User Manual

All types of insulating glass machines for beginners&professionals.

Pick your first insulated glass machines for automation factory glass industry manufacturing.

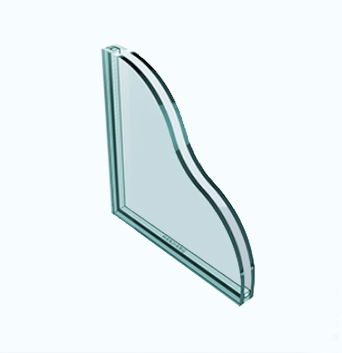

Tempered insulating glass is a glass product that uses an aluminum frame or extruder strip injected with desiccant to separate the glass between two or more pieces of tempered glass, and is sealed on all sides by sealing to keep argon-gas filling in the middle cavity at all times.

- Principle of tempered homogenization treatment

- Process of tempered homogenization treatment

1. Heating stage

The heating stage starts at the ambient temperature of all glasses and ends when the surface temperature of the last glass reaches 280℃. The temperature in the furnace may exceed 310℃, but the temperature of the glass surface cannot exceed 320℃. The time when the glass surface temperature exceeds 300℃ should be shortened as much as possible.

2. Insulation stage

The insulation stage starts when the surface temperature of all glasses reaches 280℃, and the insulation time is at least 2h. During the entire insulation stage, the temperature of the glass surface should be kept within the range of (290±10)℃.

3. Cooling stage

When the glass that finally reaches 280℃ has been kept warm for 2h, the cooling stage begins, during which the glass temperature drops to the ambient temperature. When the temperature in the furnace drops to 70℃, the cooling stage is considered to be terminated.

How to pick the appropriate tempered glass production equipment?

Tempered glass production equipment mainly includes a glass loading and transport equipment, glass cutting machine, glass edge grinding machine, glass washing and drying machine, double-chamber tempering furnace and so on. However, How to pick the appropriate tempered glass production equipment? What kinds of suggestions LIJIANG Glass could offer you, Maybe that is the key-point you got.

Glass Sheet Loading Equipment

Glass Cutting Machine

The cutting bridge is made of rigid and anti-twisting metal and is driven by a servo motor through a precise transmission device. The movements of the cutting head include X/Y/Z and head rotation. The height and pressure of the cutting head should be automatically adjusted according to the glass situation, and the cutting oil is automatically injected into the cutting wheel.

The film removal head and the cutting head share a bridge frame. The film removal wheel is driven by a motor and has a film removal and dust removal device. The height of the film removal wheel can be automatically adjusted according to the size of the grinding wheel and the thickness of the glass, and the film removal pressure can be automatically adjusted. The cutting machine can automatically detect the original size and thickness of the glass and accurately identify its position.

Glass Edge Grinding Machine

Glass Washing and Drying Machine

1. Conveying system

The conveying system adopts rubber roller conveying.

2. Inlet segment

The inlet segment is an independent frame with a pre-rinsing part on it, protective covers on both sides of the inlet segment (the protective covers are carbon steel protective covers, painted), and a water accumulation tray on the inlet segment to ensure that the rubber roller at the inlet end is immersed in water for 10 mm to achieve the self-cleaning effect of the rubber roller.

3. Washing segment

The cleaning segment has four sets of brushes, and the water sprayed from the nozzle can form a fan shape. The cleaning part includes the pre-rinsing part, which uses a water pipe with a flat nozzle.

4. Air-drying segment

The air-drying segment has three pairs of air knives, each pair of air knives has upper and lower air knives, and the air knives are made of stainless steel. The height of each air knife can be adjusted manually separately, and there are steel plates and sound insulation cotton inside the air-drying segment for sound insulation.

5. Outlet segment

The outlet segment is an independent frame with three sets of inspection lights on it, and protective covers on both sides of the outlet segment, which are carbon steel protective covers, painted.

6. Wind system

The fan is installed in a soundproof box, and the soundproof box is surrounded by soundproof cotton and porous plates, which can achieve the effect of sound insulation. The soundproof cotton is protected by porous plates to prevent dust from contaminating the fan.

7. Water system

The water tank is installed under the shelf, and a water tank in the pre-rinsing part can use clean tap water. The cleaning section is equipped with an integral water tank with casters and handles, which can be freely dragged out for cleaning.

8. Electrical control system

The electrical control system includes a control cabinet installed near the outlet of the equipment.

Double-chamber Tempering Glass Furnace

① The glass is evenly arranged in the upper section;

② It is sent to the heating furnace for uniform heating, and then sent to the wind grid section for rapid cooling after heating to complete the tempering;

③ It is transported to the lower section and the lower piece is packed manually. The double-chamber tempering furnace is mainly composed of a film-placing table, a preheating furnace, a heating furnace, a cooling device, a film-unloading table, a wind duct system, and an electrical control system.

1. Sheet placement table

The original glass is placed on the sheet placement table in a certain way. After pressing the start button, the roller starts to move forward with the glass. After triggering the photoelectric switch near the transition roller, the roller stops rotating and the glass waits for the next command here.

2. Preheating furnace

The preheating furnace adopts upper forced pure convection technology. When the glass enters the preheating furnace, the door of the preheating furnace is opened, and the sheet placement table conveying roller and the ceramic roller in the preheating furnace rotate synchronously to send the glass into the preheating furnace. Then, the preheating furnace closes the furnace door. The glass is driven by the roller in the preheating furnace and reciprocates within the set range. The glass is heated quickly and evenly, and the heating quality is better than other methods. At the same time, it can ensure that the ceramic roller does not bend or deform, extending the service life of the preheating furnace.

3. Heating furnace

The performance and configuration of the heating furnace are the same as those of the preheating furnace, that is, the upper forced pure convection technology.

4. Cooling device

The cooling device is composed of a cooling air grille and a conveying roller.

5. Lower sheet table

The lower sheet table is a horizontal roller section with heat-resistant imitation rope wrapped on the surface.

6. Air duct system

The air duct system is mainly composed of fans, air supply pipes, and air collecting boxes.

7. Electrical control system

The electrical control system mainly includes the host computer, PLC system, variable frequency drive system, fan inverter system, and heating control system.

How to produce the insulating glass units by Automatic Solution

1. Bending of aluminum spacers: First, cut and bend the aluminum spacers into a shape of appropriate size according to the glass processing size requirements. This step is usually completed by automated bending equipment to improve production efficiency and reduce manual errors. At the same time, laser coding can be performed according to the OA work order system to identify the model.

2. Filling of aluminum spacers: After the aluminum spacers are bent, the aluminum spacers are filled with adsorbents. Generally, a 3A molecular sieve is used as the adsorbent for filling.

3. Low-E film layer detection: The film layer is detected through the Low-E Glass photoelectric detection switch in the feeding section to effectively prevent the Low-E Glass from being placed upside down.

4. Washing and Drying: The cut glass blocks will go through the cleaning process to remove dirt, grease, and other impurities on the surface to ensure that the next process can proceed smoothly. Glass washing usually uses an efficient washing and drying machine, which can complete the cleaning of large quantities of glass in a shorter time.

5. Inspection: The washed glass blocks need to undergo strict quality inspection to ensure that they meet the standards and requirements. The inspection process is usually carried out by manual visual observation, which can detect the flatness, thickness, surface defects, and whether the glass is clean.

6. Assembly: The glass blocks that have passed the inspection will be sent to the insulating glass plate pressing segment for assembly. The insulating glass machine will automatically place two or more pieces of glass at the required interval and inflate them.

7. Sealing: The assembled glass undergoes a sealing process to ensure that the gas or air in the insulated layer does not leak. Sealing generally uses high-efficiency sealants, such as hot melt sealant or structural sealant, and fully automatic sealing lines for sealant application.

8. Inspection: Finally, the insulating glass is inspected again to ensure that the quality and performance meet the requirements. For example, glass appearance inspection, sealing test, thermal performance test, etc. can be carried out.

Know More

- Assemble the Aluminum Spacer Strips

- Apply the Butyl Extruder Coating

- Check Frame Sealing and Glass Plate Pressing

- Automatic Sealing

Automatic Insulating Glass Processing Solution

In case you are looking for a trusted manufacturer & brand to purchase your next automatic insulating glass processing solution at an affordable prices & high-quality components, LIJIANG Glass can be an excellent place to rely your trust on, and meet the above insulating glass produce requirements.

Intelligent Glass Storage and Sorting System

Type: LJ3000/CustomizedThe LIJIANG Glass intelligent glass storage and sorting system can be connected to most ERP software on the market. It can be used offline with automatic loading and unloading of films, or it can be connected to a insulating glass production line to form an automated connection. The equipment can automatically detect the glass size or directly read the code identifies the size of the glass and can be paired and sorted according to the size. It can pair and distinguish double glass, triple glass, quadruple glass, laminated glass, Low-E glass, frosted glass, coated glass, and other glasses. It can be divided into pieces according to customers. It can be divided into pieces according to the process card, and the process card can be printed after the pieces are placed.

Know More DetailsAutomatic Jumbo-size Double-filling and Double-plate Pressing Insulating Glass Production Line

Type: LJBZ3060/LJBZ3370The LIJIANG Glass insulating glass double-filling and double-plate pressing production line, which includes a feeding section, a washing and drying section, a washing and discharging section, a storage section, an inspection and framing section, a flat pressing feeding section, an inflatable plate pressing section and a flat pressing discharging section. The inflatable plate pressing section includes a front moving plate, a rear fixed plate, left and right sealing plates, a conveyor belt and an inflating mechanism. The inflatable plate pressing section can inflate and press two pieces of glass less than 3 meters in length at the same time as needed, or press an extra large plate of glass.

Know More DetailsHigh-speed Insulating Glass Butyl Extruder Coating Machine

Type: LJTB01/LJTB03DThe butyl extruder coating machine for insulating glass manufactured by LIJIANG Glass can quickly adjust the distance between the two coated heads to adapt to different specifications of aluminum spacer strips. It includes a frame and two independent sealant systems. Each sealant system includes a sealant extrusion cylinder and the sealant head is fixed relative to the sealant extrusion cylinder. The two sealant heads are juxtaposed with a certain distance to receive the aluminum spacer and apply butyl extruder coating on it. The frame is provided with a place for one of the coating systems to move The guide rail is used to adjust the distance between the two coated heads, and there is also a moving device that drives the coating system to move along the guide rail.

Know More DetailsAutomatic Low-E Glass Film Removal Delecting Machine

Type: LJCM2030/LJCM2545/LJCM3370Given the large number of coated glasses such as Low-E coated glass and solar control film used in the current insulating glass processing market, various films must be removed around the butyl-coated glass, otherwise the service life of the insulating glass will be affected. Generally speaking, mechanical removal of glass surface film is the first choice. The recommended parameters for the film removal wheel of LIJIANG Glass Automatic Low-E Glass Film Removal Delecting Machine are air pressure 0.8MPa ~ 1.2MPa, rotation speed 1800 ~ 1900 r/min;The grinding wheel is made of emery or stainless steel wire below 0.15mu (100 mesh). No traces remain on the surface after film removal. The development direction is to set up grinding wheels according to different film systems.

Know More DetailsThe Automatic Insulating Glass Sealing Robot Line

Type: LJTJ2030/LJTJ2532/LJTJ3070/LJTJ3370The LIJIANG Glass Insulating Glass Sealing Robot Line adopts a large touch screen human-machine interface control system to realize automatic positioning of aluminum partition frames, automatic lifting and lowering of pressing, conveying, sealant coating, automatic timing heating and other functions. The equipment adopts advanced gas-liquid boosting technology to make the system pressure more stable and energy-saving. The system is equipped with an alarm system for running out of sealing, and a dual-group and dual-sealing supply configuration. Production will not be delayed during sealant replacement. The sealing head is adjustable within the range of 6-20mm and can be fine-tuned up and down.

Know More DetailsAutomatic Multi-Storage Aluminum Spacer Bending Machine

Type: LJZW2020/LJZW2020NThe LIJIANG Glass high-precision insulating glass aluminum strips bending machine includes a transmission mechanism and a bending mechanism. The transmission mechanism includes a driving wheel, two fixed wheels and two transmission chains; the two fixed wheels are uploaded in the horizontal direction through a transmission chain dynamically connected; the driving wheel is drivingly connected to one of the fixed wheels through another transmission chain; the bending mechanism includes a rotatable pressure wheel and a height adjustment device; the pressure wheel and the two fixed wheels are located on the same vertical plane, and Located above the middle of the two fixed wheels; the height adjustment device is installed above the pressure wheel and adopts a screw structure to adjust the height of the pressure wheel with high precision.

Know More DetailsAutomatic Insulating Glass Desiccant Filling Machine

Type: LJGZ2020D/LJGZ2020X/LJGZ2020SThe LIJIANG Glass insulating glass molecular sieve filling machine has a support frame fixedly installed in the middle of one side of the main body. A filling gun is fixed symmetrically above the support frame. A fixed seat is welded to the top and middle of the support frame. A fixed base is fixedly installed in the middle of the front end of the fixed base. The fixing frame has fixing slots in the middle of both sides of the fixing frame. An L-shaped push rod is movable inside the fixing slot. A movable pressure plate is installed on one side of the outer surface of the L-shaped push rod. This equipment prevents the filling gun from pushing the aluminum spacer up and down during filling, improves the overall stability of the aluminum spacer during filling, and thereby improves the overall filling efficiency of the aluminum spacer.

Know More DetailsIntelligent Glass Storage and Sorting System

Type: LJ3000/Customized

Automatic Jumbo-size Double-filling and Double-plate Pressing Insulating Glass Production Line

Type: LJBZ3060/LJBZ3370

High-speed Insulating Glass Butyl Extruder Coating Machine

Type: LJTB01/LJTB03D

Automatic Low-E Glass Film Removal Delecting Machine

Type: LJCM2030/LJCM2545/LJCM3370

The Automatic Insulating Glass Sealing Robot Line

Type: LJTJ2030/LJTJ2532/LJTJ3070/LJTJ3370

Automatic Multi-Storage Aluminum Spacer Bending Machine

Type: LJZW2020/LJZW2020N

Automatic Insulating Glass Desiccant Filling Machine

Type: LJGZ2020D/LJGZ2020X/LJGZ2020S

Manual Rotated Sealant Spreading Table

Type: LJZT02/LJTZ03This LIJIANG Glass rotating sealant sealing table adopts forward and reverse rotation structure and can be operated freely. The whole equipment is made of welded square tubes with high strength and not easy to deform.The lifting, lowering and rotating foot valves are individually self-locking controlled to reduce misoperation. Insulating glass with different specifications can be operated flexibly and conveniently.

Know More DetailsManual Two-component Sealant Applicator Equipment

Type: LJST02A/LJST03The main pump of the LIJIANG Glass manual two-component sealant applicator equipment is driven smoothly by the hydraulic system; the fully enclosed curing agent sealant path system prevents the curing agent from contacting with air and solidifying; the two-component proportioning structure is steplessly adjusted to meet accurate proportioning requirements; it adopts Internationally popular static reciprocating mixer, mixing more evenly.

Know More DetailsInsulating Glass Sealant Gun Freezer Equipment

Type: LJSG01The LIJAING Glass insulating glass sealant gun freezer includes a box shell, a low-temperature insulation tank, a high-temperature insulation tank, a compressor, and a fan installed on the shell wall. The insulation tank is connected to the compressor through a pipeline, and the top of the shell is equipped with Has a lid to ensure long-term temperature stability of the sealant gun.

Manual Inert Argon-Gas Inflator Equipment

Type: LJCJ01/LJCJ02The LIJIANG Glass insulating glass inert gas inflator equipment is used to inject inert gas inside the insulating glass to improve the heat insulation, sealing, sound insulation, energy saving and other properties of the insulating glass. It uses a gas purity analyzer imported from the United States and a gas sensor imported from Japan to ensure the stability of the inflator. The humanized appearance design makes the equipment beautiful and easy to operate. It is currently the most advanced insulating glass inflatable equipment.

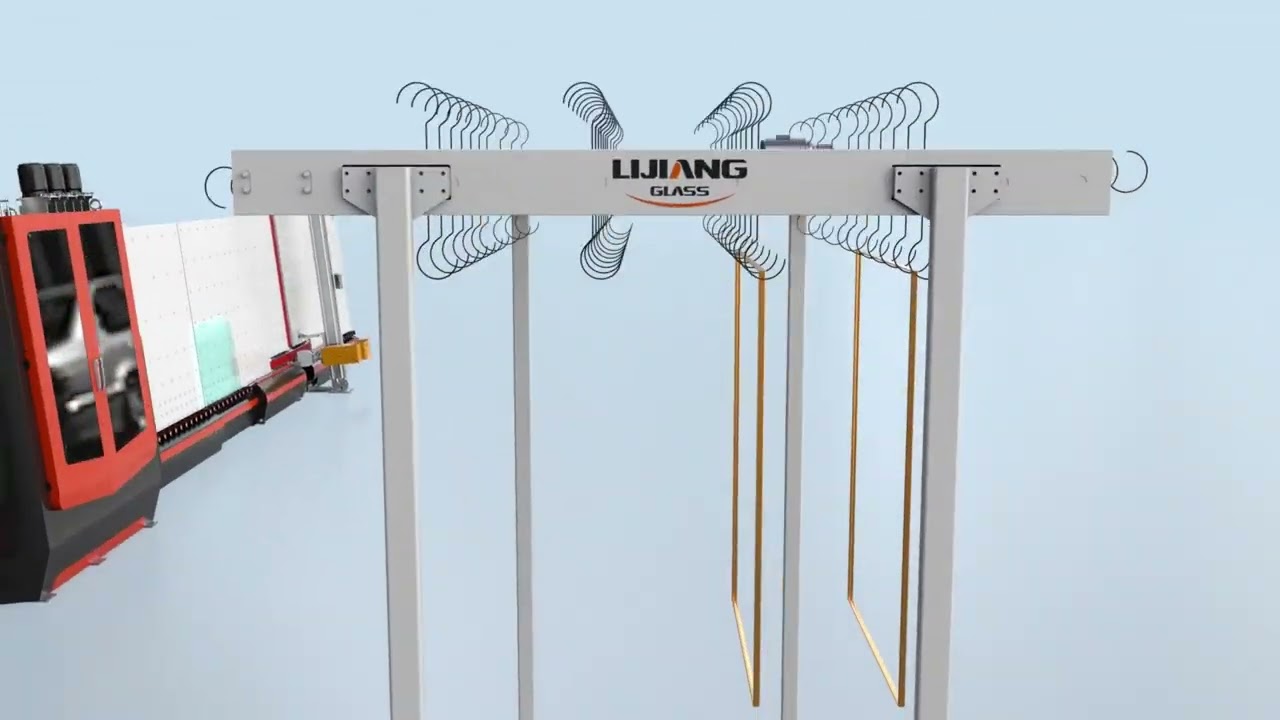

Know More DetailsThe Insulating Glass Aluminum Frame Hanging Conveyor Equipment

Type: LJSK02This equipment is the link between the insulating glass butyl extruder coating machine and the insulating glass production line. The LIJIANG Glass LJSK02 Insulating Glass Aluminum Frame Hanging Conveyor Equipment is a special equipment for after storing and conveying the aluminum frame coated with sealant by the butyl extruder coating machine during the insulating glass production process.

Know More DetailsManual Rotated Sealant Spreading Table

Type: LJZT02/LJTZ03

Manual Two-component Sealant Applicator Equipment

Type: LJST02A/LJST03

Insulating Glass Sealant Gun Freezer Equipment

Type: LJSG01

Manual Inert Argon-Gas Inflator Equipment

Type: LJCJ01/LJCJ02

The Insulating Glass Aluminum Frame Hanging Conveyor Equipment

Type: LJSK02

10 years?...

- The professional market analysis should be the first step.

- A feasibility report should be done with the labor cost, material cost, factory cost and consumptions, productivity, etc.

- Accurate company management structure and system design.

- Professional machinery plan and software setup.

- All the targets can be achieved, tracked, and monitored accurately if the above jobs are professionally done …

The louver is completely sealed inside the insulated glass louver, and the lifting and turning of the louver are controlled by the magnetic force outside the glass or a remote control. The structure is reasonable and simple, and the operation is convenient, which saves space and inconvenience, and completes the thermal insulation of the insulated glass and the sunshade of the louver. It can easily adjust the indoor light environment and is suitable for various energy-saving building exterior doors and windows. It meets our energy-saving and environmental protection requirements, and is also very fashionable and beautiful. The insulated glass louver glass mainly controls the loss of indoor heat energy to the outside by reducing heat energy and convection, and completes its insulation function with a lower heat transfer coefficient.

LIJIANG Glass Automatic Insulated Glass Louver Curtain machine is a new generation of products designed specifically for processing aluminum louvers. It is controlled by CNC technology. The length, hole spacing, and number of punching holes are input through the touch screen. It automatically completes functions such as arc pressing, punching, cutting, counting, and ladder threading, with a high degree of automation. There are 12.5, 15, 16, 25 and other specifications to choose from. It is the main equipment for producing louvers, hollow louver glass and louver partitions.

Features & Advantages:

- It can automatically feed, press arcs, punch holes, cut, and discharge materials according to parameters such as the length, number of holes, and hole spacing of the curtain piece, and has alarm and shutdown protection functions.

- It has the function of automatically threading the ladder rope, saving labor.

- PLC control, touch screen setting, easy adjustment, high precision.

Technical Parameters:

- Machine power: 1.5kw 220v 50hz

- Applicable curtain width: 12.5mm, 15mm, 16mm, 25mm

- Overall size: 3800mm*500mm*1400mm

- Weight: 300kgs