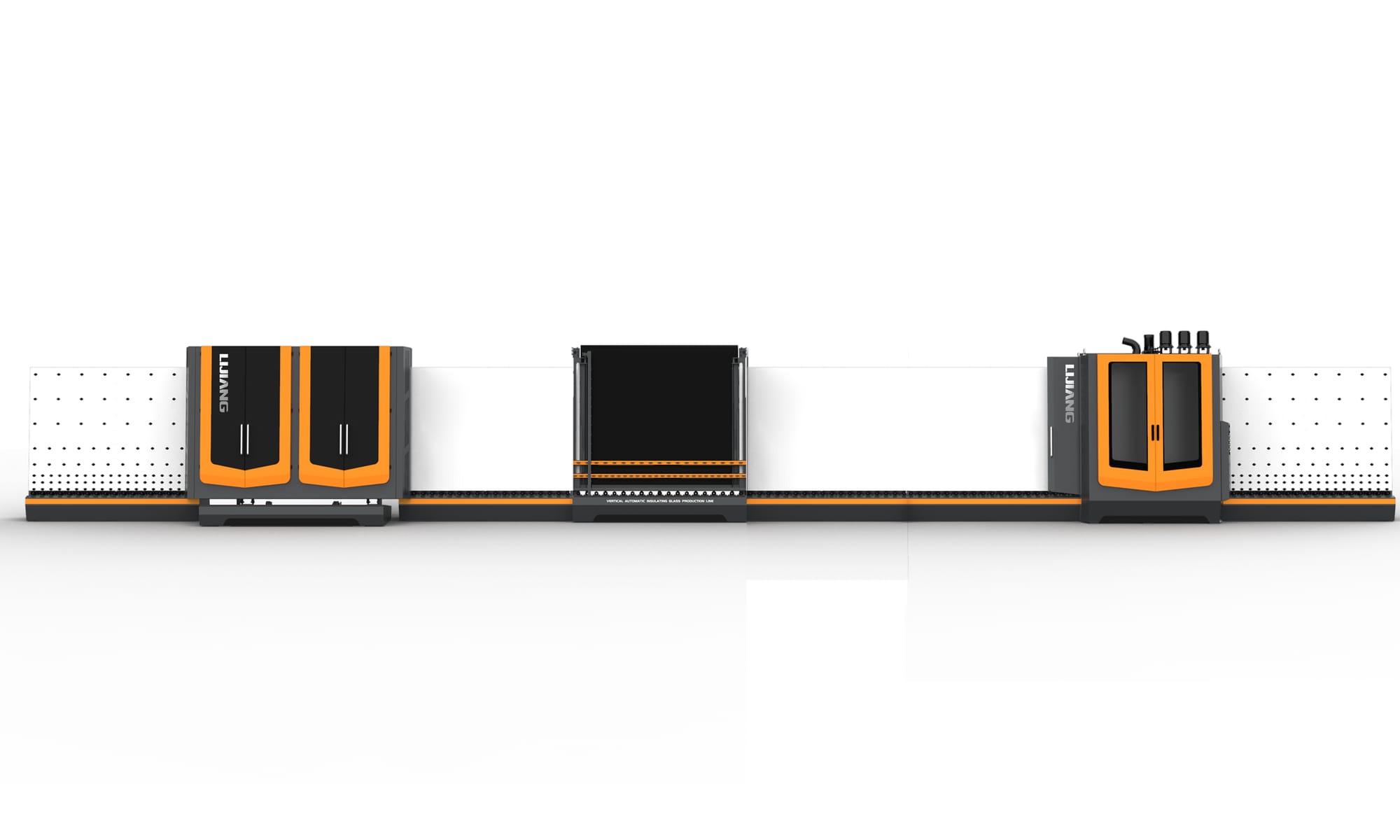

Automatic Vertical Insulated Air-floating Glass Production Line

LIJIANG Glass

More Details of Automatic Equipment

Basic Working Principle

- Air-floating back plate, to avoid the wheel scraching the glass and leaving wheel marks;

- Two pieces of IGUs or DGUs could be pressed and filled gas in once time, high work efficiency;

- Argon-gas filling in pressing, automatic filling the glass in different areas according to the size of glass;

- Germany Siemens PLC control system, touch screen interface for finger touch operating;

- Automatic identification of coated glass and Low-E glass;

- 3 pairs of soft brushes could wash online Low-E glass and offline Low-E glass;

- The washing parts adopt SS material and waterproof device;

- Water tank with automatic temperature control and water washing system;

- Air heating system;

- Air Fan automatic start and stop setting;

- Noise reduction system;

- Online display of washing speed;

- Intelligent intermittent work, saving-energy;

- Adjustable external rotary positioning system of DGUs or IGUs;

- Connection mode of aviation plug;

- ERP system is optional.

Detailed Working Steps

In addition to the technical features of the ordinary production line and the inflatable production line, the LJBZ2030GF/LJBZ2535GF series fully automatic insulating glass production line adds an air flotation function in the transmission section between the washing section and the plate press section, making the glass surface seamless during the inspection process. No human contact and no equipment parts obscuring. The standard specifications are 2000mm*2800mm and 1500mm*2200mm.

Technical Parameter

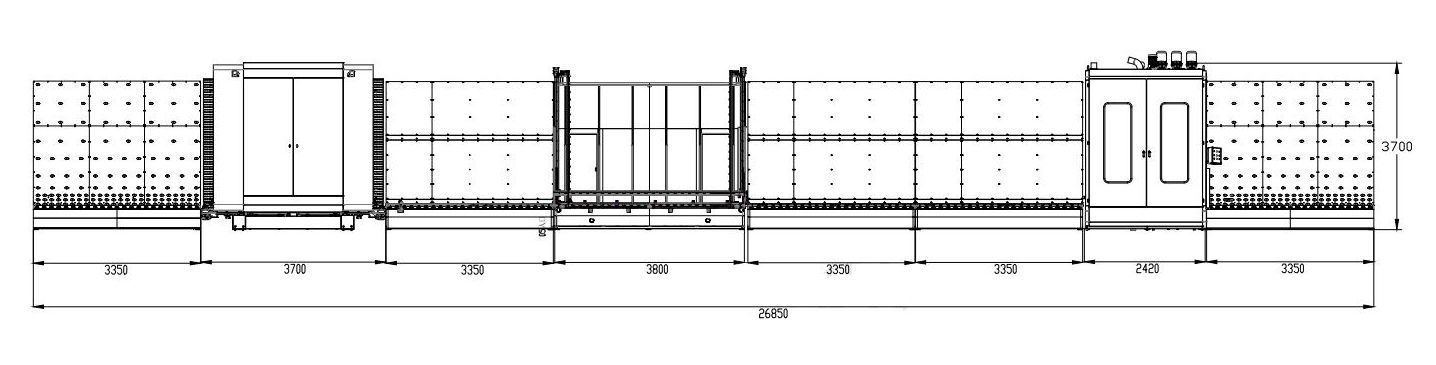

| Unit | LJBZ2030GF | LJBZ2535GF | LJBZ2535DGF | |

| Voltage | 380V 50Hz 3P | |||

| Total Power | Kw | 41 | 44.5 | 58 |

| Washing Speed | m/min | 2~10 | ||

| Maximum Working Spped | m/min | 45 | ||

| Minimum Glass Size | mm | 450*280 | ||

| Maximum Glass Size | mm | 2000*3000 2000*3500(Secondary tableting) | 2500*3500 2500*4000(Secondary tableting) 2500*5000 (Secondary tablet pressing and auxiliary suction cup mechanism) | |

| Flat Glass Thickness | mm | 3·15(can be customized 3~30) | ||

| Washing Brushes | pieces | 6 | ||

| Maximum Thickness of insulated glass | mm | 60 | ||

| Total Gas Consumption | L/min | 1200 | ||

| Conveyer Roll Height | mm | 520 | ||

| Dimension L*W*H | mm | 20200*3500*3200 | 23800*3500*3700 | 27200*3500*3700 |

Technical Description