Analysis of Patented Technology of Insulating heat-insulation Glass.

1. The preface

The construction industry is one of the important pillars of the national economy. Energy-saving design in architectural design is an important task, such as the design of energy-saving materials, thermal insulation design of building exterior walls, thermal insulation design of doors and windows, etc. Insulating glass is a glass product that evenly separates two or more pieces of glass with effective support and uses a high-strength, high-airtight adhesive to bond and seal the periphery to form a dry gas space between the glass layers. Since the thermal conductivity of the intermediate layer is much smaller than that of glass, insulating glass has the advantages of a low heat transfer coefficient and significant energy-saving effect. In the construction industry, especially building doors and windows, large areas of insulating glass products are required, and with the continuous development of the construction industry, the demand for insulating glass is increasing year by year. In the face of increasingly fierce global competition, the research and development and layout of patented technologies can help enterprises occupy an advantageous position in market competition. LIJIANG Glass analyzed the patent technology research trends of many leading foreign companies in this field, to provide a reference for the patent technology research and layout of relevant glass deep processing companies.

2. Insulating glass patent application trends and technical composition

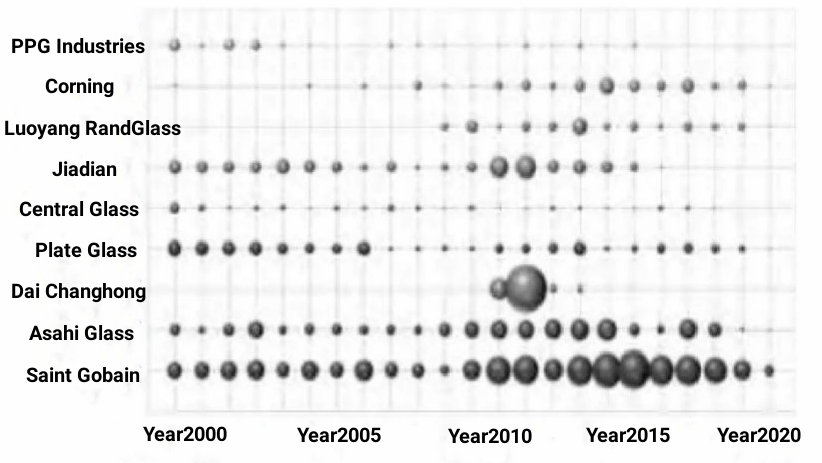

The IPC classification numbers involved in the patent technology related to architectural insulating glass are mainly concentrated in C03C27/00, C03B23/20, E06B3/66, B32B17/00 and their lower point groups, which can be searched in the intelligent review system with keywords such as insulating glass and thermal insulation. The changing trend of patent applications by major global applicants is obtained, as shown in Figure 1. Since it takes about one year from application to authorization announcement for a utility model patent, and 18 months from application to publication for an invention patent, the number of applications in 2021 and 2022 in this statistics is not the final data.

Figure 1 Trends in the number of patent applications by major global applicants

As can be seen from Figure 1, the top ten in the world are France's Saint-Gobain, Japan's Asahi Glass, China's Dai Changhong, Japan's Shen Glass and Central Glass, the United States' Guardian, China's Luoyang LandGlass, the United States' Corning and PPG Industries in the United States. Among them, France's Saint-Gobain has the largest number of applications, and the number of applications is relatively large every year; Japan's Asahi Glass and Slate Glass have more applications, and Central Glass's applications have declined overall; the United States' Guardian and PPG Industries have seen a decline in their applications after 2012. There is a downward trend, while Corning's application volume is increasing; China's Dai Changhong concentrated on applying in 2012 and 2013, and the technical means are relatively similar. Luoyang LandGlass increased its attention to technology in this field after 2010, but the number of applications was small.

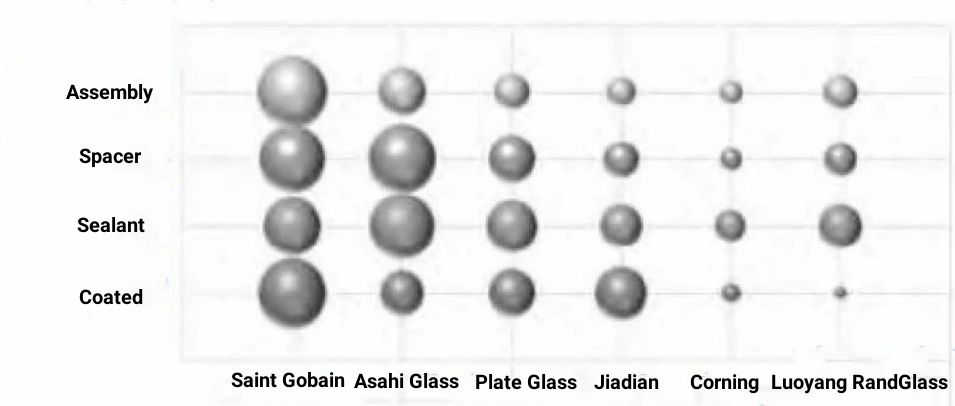

To facilitate an understanding of the technical direction of patent applications in this field, the author studied the patent applications of key applicants in this field and summarized the technical efficacy of each major applicant's patents, as shown in Figure 2. As can be seen from Figure 2, each applicant has different proportions of applications in different technical branches. Foreign applicants cover all the above technical branches because they started their research earlier. Luoyang LandGlass has relatively little research on coatings, and its patented technologies mainly focus on sealing and structure.

Figure 2 The technical effects of each main applicant’s patents

3. The sorting out the patented technologies of each enterprise

To understand the latest patent research technologies and directions of relevant foreign companies, LIJIANG Glass sorted out the patent application technologies of the above major relevant companies after 2018. The analysis is as follows.

3.1 Analysis of French Saint-Gobain’s Patent Technology

3.1.1 Insulating glass spacers

Patent application CN114981076A states that the thermal insulation performance of insulated glazing is largely affected by the thermal conductivity in the edge composite area, especially the thermal conductivity of the spacers. In the case of using metal spacers, the high thermal conductivity of the metal leads to the formation of thermal bridges at the edges of the glass. This thermal bridge causes heat losses in the edge area of the insulating glazing on the one hand and the formation of condensation on the inner glass pane in the spacer area at high air humidity and low external temperatures. To overcome the above problems, a spacer is provided that includes at least one polymer hollow profile, the spacer further includes a moisture barrier on the outer wall, the first side wall, and the second side wall of the polymer hollow profile. The moisture barrier seals the interior glass pane gap to prevent moisture penetration and prevents the loss of gas contained in the interior glass pane gap. The moisture barrier has multiple layers and has a barrier function, and has an external adhesive layer of metal or ceramic of at least 5 nm thickness, the adhesive layer is interrupted in the lateral direction by uncoated areas, the interrupted adhesive layer improves the spacer and auxiliary sealing of the adhesion of the agent is significantly reduced, while the thermal conductivity is significantly interrupted, thereby further improving the thermal insulation performance of the spacer.

3.1.2 Insulating glass functional Low-E coating

Patent application WO2019216661A1 records that glass has low emissivity and low solar heat gain ratio to increase the thermal insulation effect. Using two or more metal layers has the advantages of low emissivity and high selectivity compared to the case of using one layer. However, when using two or more metal layers that exhibit high reflectivity, there will be problems with color aberrations such as green or yellow in transmission. To have appropriate values for emissivity, uncoated surface reflectance, coated surface reflectance, selectivity, and color, a dielectric layer of a specific material is selected. The dielectric layer includes metal oxide, metal nitride, or metal nitrogen. oxide, the metal is one or more selected from the group consisting of Si, Zn, Nb, and Sn, and may include Zr as a dopant. Patent application WO2020079373A1 describes that a conventional approach to obtaining high selectivity and specific aesthetic appearance consists of developing increasingly complex functional coatings, including reflective color-modifying coatings, on the uncoated side of the substrate. On at least one side, the synergy created by the combined use of a color-modifying coating and a functional coating achieves good thermal properties and the desired aesthetic appearance.

3.1.3 Identifiable insulated glass windows

The patent application CN113330180A describes certain types of window frames and door frames for insulating glass window units, in particular, the facade construction is made overwhelmingly or at least partially from metal (aluminum, steel) which interrupts or at least greatly attenuates sub-radio The waves come from or go to the channel of the RFID transponder on the insulated glazing unit. To overcome the above problems, the essentially unfavorable outgoing and incoming radiation conditions for radio waves in the metal frame of the facade glazing are taken into account using special decoupling, in particular by attaching at least one RFID transponder as an identification element. To the insulating glazing unit, a frame is joined around the edges of the insulating glazing unit and simultaneously covers one or more transponders in the perspective direction through the glass pane, in which at least one individual metallic coupling element is inserted into the frame adjacent to the transponder for coupling output and coupling outputInput HF radiation transmitted via the transponder to the outside of the facade glazing and received from the outside.

3.2 Analysis of patented technologies of Japan’s Asahi Glass and Pan Glass Co., Ltd.

3.2.1 Insulating glass structural design

Patent application WO2020187588A1 records that existing insulating glass units have technical problems with thermally induced stress. This application improves the structural design and designs an insulating glass window unit that improves the stress level problems caused by heat and pressure while maintaining high thermal insulation performance. The insulating glass window unit is asymmetric, in which the first glass sheet is thicker than the second glass sheet and is carefully sized by specific sizes (including length ranges and width ranges), specific spacing between spacers, and a specific thickness of the second glass sheet, and wherein to provide improved The technical issues of controlling the level of induced thermal stress in insulated glazing units in multi-glazed windows for thermal performance as well as safety and/or acoustic benefits, and calculations were made for different double glazing units including insulating glazing and a single glass pane facing the building exterior. Thermal induced stresses in laminated glass configurations. The individual glazing is separated from the insulating glazing by a 15mm perimeter spacer, and the internal space is filled with argon gas.

3.2.2 Insulating glass functional Low-E coating

Patent application US2022154526A1 records that in many cases, additional equipment that radiates and/or receives radio frequency signals is set up in a building. To ensure the function of the equipment, sufficient transmittance through the glass window is required. To this end, a glazing unit capable of increasing the transmission of waves with lower frequencies below 6 GHz and millimeter waves above 15 GHz, thus attenuating losses of H or V polarization depending on the interior shape of a building or car Levels are reduced by up to -10dB, and a simple solution to the problem of RF energy reflection is to remove a portion of the coating system to avoid high reflectivity to RF radiation. However, this approach reduces the solar control benefits provided by the glazing unit and the area would be unacceptably large for equipment located inside a building, vehicle, or car. Therefore, another solution was proposed, cutting lines in the coating system to produce a frequency-selective surface, i.e. one that has a relatively high reflectance/absorption rate for solar energy, but a relatively low rate in the RF region of the electromagnetic spectrum reflectivity/absorption rate. Cutting can be performed by laser ablation, and the spacing of the slits chosen to provide selectivity at the desired frequency. Patent application CN113939485A describes that after evacuation has been carried out and the VIG assembly has been sealed, the high temperature that remains is the cause of further gas release, which affects the final residual pressure in the VIG unit and therefore the thermal performance of the VIG unit, in In this application, the sputtering conditions are defined to deposit a low-e coating on a glass plate, thereby allowing the above-mentioned inert gas amount threshold to be met.

3.3 Analysis of patent technologies of Guardian and Corning in the United States

3.3.1 Insulating glass Low-E coated shades

Patent application CN115735043A describes the conventional reduction of the solar heat gain coefficient (SHGC) through the use of static or "passive" low-emissivity (low-E) coatings, and by reduction of the solar heat gain coefficient (SHGC) through the use of spectrally selective low-E coatings. To determine the U value of the window, in this application, the first potential-driven shading object and the second potential-driven shading object are arranged in the gap of the glass, respectively close to the inner main surfaces of the first substrate and the second substrate. By creating a potential difference between the light shield and the conductive coating formed on the inner surface of the substrateTo control the shades, each of the shades can be produced using a polymer film coated with a conductive coating (e.g., a coating including a layer containing Al, Cr, ITO, etc.), aluminum coated shades are available Partial to complete reflection of visible light and up to significant amounts of total solar energy.

3.3.2 Insulating glass spacers

Patent application WO2022144756A1 describes that metal alloy spacers (e.g. alloys containing Ti, Cu, and/or Zr) have been found to have lower thermal conductivity and increased compressive strength compared to conventional annealed 316 stainless steel spacers. , alloyed metal increases resistance to compressive plastic deformation and reduces thermal conductivity, which is particularly advantageous for spacers in VIG window units. Patent application CN114375361A describes that VIG units are subjected to extreme static and dynamic loads, both during manufacturing (e.g. during evacuation and heat sealing processes) and throughout their service life (e.g. during wind loads or mechanical and thermal shocks) stress during the period. Pillar spacers used to mechanically support the gap between the two substrates tend to indent the glass surface they contact, thereby creating indented areas from which cracks may propagate and thus weaken the glass structure, thus providing aA composite spacer system design in which the outermost layer of the spacer is a metal or metal layer and at least one polymer-based layer is disposed therebetween. One or more metals or metal layers having strains that would otherwise be applied to the polymer and provide mechanical strength to the polymer, the polymer helping to provide thermal fracture and therefore increase the R-value of the VIG unit, and compositeThe material as a whole helps increase the yield of the VIG unit because the struts are strong but somewhat flexible, so the VIG unit is less likely to develop cracks etc.

3.3.3 Insulating glass functional Low-E coating

Patent application CN112384486A describes that low emissivity, low sheet resistance, and low sheet resistance properties allow such coated articles to block a large amount of IR emissions to reduce undesirable heating, such as inside vehicles or buildings, which was found to provide clamping An absorber layer placed between a pair of dielectric layers to tailor visible light transmission, Nitrogen-containing silicon oxide in the lower dielectric portion of the coating, between the glass substrate and the lowermost IR reflective layer (e.g., silver, etc.) The layer of zirconium improves the quality of the IR reflective layer, allowing the coated article to achieve low emissivity values with low tolerance variations. In the lower dielectric part of the coating, providing zirconium silicon nitride oxynitride below the zinc stannate layer or zinc stannate-containing layer and below the zinc oxide layer or zinc oxide-containing layer improves the quality of the silver and thereby improves the quality of the silver. Lower emissivity values and lower emissivity tolerance values are obtained in the desired manner. CN112585100A describes the provision of as-deposited crystalline or zinc oxide doped with at least one dopant (for example, Sn) directly beneath an infrared (IR) reflective layer having or containing silver in a low-E coating. A layer that is substantially crystalline (eg, at least 50% crystalline, more preferably at least 60% crystalline) has the effect of significantly improving the thermal stability of the coating (ie, reducing the ΔE* value). CN114430732A describes that certain known steps taken to adjust or improve visible light transmission characteristics and/or durability before heat treatment tend to reduce post-heat treatment durability and thermal stability. Therefore, it is often difficult to obtain the desired combination of visible light transmittance values, thermal stability of color, and good durability. The present application provides an absorbent film in a low-E coating designed to modulate visible light transmission and provide the desired coloration to the coated article while maintaining durability and/or thermal stability. The absorber film may be a multilayer absorber film including a first layer having or containing silver (Ag), and a second layer having or containing NiCr (NiCrOx) which may be partially or fully oxidized. Accordingly, in certain exemplary embodiments, such multilayer absorber films may be composed of a sequence of layers of Ag/NiCrOx.

4. The conclusion

Through sorting out the patent applications of leading foreign companies in insulating glass technology, it was found that although the technical research focuses of companies in different countries are different, the design of traditional spacers and functional membranes is still the subject of patent technology research and application by foreign companies. focus, and dig deeper into the technology. Secondly, with the continuous development of smart components, applying them to insulating glass is also a new direction. For example, related companies in France and Japan have already focused on improving the film layer and structural design of insulating glass according to the needs of intelligent components. In addition, with the continuous development of the construction market in developing countries, foreign companies in developed countries are paying more and more attention to the patent layout in developing countries. To prevent patent disputes, glass deep processing companies in various countries should conduct patent technology research and development and layout as soon as possible to reduce the market risk.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.