leakage in the machine pipeline. If there is air leakage, never start the machine.

5. Turn on the power switch and check whether there are any obstacles on the working surface and guide rails. If there are any obstacles, they must be removed.

6. Two people lift the glass to be cut to the cutting table, making sure it is firmly attached to prevent shaking. Before lifting the glass, you must confirm that there are no cracks in the glass itself to avoid the phenomenon of automatic separation of the glass during lifting.

7. Press the blow button to make the glass float on the table and move freely.

8. After the glass is positioned, press the stop button, and then press the suction device to firmly fix the glass at the designated position to achieve the positioning effect.

9. When the cutting is completed, press the stop button and then press the air blow switch.

10. When the whole piece of glass that has been cut is moved to the breaking table, turn on the blowing motor of the breaking table before moving. Only after the first piece is confirmed to be qualified can it be mass-produced. When measuring, the first row horizontally and vertically is used as the measurement object, and a full inspection is performed if necessary.

11. Divide the dough into small pieces horizontally and vertically according to the knife marks, and place the remaining material in the designated position. Stack the broken pieces of glass neatly and place them on the glass shelf.

12. Before shutting down, close all air valves and vent the remaining gas in the air circuit. If a backfire is found in the pipeline, the power and gas must be cut off immediately.

13. Use a rag to clean the glass fragments on the cutting table and breaking table.

How to choose an automatic glass cutting machine?

It seems that the model of the automatic glass cutting machine is composed of a simple string of letters and numbers, but it represents the factory age, technical equipment, and other contents of the cutting machine, so you should first determine which series of equipment you want to buy, and then distinguish the differences between different models. After all, each customer will set a budget first, and then purchase a cost-effective machine under a reasonable budget.

In addition, you should also look at the specific parameters of the automatic glass cutting machine, such as the cutting efficiency and the whole machine service mode. These parameters determine whether the equipment is convenient to use and the technical level of the equipment itself. What we have to do is to purchase machines with high precision and high speed as much as possible, so as not to delay future use.

The above are the precautions for purchasing automatic glass-cutting machines. In fact, in addition to purchasing specialists, if you can bring factory technicians, they come from the front line of operation, will be very familiar with the technology and use of the cutting machine, and will also give reasonable suggestions during the trial to avoid detours.

People can visit several automatic glass cutting machine manufacturers and compare automatic glass-cutting machines of different models and batches. I believe that they will have a deeper understanding of the industry and will be more adept at purchasing.

What parts does the automatic glass cutting line include?

To judge the performance of the glass cutting line, you need to look at the material of the whole machine to see if it has passed the national standard. At the same time, you should also judge the details, such as whether it has been oxidized to prevent rust. Is the vacuum degree and reliability achieved? If a system is not set up perfectly, it will inevitably affect the operation of the entire line, so you must be careful when checking.

For technicians, people especially hope that the glass cutting line has a one-button reset function, so that there is no need to operate it repeatedly, and it can also speed up the timeliness and speed of preparation work. For safety reasons, the equipment especially needs to have an alarm device, so that an alarm can be issued when the operation is not professional. People can repair and maintain according to the alarm, and they can also have a better understanding of the machine equipment.

The glass cutting line is relatively complex, and its mechanical configuration is very complete. Most of them adopt high-precision and high-density designs, which not only beautify the compactness of the appearance but also do not affect everyone's use. The indicators for reference when purchasing include the external dimensions, the size and thickness of the film, the film retrieval cycle, and also include power supply, power, etc.

The above is a specific introduction to the glass cutting line. It can be seen that the requirements for purchasing personnel are very high. Only by fully understanding the various components of the line can the purchase process be handy and the budget can be made to meet the factory's expectations. At present, many glass-cutting line manufacturers will carry out structural optimization work, to continuously upgrade technology and launch new products.