Insulated Glass High Speed Butyl Extruder Coating Machine

LIJIANG Glass

More Details of Automatic Equipment

Basic Working Principle

- The butyl extrusion speed could reach 47 m/min;

- Saving butyl by compared with ordinary machine, the glue could reach 7 g/m;

- Manual exhaust, simple operation;

- Adopt non adhesive synchronous belt, talc powder is not required to clean it;

- Main accessories are made of German brand, PLC Program control, stable performance;

- Using movable vertical butyl release and horizontal extrusion, convenient and practical;

- Adjust the width of glue head automatically, ensure the double side gluing is consistent with the quick opening value integrated control;

- The height adjustment of beam is convenient, effective to solve the problem of write line;

- Use touch screen operation, simple trial;

- Adjust the butyl output automatically according to the speed change;

- Adopt brand hydraulic system to ensure uniform and full rubber output;

- The buytl cylinder adopts the pull-up structure, which is convenient for changing the butyl extruder coating.

Detailed Working Steps

Operation Steps

The following steps should be followed before and after each operation:

1. Start the conveyor belt

Adjust the conveyor belt to the appropriate speed, with an adjustable range of 8-30m/min.

2. Adjust the position of the rubber extrusion head

According to the width requirements of the spacer, adjust the distance between the two extrusion heads, the range is 6-16mm. When adjusting, the spacer (frame) should be centered with the small pressure wheel and the butyl extrusion nozzle, and the positions of the conveyor belt frame, butyl extrusion seat, and butyl extrusion head should be adjusted according to the height of the adhesive tape.

3. Butyl extruder temperature adjustment before work

Generally, the heating control switch is turned on about 1-2 hours before work, and the glue head temperature is set to 120-140℃ and the glue tank temperature is 110-120℃. Since the heating temperatures and process parameters specified for butyl rubber produced by various manufacturers are different, the above heating temperatures and times are for reference only.

4. Adjustment of opening and closing of the butyl extruder valve

After the heating system reaches the set temperature, do not open the hydraulic station first, but proceed as follows:

Process time setting:

According to the screen prompts, switch to the screen that needs to be adjusted, press the SET key, and the adjustable value will flash. The "←, →" keys change the position of the value; press the "↑" key to increase the value; press the "↓" key to decrease the value. After setting, press the ENT key and the data will be automatically stored, otherwise, the data will remain at the original value.

A. Adjust the time of the right pressing wheel: Make the front end of the spacer frame (strip) on the conveyor belt and the center of the extrusion head, so that the right pressing wheel presses on the aluminum spacer frame (strip). Before the end of the spacer frame (strip) passes through the right pressure wheel, the right pressure wheel can be lifted smoothly, which is very important for the bent spacer frame.

B. Adjust the time of the left pressing wheel: make the front end of the spacer frame (strip) on the conveyor belt, and make the left pressing wheel press on the aluminum spacer frame (strip). Before the end of the spacer frame (strip) passes through the left pressure wheel, the left pressure wheel can be lifted smoothly, which is very important for the bent spacer frame.

C. Adjust the butyl extruder spraying time: When the front end of the spacer frame (strip) is on the conveyor belt and is in the center of the butyl extrusion head, the butyl valve cylinder moves and the buytl valve opens; when the end of the spacer frame (frame) passes the butyl nozzle, close the butyl valve, no excess butyl leaks out.

5. Turn on the hydraulic station:

Before opening the hydraulic station, check the relative positional alignment of the butyl extrusion piston and the center of the butyl cylinder to ensure that the butyl extrusion piston can be correctly pressed into the butyl cylinder. Otherwise, damage to the butyl cylinder and the oil cylinder will occur. When the pumping station starts, the cylinder lift switch should be adjusted to the middle position (zero position). At this time, the pressure regulating valve should be in the open state. After the pumping station starts, gradually adjust the pressure regulating valve to increase the system pressure to the working pressure, but The working pressure shall not exceed 18MPa. When the room temperature is too high in summer and the hydraulic station works for a long time, the temperature will rise too high and the hydraulic oil will become thinner and lose working pressure. At this time, the hydraulic station should be suspended and restarted after the oil temperature drops.

6. Butyl extruder injection

A. Adjust the cylinder lift switch to the middle position and start the hydraulic station. When the hydraulic station starts and stabilizes, turn the cylinder lift switch to the "up" position to lift the cylinder piston away from the rubber tank and reach the highest position.

Note: If there is still butyl left in the glue tank and the piston of the butyl tank is not lifted after operation, the piston of the butyl tank should be heated to the specified temperature before lifting, otherwise the equipment will be damaged.

B. Start operating the swing mechanism

First, lift the piston of the butyl tank to leave the butyl tank, push the cylinder by hand to leave the cylinder mouth, and then insert the butyl ingot. After completion, reset the cylinder piston.

7. Air pressure adjustment:

The pressure of the doublet shall not be less than 0.6MPa. The air pressure of the swing motor that drives the small pressure wheel is individually adjusted to 0.15-0.4MPa by the pressure regulating valve.

The following steps should be followed before and after each operation:

1. Start the conveyor belt

Adjust the conveyor belt to the appropriate speed, with an adjustable range of 8-30m/min.

2. Adjust the position of the rubber extrusion head

According to the width requirements of the spacer, adjust the distance between the two extrusion heads, the range is 6-16mm. When adjusting, the spacer (frame) should be centered with the small pressure wheel and the butyl extrusion nozzle, and the positions of the conveyor belt frame, butyl extrusion seat, and butyl extrusion head should be adjusted according to the height of the adhesive tape.

3. Butyl extruder temperature adjustment before work

Generally, the heating control switch is turned on about 1-2 hours before work, and the glue head temperature is set to 120-140℃ and the glue tank temperature is 110-120℃. Since the heating temperatures and process parameters specified for butyl rubber produced by various manufacturers are different, the above heating temperatures and times are for reference only.

4. Adjustment of opening and closing of the butyl extruder valve

After the heating system reaches the set temperature, do not open the hydraulic station first, but proceed as follows:

Process time setting:

According to the screen prompts, switch to the screen that needs to be adjusted, press the SET key, and the adjustable value will flash. The "←, →" keys change the position of the value; press the "↑" key to increase the value; press the "↓" key to decrease the value. After setting, press the ENT key and the data will be automatically stored, otherwise, the data will remain at the original value.

A. Adjust the time of the right pressing wheel: Make the front end of the spacer frame (strip) on the conveyor belt and the center of the extrusion head, so that the right pressing wheel presses on the aluminum spacer frame (strip). Before the end of the spacer frame (strip) passes through the right pressure wheel, the right pressure wheel can be lifted smoothly, which is very important for the bent spacer frame.

B. Adjust the time of the left pressing wheel: make the front end of the spacer frame (strip) on the conveyor belt, and make the left pressing wheel press on the aluminum spacer frame (strip). Before the end of the spacer frame (strip) passes through the left pressure wheel, the left pressure wheel can be lifted smoothly, which is very important for the bent spacer frame.

C. Adjust the butyl extruder spraying time: When the front end of the spacer frame (strip) is on the conveyor belt and is in the center of the butyl extrusion head, the butyl valve cylinder moves and the buytl valve opens; when the end of the spacer frame (frame) passes the butyl nozzle, close the butyl valve, no excess butyl leaks out.

5. Turn on the hydraulic station:

Before opening the hydraulic station, check the relative positional alignment of the butyl extrusion piston and the center of the butyl cylinder to ensure that the butyl extrusion piston can be correctly pressed into the butyl cylinder. Otherwise, damage to the butyl cylinder and the oil cylinder will occur. When the pumping station starts, the cylinder lift switch should be adjusted to the middle position (zero position). At this time, the pressure regulating valve should be in the open state. After the pumping station starts, gradually adjust the pressure regulating valve to increase the system pressure to the working pressure, but The working pressure shall not exceed 18MPa. When the room temperature is too high in summer and the hydraulic station works for a long time, the temperature will rise too high and the hydraulic oil will become thinner and lose working pressure. At this time, the hydraulic station should be suspended and restarted after the oil temperature drops.

6. Butyl extruder injection

A. Adjust the cylinder lift switch to the middle position and start the hydraulic station. When the hydraulic station starts and stabilizes, turn the cylinder lift switch to the "up" position to lift the cylinder piston away from the rubber tank and reach the highest position.

Note: If there is still butyl left in the glue tank and the piston of the butyl tank is not lifted after operation, the piston of the butyl tank should be heated to the specified temperature before lifting, otherwise the equipment will be damaged.

B. Start operating the swing mechanism

First, lift the piston of the butyl tank to leave the butyl tank, push the cylinder by hand to leave the cylinder mouth, and then insert the butyl ingot. After completion, reset the cylinder piston.

7. Air pressure adjustment:

The pressure of the doublet shall not be less than 0.6MPa. The air pressure of the swing motor that drives the small pressure wheel is individually adjusted to 0.15-0.4MPa by the pressure regulating valve.

Technical Parameter

| Item. | Spec. |

| Voltage | 380V 50Hz 3P |

| Power | 5.7 Kw |

| Butyl Extrusion Pressure | 10·25 MPa |

| Temperature | 110~140 ℃ |

| Glue Thickness | 0.3~0.5 mm |

| Glue Width | 3.5 mm |

| Aluminum Spacer Width | 5.5~26.5 mm |

| Speed | 0~47 m/min |

| Diameter of Butyl Cylinder | 200 mm |

| Air Supply | Flow 0.4 m³/min |

| Air Pressure | ≥ 0.6 MPa |

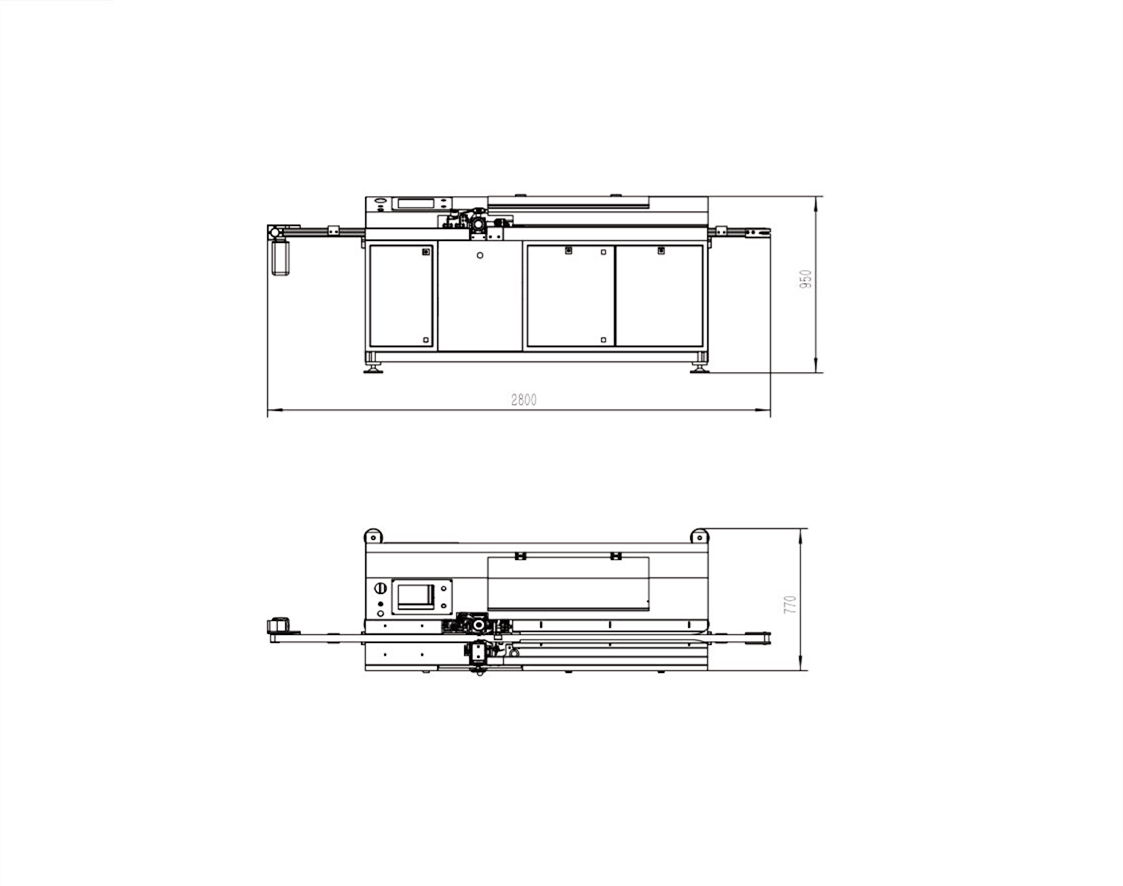

| Dimension(L*W*H) | 2800*700*900 mm |

Technical Description

LJTB01 Insulating Glass Butyl Extruder Coating Machine

LJTB01 Insulating Glass Butyl Extruder Coating Machine