Study on the Effect of Insulating Glass Interlayer Thickness on Heat Transfer Coefficient.

1. The Preface

Insulating glass is a commonly used window glass that has the advantages of heat insulation and sound insulation. It consists of two pieces of glass separated by a certain thickness of air or desiccant. The thickness of the insulating glass interlayer has an important impact on its performance, but there are still relatively few relevant studies. LIJIANG Glass aims to explore the effect of the thickness of the insulating glass interlayer on the heat transfer coefficient and provide a reference for the design and application of insulating glass.

2. The significance of studying the influence of the thickness of the insulating glass interlayer on the heat transfer coefficient

In the production process of insulating glass, the impact of interlayer thickness on the heat transfer coefficient is crucial. The heat transfer coefficient is an important parameter to measure the heat transfer ability of glass, which directly affects the energy consumption and environmental comfort of the building. Therefore, it is of great significance to study the effect of interlayer thickness on heat transfer coefficient.

(1) The production process of insulating glass includes edge sealing of two glass sheets and an air layer in the middle.

The interlayer thickness directly affects the heat transfer method of insulating glass. When the temperature rises, the insulating glass conducts heat through the air layer in the interlayer thickness. The smaller the thickness of the interlayer, the faster the heat conduction and the higher the heat transfer coefficient. However, when the interlayer thickness is too large, the air layer will become thinner, thereby reducing the heat transfer effect of the insulating glass. Therefore, the interlayer thickness needs to be precisely controlled to obtain the optimal heat transfer coefficient.

(2) The heat transfer coefficient of insulating glass is crucial to energy-saving buildings.

The main purpose of energy-saving buildings is to reduce the energy consumption of the building to reduce the impact on the environment. Insulating glass is one of the key components of energy-saving buildings because it can effectively control indoor temperature. Taking the mid-to-high latitudes of the northern hemisphere as an example, in winter, insulating glass can keep the indoor temperature warm and comfortable while preventing excessive energy consumption; in summer, insulating glass can prevent overheating and keep the room cool. The interlayer thickness is one of the important factors affecting the heat transfer coefficient of insulating glass. Therefore, studying the effect of interlayer thickness on heat transfer coefficient will help to design more efficient energy-saving buildings.

(3) Understanding the effect of interlayer thickness on the heat transfer coefficient of insulating glass will help develop more efficient insulating glass products.

Precise control of interlayer thickness can optimize the heat transfer performance of insulating glass, thereby improving its energy-saving effect. This is of great significance for promoting sustainable development and reducing carbon emissions.

3. Test plan

To study the effect of interlayer thickness on the heat transfer coefficient of insulating glass, LIJIANG Glass built an insulating glass heat transfer coefficient testing platform. In the test platform, two extraction vacuum pumps and a measuring pressure sensor are used to maintain the stability of the gas pressure in the interlayer. At the same time, a temperature sensor is installed on the glass to monitor the temperature in the interlayer, and the test is collected in real-time through high and low-temperature probes.data during the testing process. A pressure sensor is installed in the test platform, which can monitor the gas pressure changes in the interlayer in real-time. During the test, the gas pressure in the interlayer was changed by controlling the air extraction volume of the air extraction system and the air extraction rate of the vacuum pump, to obtain the influence of interlayers of different thicknesses on the heat transfer coefficient of insulating glass.

During the test, since the air layer between the inner and outer glass layers of the insulating glass cannot be completely sealed, a large amount of air will pass between the inner and outer glass layers during the test process. Therefore, the insulating glass needs to add a heat insulation layer. Special insulation materials for insulating glass or composite laminated insulation materials can be used to make the insulating glass insulation layer. The material selected in the LIJIANG Glass article is Low-E Low-Emissivity coated glass, and its thermal insulation performance is similar to ordinary Low-E insulating glass.

4. Test principle

The heat transfer coefficient of insulating glass refers to the convection heat transfer coefficient between air and glass through radiation heat transfer. During the test, due to the air layer between the inner and outer layers of glass, there is convection heat transfer between the air and the glass. Therefore, to obtain the heat transfer coefficient of insulating glass with different thicknesses during the test, two factors need to be considered:

(1) The thickness of the insulation layer;

(2) The heat transfer coefficient of the air in the insulating glass.

To ensure that the two factors do not mutate, a vacuum pump is used to pump the gas in the interlayer to a certain pressure during the test. Since the thermal conductivity of air is much smaller than that of glass, during the test process, it is necessary to control the pumping volume and pumping speed of the vacuum pump to control the gas pressure in the interlayer.

5. Test device and test platform

5.1 Test device

The device used in this test mainly consists of a vacuum pump, vacuum gauge, pressure sensor, temperature sensor, and thermocouple.

(1) Vacuum pump: The vacuum pump model selected for this test is XS-WXB-2, with a maximum pumping rate of 30m3/h, a minimum pumping rate of 20m3/h, and a maximum vacuum degree of 300Pa.

(2) Pressure sensor: The pressure sensor model selected for this test is SHB-1, its accuracy is 1x10-5Pa, and its measurement range is 0~100Pa.

(3) Data acquisition system: The data acquisition system model selected for this experiment is JHT-200S, and its range and accuracy are the same as the temperature sensor.

The data acquisition system takes the pressure sensor as an example. Its working principle is to determine the pressure change by measuring the temperature change felt by the temperature sensor. When the gas pressure changes, the temperature sensed by the temperature sensor also changes, and the pressure is calculated. This test uses high and low-temperature probes for data collection. The high and low-temperature probes can reflect the temperature of the external environment and the internal pressure on the computer in real-time, and the test data can be analyzed and processed through the computer.

(4) Cooling system: The cooling system model selected for this test is the WY-2H cooling pump.

5.2 Components of the test platform

- Mainframe (made of stainless steel),

- Insulation material,

- Measuring device,

- Water heating system,

- Data acquisition system,

- Temperature control system (control heating temperature).

The measurement platform of this test consists of the above parts. Each part is connected through sensors to form a complete system. This platform can control and measure the temperature of insulating glass stably and reliably. When performing temperature control and measurement, the measured temperature is transferred to the computer by adjusting the temperature sensor of the temperature control system. After the computer collects the temperature data of each part, it transmits the data to the central control room for analysis and processing.This test platform can control and measure the temperature inside and outside the insulating glass, the gas pressure in the interlayer, and the thickness of different interlayers. The test platform has the characteristics of a simple structure, easy operation, convenient installation, and simple operation. It has high testing accuracy and is suitable for testing and researching the heat transfer coefficient of insulating glass.

6. Test content

This test uses the insulating glass heat transfer coefficient test platform established by LIJIANG Glass, which includes a measurement system, control system, data acquisition system, auxiliary devices, etc. The measurement system includes a temperature sensor, gas pressure sensor, data acquisition card, and data acquisition instrument. When the insulating glass under test is Low-E glass, a gas pressure sensor is used to convert the pressure signal of the test gas into an electrical signal. The electrical signal is converted into a digital quantity through the data acquisition card, and then the temperature and pressure signal is converted into digital quantity and output.The temperature sensor and pressure sensor in the measurement system adopt high-precision digital thermometers and high-precision pressure gauges, which can accurately measure the temperature and pressure of the insulating glass being measured.

During the test, the temperature sensor used can be set accordingly according to the test environment to effectively improve the measurement accuracy.

During the test, it is also necessary to collect the temperature and pressure signals in the control system and correct the measured values through the software to obtain the actual heat transfer coefficient of the insulating glass under test.

During the test process, the data acquisition card used was connected to the computer through the USB interface and computer software was used to process the data generated during the test process. The data acquisition instrument can also calculate and analyze the heat load generated during the test. The data collector used in this test can automatically record all measurement values that occur during the test and has the functions of real-time data saving and curve drawing. The measurement results can also be visually displayed through curve charts, providing the necessary data basis for subsequent calculations.

7. Test result analysis

According to the above experiments, it can be seen that under the same solar radiation intensity, the higher the gas pressure of the insulating glass interlayer, the lower the heat transfer coefficient of the insulating glass.

7.1 Test conditions

(1) Test equipment: JWL-4B flat-panel thermal measuring instrument, model ZH3-5Y, with a resolution of 0.1°C; RY1 electronic thermometer with an accuracy of 0.001°C.

(2) Test environment: The temperature in summer is 25℃, and the temperature in winter is 18℃. The test area is 0~90m outside the room plane and the sky area within 60m inside the wall.

(3)Measurement conditions: Before the test, the glass surface should be cleaned.

- Before the test, the windows should be opened for more than 1 hour to allow natural air convection.

- During the test, the windows should be closed to keep the indoor and outdoor temperature difference within 1°C.

- During the test, the window cannot be opened. When the ambient temperature is lower than 5℃, the temperature of the glass surface should reach above 5℃.

- During the test, when the indoor air temperature is lower than 5℃, the air conditioner or heating equipment should be turned on to heat the room.

(4) During the test, the glass model used was Low-E glass (composed of two layers of high-strength structural glue and one layer of low-strength structural glue). The heat load is calculated by the "Construction Quality Acceptance Code for Building Energy Saving Projects".

(5) During the test, the relative humidity in the room was maintained at 50%~70%

(6) Before the test, all indoor doors and windows should be closed for more than 1 hour.

7.2 Interlayer gas pressure

(1) When the interlayer gas pressure is high, the air inside the insulating glass will compress inward. At the same time, because there is more air in the interlayer, the heat inside the insulating glass will continue to be transferred inward from the interlayer, causing the inside of the insulating glass to surface temperature continues to rise.

(2) Under the same solar radiation intensity, when the interlayer gas pressure is high, the inner surface temperature of the insulating glass will continue to rise. When the temperature reaches a certain value, it will cause the generation of thermal bridges inside the insulating glass. Thermal bridges are weak points connecting the air and aluminum strips inside the insulating glass. When thermal bridges occur, the heat transfer coefficient of insulating glass decreases as the interlayer gas pressure increases.

(3) When the gas pressure in the hollow glass interlayer exceeds a certain value, the air will condense due to the high external ambient temperature. At this time, if there is still gas inside the insulating glass, the gas will absorb the heat in the outside air and transfer it inward. Due to the high moisture content in the air, moisture will continue to transfer inward from the interlayer. As the temperature continues to rise, the evaporation rate of water outside the clip will also continue to accelerate. When the water evaporates to a certain extent, the heat inside the insulating glass will continue to be transferred outward, eventually causing the heat transfer coefficient of the insulating glass to decrease as the interlayer gas pressure increases.

(4) When the solar radiation intensity is low, the gas pressure in the insulating glass interlayer and the outside temperature will not change significantly; when the solar radiation intensity is high, as the temperature difference between the inside and outside increases, there will be a gap between the air and the aluminum strip. Condensation occurs. The condensed air and aluminum strips will be passed outward through the insulating glass.

7.3 Sandwich thickness

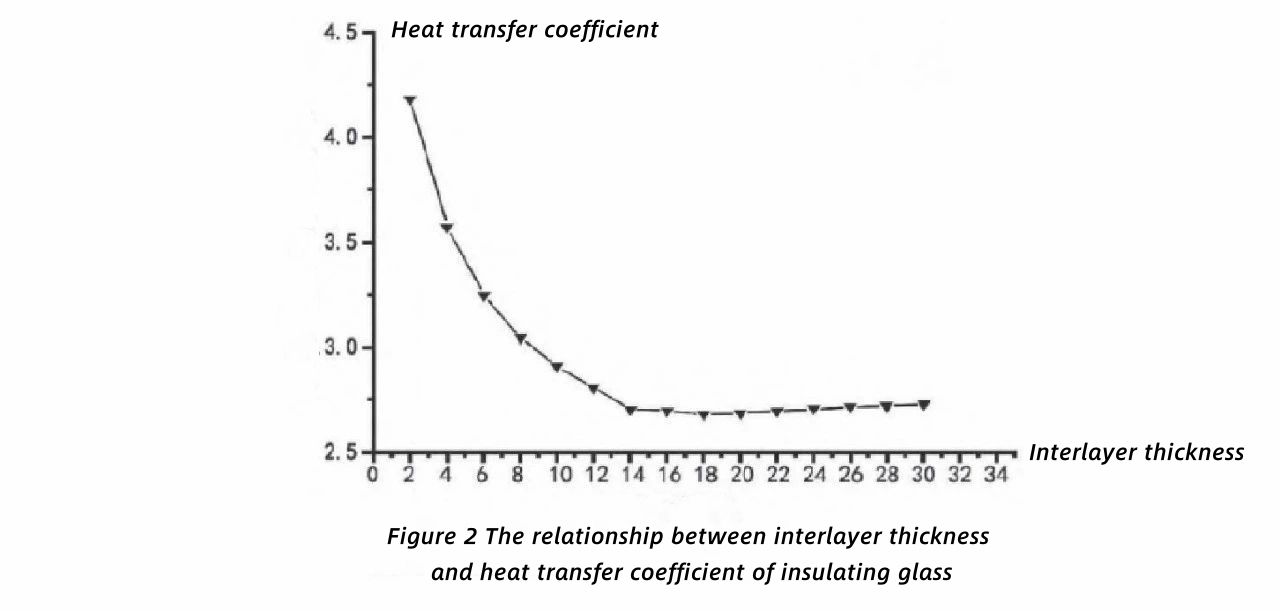

(1) When the interlayer thickness is between 2 and 14 mm, the greater the interlayer thickness, the smaller the heat transfer coefficient of the insulating glass. This is because the greater the thickness of the interlayer, the greater the thermal resistance of the filling gas. In a closed space, due to the thermal effects of the hot wall and the cold wall, the filling gas will undergo convection heat transfer. The gas on the cold side sinks and the gas on the hot side rises. The gas forms an annular flow. The smaller the thickness, the more serious the convection phenomenon.

(2) When the interlayer thickness is greater than 15mm, the heat transfer coefficient of insulating glass shows an overall stable trend as the interlayer thickness increases. This is because when the thickness of the interlayer reaches a certain value, it is difficult for the filling gas to form an annular flow, the convection heat transfer area is stable, and the heat transfer coefficient of the insulating glass tends to be stable.

(3) When the thickness of the interlayer is small, the convective heat transfer of the gas fluid in the interlayer has a greater impact. As the thickness of the interlayer increases, the flow state of the filling gas transitions from turbulent flow to laminar flow. The heat transfer in turbulent flow is large, while the heat transfer in laminar flow is small. Therefore, the change in interlayer thickness is small at this time, and the heat transfer coefficient of the insulating glass remains. There is a large amount of variation.

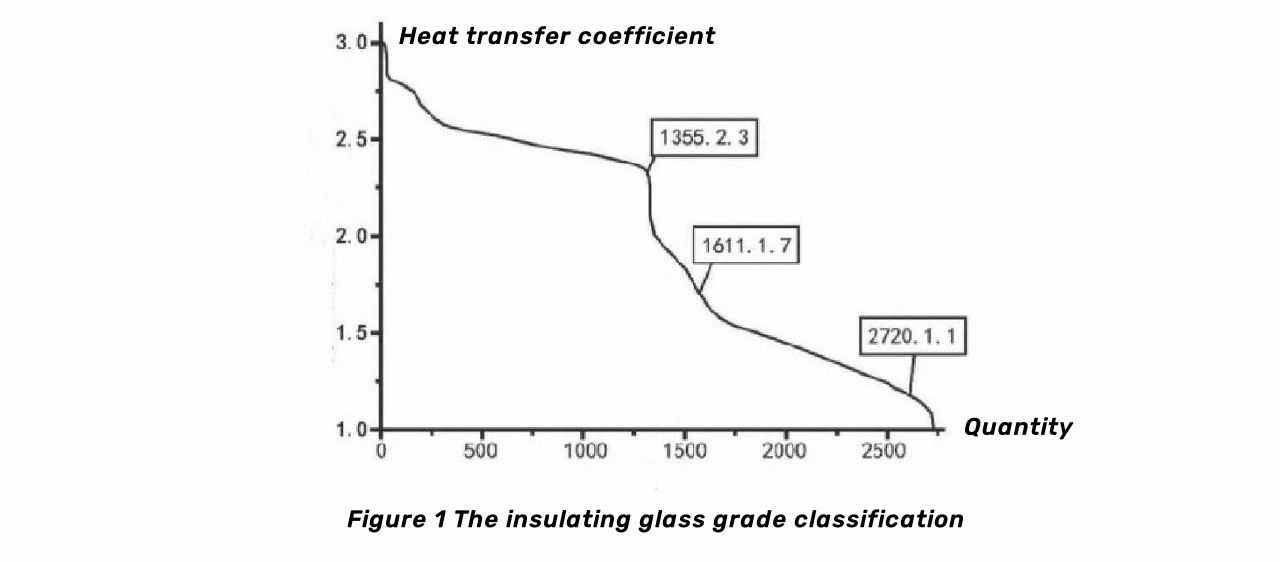

Figure 1 The classification of insulating glass

Sandwich thickness/mn

Figure 2 Relationship between interlayer thickness and heat transfer coefficient of insulating glass

7.4 Other factors

(1) As the interlayer gas pressure increases, the heat transfer coefficient of the insulating glass gradually decreases, mainly because the heat transfer coefficient of the insulating glass is related to the heat transfer coefficient in the air layer and the heat transfer coefficient in the air layer is related to the solar-related to radiation intensity. As the intensity of solar radiation increases, the heat transfer coefficient in the air layer inside the insulating glass also increases.

(2) As the thickness of the interlayer increases, the heat transfer coefficient of the insulating glass gradually decreases, mainly because the heat transfer coefficient in the air layer inside the insulating glass is proportional to the thickness of the interlayer. When the interlayer thickness is 5mm, the heat transfer coefficient of insulating glass is the lowest; when the interlayer thickness is 3mm, the heat transfer coefficient of insulating glass is the highest; when the interlayer thickness is 5mm, the heat transfer coefficient of insulating glass remains at a low level.

(3) Under the same solar radiation intensity, when the interlayer gas pressure is lower than 1.8MPa, the thermal insulation performance of the insulating glass is relatively good; but when the interlayer gas pressure exceeds 1.8MPa, the thermal insulation performance will decrease; When the intensity of solar radiation is constant, as the thickness of the interlayer increases, the thermal insulation performance of the insulating glass will gradually decrease.

8. Conclusion

(1) Increasing the interlayer thickness can effectively reduce the heat transfer coefficient of insulating glass. As the interlayer thickness increases, the heat transfer coefficient of insulating glass shows a trend of first decreasing and then increasing.

(2) When other conditions remain unchanged, as the gas pressure in the interlayer increases, the heat transfer coefficient of insulating glass decreases;

(3) Increasing the gas pressure in the interlayer can further reduce the heat transfer coefficient of insulating glass, but the impact of system resistance needs to be considered;

(4) According to the climate conditions and building energy-saving design standards of a certain region, on the premise of ensuring that the insulating glass meets the strength requirements, and considering the impact of system resistance on the sandwich gas pressure, 5mm core gas pressure is selected as the interlayer thickness.

For more information about insulating glass processing equipment and glass processing machinery, please click here to learn more.