The insulating glass sealant explains the insulating glass inflation processing.

The most important part in the production process of insulating glass is the sealing process. In addition, there is another equally important and more difficult operation factor. The selling point of insulating glass lies in a series of excellent properties such as sound insulation and heat preservation. These properties are basically based on the middle inflation and subsequent sealing. These two steps determine the quality and performance of the insulating glass. So, LIJIANG Glass will tell you about the production conditions and assembly requirements of insulating glass.

The performance characteristics of intelligent insulating glass inflation

1. Two types of insulating glass inflation methods

(1) Manual control method: the inflation process can be controlled by the "Start" and "Stop" buttons.

(2) Automatic control mode: The concentration of the inflated body is automatically detected through the control system, and it will automatically stop when it is full.

2. High working efficiency: four pieces of insulating glass can be filled at the same time at one time.

3. Adjustable parameters: The gas concentration can be set by yourself, which is convenient and flexible.

4. The whole working process has an indicator light display, the working status is intuitive, and it is convenient for the operator to monitor.

5. Simple operation: simple operation, no training required, no matter what kind of inflation method, just press the "start" and "stop" keys to complete the entire operation.

6. The equipment is controlled by the originally imported controller, the control system is stable and the service life is long.

7. The control components of the detection part of the equipment adopt original British imported components, with high precision and stable performance.

8. The device is a portable device, small in size, light in weight, easy to transport and install, especially on-site operation is more convenient.

9. The inflatable method is novel, does not damage the appearance of the aluminum spacer, and maintains the overall appearance of high-quality insulating glass.

10. Two types of inflators, portable type and push-pull type, can be selected.

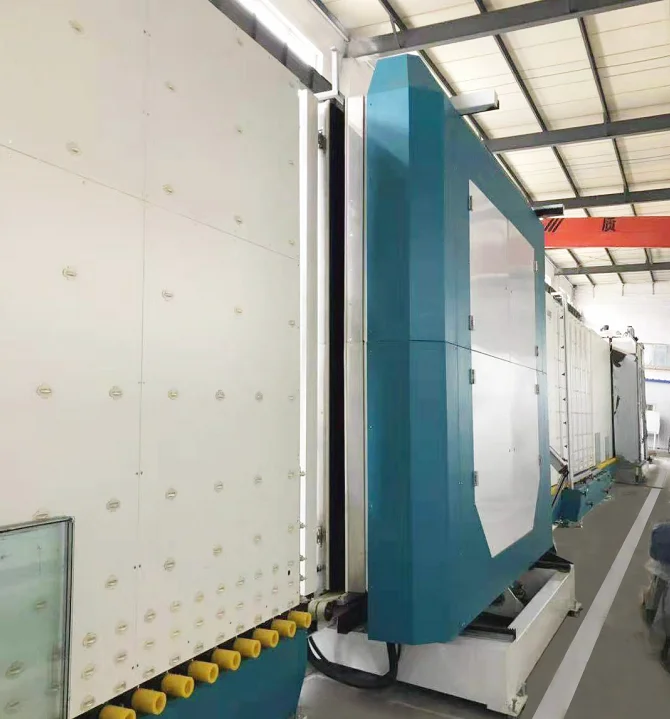

The manual insulating glass inflation process 1

The automatic insulating glass inflation processing of IG line 1

The Insulating glass glue explains the insulating glass inflation processing

The interlayer of the hollow glass must be filled with inert gas, which is not easy to react with the outside, so this can make the hollow glass have excellent properties such as sound insulation and heat insulation. Argon is mostly used as inert gas in hollow glass, but argon is a colorless and odorless gas, and its filling concentration is not easy to measure. You can't help but ask, how should the processor measure the inflated insulating glass.

The production process control concept of gas-filled insulating glass is to ensure that the production process of gas-filled insulating glass is in a controlled state, and the analysis, diagnosis and real-time monitoring of the operation technology and production process that affect the quality of the gas concentration. Its function is to systematically arrange the quality control of the production process, to focus on the factors that directly or indirectly affect the quality of the process, and to formulate and implement control plans to ensure the quality of the process.

The current test methods can be roughly divided into two types:

(1) The sensor compares the gas collected from the exhaust hole with the set gas concentration to determine whether it meets the requirements.

(2) The sensor dynamically compares the gas collected by the exhaust hole with the set gas concentration and provides real-time curves of concentration, air pressure, and flow rate. It is judged not only from the concentration but also from the shape of the curve, the actual concentration of the gas. Compared with the two, because the second method is not only a comparison of two values, but a description of the entire inflation process, it is currently an advanced production control method for real-time monitoring of the inflation process.

Matters needing attention in the process of inflatable production of insulating glass:

The argon gas in the gas-filled insulating glass needs about 6 to 8 hours to completely diffuse. Therefore, the detection of the initial concentration of the argon gas in the insulating glass can only be carried out after the gas is completely diffused. Therefore, whether it is the online detection of the concentration of the gas-filled insulating glass or the detection after 6 to 8 hours after the inert gas has completely diffused.The main reason for the low initial concentration of gas-filled insulating glass is the turbulence that occurs during the inflation process. The significance of the production control of the inflatable insulating glass is to monitor the entire inflation process in real time, so as to effectively avoid the turbulence that may occur during the inflation process of the insulating glass, and to improve and ensure the stability of the inflation quality.

Assembly requirements for insulating glass

Requirements for the environment:

The temperature should also be between 10-30 degrees;Relative humidity requirements: This kind of insulating glass has slightly lower requirements for relative humidity, and it is normal. However, it should be noted that the desiccant should be a qualified product from a regular manufacturer to ensure the effective use of the desiccant. The desiccant can be used up within 24 hours after opening, because the polysulfide rubber has high air permeability and poor sealing performance, so double sealing is required. Use butyl rubber as a seal to prevent gas. Polysulfide glue is used as the second seal, the main function is adhesion, and the second is gas barrier. Practice has proved that the life of single-production sealed insulating glass is only about 5 years, while the life of double-sealed insulating glass can be as long as 20 years or even more than 40 years.

For more information about Jinan LIJIANG Glass insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.