High Speed Glass Double Edge Polishing and Grinding Production Line

LIJIANG Glass LGZM3525 high-speed glass intelligent double-edge polishing and grinding production line is a kind of machine specially used to process double-straight edges of flat glass. It is suitable for deep processing of glass in glass curtain wall construction, glass partition furniture, applied home appliances and other industries.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LIJIANG Glass LGZM3525 high-speed glass intelligent double-edge polishing and grinding production line

Equipment Description

| Automatic glass detecting table | Intelligent High Speed Double Edge Polishing Machine | Glass Transfer Table | |

Processed glass thickness | 3~28 mm | 3~28 mm | 3~28 mm |

Processing size range | 350~4200 mm | 350~4200 mm | 350~4200 mm |

Processing speed | 1~60 m/min | 1~15 m/min | 1~30 m/min |

| Width adjustment speed | - | 1~15 m/min | - |

Grinding amount | - | Chamfer width 45°: 1~3 mm Bottom edge grinding amount: 1~6 mm | - |

Machining precision | ±0.2 mm | Chamfer width error 45°: ≤0.2 mm/m Parallelism error: ≤0.2 mm/m Diagonal error: ≤0.5 mm/m | - |

| Air pressure | 0.6~0.8 Mpa | 0.6~0.8 Mpa | 0.6~0.8 Mpa |

| Power | 3 KW | 58 KW | 5 KW |

| Working height | 900±30 mm | 900±30 mm | 900±30 mm |

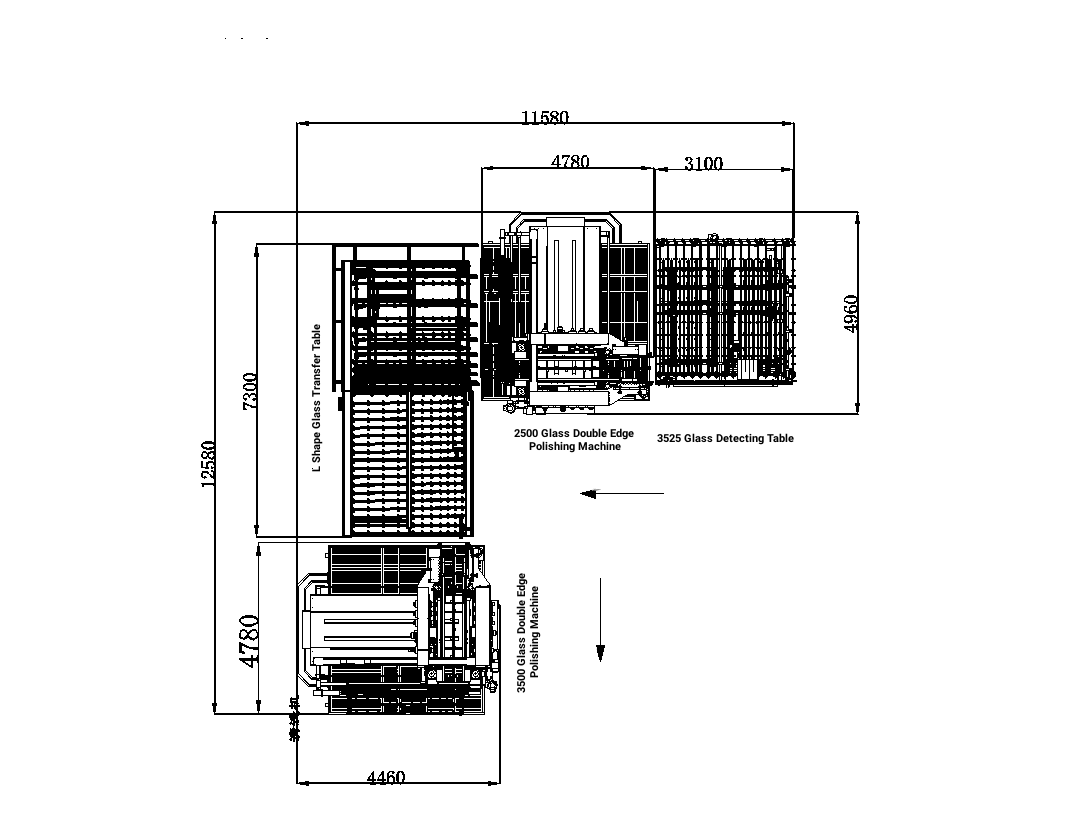

Figure 1 Schematic diagram of transfer connection of glass high-speed intelligent edge grinding production line

Figure 1 Schematic diagram of transfer connection of glass high-speed intelligent edge grinding production line

Equipment Configuration

| Item. | Spec. |

| Main machine frame | Strong welding steel base, annealing treatment |

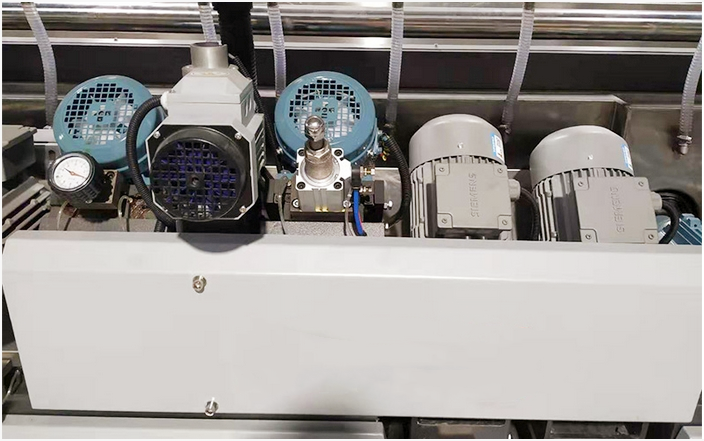

| Grinding wheels motor | #1#2#3#4#5:Siemens, others:Shanghai ABB |

| Linear rail | Taiwan Andner |

| Ball screw | Taiwan TBI Ф50 |

| Synchronous belt | Italy Megadyne |

| Pneumatic elements | Taiwan Airtac |

| Frequency converter | Germany Rexroth |

| Photoelectric switch | Germany pepperl+Fuchs |

| HMI | Beijing Kunluntongtai MCGS 10.1 inch |

| Encoder | Shenzhen keepnewtech |

| PLC | Japan Mitsubishi |

| Servo motor | Shenzhen Inovance |

| CPU | Germany Beckhoff |

| Button switch | Chint |

| Contractor, thermal relay | Schneider |

| Transformer | Tengen |

| Breaker | Tengen |

| Power breaker | Aoyi |

| Ammeter, voltmeter | Italy LKA |

Grinding Wheel Details

| Wheel number | Wheel type | Motor | Compensation | |||

| 1 (bottom edge) | Diamond | Ф175 #100 | Siemens | 3kw | 4600rpm | Manual |

| 2(bottom edge) | Diamond | Ф175 #140 | Siemens | 3kw | 4600rpm | Manual |

| 3(bottom edge) | Resin | Ф175 #180 | Siemens | 2.2kw | 4600rpm | Manual |

| 4(bottom arris) | Resin | Ф150 #240 | Siemens | 1.5kw | 3300rpm | Manual |

| 5(bottom arris) | WEL800 | Ф150 | Siemens | 1.5kw | 2850rpm | Manual |

| 6(upper arris) | Resin | Ф150 #240 | ABB | 2.2kw | 2850rpm | Manual |

| 7(upper arris) | WEL800 polish | Ф150 | ABB | 2.2kw | 2850rpm | Manual |

| 8(bottom edge) | WEL600 polish | Ф150 | ABB | 2.2kw | 2850rpm | Manual |

| 9(bottom edge) | WEL600 polish | Ф150 | ABB | 2.2kw | 2850rpm | Manual |

| 10(bottom edge) | WEL800 polish | Ф150 | ABB | 2.2kw | 2850rpm | Manual |

| 11(bottom edge) | CE2 polish | Ф150 | ABB | 2.2kw | 2850rpm | Manual |

Bright even polishing for bottom edge chamfer without scratch, white pots, chips. | ||||||

| Parallel error ≤0.2mm, diagonal error ≤0.5mm, chamfer width error ≤0.2mm. | ||||||

Spare Part Listing

| Item. | Name of goods | Quality |

| 1 | Water Pipe 3/8-A-7.5-L300 | 10pcs |

| 2 | Water-proof Cover | 5pcs |

| 3 | Orange side wheels of in-feed section | 20pcs |

| 4 | Oil Pipe Connection HEGU PA-4 | 2sets |

| 5 | Seal Ring HEGU PB-4 | |

| 6 | Straight Joint HEGU PD-406 | |

| 7 | Oil Pipe Connection HEGU PA-6 | |

| 8 | Seal Ring HEGU PB-6 | 2sets |

| 9 | Right Angle Connector HEGU PL-610 | |

| 10 | Belt for Grinding Wheel 10PJ-483 GB/T16588-1996 | 1pc |

| 11 | Belt for Grinding Wheel 10PJ-838 GB/T16588-1996 | 1pc |

| 12 | Thermal relay, contractor | 2sets |

| 13 | Tool cases | 1pc |

Equipment Characteristics

Standard function

Connecting control function

The vertical computer is the main controller for the whole processing line control include stop and start for the whole line, the actions of edger 1 and edger 2, transfer table, detecting table. The computer of edger 1 is to control the common functions itself include change the grinding wheels, lift the linear rail, zero point, etc. The computer of edger 2 is to control the common functions itself include change the grinding wheels, lift the linear rail, zero point, etc.

Admin

System provides 3 user levels for password changing, user adding, user deleting.

Alarm

If there is problems in machine running, the alarm light will be on at the bottom of operation page, user can check the alarm information for details with real time status of PLC input and output, yield, etc.

Processing margin detecting

standard processing margin range is 2mm, if the processing margin of current glass exceed 2mm, the edger will automatically slow down the grinding speed to avoid chipping. The total processing margin shall be 1~6mm, if exceed this range, the edger will more and more slower even stop running.

Washing machine connecting

Washing machine shall be connected with edger 2. If the washing machine stop running, edger 2 will stop conveying the glass to avoid impact. Washing machine & edger 2 shall be connected by cable to make this synchronization function.

Benefits and Advantages

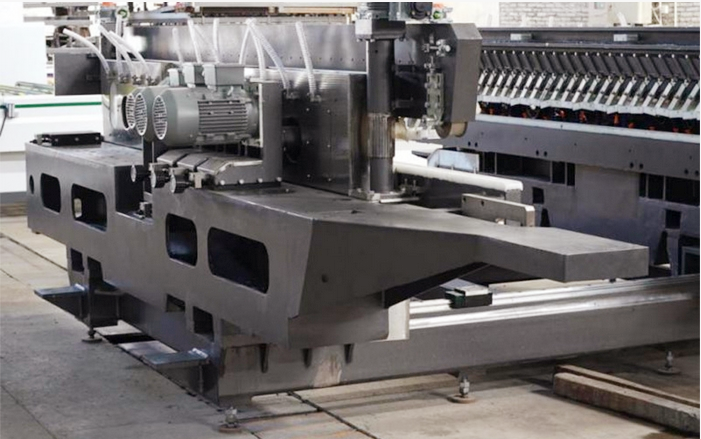

Equipment base bed

The base bed is made of formed square tubes with a thickness of 12mm and a size of 200*300, which can ensure stability and durability. After annealing according to the process requirements, the base bed is processed once with a large gantry milling machine, and anti-rust treatment is carried out in strict accordance with the process.

Figure 1 Equipment base bed can ensure stability and durability

Figure 1 Equipment base bed can ensure stability and durability

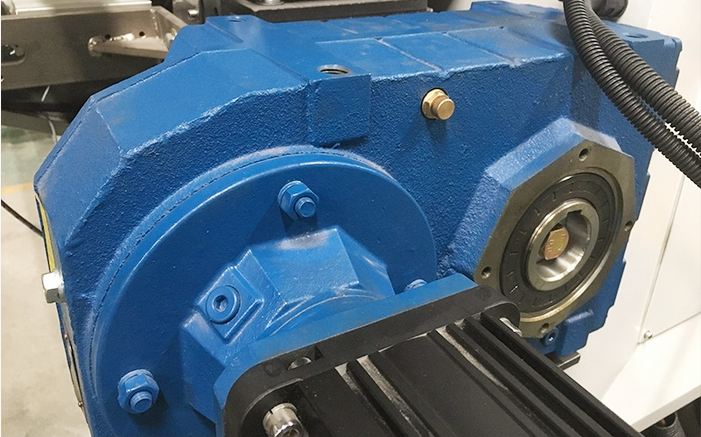

Main drive mechanism and width adjustment mechanism

The main drive uses two sets of servo motors to achieve synchronous operation, and the reducer uses a hard-tooth surface gear reducer, which has high transmission efficiency, fast speed and large load capacity.

The machine width adjustment is driven by a servo motor system using Taiwan's TBI high-precision ball screw. The screw adopts a diameter of 50mm. This is the largest diameter ball screw in the glass machinery industry. It plays a decisive role in the stability of high-speed opening and closing. Its advantages , fast running speed, high precision, and the maximum speed of dimensional change can reach 15m/min. It can cooperate with intelligent equipment such as inspection tables and loading and unloading tables to achieve fully automatic processing.

Figure 2 Main drive mechanism and width adjustment mechanism

Figure 2 Main drive mechanism and width adjustment mechanism

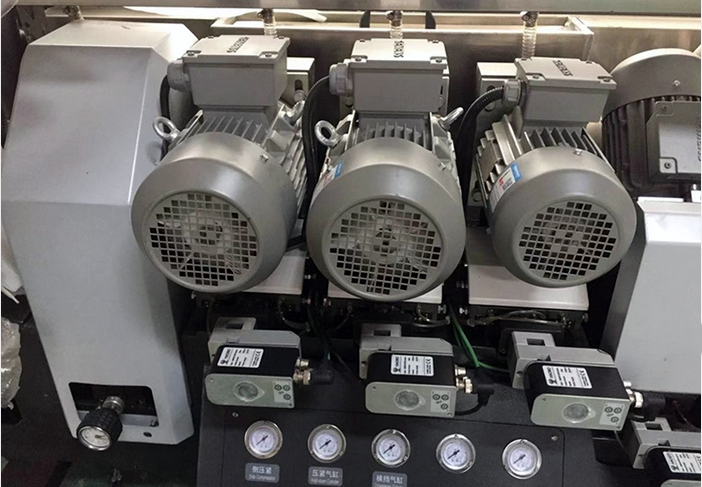

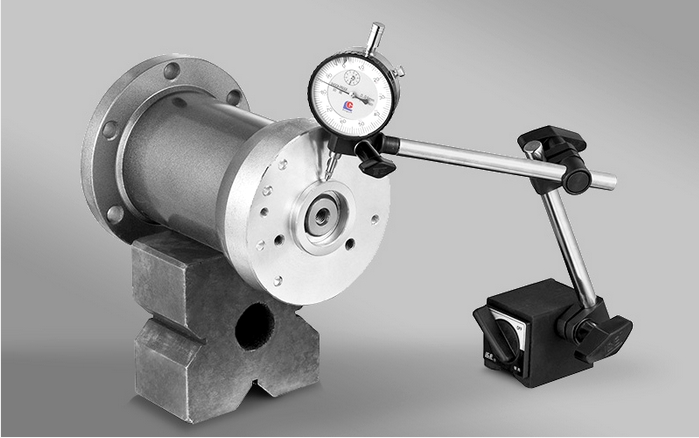

Manufacturing accuracy of grinding head motor

LIJIANG Glass manufactures some key parts of mechanical grinding heads and cooperates with domestic CNC machine tool companies to design a grinding head spindle assembly that is more suitable for LIJIANG Glass based on CNC spindle standards. The spindle has enlarged angular contact ball matching bearings. The motor is a Siemens energy-saving motor with a belt speed change and a rotation speed of 4500r/min.

Figure 3 High accuracy of grinding head motor

Figure 3 High accuracy of grinding head motor

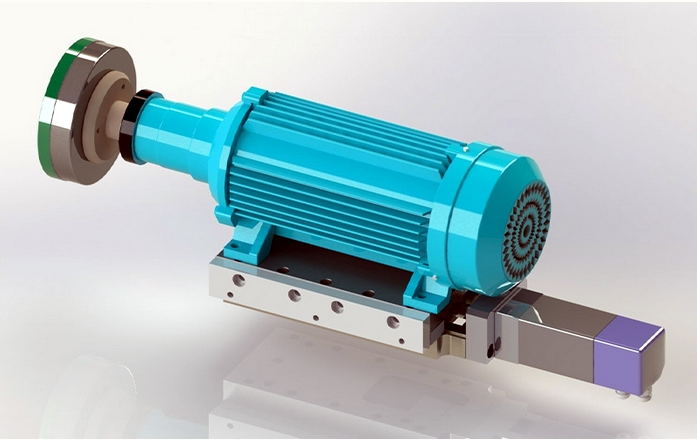

Upper and lower chamfering grinding head device

The lower chamfer design installs the Siemens motor at the top instead of the bottom, which can avoid the problem of water intrusion and damage to the motor.

The upper chamfering adopts a special grinding head motor, and uses variable frequency speed regulation to increase the motor speed to 4000r/min. It is easy to maintain. At the same time, it also uses a positioning system for automatic position adjustment.

Figure 4 The upper and lower chamfering grinding head devices can automatically adjust their position.

Figure 4 The upper and lower chamfering grinding head devices can automatically adjust their position.

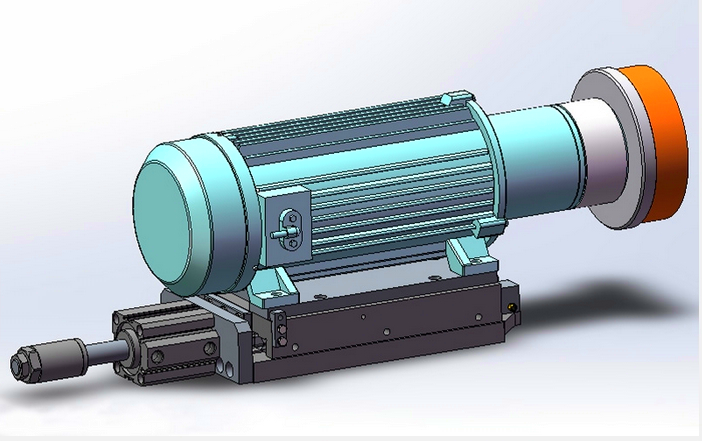

Processing performance of overall grinding

The coarse grinding head assembly of Siemens motor has a rotation speed of 4500r/min, which results in faster grinding speed and better processing quality.

The spindle part adopts a waterproof design with core technology. During high-speed operation, internal pressure will be generated inside the spindle and the water vapor will be discharged by itself, ensuring the stability of grinding and avoiding the problem of water intrusion into the spindle.

When choosing a direct-connected grinding head model, the grinding head is equipped with frequency conversion speed regulation, and the motor speed is also 4500 rpm. This can realize that when no glass enters, the equipment enters a dormant state, and when glass enters, the machine resumes processing status. Realize energy saving function.

Figure 5 Improved processing performance of overall grinding

Figure 5 Improved processing performance of overall grinding

Coarse grinding automatic feeding system

The working principle of the intelligent grinding head device is through a manual-automatic integrated reducer connected to a precision ball screw. The main computer system or PLC issues position instructions. The high-precision motor is connected to the ball screw to rotate and drive the grinding head motor and grinding head. The spindle assembly automatically moves to the position required by the instruction. When the grinding wheel detection assembly meets the detection conditions, it is controlled by the main computer system or PLC to start the detection. The detection block is retracted to the detection position by the cylinder, and then the intelligent grinding head feeding system drives the grinding wheel movement to touch and push the detection block. The grinding wheel size can be detected through feedback from the proximity switch or electronic ruler.

Figure 6 Coarse grinding automatic feeding system

Figure 6 Coarse grinding automatic feeding system

Automatic polishing system

The polishing cylinder adopts Taiwan Airtac φ50 adjustable cylinder with locking structure. The locking accuracy is high and the gap is small.

Figure 7 The automatic polishing cylinder system

Figure 7 The automatic polishing cylinder system

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.