Analysis of insulating glass quality identification and quality control methods.

In recent years, the insulating glass industry has developed rapidly, and its popularity in glass curtain walls and other industries is getting higher and higher. However, due to the lack of a basic theory of insulating glass in some developing countries, and the random exaggeration of publicity by some material manufacturers out of interest, many of The actual service life of the insulating glass does not reach the time limit mentioned in the propaganda and it has expired. Some curtain walls fail after only 10 years of construction, making the hidden frame curtain wall likely to cause safety accidents. Not only does this fail to achieve the goal of energy saving and efficiency improvement, but it also increases social costs. LIJIANG Glass here introduces several simple methods to identify the advantages and disadvantages of insulating glass, for readers' reference only.

If any piece of insulating glass is extracted from the finished product and any of the following phenomena are found, consumers can determine it as a substandard product and request a return.

1. Use a knife to cut a cross-section of the second seal. If there are many small pores in the cross-section (similar in appearance to the honeycombs), this indicates two possibilities. One is manual sealing, which will trap air and produce bubbles; the other is the first possibility is that the secondary sealant produced with low-level technology will still have pores even if it is applied by machine. As long as there are pores in the cross-section, its service life will be short.

Figure 1 The secondary sealant of insulating glass is prone to bubbles 1

2. Use a knife to cut any connection corner of the insulating glass to see if the connection corner is effectively wrapped with butyl sealant. Actual theory shows. Double-channel sealed insulating glass made by connecting corners has water permeability paths mainly at the four corners. Its water permeability is 70%, while the edge water permeability only accounts for 30%. Therefore, try to use continuous bent tube aluminum strips or use butyl sealant to effectively wrap the four connection corners, which can greatly extend the service life of the insulating glass. If the four corners are not effectively wrapped with butyl sealant, double sealing, the actual significance is not great.

Figure 2 The secondary sealant of insulating glass is prone to bubbles 2

3. Use a knife to cut the two sections where the secondary seal and the glass are bonded by a few centimeters, and then tear the sealant outward with your hands. If the glass surface is relatively smooth after tearing and there is no residual glue, it means that the sealant and the glass surface have no adhesion, so the sealing effect can be imagined.

4. Supplement the above methods to check whether standard molecular sieves are used, whether butyl sealant is continuous (no disconnection), and if it is not polysulfide sealant, whether other second sealants have undergone compatibility experiments (must do compatibility tests) Experiment, otherwise there may be endless trouble). If the window frame is not sealed with standard strips, but with ordinary silicone sealant, be sure to do a compatibility test between the silicone sealant used and the insulating glass edge sealant, otherwise, there may be endless troubles (some door and window installations which are the company purchased inferior oil-filled silicone sealant to seal the window frame. Over time, the mineral oil migrated out and corroded the entire insulating glass sealing system. Since it takes a while for this negative effect to manifest, it must be prevented in advance).

The insulating glass quality control approach

Although the basic theory of insulating glass systems in some developing countries is not very complete at present, insulating glass has developed rapidly in some developing countries in recent years, and various types of insulating glass production equipment have been widely used in production practice. At the same time, LIJIANG Glass has accumulated a lot of practical experience in both positive and negative aspects of the sales process of automated insulating glass processing equipment in the past 20 years. The following quality control methods are now summarized as follows:

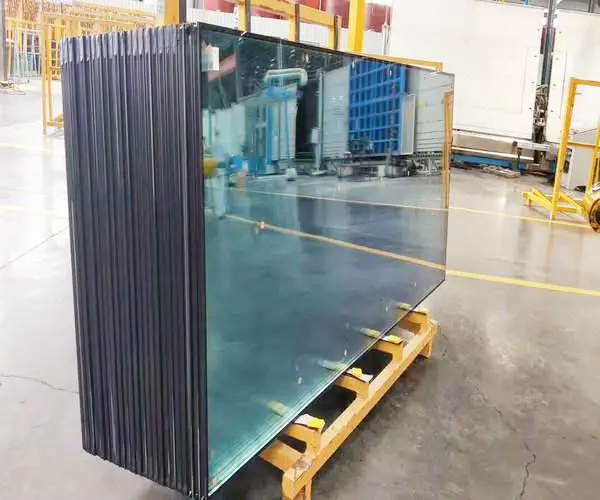

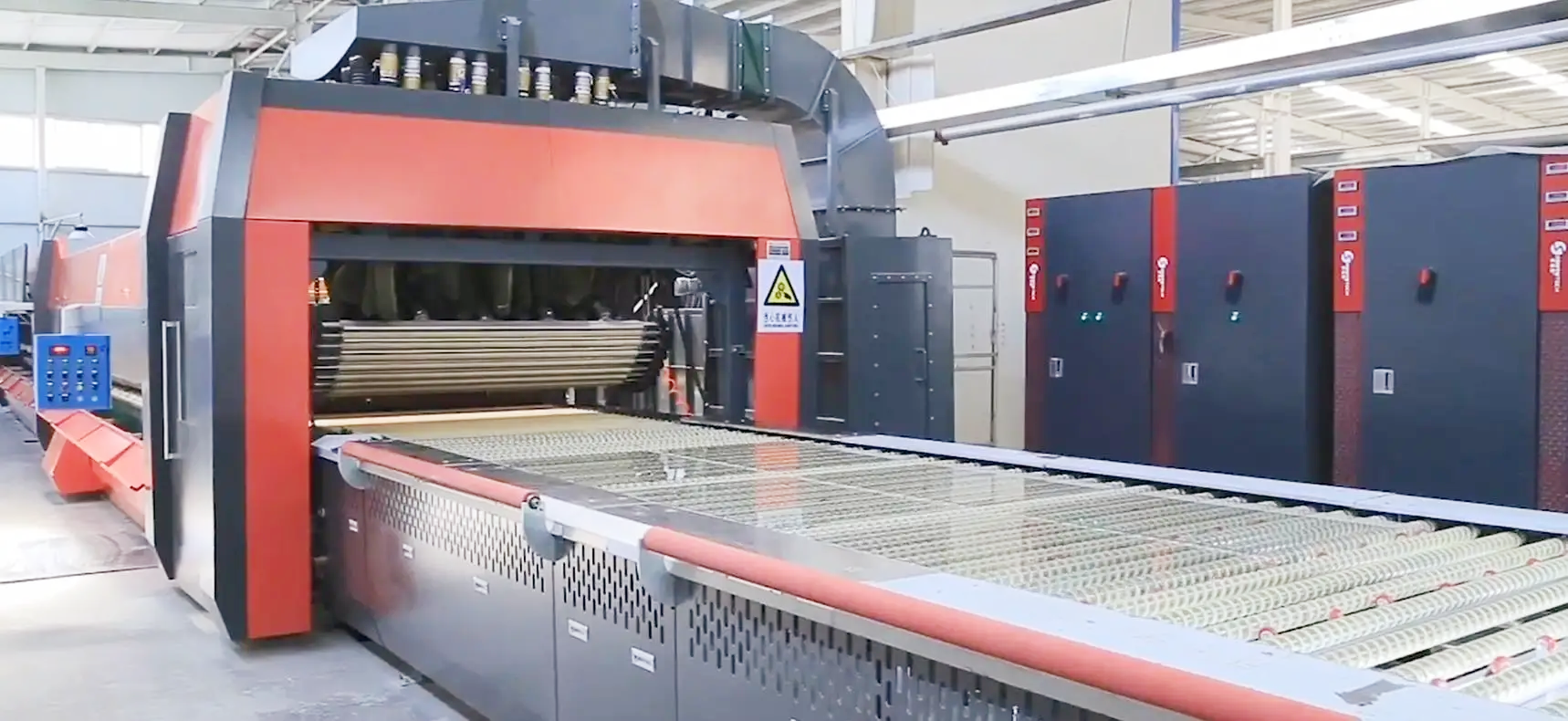

1. Better technology is an effective way to improve the quality of insulating. For the insulating glass industry, a good production technology must have the following elements. First, using a continuous insulating glass production line. Only a continuous production line can ensure that insulating glass products have the consistent quality from raw glass sheets to qualified finished products, and can maximize production efficiency; second, whether it is the first sealing or the second sealing equipment, sealing equipment with a high degree of automation should be used as much as possible. Only in this way can the impact of human factors on quality be reduced as much as possible.

Figure 3 Using a continuous insulating glass production line

2. Improve the insulating glass production environment. The insulating glass must be produced in an environment free of dust, solvent pollution, and suitable temperature. Dust pollution in the production workshop will have a great adverse impact on the bonding effect of each component of the insulating glass sealing system. The sealing performance and functional life of insulating glass products with poor sealing effect can be imagined. The presence of solvent will cause the butyl sealant (PIB) to lose its adhesive force, causing the first seal to fail. Therefore, do not use volatile substances in the workshop, and keep the air ventilated. A suitable temperature is a necessary condition for the second seal to achieve effective results. The supply temperature of the second sealant should be kept above 10°C as much as possible. Only a suitable temperature can achieve the use effect of the sealant within the specified time, such as the initial adhesion. Relay, shear strength, elastic modulus, sealing performance, etc.

Figure 4 The insulated glass production dust-free workshop

3. With excellent insulating glass production equipment, a good production environment, and without good management, insulating glass with stable quality and excellent performance will never be produced. The particularity of insulating glass production determines that the following aspects of management work are particularly important.

- The aluminum strips are connected with angled angles. Check whether the 4 connecting corners are effectively sealed with butyl sealant (PIB);

- After filling the molecular sieve, whether it exceeds the 40 minutes specified in the regulations for encapsulating the secondary sealant;

- Whether the coated glass that needs to be edged meets the edge grinding requirements;

- Whether the width and thickness of butyl sealant (PIB) and secondary sealant meet the values specified in relevant standards;

- If silicone sealant is used for the second seal, whether a compatibility test has been conducted (according to the insulating glass sealant industry standards, if the second sealant uses silicone sealant, a compatibility test should be conducted).

4. Selecting qualified supporting materials is a necessary and sufficient condition for producing qualified insulating glass. It is impossible to produce high-performance insulating glass products without qualified supporting materials. Therefore, material selection is a critical link. According to the current status of domestic insulating glass production, double-pass sealing is the mainstream production process, and other processes are in a supplementary position. Therefore, the quality of various components that constitute the double-pass sealing process is the focus of discussion. The main components that constitute the double-pass sealing process which are butyl sealant (PIB), polysulfide sealant, silicone sealant, aluminum spacer strips, desiccants, connectors, etc. As a relatively mature and relatively reliable double-pass sealing process formed by butyl sealant + polysulfide sealant, due to its energy saving, It has been successfully used in the door and window industry for more than 25 years, so it has been recognized by the industry as the first choice for producing high airtight insulating glass products.

With the continuous innovation and development of modern architecture, the emergence of glass curtain walls has put forward higher requirements for the double-pass sealing process of insulating glass. The insulating glass of the curtain wall must not only reflect the appearance but also achieve energy-saving effects within its functional life. At the same time, safety performance must be reflected.

Because silicone sealant has excellent UV resistance, shear strength, and other properties, it has become the first choice for the secondary sealing material of insulated glass in hidden frame curtain walls. To ensure the functional life of its seal, the thickness of its glue layer should be listed as the designer's main consideration. Considering the content, this is mainly because although silicone sealant has excellent aging resistance, its airtightness is relatively insufficient.

Especially once water vapor enters the insulated glass, the functional life of the insulated glass will end immediately. The moisture condensed inside the insulating glass will have a fatal impact on the entire insulating glass component, which in turn will lead to non-safety factors and increase social costs. Therefore, the appropriate sealant layer thickness should be designed to extend the function of the sealant. It is the best choice to not only ensure the safety of curtain wall insulating glass but also extend its functional life. Conducting compatibility experiments on various sealing materials and using bendable aluminum strips and molecular sieves with appropriate adsorption rates are also effective ways to control the quality of insulating glass and extend its functional life.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.