Can You Drill Holes in Tempered Glass?

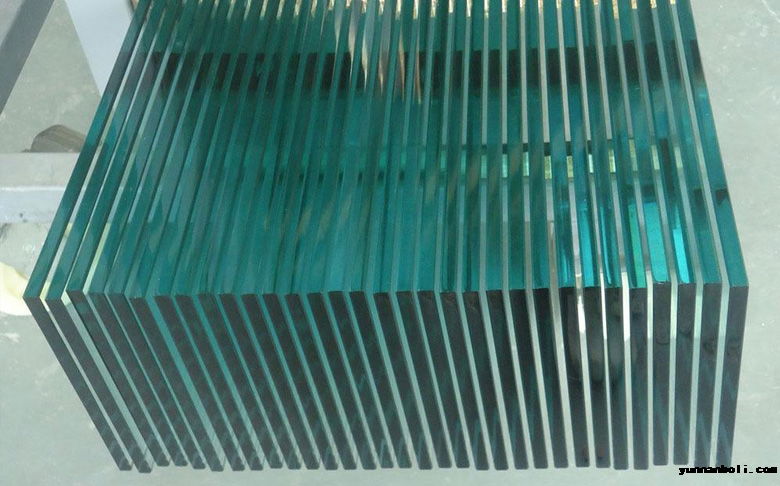

The short answer: No, it is not recommended to drill holes in tempered glass.Tempered glass undergoes a specific heat-treatment process that creates internal stress, making it much stronger than ordinary glass. However, this stress distribution is crucial to its structural integrity. Drilling, cutting, or any form of mechanical modification after tempering will disrupt the internal stress balance, causing the glass to shatter instantly or eventually break due to stress concentration.Why Does Tempered Glass Shatter When Drilled?Internal Stress Balance: During tempering, the outer layers of the glass cool faster than the core, creating compressive stress on the surface and tensile stress in the center. This balance gives the glass its strength.Disruption of Stress: Any attempt to drill a hole (even with specialized tools) introduces micro-cracks or stress points. The pre-existing internal stress then causes the glass to shatter into small, safe pieces (a characteristic of tempered glass designed to reduce injury risk).Alternative Solutions for Holes in GlassIf you need glass with holes, consider the following steps before tempering:Drill Holes in Untempered Glass First:Cut and drill the glass to the desired shape and specifications while it is still in its annealed (untempered) state.Ensure all drilling, cutting, and edge-finishing (e.g., polishing) are completed before tempering. This prevents stress disruption after the glass is strengthened.Use Specialized Glass Types or Techniques:Laminated Glass: If drilling is necessary after fabrication, laminated glass (with a plastic interlayer) may hold together even if cracked, but it is still challenging and not ideal.Hire Professionals: For complex projects, consult glass manufacturers who can design and temper glass with pre-drilled holes using precise equipment.Tools and Tips for Drilling Untempered Glass (If Applicable)If you’re working with annealed glass before tempering, follow these guidelines:Use the Right Tools:Diamond-tipped drill bits or carbide-tipped bits designed for glass.A slow-speed drill (high speeds generate heat and cause cracking).Cooling and Lubrication:Apply water or a lubricant to the drilling area to reduce heat and friction, which can cause the glass to crack.Steady Pressure:Apply gentle, consistent pressure without forcing the bit. Let the tool do the work to avoid sudden stress on the glass.Backing Material:Place a piece of wood or rubber beneath the glass to support it and prevent vibration, which can lead to cracks.Key TakeawaysTempered glass cannot be drilled safely after tempering due to its internal stress structure.All modifications (drilling, cutting) must be done before the tempering process.If you need tempered glass with holes, work with a professional glass fabricator who can handle the process from design to tempering.Attempting to drill tempered glass is risky and likely to result in breakage. Always plan for holes and modifications before the glass is tempered to ensure safety and success.