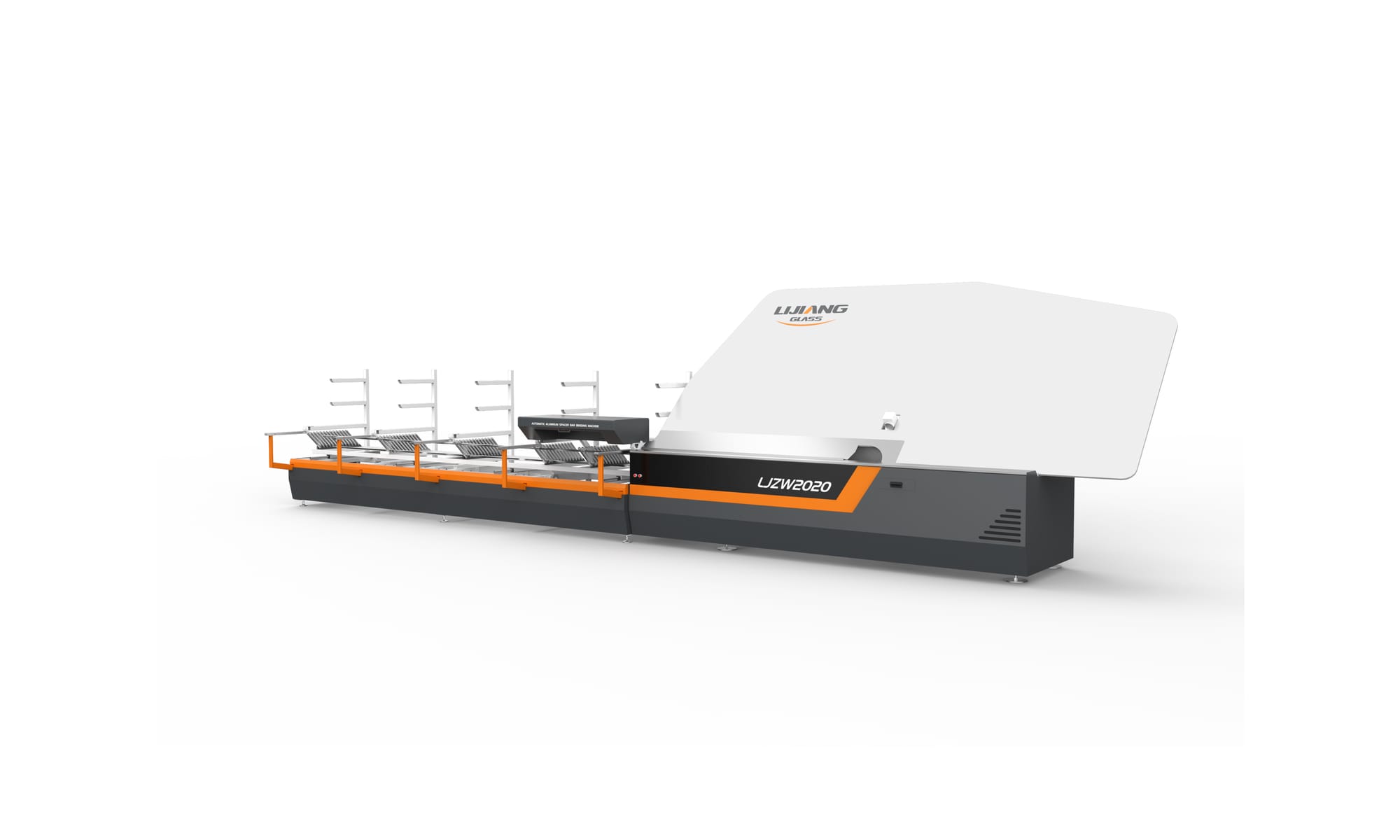

Automatic Insulated Glass Aluminum Spacer Bending Machine

LIJIANG Glass

More Details of Automatic Equipment

Basic Working Principle

General Performance

Optional Performance

- Adopts the servo control feeding system, the size of aluminum spacers could be adjusted with an accuracy of 0.1 mm/m;

- CNC Bending angle control system with adjustable accuracy of 0.1°;

- Sets up four groups of aluminum spacers and stainless steel spacers storage units;

- Aluminum spacer bars with multiple sizes could be selected at will;

- Automatically adjust the bending speed according to the size of the aluminum spacer or stainless steel spacer to avoid the deformation of the large spacer and ensure the high speed and continuity of the small frame;

- Automatic continuous connection of spacer, cutting spacer, avoidance of spacer joint;

- No material prompt, sleep prompt, fault prompt, work prompt, unreasonable data refuse processing and prompt support arc-shaped aluminum spacer and special shaped aluminum spacer bending;

- USB function, which could read EXCEL directly;

Optional Performance

- Could connect with ERP system;

- Could optional the function of automatic printing code, automatic printing label, bending the stainless steel spacer, bending the warm edge spacer, bending the stainless steel composite warm edge strips, bending the glass fiber warm edge strips, and bending the pure opaque steel strips.

Detailed Working Steps

Operating Steps

- Turn on the power, turn on the operating switch on the control console, and press the oil pump to start.

- Adjust the stroke. Pay attention to adjusting the stroke before use; and a gap must be set when the bending machine travels up and down to the bottom. Setting without gap will cause certain wear and tear on the bending machine equipment.

- Selection of the notch of the bending machine. The selection basis is: the thickness of the glass plate is about 8 times the width. For example, if the thickness of the glass plate is 5cm, then the notch needs to be 40cm.

- Manually or electrically fine-tune the stopper behind the bending machine.

- Press the foot pedal switch to perform bending.

- During the processing, the status and processing effect of the glass must be observed at all times to prevent equipment failure or defective products.

- When the bending machine stops working, turn off the operating switch on the operating table, then turn off the power, and clean the work surface of the bending machine to make the surface clean and tidy for next use.

Technical Parameter

| Item. | Spec. |

| Max. Bending Size | 1800*2000 mm (in once)/ 2500*4000 mm(in twice) |

| Min. Bending Size | 150*300 mm |

| Aluminum Spacer Width | 5.5-26.5 mm |

| Spacers Racks | 4 |

| Spacer Size Error | ±0.5 mm |

| Angle Error | ±1° |

| Conveying Speed | 1250 mm/s |

| Air Pressure | ≥0.65 MPa |

| Voltage | 380 50Hz 3P |

| Total Power | 2.5 Kw |

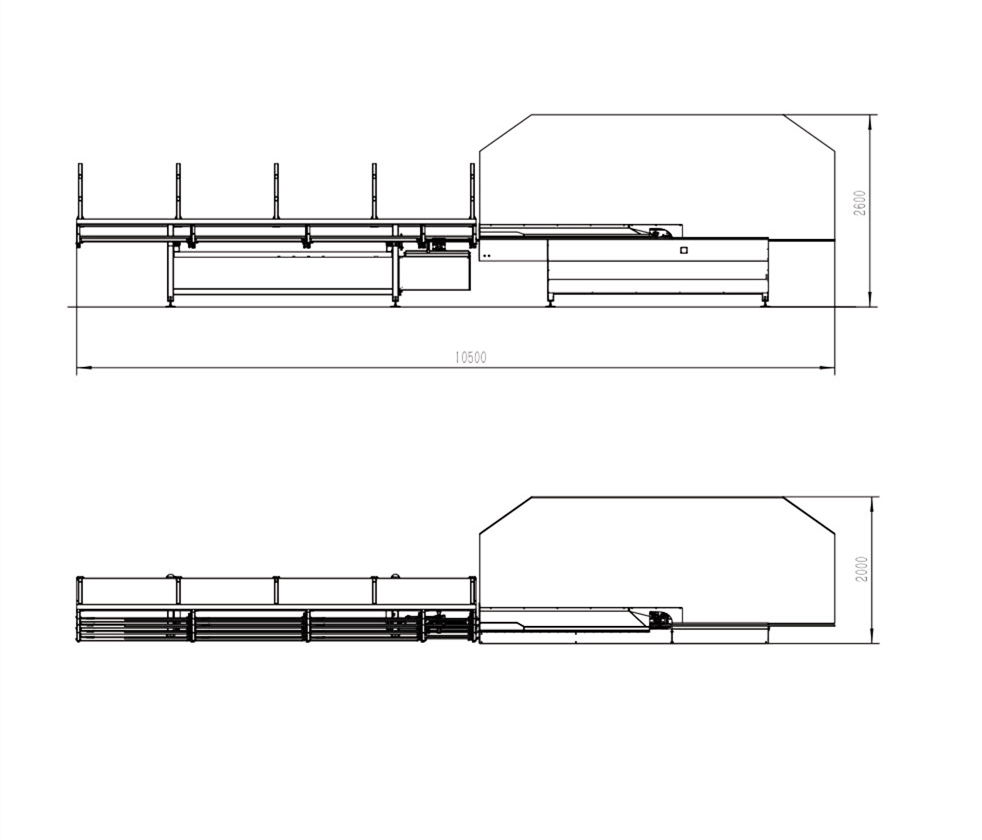

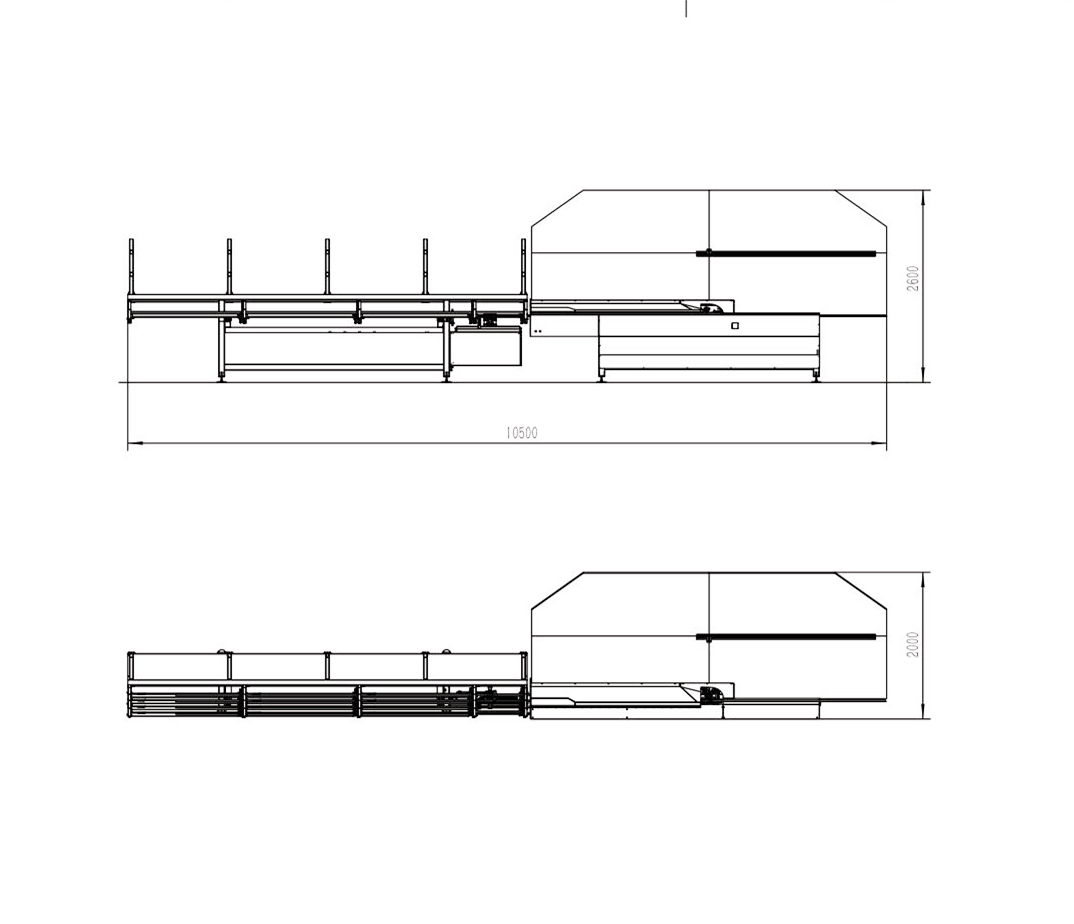

| Dimension(L*W*H) | 10500 mm*2200 mm*2600 mm |

| Weight | 1580 kg |

Technical Description

LJZW2020 Insulating Glass Aluminum Spacer Bending Machine

LJZW2020 Insulating Glass Aluminum Spacer Bending Machine LJZW2020A Insulating Glass Aluminum Spacer Bending Machine

LJZW2020A Insulating Glass Aluminum Spacer Bending Machine