The 23rd Russian MIR STEKLA Glass Exhibition

MIR STEKLA – international exhibition of glass, technologies and equipment for manufacture and processing of glass, organized by Expocentr with the support of the Ministry of industry and trade of the Russian Federation and held under the patronage of the Chamber of Commerce and Industry of the Russian Federation.

- Date:02/28/2023 08:30 AM - 03/03/2023 05:30 PM

- Location Moscow, Krasnopresnenskaya nab., 14, 123100 (Map)

- More Info:Pavilion No.3, Expocentre Fairgrounds, Moscow

Description

About the Mir Stekla

MIR STEKLA is an international exhibition of glass products, technologies and equipment for glass production and processing. The exhibition covers the entire range of production: modern equipment, technologies and technical means, tools, auxiliary equipment for the production, processing and decoration of glass, control and measuring equipment and software.

The theme and exposition of the MIR STEKLA exhibition cover the entire range of glass production: modern equipment, technologies and technical means, tools, auxiliary equipment for glass production, processing and decoration, control and measuring equipment and software.

MIR STEKLA, held simultaneously with the RosBuild exhibition as part of Russian Construction Week, will give glass companies an opportunity to learn about the state of the industry market, find the best suppliers in all areas of interest, and expand their circle of clients and partners at a single exhibition venue.

EXPOCENTRE AO is organising the exhibition under the auspices of the Russian Chamber of Commerce and Industry, with the support of the Russian Ministry of Industry and Trade, the Russian Union of Builders, the Russian Glass Union, the Russian Union of Designers.

Leading manufacturers and suppliers of glass products will introduce professionals to advanced developments and effective solutions in the field of import substitution in the glass industry.

100 companies from the Czech Republic, France, Hong Kong (China), Hungary, India, Italy, China, Russia, Turkiye, and the USA will take part in the exhibition.

The MIR STEKLA 2023 exhibition stands covering 5,860 sq. m will showcase all aspects of the modern glass industry, the nuances of glass production and processing: equipment and technology for the production of flat glass, glass containers, tools and materials, innovations, scientific and design developments, medical, construction, furniture, interior, automotive glass, and artistic and decorative glass products.

Industry professionals will learn about software for glass manufacturers and processors, architects, designers and contractors. Research institutes and training centers will showcase their innovative developments.

About LIJIANG Glass

LIJIANG Glass is committed to becoming an intelligent connection system service manufacturer in the international glass deep processing industry. It is an intelligent manufacturing enterprise with equipment such as machine and insulating glass production line, and provides high-end intelligent equipment to serve glass deep-processing enterprises such as architectural glass and furniture glass.

LIJIANG Glass will bring prototypes equipment - fully automatic all-in-one feeding and cutting machine, slicing storage cutting machine to participate in this exhibition.

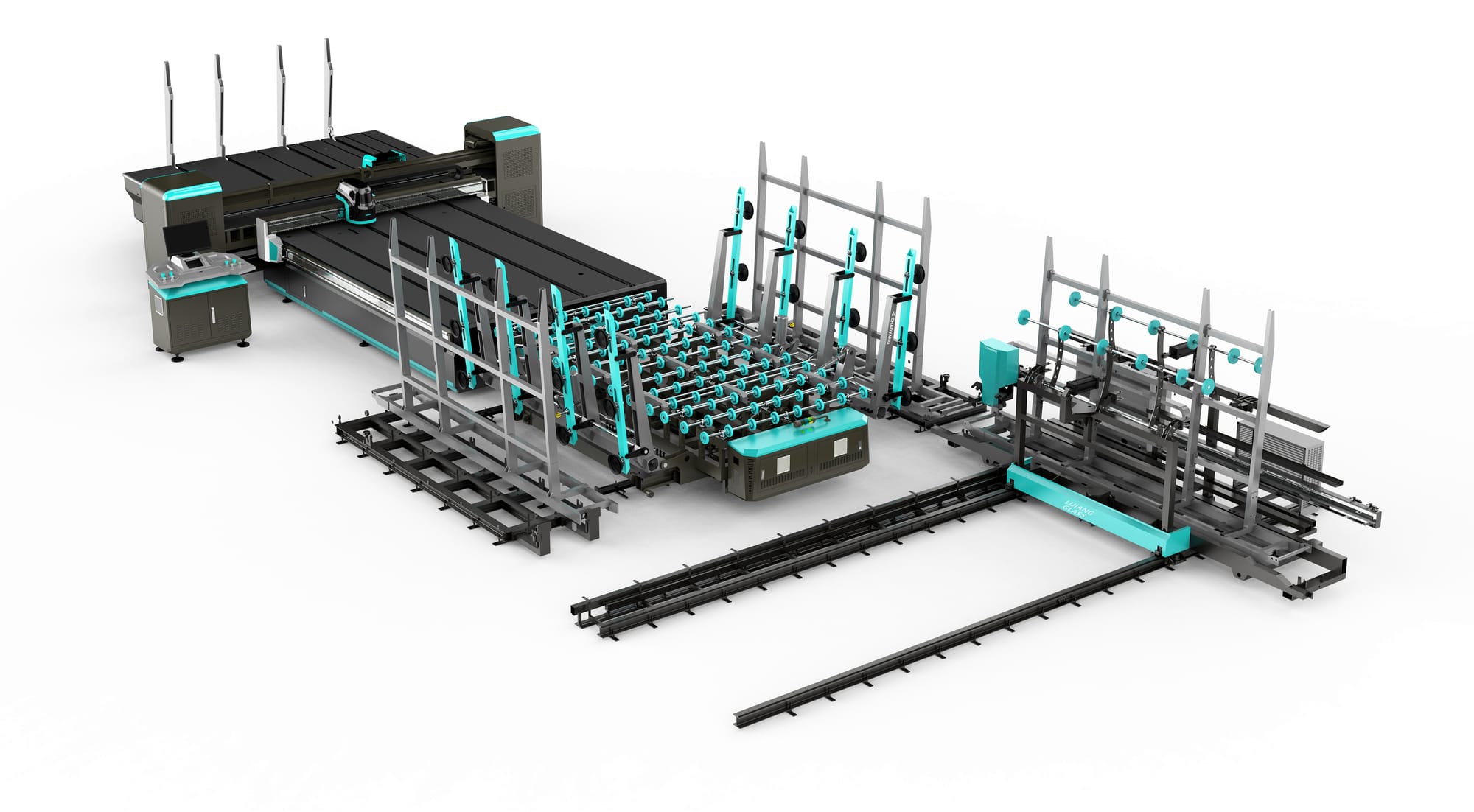

Fully automatic all-in-one feeding and cutting machine

Fully automatic all-in-one feeding and cutting machine

1. Fundamental

Its working principle is to transport the glass to be cut to the workbench by the conveyor belt. Firstly, the position of the glass is adjusted by mechanical positioning. The cutting head with the diamond cutter wheel moves along the X direction and the Y direction respectively by program control, and the substrate is cut. cutting. The control part of the machine adopts a CNC motion control card, and the driving part uses an advanced AC servo motor.

2. Equipment composition

Fully automatic glass cutting machine: It consists of a chassis mechanism, a beam mechanism, a glass processing table, a knife head mechanism, a conveying mechanism, a mechanical positioning mechanism, and an electrical control system.

3. Detailed work steps

The whole working process can be completed by PLC automatic control or manual control. The manual mode is mainly suitable for equipment adjustment and maintenance. Each action can be completed independently or used for normal work. After giving the pick-up signal (both manual and automatic), turn over and the system works, the motor drives the mechanical reversing mechanism to turn up the suction cup arm, and when it reaches the same inclination angle as the glass, the flip stops and the forward movement of the motor makes the suction cup move. When the detection switch next to the top suction cup touches the glass, the forward motor stops. At this time, the vacuum system works, and the suction cup starts to absorb the glass. When the vacuum pressure switch reaches the set pressure, the vacuum pump, which can be adjusted according to the thickness of the glass, stops. The telescopic linkage mechanism of the suction cup lifts the glass through the motor drive and stops at this station for a few seconds. Finally, to ensure that the single piece of glass is sucked up, the motor drives the mechanical turning mechanism to reverse the glass to the conveying table, the telescopic linkage mechanism makes the suction cup and the glass drop at the same time, and the suction cup blows compressed air to quickly release the glass, and the transmission mechanism starts to send the glass piece to the upper The front end of the chip machine stops at the signal point. Then the whole frame moves automatically to find the zero position and then stops. Waiting for the signal from the cutting table, the glass sheet can be sent to the cutting table at the same speed as the cutting table. After the glass is sent out, it will automatically cycle the loading program. The thickness of the glass needs to be selected at any station to take the sheet.

4. Equipment performance

1) The underframe material is made of national standard manganese-containing profile bridge steel (Q345A) welded and formed and subjected to aging treatment. This kind of steel has good comprehensive mechanical properties, good plasticity, and welding performance. The surface undergoes a special de-rusting process to remove surface rust spots and surface oxide layer, the bottom layer is sprayed with high-grade epoxy primer, and the surface is sprayed with high-grade automotive paint;

2) The equipment has been analyzed by professional structural software to ensure the stability, dynamic balance, and mechanical strength of the machine to achieve the most perfect fit, and to ensure that the table structure does not deform;

3) The device has a one-button reset function, and all the preparations before automatic startup can be completed by just pressing the touch screen, which greatly improves work efficiency;

4) The overall cable and air pipe layout is reasonable and completely sealed;

5) Cutting oil supply mode: There are double oil circuits (divided into general cutting oil and advanced cutting oil), and an air filter device to ensure the use of cutting oil clean, automatic oil filling during cutting, and synchronization with the lower knife (two kinds of cutting Oil can also be injected at the same time, mainly for TCO, Low-e and other glass);

6) The guide rail only uses high-speed silent linear guide rail, which has high cutting precision and low noise;

7) The driving part adopts an advanced Japanese Yaskawa servo motor, which makes the equipment reliable, with small error, and high efficiency;

8) The cutting operation adopts the Japanese SMC proportional solenoid valve, which automatically adjusts the pressure according to the thickness of the glass. The cutter head rotates 360 degrees, buffers up and down, and cuts with the lower knife (can accurately cut any straight line and various shaped glass), and the cutter head is equipped with crawling wheels. Effectively prevent accidental damage to the cutter head assembly and glass;

9) The cutter head is equipped with a knife-down protection function. If the cutter head falls outside the glass or at the glass gap, the program will automatically stop, effectively preventing damage to parts and glass;

10) Conveyor device, a synchronous automatic transfer device, convenient for glass upper and lower sheet transfer;

11) Positioning device, photoelectric scanning positioning system, and mechanical positioning are used together;

12) Compensation function, tool eccentric compensation, gap compensation, and pitch compensation.

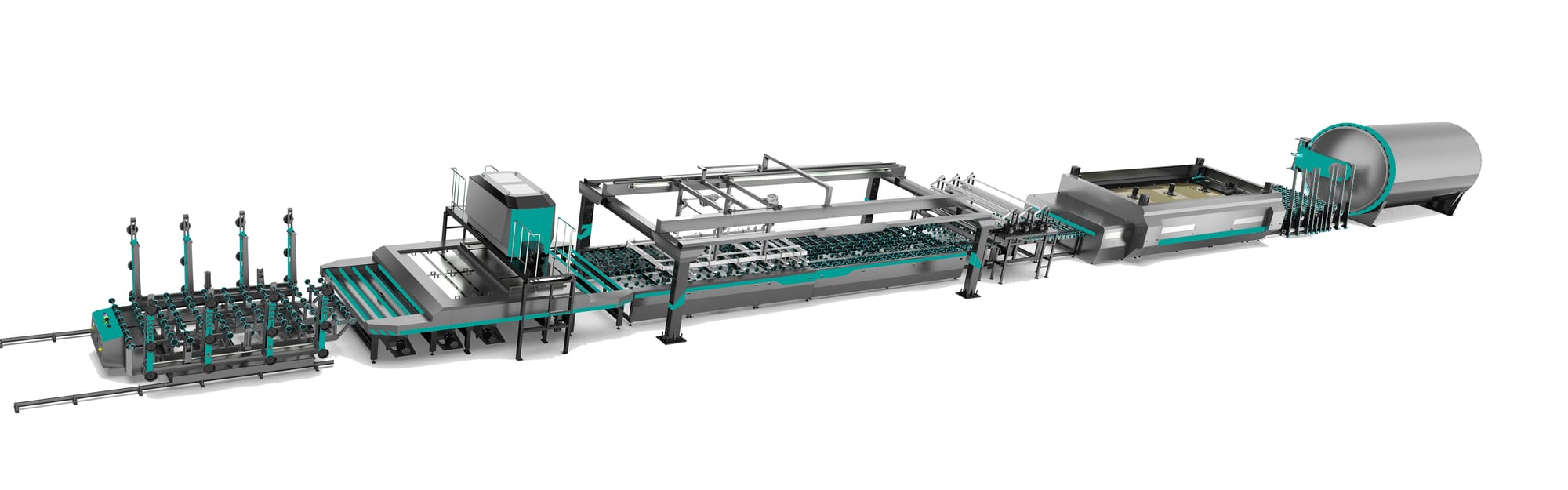

Automatic tempered glass washing and cutting production line

Automatic tempered glass washing and cutting production line