Key points of online Low-E glass application technology.

1. The introduction

Insulated Low-E glass is widely used in building doors, windows, and glass curtain wall projects due to its excellent light and thermal properties. The commonly used Low-E glass is produced by an offline process, that is, the surface of the glass plate is cleaned, vacuum magnetron sputtering equipment is used, and a layer of silver film and multi-layer functional films are coated on the surface of the glass plate, which affects the light and thermal properties of the glass. It is this silver film that plays the main role. Those coated with one-layer silver film are called single silver Low-E glass, those coated with two silver films are called double silver Low-E glass, and those coated with three silver films are called triple silver Low-E glass. Since the vacuum magnetron sputtering process and equipment are used to coat the Low-E film on the glass plate, there is a molecular bond between the film layer and the surface of the glass plate. The firmness between the film layer and the glass surface is low, and the film itself is relatively small. "Soft" is easy to scratch and abrade, and the silver film is easily oxidized and denatured when exposed to the air for a long time. Therefore, offline Low-E glass film is also commonly known as "soft film". Low-E glass is usually made into insulating glass, and the Low-E film is located in the air cavity of the insulating glass to protect the Low-E film from scratches, abrasions, and oxidation, that is, offline Low-E glass cannot be used bare.

Online Low-E glass is produced on a float glass production line. In the process of producing float glass, a chemical vapor deposition method is used to coat a layer of semiconductor oxide film on the surface of the glass plate. This film layer has the same characteristics as the offline Low-E film. Similar excellent light and thermal properties are called online Low-E glass. There is a chemical bond between the online Low-E film layer and the surface of the glass plate. The firmness between the film layer and the glass surface is high. The film layer itself is very "hard" and is not easy to be scratched or abraded. The film layer is exposed to the air for a long time. There are no oxidation or denaturation problems in the film, so online Low-E glass film is also commonly known as "dural film". Online Low-E glass can be used alone, that is, Online Low-E glass can be used bare.

2. The Low-E glass energy-saving mechanism

Low-E glass is Low-E glass. Any object with an absolute temperature above 0K radiates electromagnetic waves and absorbs electromagnetic waves. The band range is usually 5-50μm, which is commonly referred to as ambient heat. In general, the radiation ability of an object is equal to the absorption ability. Radiation from an object obeys the Stefan-Boltzmann law:

In the formula:

E - the radiant energy flow density of the object;

T - the absolute temperature of the object;

C - the radiation coefficient of the object, which is also equal to the absorption coefficient.

The absorption coefficient Cb of the black body is the largest, that is, the radiation coefficient Cb is the largest, Cb is 5.68. Other objects are called gray bodies, and their radiation coefficients C are smaller than Cb. The ratio of the object's radiation coefficient C to the blackbody radiation coefficient Cb is called the object's emissivity. The object's emissivity is less than 1. Materials with low emissivity are called Low-Emissivity materials. National standards stipulate that the emissivity of offline Low-E glass film should not be greater than 0.15ε; the emissivity of online Low-E glass film should not be greater than 0.25ε, that is, the radiation ability of offline Low-E glass to ambient heat is lower.

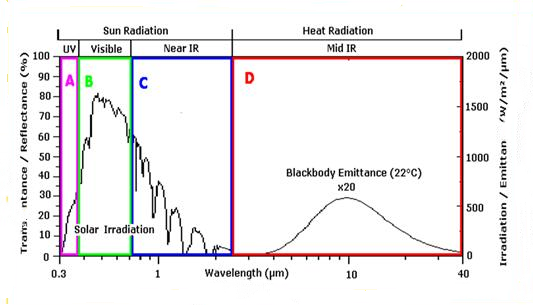

The solar spectrum and ambient heat spectrum are shown in Figure 1.

In the solar spectrum, energy is mainly concentrated in 0.30-2.5μm intervals, 0.30-0.384μm is ultraviolet light, 0.38-0.78μm is visible light, 0.78-2.5μm is near-infrared rays. The ambient heat is distributed between 2.5-40μm. Between, in the solar spectrum, there are no far infrared rays, i.e. no ambient heat.

Figure 1 Solar spectrum and ambient heat spectrum

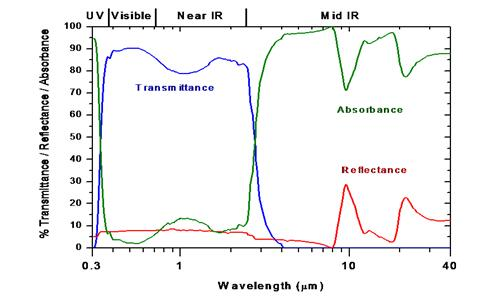

The spectrum of flat glass is shown in Figure 2. As can be seen from Figure 2, within the solar spectrum range, the transmittance of flat glass is very high, that is, flat glass is almost completely transparent to sunlight, so the shading coefficient of flat glass is large and the shading performance is poor. Within the ambient heat spectrum range, flat glass is completely opaque, that is, the transmittance is zero, so flat glass has thermal insulation properties and can be used as building exterior maintenance materials. However, the thermal insulation performance of flat glass is poor and the heat transfer coefficient is large. The reason is that within the environmental heat spectrum range, the absorptivity of flat glass is very high and the reflectivity is low. When there is a temperature difference on both sides of the flat glass, the flat glass absorbs The heat on the high-temperature side increases its temperature, and transfers the heat to the low-temperature side. This is the mechanism of poor thermal insulation performance of flat glass.

Figure 2 The spectrum of flat glass

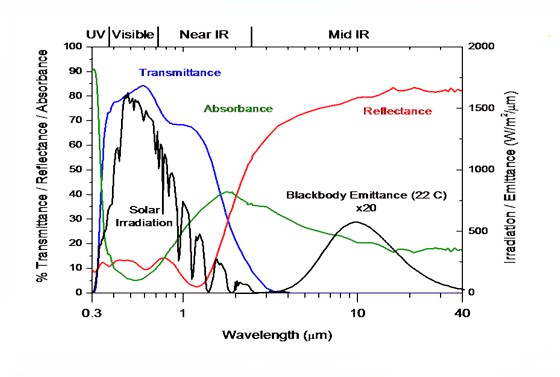

The spectrum of Low-E glass is shown in Figure 3. As can be seen from Figure 3, the transmittance of Low-E glass in the visible light range is still high, but it is lower than that of flat glass. In the near-infrared range of the solar spectrum, the transmittance of Low-E glass drops more, that is, Low-E glass has better shading performance and lower shading coefficient. Within the ambient heat range, Low-E glass has lower absorptivity and higher reflectivity. When there is a temperature difference on both sides of Low-E glass, Low-E glass will reflect the heat from the high-temperature side to the high-temperature side, only Less heat is transferred to the low-temperature side, which is the reason why Low-E glass has good thermal insulation performance.

Figure 3 The Low-E glass spectrum

3. Monolithic online Low-E glass application

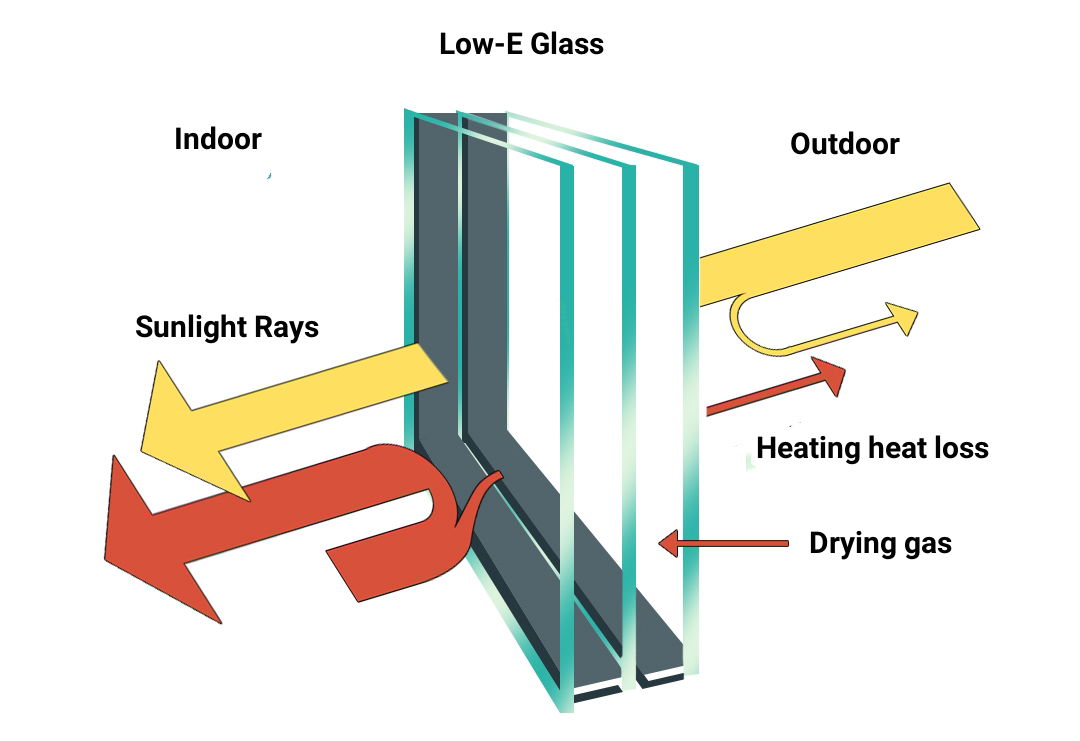

Since the online Low-E glass film layer is relatively "hard", it can be used as a single piece. During use, the Low-E membrane surface should be set indoors, see Figure 4. This not only retains the better shading performance of online Low-E glass but also optimizes its thermal insulation performance, that is, the heat transfer coefficient is lower. The mechanism for reducing the heat transfer coefficient of online Low-E glass is: the heat transfer coefficient within the glass is:

Figure 4 Monolithic online Low-E glass

In the formula:

hi —— Indoor surface heat transfer coefficient;

hc —— Indoor surface convection heat transfer coefficient, usually 3.6;

hy —— Indoor surface radiation heat transfer coefficient;

ε —— Indoor surface emissivity.

For ordinary glass, its surface emissivity is 0.837, and the calculated heat transfer coefficient of the inner surface of ordinary glass is 8W/㎡*K. If there is an online Low-E film on the inside of the glass, for example, take its emissivity is 0.1, then the heat transfer coefficient of the glass indoor surface drops to 4.1W/㎡*K, the heat transfer coefficient of ordinary single-piece glass is generally 5.6-6.0W/㎡*K, the heat transfer coefficient of a single piece of online Low-E glass can be reduced to 3.4-3.7W/㎡*K, the energy-saving effect is extremely obvious.

The main focus of building energy conservation in areas with hot summers and warm winters is the shading coefficient of glass. The heat transfer coefficient of glass is not required to be high. In many cases, the heat transfer coefficient is required to be 3.5-4.7W/㎡*K, using a single piece of online Low-E glass can meet the requirements for glass shading coefficient and heat transfer coefficient.

The application technology of laminated online Low-E glass is the same as that of monolithic online Low-E glass. The Low-E film should also be installed on the indoor side so that the thermal performance of the glass can be optimal. If the Low-E film is installed in the laminated layer, the contribution of the Low-E film to the heat transfer coefficient of the glass will be reduced to zero. At the same time, there may also be an incompatibility problem between the PVB film and the Low-E film, causing the laminated online Low-E glass. PVB film cracks and fails during use.

4. The insulating online Low-E glass

The sealing performance around the insulating glass is very important. If the sealing performance is not good, ambient air will enter the insulating glass cavity, and water vapor in the air will also enter the insulating glass cavity. When the water vapor concentration in the cavity reaches a certain level, internal condensation will occur in the insulating glass, and the insulating glass will fail. When ambient air enters the insulating glass cavity, oxygen in the air also enters the cavity. When the oxygen concentration in the cavity reaches a certain level, the offline Low-E film will be oxidized and denatured, and the insulated offline Low-E glass will fail. In comparison, the oxidation of the Low-E film of insulating offline Low-E glass is more sensitive and easier to occur than internal condensation, and the oxidation of the Low-E film is irreversible. The peripheral sealing of insulating glass is relative, and the penetration of gas is absolute. When the amount of air penetration is small, the insulating glass has not yet reached internal condensation, but it may cause oxidation of the offline Low-E film. If online Low-E glass is used to form insulating Low-E glass, since the online Low-E film has no oxidation problem, using online Low-E glass to form insulating glass can make up for the problem of poor sealing performance of insulating glass. For cases where internal condensation has not yet reached, but there is a small amount of air penetration, using offline Low-E film glass may oxidize and fail, but using online Low-E glass can keep the insulating glass still in normal use.

5. The super energy-saving insulating glass

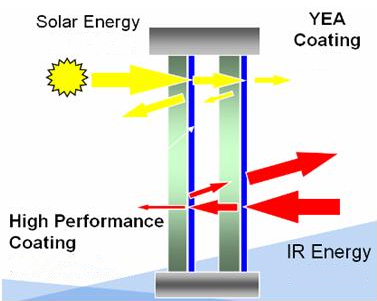

In recent years, some developed and developing countries have increasingly higher requirements for building energy conservation and stricter thermal performance requirements for materials. For example, Germany, a developed country in mid-to-high latitudes, requires heat transfer coefficients for exterior windows of residential buildings. The limit is 1.5-2.0W/㎡*K. Since the heat transfer coefficient of window frames is generally greater than or much greater than 2.0W/㎡*K, so the heat transfer coefficient of the glass should be as low as possible to ensure that the heat transfer coefficient of the entire window reaches 2.0W/㎡*K the following.The heat transfer coefficient of commonly used 6+12A+6 Low-E (offline) insulating glass is approximately 1.8W/㎡*K, unable to meet the entire window heat transfer coefficient to reach 2.0W/㎡*K The following requirements. If the two pieces of glass that make up the insulating glass are both made of offline Low-E glass. Its heat transfer coefficient is only reduced by 0.1W/㎡*K, which is 1.7W/㎡*K, the reason is that the offline Low-E membrane can only be located in the insulating glass cavity, and the two Low-E membranes have repeated functions, and their functions are not fully exerted. If the outer piece of insulating glass is made of offline Low-E glass, the inner piece is made of online Low-E glass, and the Low-E film glass of the inner piece of glass is installed on the indoor side, see Figure 5.

Figure 5 Super energy-saving insulating glass

The two Low-E films of this insulating glass fully exert their functions, so the heat transfer coefficient of 6 Low-E (offline)+12A+6 Low-E (online) insulating glass can be as low as 1.4. Its excellent thermal performance is used in many applications. Buildings with high requirements for glass curtain walls and building exterior windows can meet the requirements. Avoid using triple-glazed, two-cavity-insulated Low-E glass, because triple-glazed, two-cavity-insulated Low-E glass products are high in cost, extremely heavy, and difficult to process and produce. The insulating glass composite process requires the use of automated heavy-duty steel beam structural plate pressing function insulating glass production line for insulated, and the application cost is also high. Given the particularly excellent thermal performance of insulating glass composed of a piece of offline Low-E glass and a piece of online Low-E glass, it is named super energy-saving insulating glass to distinguish it from ordinary insulating Low-E glass. We believe that as the awareness of super energy-saving insulating glass continues to increase, its market application will become larger and larger, and its social benefits will be increasingly praised by the industry.

6. The conclusion

Policies and regulations are the vane of market demand, and market demand is the driving force for technological innovation. As various countries and regions continue to improve building energy conservation requirements, super energy-saving online Low-E glass and its series of products will be continuously developed and applied.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.