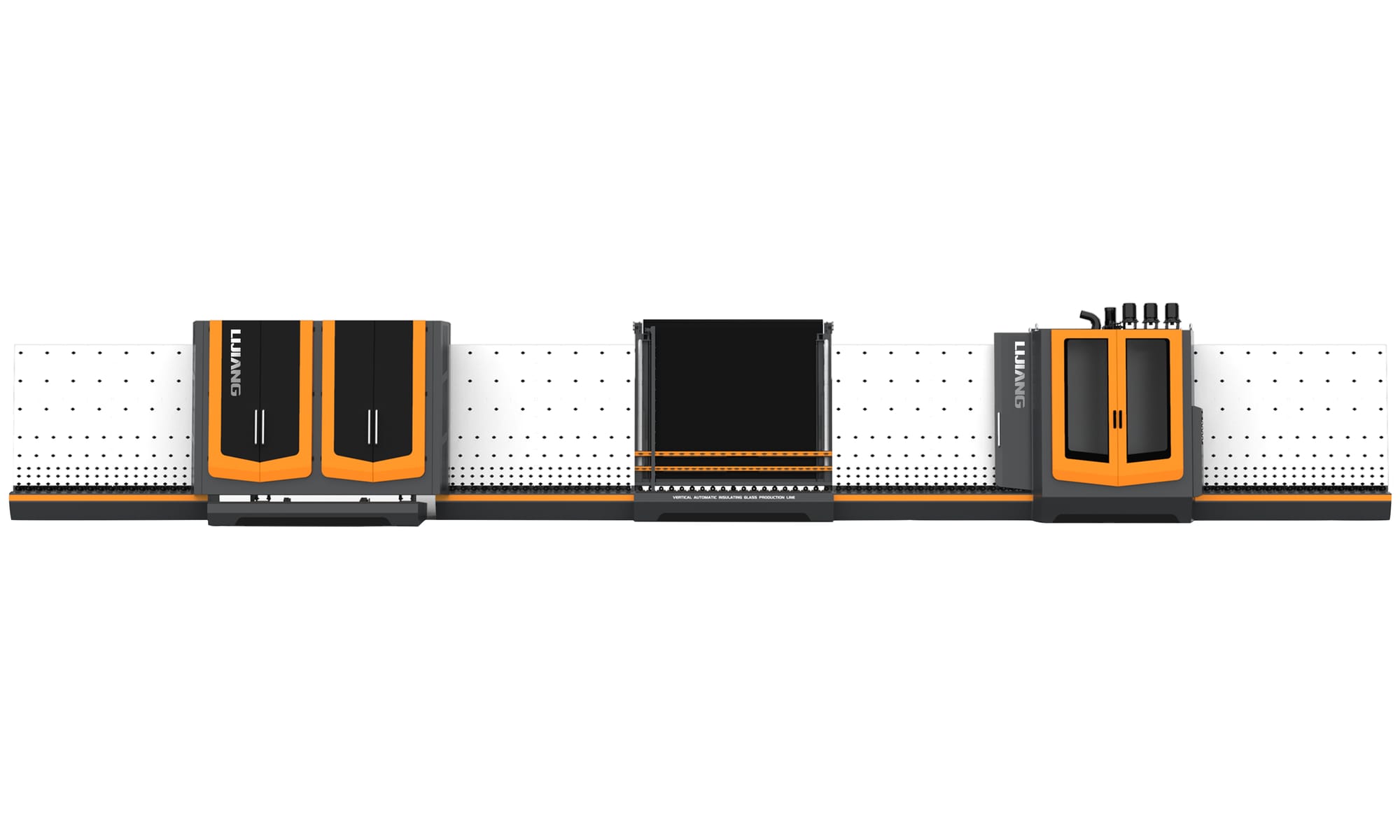

Automatic Vertical Insulated Glass Production Line

LIJIANG Glass

More Details of Automatic Equipment

Basic Working Principle

- Germany Siemens PLC control system, touch screen interface for finger touch operate

- Automatic identification of coated glass and Low-E glass;

- 3 pair of soft brushes could wash online Low-E glass and offline Low-E glass;

- The washing parts adopt SS material and waterproof device;

- Water tank with automatic temperature control and water washing system.

- Air heating system;

- Air Fan automatic start and stop setting;

- Noise reduction system;

- Online display of washing speed;

- Intelligent intermittent work, saving energy;

- Adjustable pressing board to keep the plate pressing surface straight;

- Connection mode of aviation plug;

- Applicable to produce triple IGUs and Shaped IGUs.

Detailed Working Steps

- Pre-washing Function;

- Automatically accurate positioning for 3 or 4 side step DGUs;

- Automatic Argon-gas filling could set gas value and display the process of filling online with high gas concentration.

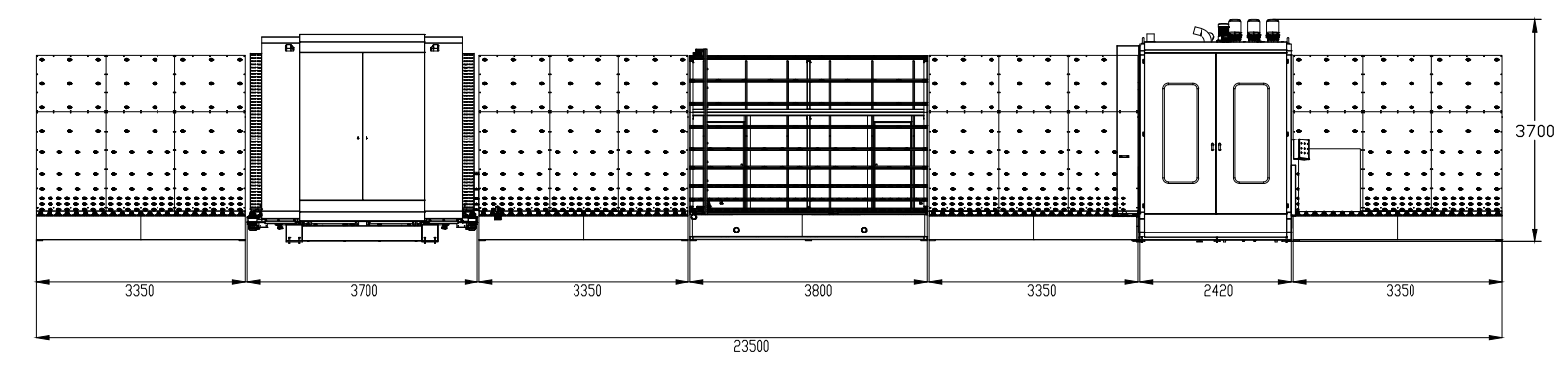

Technical Parameter

| Unit | LJBZ2030 | LJBZ2030G | LJBZ2535 | LJBZ2535G | LJBZ2535DG | |

| Voltage | 380V 50Hz 3P | |||||

| Total Power | Kw | 39.5 | 36 | 41 | 39.5 | 44 |

| Washing Speed | m/min | 2-10 | ||||

| Maximum Working Speed | m/min | 45 | ||||

| Minimum Glass Size | mm | 450*280 | ||||

| Maximum Glass Size | mm | 2000*3000 2000*3500 (Secondary Tableting) | 2500*3500 2500*4000(Secondary Tableting) 2500*4500(Secondary tablet pressing and auxiliary suction cup mechanism) | |||

| Flat Glass Thickness | mm | 3~15(Could be customized 3~30) | ||||

| Washing Brushes | pieces | 6 | ||||

| Maximum Thickness of Insulating Glass | mm | 60 | ||||

| Total Gas Consumption | L/min | 1200 | ||||

| Conveyer roll Height | mm | 520 | ||||

| Dimension L*W*H | mm | 20200*3500*3200 | 23800*3500*3700 | 27200*3500*3700 | ||

Technical Description