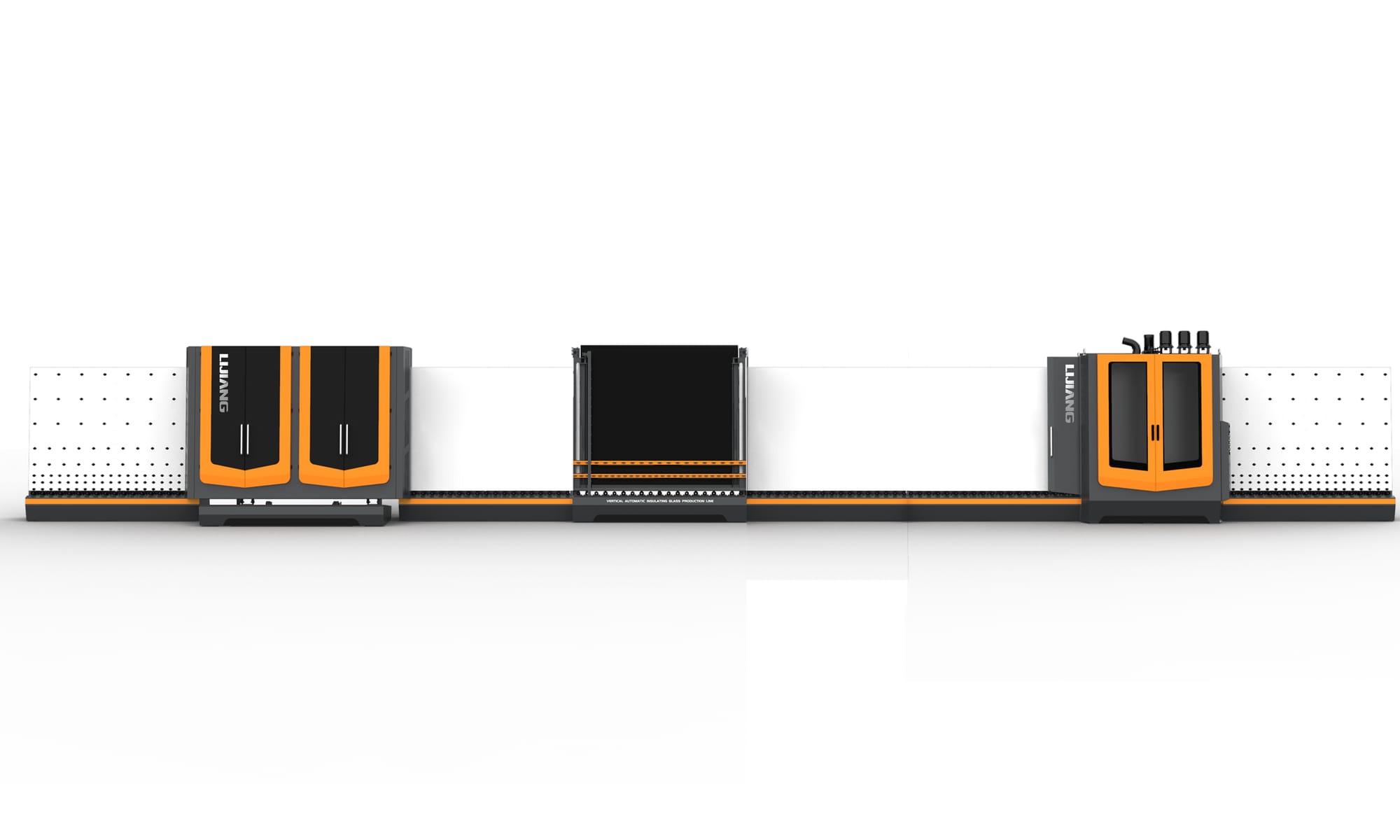

Automatic Insulated Glass Production Line(Double Glass Machine)

LIJIANG Glass provides complete turnkey solutions for insulating glass production, covering glass cutting, washing, spacer bending, IG assembly, gas filling, sealing robots, and final inspection. Our automated systems are designed for factories seeking higher efficiency, stable quality, and faster delivery times.

Are you doing research on buying affordable insulated glass producing equipment for glass deep-processing with any budget in USA, UK, UAE, Canada, Australia, Russia, South Africa, China, India, or other countries from Asia, Europe, North America, South America, Africa, and Oceania?

Review 2025 best budget automatic double glazing producing machinery buyer's guide for glass workers, glass processing machinists, glass fabricators, builders, carpenters operators, craftsmen, and beginners.

LIJIANG Glass Machinery will offer you 2025 top rated automatic insulating glass processing machines with custom CNC glass cutting, washing and drying, loading and unloading, tempering, and insulating service to fit your glass processing projects, plans, and ideas in glass produce and process instruments.

Insulated Glass Production Line Buying Guide

Before you get a insulating glass processing machine of your own, whether you are a insulating glass processing machine novice or an expert, you should understand what your purpose in buying it. What do you need it to do for your projects? Is it argon-gas filling or plate pressing, washing, or sealing? Once you are familiar with your purpose and needs, as well as your budget, you will be able to make a targeted purchase of the insulating glass processing machine that best matches your business.

What is the automatic insulating glass production line?

An insulating glass production line is a kind of glass deep processing equipment, which is mainly used to process and make insulating glass instruments. It mainly goes through glass washing, drying, making spacer frames, filling desiccant, and the first sealing (coated with butyl extruder). , inspection, frame placement, sheet pressing, second sealing (polysulfide sealants or silicone sealants), and next sheet...

Know More

What is the basic performances of insulated glass production line?

At present, due to the improvement of the quality of the environment-friendly living environment, insulating glass, as a product with advantages such as heat insulation, sound insulation, and fire prevention, is more and more used in building curtain walls and home decoration, thus driving the development of insulating glass production lines. Has the following characteristics:

Know More

What is the design scheme of the automated insulating glass production line?

Insulating glass is a new type of building material with excellent features such as sound insulation, heat resistance, and heat preservation. It is particularly necessary and urgent to improve the automation productivity of insulating glass and promote the automation, digitization and intelligence of the insulating glass production process...

Know More

What are the application scenarios of insulating glass production lines?

Insulating glass production lines are widely used in construction, automobiles, ships, and other fields. It can produce insulating glass products of different specifications and uses to meet the needs of various industries and has practical value.

Know More

How to choose the configuration scheme of insulating glass equipment?

The equipment required to open an insulating glass processing plant includes: tempering furnace, washing and drying machine, clamping machine, sealing aluminum strip spraying machine, cutting machine, gasket application machine, Low-E glass edge banding machine, and transportation equipment, etc. In addition, auxiliary equipment and facilities such as computer control systems are required. Actual configurations may vary by manufacturer, production scale and product requirements.

Know More

How much does a insulated glass production line cost?

It all depends on your specific needs when you make a plan to purchase a automatic insulating glass production line for glass processing, double glazing production line vary in cost. There is a wide variety of types of insulated glass production line based on table sizes (work areas), features, durability, performance, quality, brand, manufacturer, and customer service which all factor into a IG line's price.

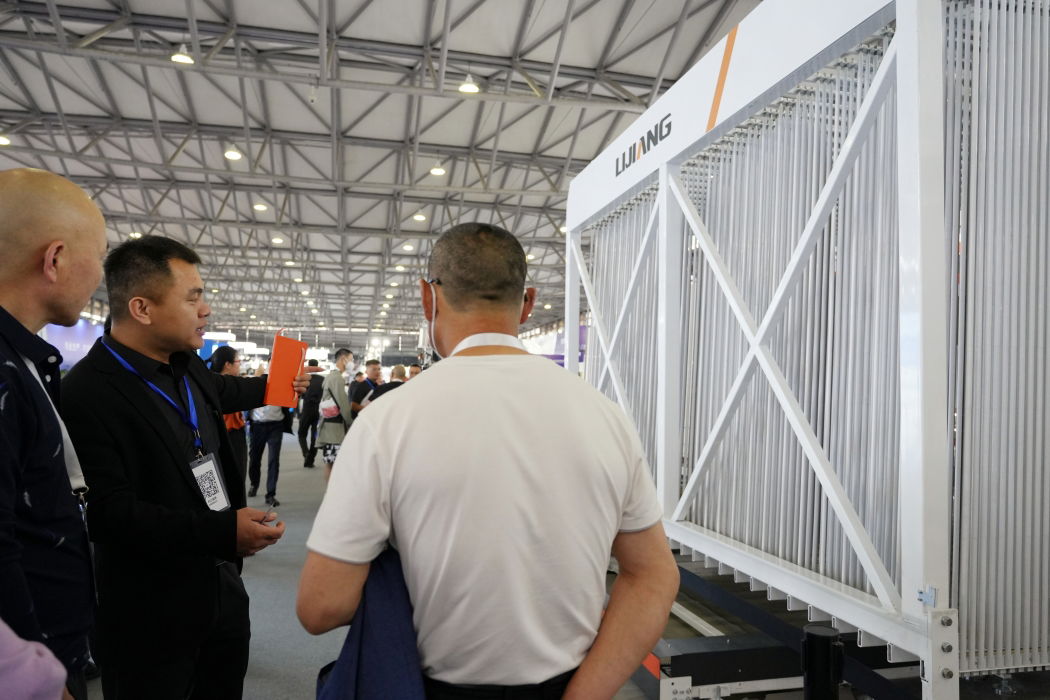

Know MoreTwo Structures of Large-panel Insulating Glass Production Line

The Inside Pressing Combination VS The Outside Pressing Combination

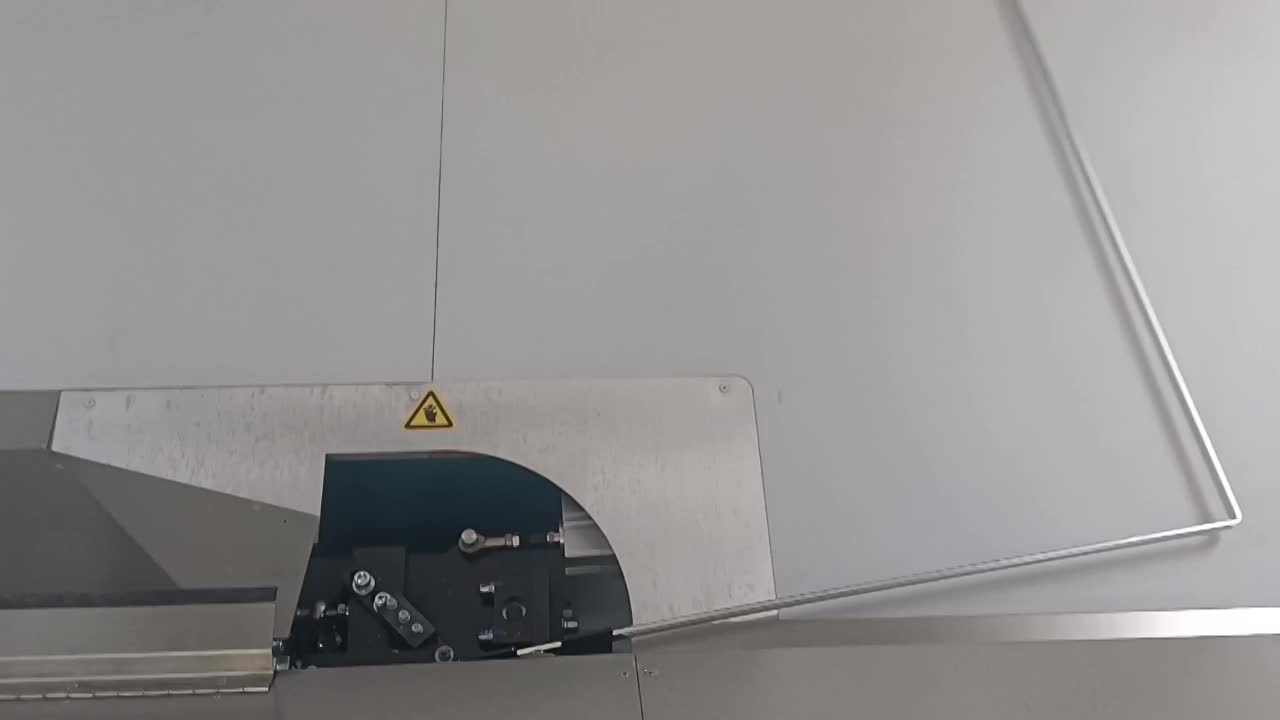

LIJIANG Glass adopts the inside panel pressing function, which can realize the simultaneous pressing and inflating of two pieces of insulating glasses, which effectively improves production rate; Other suppliers generally adopt the outside panel pressing function. Before the glass enters the plate pressing section of the insulating glass production line, the glass needs to be pressed first, and which the production rate is reduced.

The One-time Plate Press Forming VS The Multiple Plate Press Forming

LIJIANG Glass has specially designed two plate pressing sections, which can realize the one-time plate pressing molding of large-panel insulating glass; Other supppliers generally only design a single plate pressing section, and need to press large plates of insulating glass multiple times before the glasses can be pressed into shape.

Automatic Insulated Glass Equipment

If you're purchasing a new insulating glass processing machine in today's marketplace, you'll find similar products everywhere. Whether you're a novice or an expert, it's hard to pick the best one for your business. You'll have to compare similar features and costs, shop around for the best price, and know how to deal with the transaction. Here are four easy-to-follow steps a buyer would take to purchase a new insulating glass processing machine.

- Germany Siemens PLC control system, touch screen interface for finger touch operate

- Automatic identification of coated glass and Low-E glass;

- 3 pair of soft brushes could wash online Low-E glass and offline Low-E glass;

- The washing parts adopt SS material and waterproof device;

- Water tank with automatic temperature control and water washing system.

- Air heating system;

- Air Fan automatic start and stop setting;

- Noise reduction system;

- Online display of washing speed;

- Intelligent intermittent work, saving energy;

- Adjustable pressing board to keep the plate pressing surface straight;

- Connection mode of aviation plug;

- Applicable to produce triple IGUs and Shaped IGUs.

- Pre-washing Function;

- Automatically accurate positioning for 3 or 4 side step DGUs;

- Automatic Argon-gas filling could set gas value and display the process of filling online with high gas concentration.

| Unit | LJBZ2030 | LJBZ2030G | LJBZ2535 | LJBZ2535G | LJBZ2535DG | |

| Voltage | 380V 50Hz 3P | |||||

| Total Power | Kw | 39.5 | 36 | 41 | 39.5 | 44 |

| Washing Speed | m/min | 2-10 | ||||

| Maximum Working Speed | m/min | 45 | ||||

| Minimum Glass Size | mm | 450*280 | ||||

| Maximum Glass Size | mm | 2000*3000 2000*3500 (Secondary Tableting) | 2500*3500 2500*4000(Secondary Tableting) 2500*4500(Secondary tablet pressing and auxiliary suction cup mechanism) | |||

| Flat Glass Thickness | mm | 3~15(Could be customized 3~30) | ||||

| Washing Brushes | pieces | 6 | ||||

| Maximum Thickness of Insulating Glass | mm | 60 | ||||

| Total Gas Consumption | L/min | 1200 | ||||

| Conveyer roll Height | mm | 520 | ||||

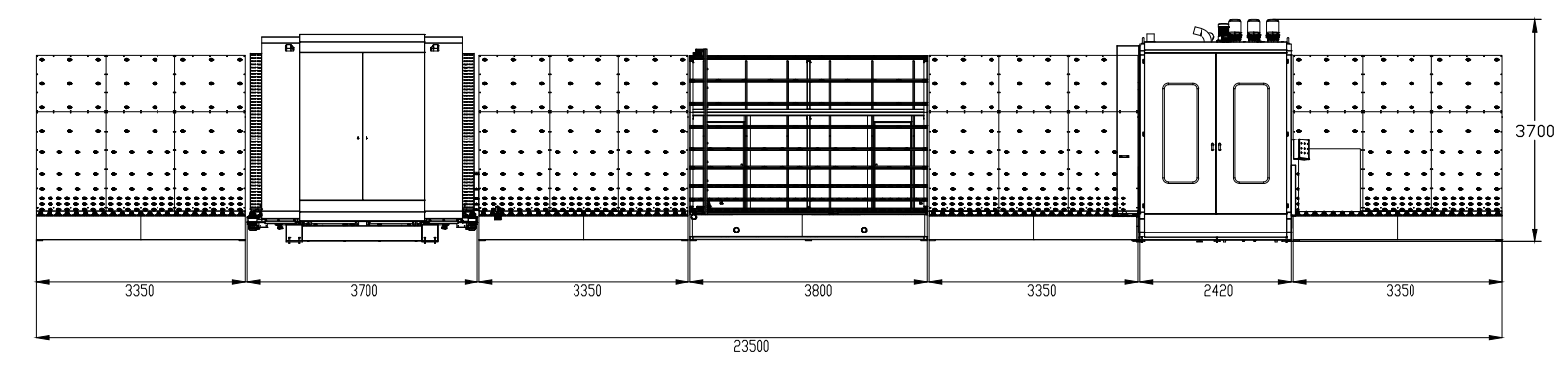

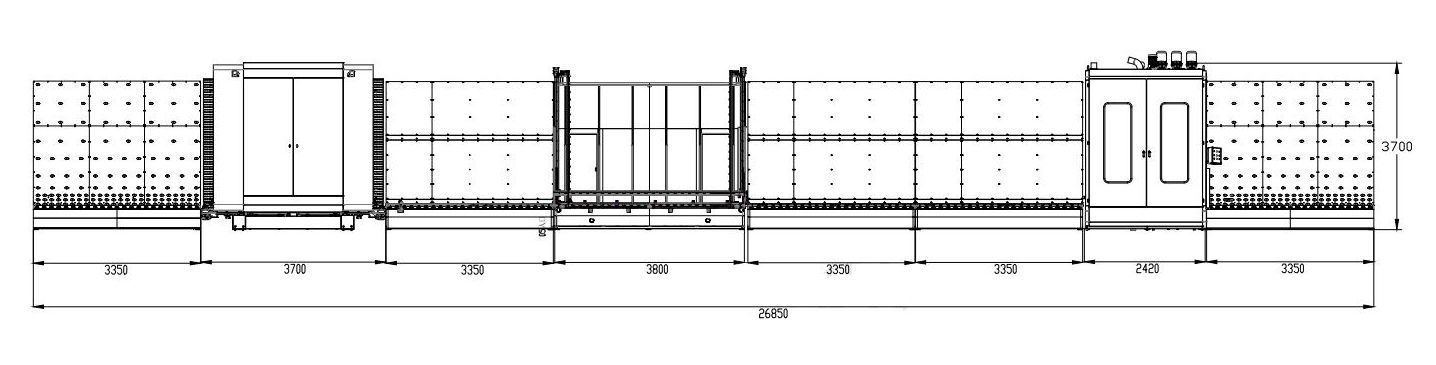

| Dimension L*W*H | mm | 20200*3500*3200 | 23800*3500*3700 | 27200*3500*3700 | ||

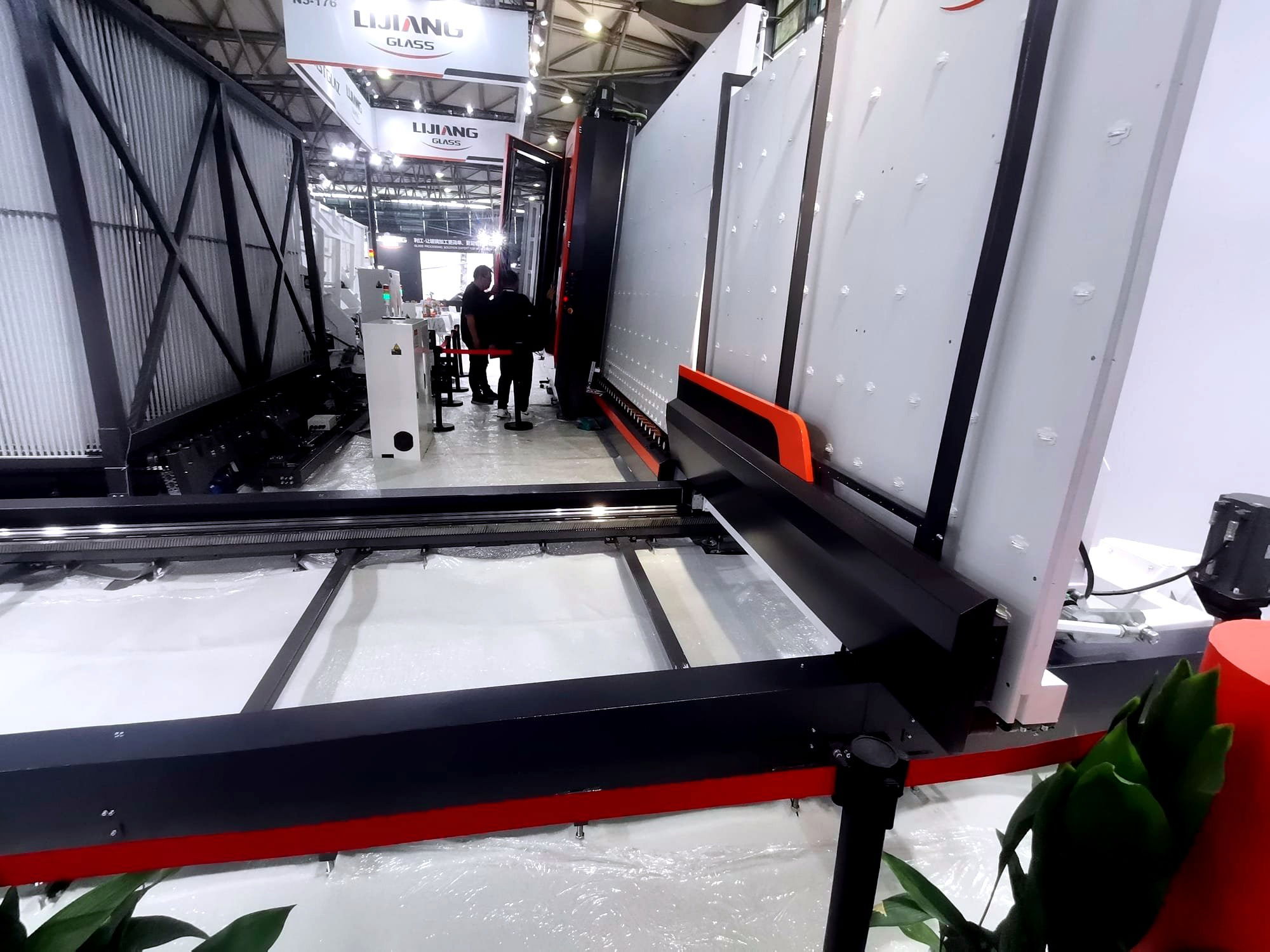

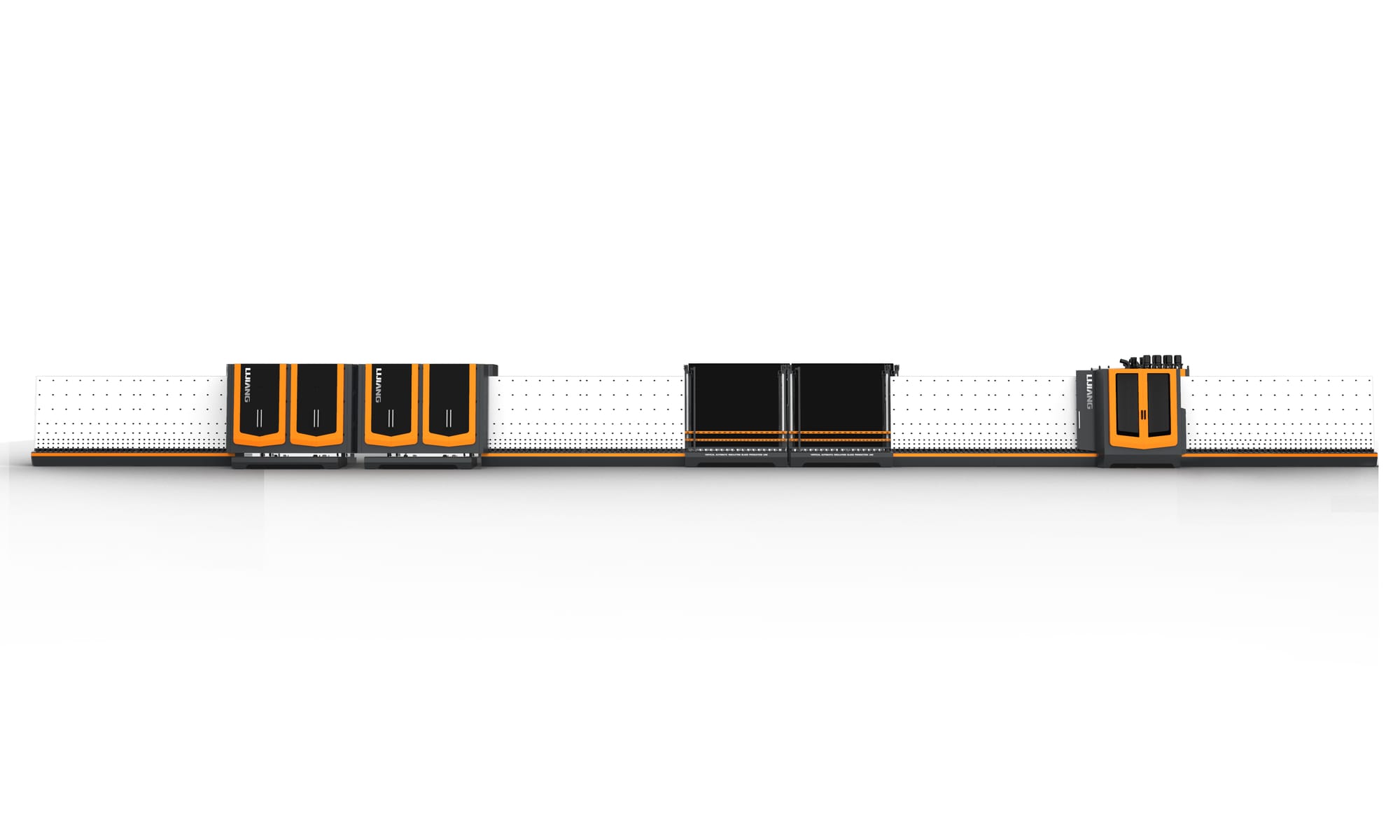

Automatic Vertical Insulated Air-floating Glass Production Line

- Air-floating back plate, to avoid the wheel scraching the glass and leaving wheel marks;

- Two pieces of IGUs or DGUs could be pressed and filled gas in once time, high work efficiency;

- Argon-gas filling in pressing, automatic filling the glass in different areas according to the size of glass;

- Germany Siemens PLC control system, touch screen interface for finger touch operating;

- Automatic identification of coated glass and Low-E glass;

- 3 pairs of soft brushes could wash online Low-E glass and offline Low-E glass;

- The washing parts adopt SS material and waterproof device;

- Water tank with automatic temperature control and water washing system;

- Air heating system;

- Air Fan automatic start and stop setting;

- Noise reduction system;

- Online display of washing speed;

- Intelligent intermittent work, saving-energy;

- Adjustable external rotary positioning system of DGUs or IGUs;

- Connection mode of aviation plug;

- ERP system is optional.

| Unit | LJBZ2030GF | LJBZ2535GF | LJBZ2535DGF | |

| Voltage | 380V 50Hz 3P | |||

| Total Power | Kw | 41 | 44.5 | 58 |

| Washing Speed | m/min | 2~10 | ||

| Maximum Working Spped | m/min | 45 | ||

| Minimum Glass Size | mm | 450*280 | ||

| Maximum Glass Size | mm | 2000*3000 2000*3500(Secondary tableting) | 2500*3500 2500*4000(Secondary tableting) 2500*5000 (Secondary tablet pressing and auxiliary suction cup mechanism) | |

| Flat Glass Thickness | mm | 3·15(can be customized 3~30) | ||

| Washing Brushes | pieces | 6 | ||

| Maximum Thickness of insulated glass | mm | 60 | ||

| Total Gas Consumption | L/min | 1200 | ||

| Conveyer Roll Height | mm | 520 | ||

| Dimension L*W*H | mm | 20200*3500*3200 | 23800*3500*3700 | 27200*3500*3700 |

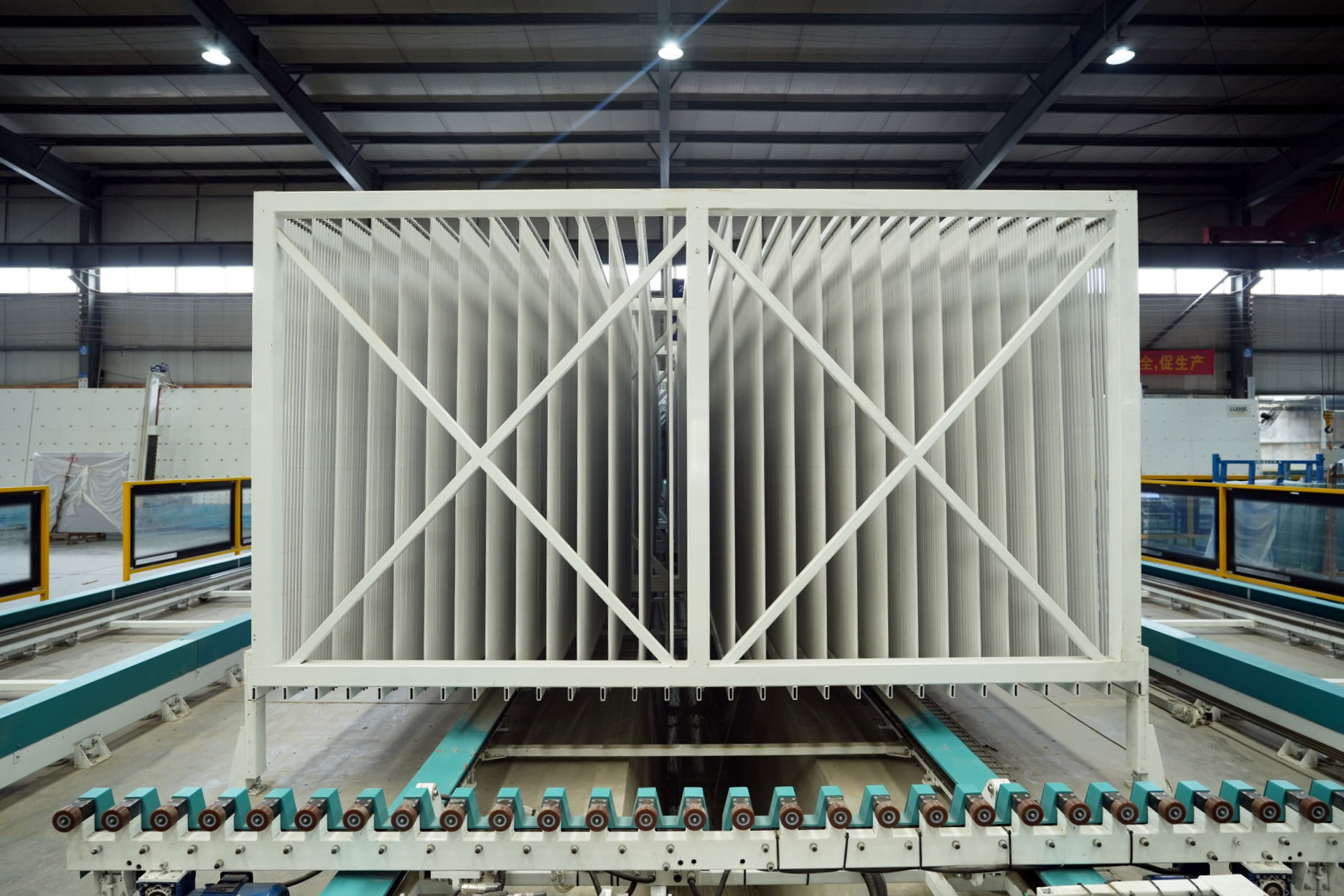

Automatic Jumbo Size Double Plate Pressing Argon-gas Filling Insulated Glass Production Line

- Germany SIemens PLC control system, touch screen interface to finger touch operating;

- Automatic identification of coated glass and Low-E glass;

- 3 pairs of soft brushes could wash online Low-E glass and offline Low-E glass;

- Water tank with automatic temperature control and water washing system;

- Air heating system;

- Air Fan automatic start and stop setting;

- Noise reduction system;

- Online display of washing speed;

- Intelligent intermittent work, saving-energy;

- Adjustable pressing board to keep the plate pressing surface straight;

- Connection mode of aviation plug

- Applicable to produce triple IGUs and shaped IGUs.

Optional Function

- Pre-washing Function;

- Automatically accurate positioning for 3 side step DGUs or 4 side step IGUs;

- Automatic argon-gas filling could set gas value and display the process of filing online with high gas concentration.

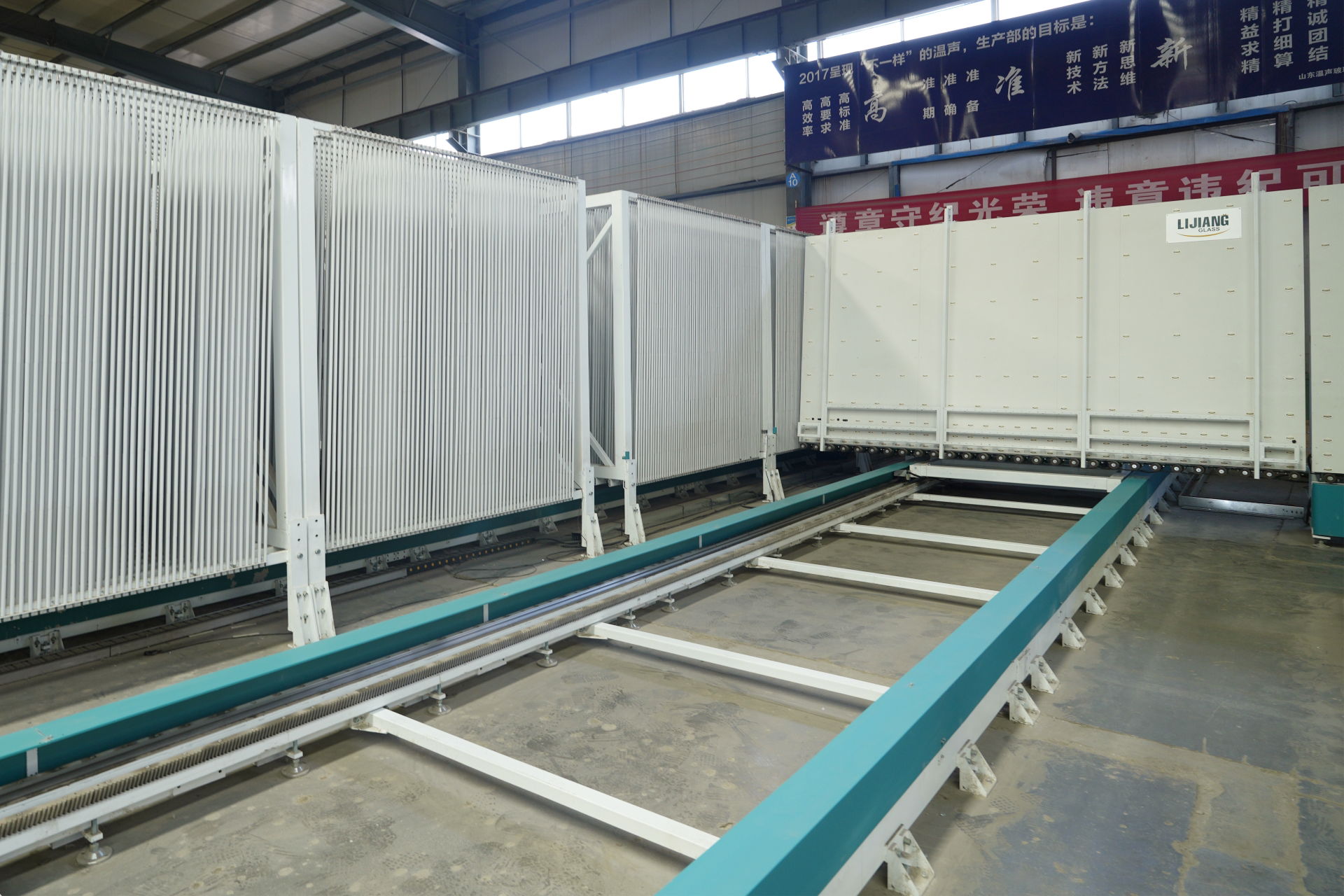

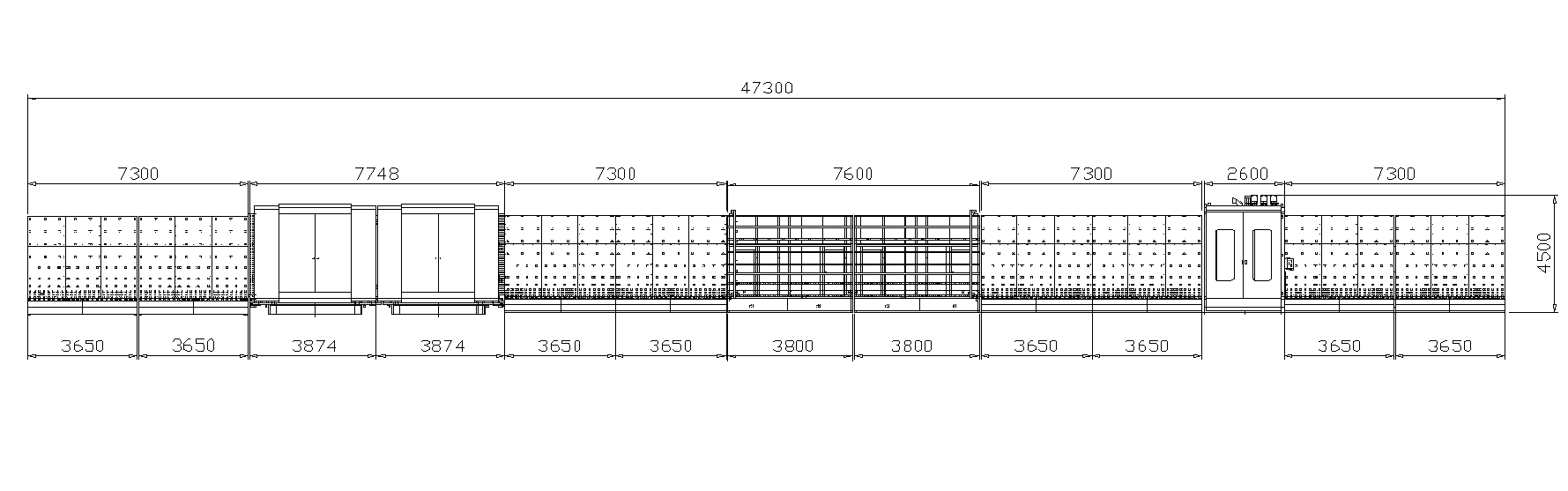

For example, the maximum size of insulating glass required for a construction project is 3m*6m.

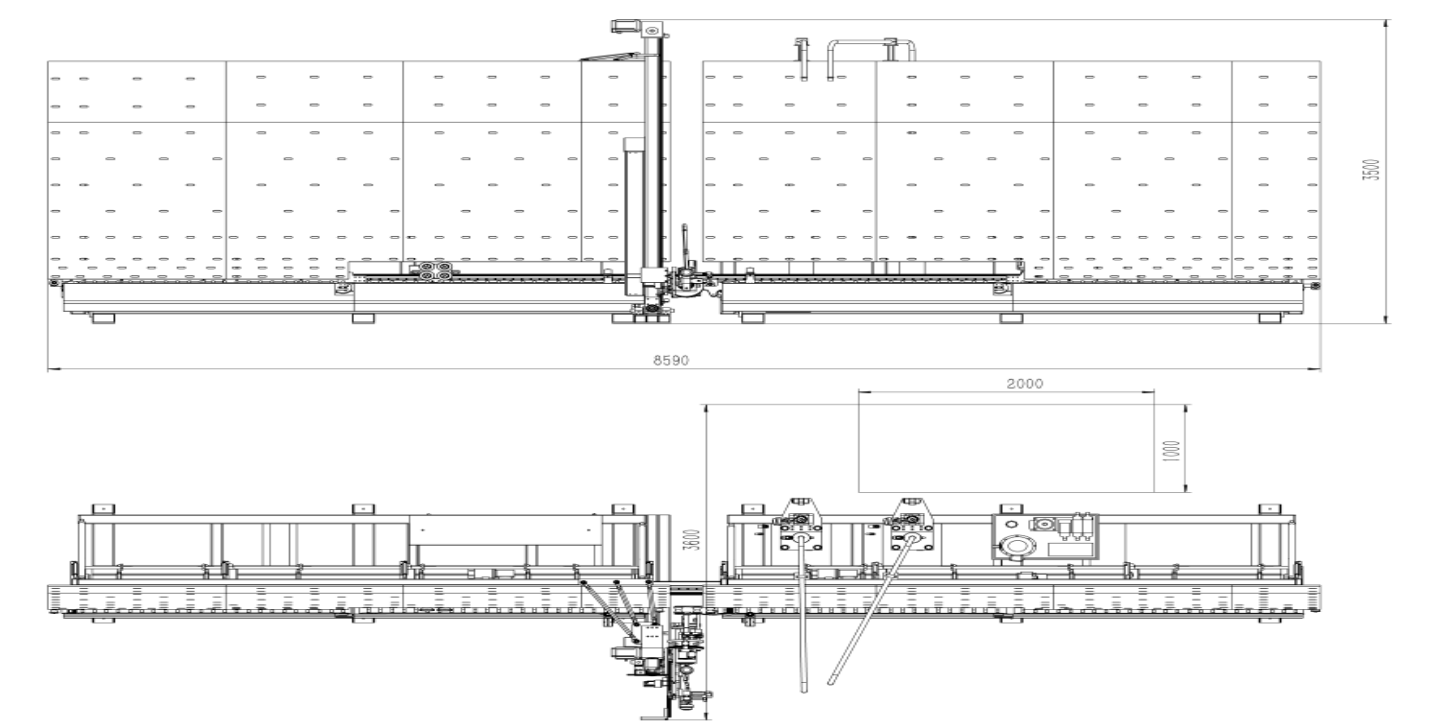

① The equipment structure:

Extended size equipment + Inside combination technology + Two plate-pressing sections + Online argon-gas filling function

Each section of the production line needs to be designed and extended to the maximum size of the large-panel insulating glass, and the equipment size of all processing sections except the vertical glass washing and drying machine is upgraded to more than 6m. At the same time, the plate pressing section is made into two sections, and the processing method of combining the plates inside the plate is adapted to meet the requirement that the maximum length reaches 6m.

Advantage:

1. It can realize the one-time plate press molding of large plate insulating glass, and complete the argon filling function at one time, without the need for multiple processing operations;

2. It can realize simultaneous pressing and inflating of two pieces of insulating glass to improve production efficiency.

Disadvantages:

1. The production line occupies a large workshop area;

2. The price is relatively high.

Know More

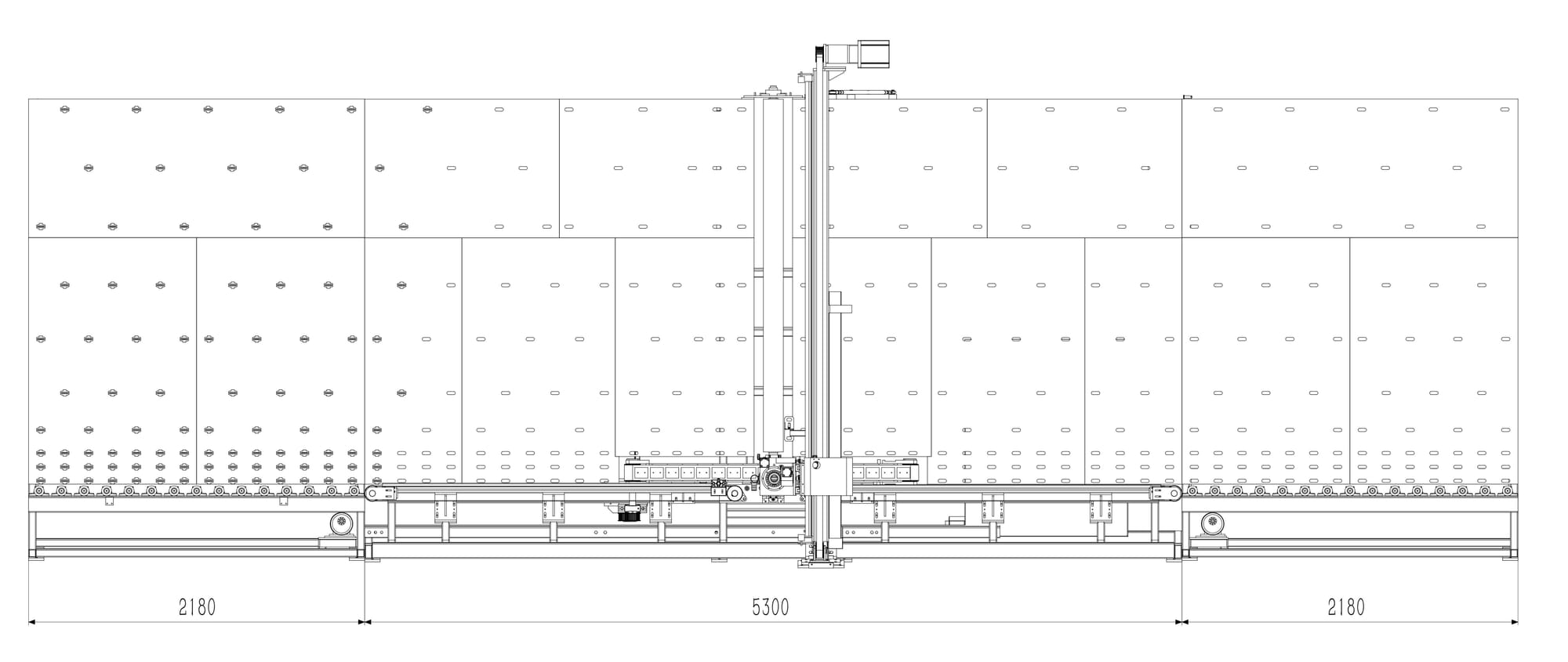

②The equipment structure:

Normal size equipment + Outside combination technology + Only one plate-pressing sections + Offline argon-gas filling function

It using the method of outside combination sheet + single plate press, it is necessary to combine two pieces of 3m*6m glass together outside the plate press, and the glass enters the plate press two or more times Pressing for the second time, and then manually inflating to complete the processing of insulating glass.

Advantage:

1. The equipment of the second structure is about 4 meters shorter than the double-plate press of the first structure, and the floor space is smaller.

2. The price is relatively lower than LIJIANG Glass LJBZ3370 Automatic Jumbo Size Insulating Glass Production Line.

Disadvantages:

1. The length of the plate press is not enough, it needs to be pressed twice or more times, which will cause uneven pressing of the first sealant butyl rubber coating and affect the sealing effect of the glass.

2. There is no way to fill the glass with argon gas online. The only way is to move the glass offline to punch holes and then manually inflate the gas. Manual inflation takes a long time, and it is difficult to meet the standard requirements of a gas content.

3. During the processing of large glass plates, multiple pressings are required, and the production efficiency will also be reduced.

| Unit | LJBZ3370 | |

| Voltage | 380V 50Hz 3P | |

| Total Power | Kw | 54.5 |

| Washing Speed | m/min | 2~10 |

| Maximum Working Speed | m/min | 45 |

| Minimum Glass Size | mm | 450*280 |

| Maximum Glass Size | mm | 3300*7000(Single-Press Mode) 3000*3000(Double-Press Mode) |

| Flat Glass Thickness | mm | 3~30 |

| Washing Brushes | pieces | 6 |

| Maximum Thickness of Insulated Glass | mm | 80 |

| Total Gas Consumption | L/min | 1500 |

| Conveyer Roll Height | mm | 520 |

| Dimensions(L*W*H) | mm | 47200*3500*4500 |

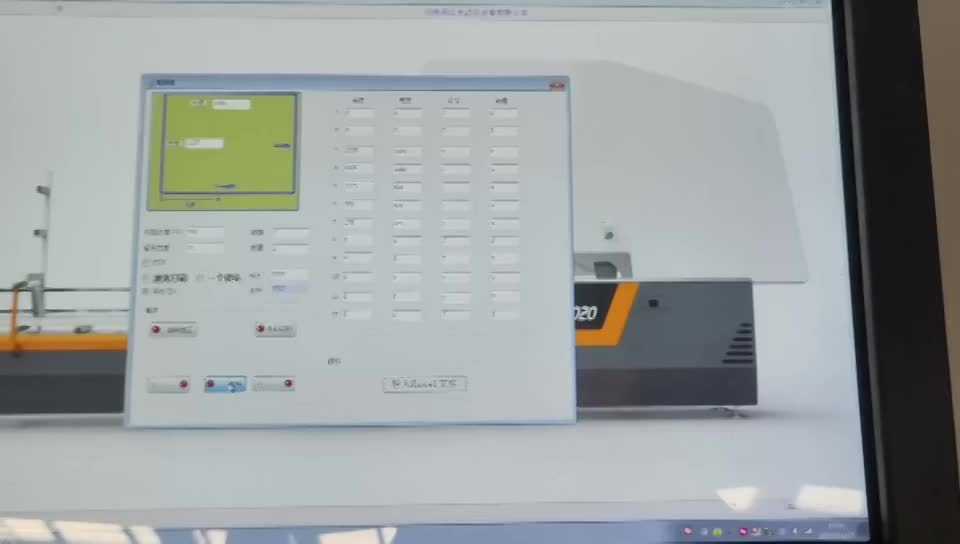

- Six sets of servo motors, British TRIO system;

- Inlet-outlet with two-diection, 4 directions are available;

- Automatically measure glass size;

- Automatically distinguish Low-E glass coating;

- The width of Low-E glass edge deletion is adjustable;

- Adopts PLC control system, touch screen interface for finger touch operating;

- Intelligent control system, could recognize batch processing.

- Deleting shaped Low-E glass;

- Automatically recognize of Low-E glass film.

| Item. | Spec. |

| Voltage | 380V 50Hz 3P |

| Max. Glass Processing Size | 2500 mm*4500 mm |

| Min. Glass Processing Size | 300 mm*400 mm |

| Glass Thickness | 3-15 mm |

| Low-E Edge Deleting Width | 10-500 mm |

| Glass Conveying Speed | 0-30 m/min |

| Low-E Glass Edge Deleting Speed | 2-29 m/min |

| Grinding Wheel Width | 10/12/15 mm |

| Total Power | 15 Kw |

| Dimension(L*W*H) | 9700*2500*3400 mm |

| Weight | 2600 Kg |

- Adopts Japan Yaskawa servo control system, full automatic and high-efficiency;

- Automatic memory function, no need to input parameters repeatedly;

- Automatically repair glass corners with scraper and roller;

- The conveying section of equipment could be divided into four sections, and glass can be pre-stored;

- Automatically measure glass size and glass depth, adjust sealing speed;

- Adopt timing belt, smooth transfer and accurate position;

- Every automatic-function is with manual operation;

- Could coat the double glazing, shaped glass, step glass, triple glass.

- One set of booster pump control two groups of sealants;

- Automatic timing sealant discharging function;

- The sealant mixing system adopts anti-blocked structure and is easy to clean.

Set parameters: a. On the control interface of the sealing line, set relevant parameters, such as glass plate size, sealing speed, sealing width, sealing thickness, etc. Set parameters according to product requirements and process specifications. b. If using two-component glue, you need to set the glue ratio and mixing time.

Start the sealing robot equipment: a. Press the start button to start the sealing robot equipment. Ensure the safety of the insulating glass production line and wait for the sealing robot equipment to enter normal working conditions.

Automatic conveying of glass plates: a. Place the glass plate to be sealed on the conveyor belt or transmission mechanism to ensure that the position and positioning of the glass plate are accurate.

Automatic sealant sealing application: a. The sealing line will automatically apply sealant evenly to the edge of the glass plate or the parts that need to be sealed according to the set parameters. Ensure that the sealing robot equipment works stably and the glue is sprayed evenly.

Glass plate fixing: a. After the sealant is sprayed, the sealing line will fix another glass plate to be sealed on the glass plate that has been coated with sealant. Make sure the glass panels are aligned accurately and sealed tightly.

Sealant sealing and compression: a. The insulating glass sealing robot machine will perform a certain pressure treatment on the two glass plates to ensure a tight combination of the sealant and the glass plates. Set appropriate pressure and duration based on product requirements and equipment capabilities.

| Item. | Spec. |

| Max. Glass Size | 2000*3000 mm/2500*4000 mm/3300*7000 mm |

| Min. Glass Size | 400*300 mm |

| Glass Thickness | 12-56 mm/12-56 mm/12-80 mm |

| Working Speed | 5-40 mm |

| Air Pressure | 0.6-0.8 MPa |

| Squeeze Pressure | <35 MPa |

| Voltage | 380V 50Hz 3P |

| Power | 15 Kw/15 Kw/20 Kw |

| Overall Dimension(L*W*H) | 3700*2500*3000 mm/8700*2500*3500 mm/ 15000*2500*4300 mm |

| Weight | 4300 kg/5000 kg/7000 kg |

LJTJ2030/LJTJ2540 Automatic Insulated Glass Sealing Robot Equipment 2

LJTJ2030/LJTJ2540 Automatic Insulated Glass Sealing Robot Equipment 2 Automatic Insulated Glass Aluminum Spacer Bending Machine

- Adopts the servo control feeding system, the size of aluminum spacers could be adjusted with an accuracy of 0.1 mm/m;

- CNC Bending angle control system with adjustable accuracy of 0.1°;

- Sets up four groups of aluminum spacers and stainless steel spacers storage units;

- Aluminum spacer bars with multiple sizes could be selected at will;

- Automatically adjust the bending speed according to the size of the aluminum spacer or stainless steel spacer to avoid the deformation of the large spacer and ensure the high speed and continuity of the small frame;

- Automatic continuous connection of spacer, cutting spacer, avoidance of spacer joint;

- No material prompt, sleep prompt, fault prompt, work prompt, unreasonable data refuse processing and prompt support arc-shaped aluminum spacer and special shaped aluminum spacer bending;

- USB function, which could read EXCEL directly;

Optional Performance

- Could connect with ERP system;

- Could optional the function of automatic printing code, automatic printing label, bending the stainless steel spacer, bending the warm edge spacer, bending the stainless steel composite warm edge strips, bending the glass fiber warm edge strips, and bending the pure opaque steel strips.

- Turn on the power, turn on the operating switch on the control console, and press the oil pump to start.

- Adjust the stroke. Pay attention to adjusting the stroke before use; and a gap must be set when the bending machine travels up and down to the bottom. Setting without gap will cause certain wear and tear on the bending machine equipment.

- Selection of the notch of the bending machine. The selection basis is: the thickness of the glass plate is about 8 times the width. For example, if the thickness of the glass plate is 5cm, then the notch needs to be 40cm.

- Manually or electrically fine-tune the stopper behind the bending machine.

- Press the foot pedal switch to perform bending.

- During the processing, the status and processing effect of the glass must be observed at all times to prevent equipment failure or defective products.

- When the bending machine stops working, turn off the operating switch on the operating table, then turn off the power, and clean the work surface of the bending machine to make the surface clean and tidy for next use.

| Item. | Spec. |

| Max. Bending Size | 1800*2000 mm (in once)/ 2500*4000 mm(in twice) |

| Min. Bending Size | 150*300 mm |

| Aluminum Spacer Width | 5.5-26.5 mm |

| Spacers Racks | 4 |

| Spacer Size Error | ±0.5 mm |

| Angle Error | ±1° |

| Conveying Speed | 1250 mm/s |

| Air Pressure | ≥0.65 MPa |

| Voltage | 380 50Hz 3P |

| Total Power | 2.5 Kw |

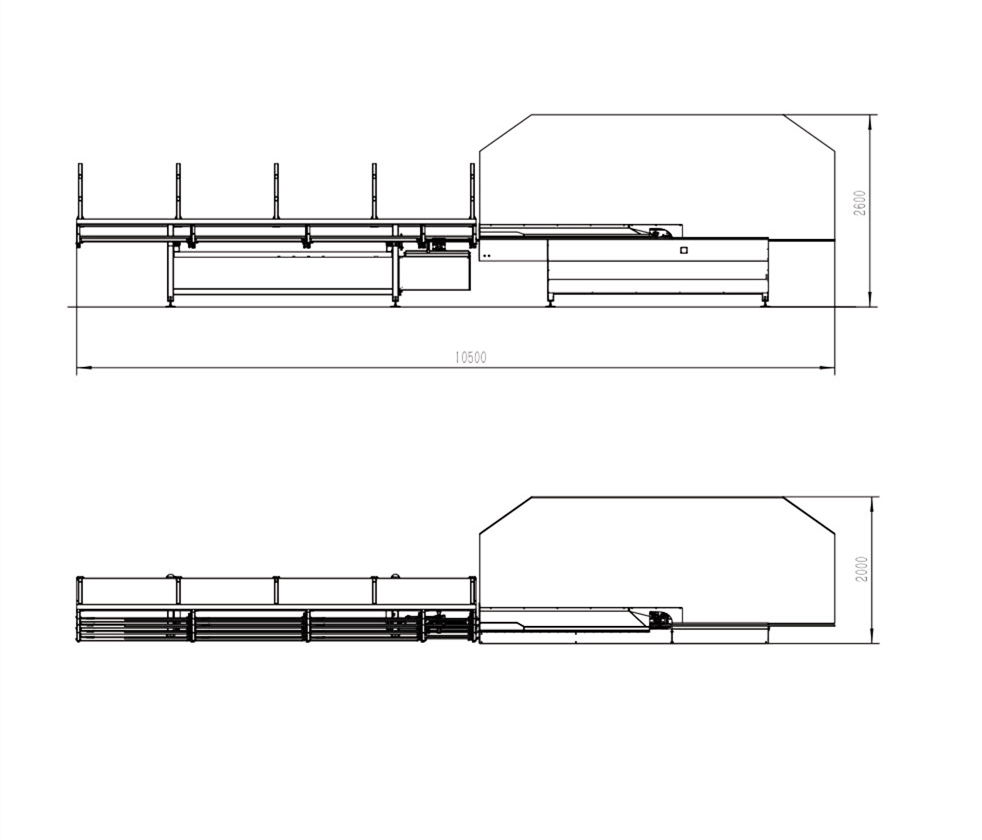

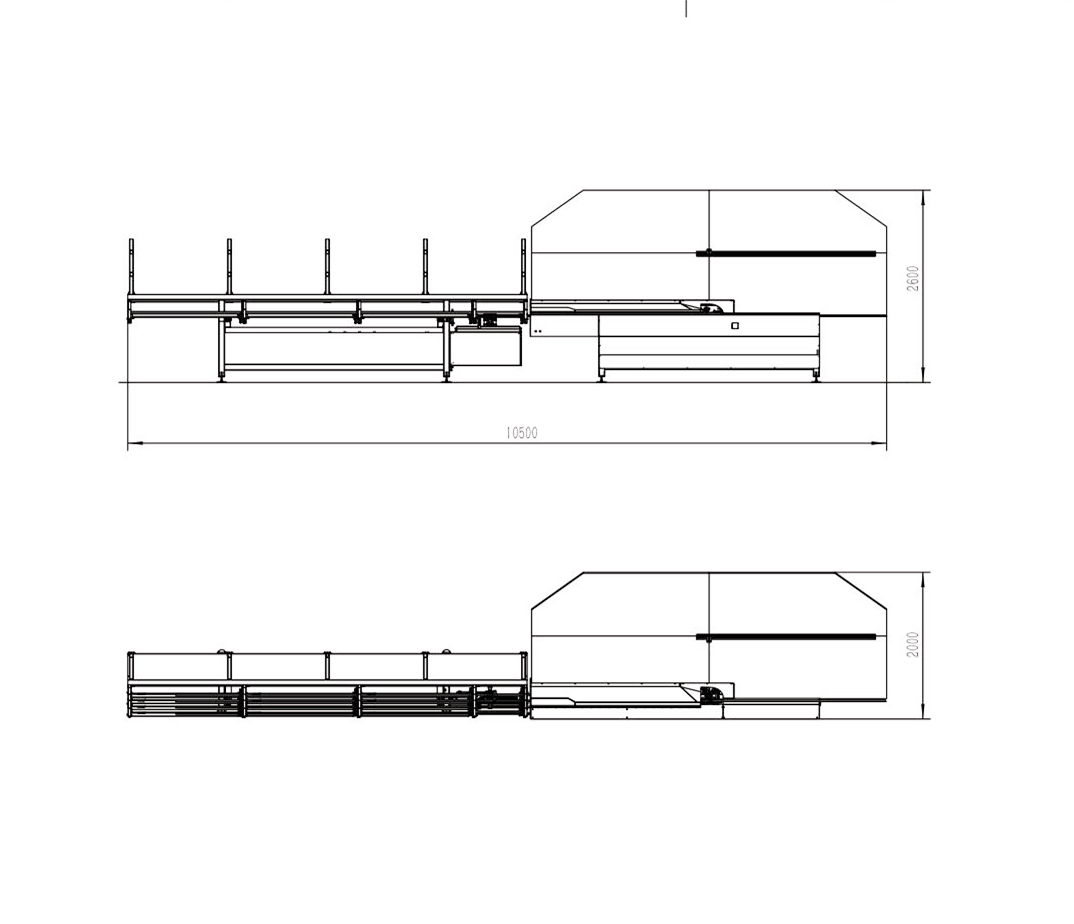

| Dimension(L*W*H) | 10500 mm*2200 mm*2600 mm |

| Weight | 1580 kg |

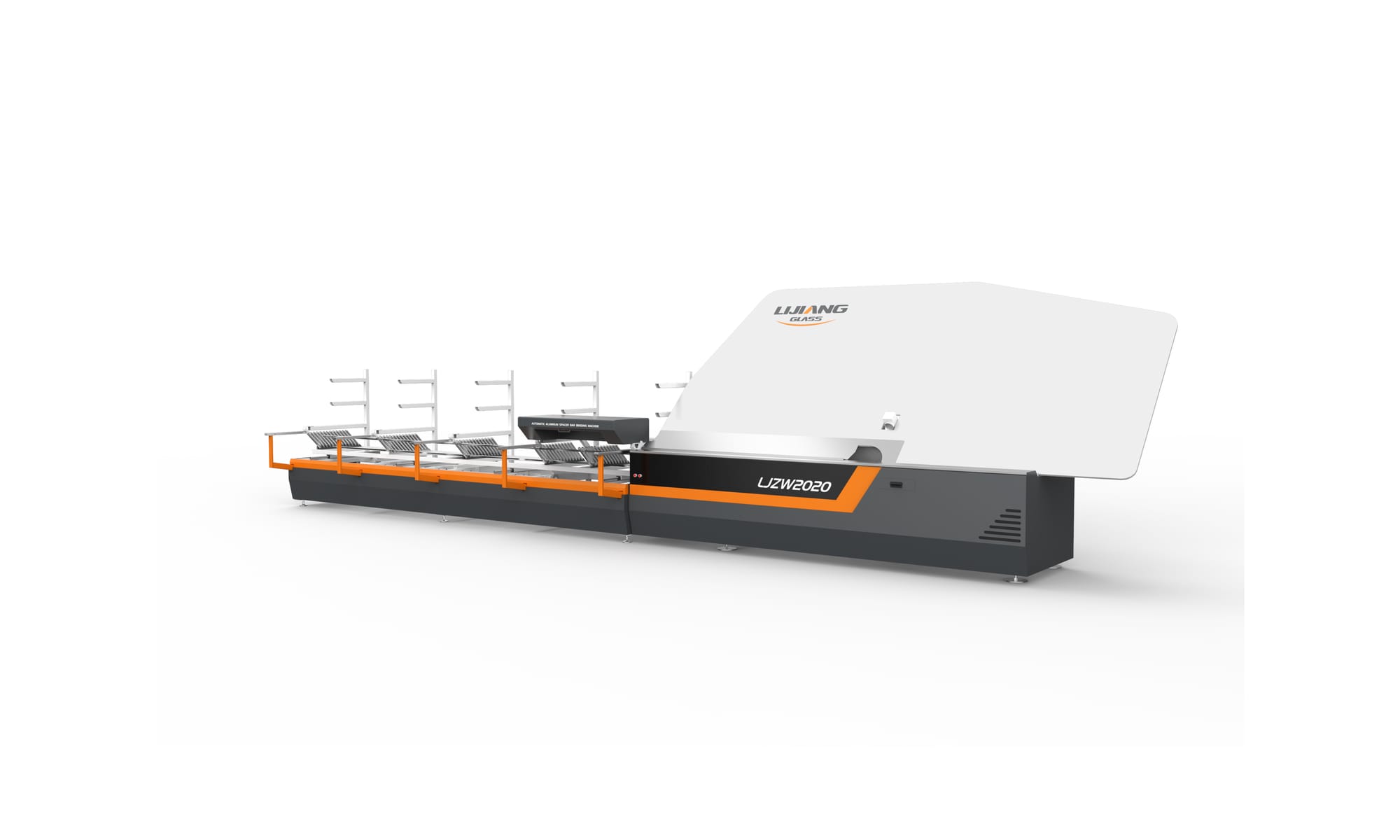

LJZW2020 Insulating Glass Aluminum Spacer Bending Machine

LJZW2020 Insulating Glass Aluminum Spacer Bending Machine LJZW2020A Insulating Glass Aluminum Spacer Bending Machine

LJZW2020A Insulating Glass Aluminum Spacer Bending Machine - The butyl extrusion speed could reach 47 m/min;

- Saving butyl by compared with ordinary machine, the glue could reach 7 g/m;

- Manual exhaust, simple operation;

- Adopt non adhesive synchronous belt, talc powder is not required to clean it;

- Main accessories are made of German brand, PLC Program control, stable performance;

- Using movable vertical butyl release and horizontal extrusion, convenient and practical;

- Adjust the width of glue head automatically, ensure the double side gluing is consistent with the quick opening value integrated control;

- The height adjustment of beam is convenient, effective to solve the problem of write line;

- Use touch screen operation, simple trial;

- Adjust the butyl output automatically according to the speed change;

- Adopt brand hydraulic system to ensure uniform and full rubber output;

- The buytl cylinder adopts the pull-up structure, which is convenient for changing the butyl extruder coating.

The following steps should be followed before and after each operation:

1. Start the conveyor belt

Adjust the conveyor belt to the appropriate speed, with an adjustable range of 8-30m/min.

2. Adjust the position of the rubber extrusion head

According to the width requirements of the spacer, adjust the distance between the two extrusion heads, the range is 6-16mm. When adjusting, the spacer (frame) should be centered with the small pressure wheel and the butyl extrusion nozzle, and the positions of the conveyor belt frame, butyl extrusion seat, and butyl extrusion head should be adjusted according to the height of the adhesive tape.

3. Butyl extruder temperature adjustment before work

Generally, the heating control switch is turned on about 1-2 hours before work, and the glue head temperature is set to 120-140℃ and the glue tank temperature is 110-120℃. Since the heating temperatures and process parameters specified for butyl rubber produced by various manufacturers are different, the above heating temperatures and times are for reference only.

4. Adjustment of opening and closing of the butyl extruder valve

After the heating system reaches the set temperature, do not open the hydraulic station first, but proceed as follows:

Process time setting:

According to the screen prompts, switch to the screen that needs to be adjusted, press the SET key, and the adjustable value will flash. The "←, →" keys change the position of the value; press the "↑" key to increase the value; press the "↓" key to decrease the value. After setting, press the ENT key and the data will be automatically stored, otherwise, the data will remain at the original value.

A. Adjust the time of the right pressing wheel: Make the front end of the spacer frame (strip) on the conveyor belt and the center of the extrusion head, so that the right pressing wheel presses on the aluminum spacer frame (strip). Before the end of the spacer frame (strip) passes through the right pressure wheel, the right pressure wheel can be lifted smoothly, which is very important for the bent spacer frame.

B. Adjust the time of the left pressing wheel: make the front end of the spacer frame (strip) on the conveyor belt, and make the left pressing wheel press on the aluminum spacer frame (strip). Before the end of the spacer frame (strip) passes through the left pressure wheel, the left pressure wheel can be lifted smoothly, which is very important for the bent spacer frame.

C. Adjust the butyl extruder spraying time: When the front end of the spacer frame (strip) is on the conveyor belt and is in the center of the butyl extrusion head, the butyl valve cylinder moves and the buytl valve opens; when the end of the spacer frame (frame) passes the butyl nozzle, close the butyl valve, no excess butyl leaks out.

5. Turn on the hydraulic station:

Before opening the hydraulic station, check the relative positional alignment of the butyl extrusion piston and the center of the butyl cylinder to ensure that the butyl extrusion piston can be correctly pressed into the butyl cylinder. Otherwise, damage to the butyl cylinder and the oil cylinder will occur. When the pumping station starts, the cylinder lift switch should be adjusted to the middle position (zero position). At this time, the pressure regulating valve should be in the open state. After the pumping station starts, gradually adjust the pressure regulating valve to increase the system pressure to the working pressure, but The working pressure shall not exceed 18MPa. When the room temperature is too high in summer and the hydraulic station works for a long time, the temperature will rise too high and the hydraulic oil will become thinner and lose working pressure. At this time, the hydraulic station should be suspended and restarted after the oil temperature drops.

6. Butyl extruder injection

A. Adjust the cylinder lift switch to the middle position and start the hydraulic station. When the hydraulic station starts and stabilizes, turn the cylinder lift switch to the "up" position to lift the cylinder piston away from the rubber tank and reach the highest position.

Note: If there is still butyl left in the glue tank and the piston of the butyl tank is not lifted after operation, the piston of the butyl tank should be heated to the specified temperature before lifting, otherwise the equipment will be damaged.

B. Start operating the swing mechanism

First, lift the piston of the butyl tank to leave the butyl tank, push the cylinder by hand to leave the cylinder mouth, and then insert the butyl ingot. After completion, reset the cylinder piston.

7. Air pressure adjustment:

The pressure of the doublet shall not be less than 0.6MPa. The air pressure of the swing motor that drives the small pressure wheel is individually adjusted to 0.15-0.4MPa by the pressure regulating valve.

| Item. | Spec. |

| Voltage | 380V 50Hz 3P |

| Power | 5.7 Kw |

| Butyl Extrusion Pressure | 10·25 MPa |

| Temperature | 110~140 ℃ |

| Glue Thickness | 0.3~0.5 mm |

| Glue Width | 3.5 mm |

| Aluminum Spacer Width | 5.5~26.5 mm |

| Speed | 0~47 m/min |

| Diameter of Butyl Cylinder | 200 mm |

| Air Supply | Flow 0.4 m³/min |

| Air Pressure | ≥ 0.6 MPa |

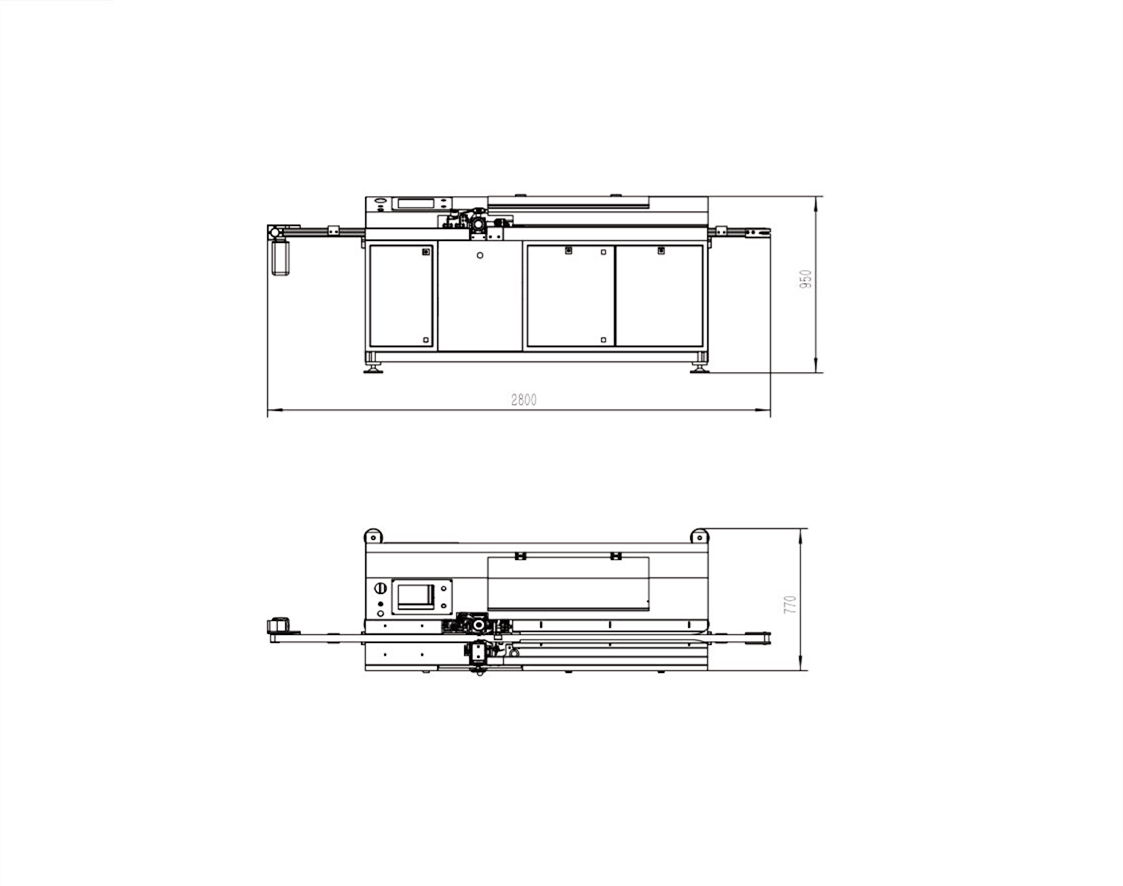

| Dimension(L*W*H) | 2800*700*900 mm |

LJTB01 Insulating Glass Butyl Extruder Coating Machine

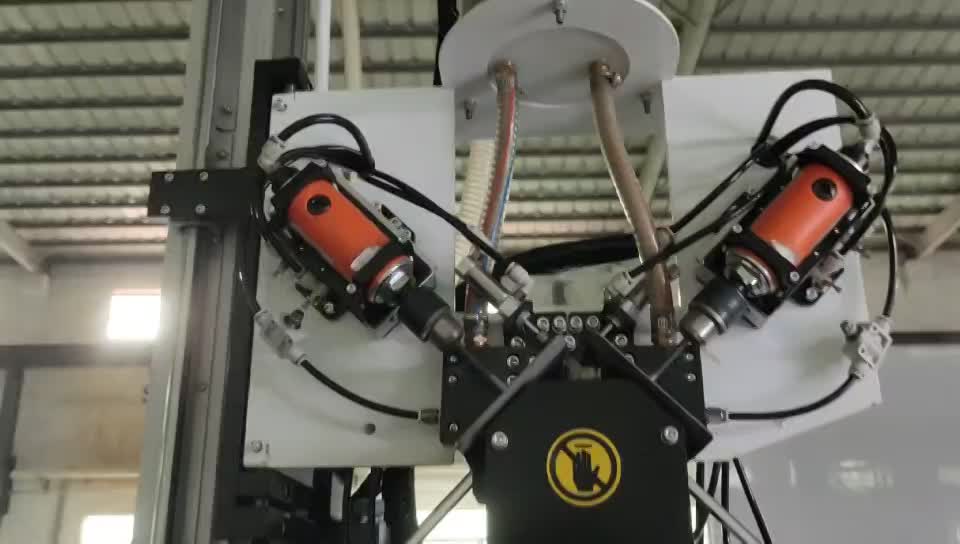

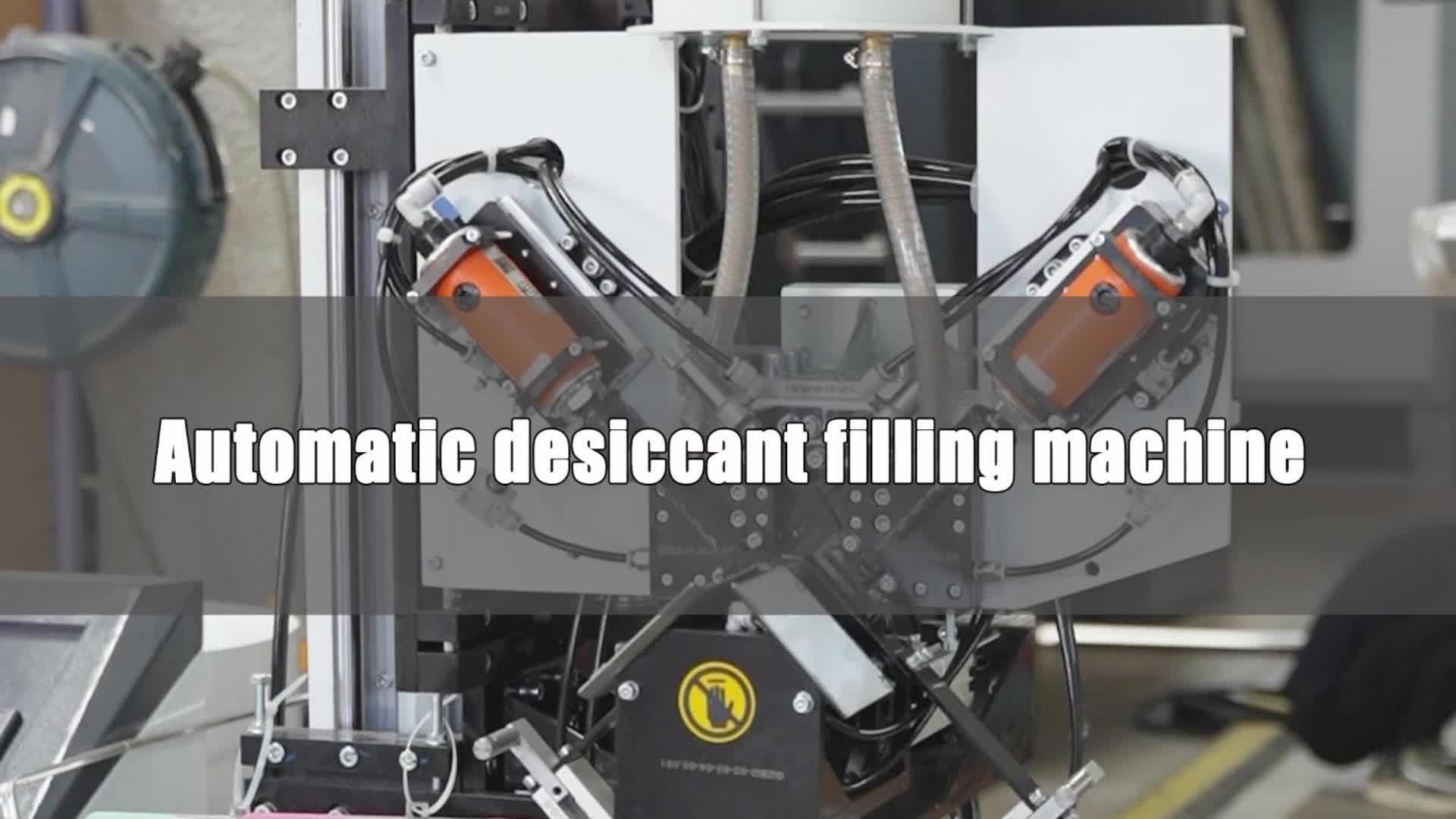

LJTB01 Insulating Glass Butyl Extruder Coating Machine Automatic Insulated Glass Desiccant Filling Machine

- Adopts the Germany Siemens PLC control system, stable performance;

- Automatically drilling, filling and sealing;

- The machine height could be adjusted according to the size of aluminum spacer or stainless steel spacer;

- Automatically loading and replenish molecular sieve;

- Advanced feeding device designed according to the principle of gas flow;

- Adopts industrial plastic spraying treatment of all aluminum frames;

- Core parts adopts famous imported brand.

- Using big plastic barrel, save feeding time and improve efficiency;

- Protection device for machine head

- Filling shaped aluminum spacer or stainless steel spacer

- could filling the large particle molecular sieve which the sizes are 1.0~1.5 mm

LJGZ2020X Insulated Glass Desiccant Filling Machine

- With the guide rail lifting device

- The head is stable when working

- With large spacer auxiliary function

LJGZ2020S Insulated Glass Desiccant Filling Machine

- Two filling stations could work at the same time of improve work efficiency;

- Two station could realize different combinations of ordinary filling, special-shaped filling and large particle filling. (optional)

| Item. | Spec. |

| Max. Frame Size | 2000 mm*2000 mm |

| Min. Frame Size | 300 mm*250 mm |

| Aluminum Specification | 5.5~26.5 mm |

| Air Pressure | ≥ 0.65 MPa |

| Voltage | AC 220V 50Hz |

| Power | 1Kw |

| Molecular Sieve Diameter Needed | 0.5~0.9 mm(Could be customized 1.0~1.5 mm) |

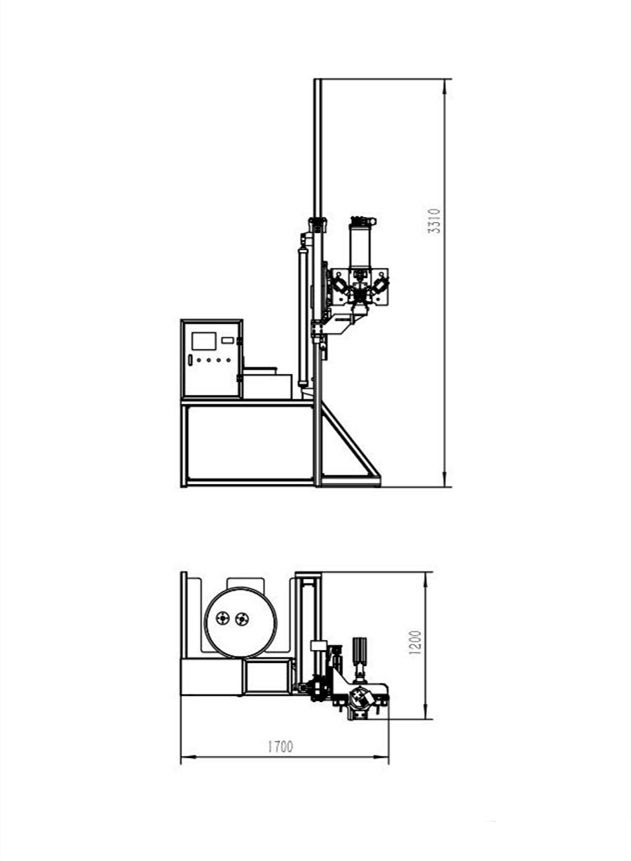

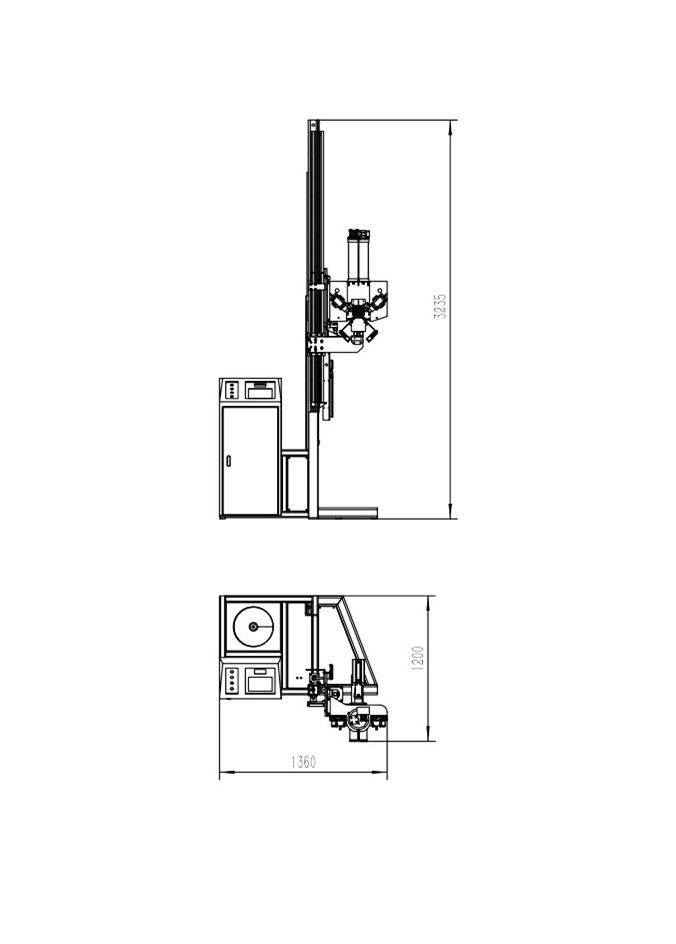

| Dimension(L*W*H) | 1400*1200*3600 mm |

| Weight | 3000 kg |

LJGZ2020A Insulating Glass Desiccant Filling Machine

LJGZ2020A Insulating Glass Desiccant Filling Machine LJGZ2020X Insulating Glass Desiccant Filling Machine

LJGZ2020X Insulating Glass Desiccant Filling Machine Purchasing Plan Reservation

Explore the most practiced automatic glass processing machines both online and in-store. Quote online from LIJIANG Glass's selection of trending deals for every budget. Enjoy great savings and discover the latest promotions for your next machine tool. The best deals and offers belong here. You'll get the lowest price on the hottest stuff.

LIJIANG Glass could offer you a real-time meetings by Google. Using your browsers, share your videos, desktop, and presentations with customers.

- Category: Pre-sales Service

- Service Length: 02:00 Hours

- Location:Google Meeting Link

- Price:Free Service

Customized Demand & Service

Procurement of Insulating Glass Using Auxiliary Materials

Most Popular

- Purchase other insulating glass processing accessories (such as Aluminum Spacer Strip Bars or Buytl Extruder Silicone Sealants)and export them together with the same containers. No purchase sourcing cost.

Equipment On-site Installation and Guidance

Most Popular

- It is necessary to dispatch some years-experience after-sales services engineers with on-site automatic equipment installation and commissioning guidance 200usd per day with the those terminal users around the world.

Care the Equipment's Full-life Cycle Maintenance

Most Popular

- Provide a copy of spare parts and fragile parts commonly used in automatic insulating glass equipment and purchase them together, takes responsible for the full-time life cycle maintenance of insulating glass equipment.

Re-plan Your Factory Workshop Layout.

Most Popular

- Based on years+ of experience in insulated glass processing, LIJIANG Glas will give customers reasonable suggestions on re-plan your factory workshop layout from the perspective of water, electricity, and argon-gas, effectively improving...

- Wholesale Equipment's Spare Parts Price

- Fast Production Turn-around

- Free Insulated Glass Samples/Sealed Results

- High Machinery Quality

- Worry-free After-sales Service

- Support the interconnection of various types of terminal equipment:

- Provide one-stop service

- Cost saving:

- Wide coverage:

More Processing of Special-shaped Insulating Glass

Find & explore special glass shape proucing projects for your automation solution plans & ideas to make custom signs for beginner & professional.

The Special-shaped Insulating Glass

In terms of size, a rectangle + trapezoid combination is made. The size of the glass on the outer surface of the special-shaped insulating glass is customized according to the actual maximum size. The other layer of glass is measured according to the width of the installation groove. The same size is retracted 40mm from the periphery of the large size to the inside, and then it can be used LIJIANG Glass automation equipment is used for processing and production. It is isolated by spacer strips and filled with argon gas, and then glued and sealed.

Know MoreThe Three-cavity, Two-glass Low-E+ Warm Edge Insulating Glass

The thermal insulation performance of Three-cavity Two-glass Low-E Glass is better than that of ordinary three-white glass. The light transmission law, sound insulation effect and heat transfer coefficient of Low-E glass are better than that of ordinary white glass. Identify Low-E glass with the naked eye.

Know MoreThe Flash Colored Glazed Insulating Glass

Glass flash means that when the insulating glass or laminated glass is combined, one piece of glass is larger than the other piece of glass on one or several sides, that is, the two pieces of glass are not the same size (the situation is similar for multiple pieces of glass). The colored glaze is an inorganic colored glaze made of the same glass material. It does not fade or peel off, so the original color tone remains consistent with the life of the glass curtain wall.

Know MoreThe Lattice Decorative Insulating Glass

Glass decorative grids are suitable for insulating glass and can replace original plastic spacers. Using electrostatic powder spraying, it has various colors, good strength and anti-aging. Wall thickness: thick, medium, thin, specifications: flat grid 8*18, square grid 8*18, 8*18, 9*18, etc. Color: red walnut, black walnut, sapele, white oak, champagne, huanghuali, red rosewood, red cherry, electrophoresis mahogany, white, Australian mahogany, silver, gold, etc. Using craft coloring, the atmosphere and color will last for a long time. Due to the wide variety, prices vary.

Know MoreThe Beautiful View Strip Insulated Glass

The Beautiful View Strip Insulated Glass, which also called the Scenic Strip Insulated Glass, places decorative strips in the insulating glass. The Scenic strips are decorative strips, which greatly increase the aesthetics of the glass and enrich people's daily home life. There are three types of beauty strips: European-style single-color beauty strips, European-style two-color beauty strips, and Chinese-style single-color beauty strips.

Know MoreThe Special-shaped Three-cavity Two-glass Insulating Glass

The air in the insulating glass chamber has poor thermal conductivity. By increasing the number of chambers and reducing the chamber spacing, the heat transfer can be greatly reduced. This efficient thermal insulation performance allows insulating glass to effectively reduce indoor heat loss in cold winters, reduce energy consumption for home heating and commercial air conditioning, thereby saving energy and reducing carbon dioxide emissions. In addition, by adding a sandwich between the two layers of glass, noise and vibration from the outside can be effectively isolated, while having excellent sound insulation effect.

Know MoreFeature Stories & Articles

Rising energy costs are driving glass factories to adopt fully automatic insulating glass production lines to reduce energy use, labor costs, and improve efficiency.

Sales Promotion & Discounts

LIJIANG Glass After-Sales Department will help you if you have any questions or problems – the range of services at your disposal includes everything from start-up to product returns.

If necessary, a member of our staff will be on the site within a very short period to work together with you and to take care of your issues and interests. Our employees in after-sales service are not only glass experts—they are also qualified in many other specific areas. For example, our team includes experienced designers who are pleased to provide any additional machine processing suggestions for any specific events.

$0

The Planning Layout of IGUs Factory Workshop

Customer Reviews & Testimonials

Don't take our words as everything. Find out what customers say about our glass machine they have owned or experienced. Why is LIJIANG Glass considered a credible brand and manufacturer to buy a new glass machine? We can talk all day about our quality products, 24/7 excellent customer service and support, as well our 30-day return and refund policy. But wouldn't it be more helpful and relevant for newbies and professionals alike to hear real-life customers experience...

Solution Experts