LJCM2030 Automatic Vertical Low-E Glass Film Deleting Machine

LIJIANG Glass LJCM2030 Automatic Vertical Low-E Glass Film Deleting Machine is used to delete the edge film of the Low-E Glass. The glass edge deleting machine adopts imported servo control system, positioning accurately with smooth operation. High quality grinding wheels are durable, could produce neat and prefect grinding crack...

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LJCM2030 Automatic Vertical Low-E Glass Film Deleting Machine

Product Description

Advantages & Features

- Adopting an advanced PLC control system and equipped with an imported brand PLC controller, it has a high degree of automation and easy operation.

- Using a human-computer interaction interface, it can monitor the working status and self-diagnose equipment faults

- 8-axis servo motor + reduction gear linkage system

- Can automatically detect the size of Low-E Glass and perform unequal Low-E Glass film removal processing

- Using linear slide rail positioning to ensure processing accuracy

- Equipped with automatic dust removal system and automatic grinding wheel dressing function

- Special-shaped glass can be processed according to 11 different graphics in the Low-E Glass graphic library

- Configure Low-E separator film removal function

- Optional remote communication function

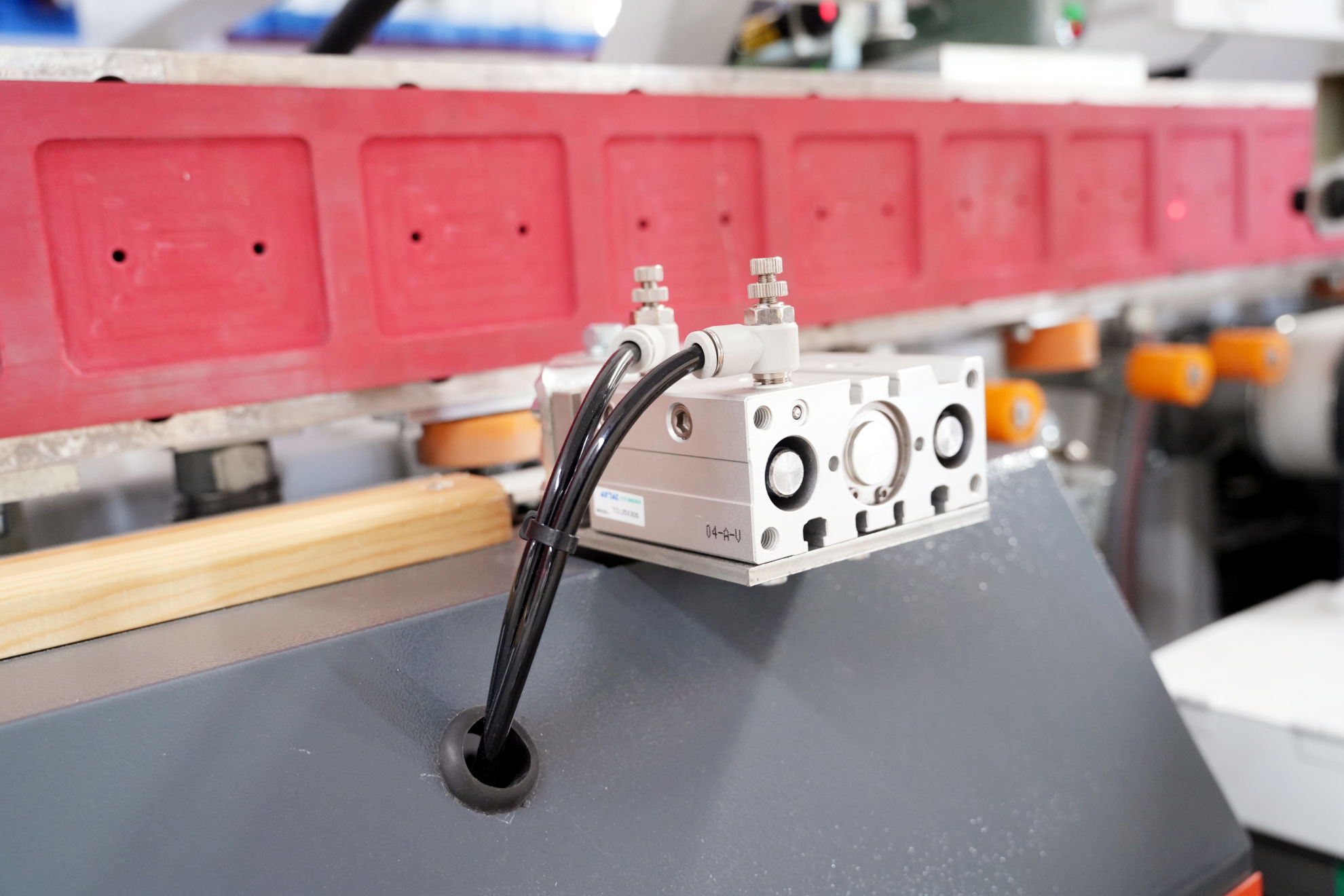

Figure 1 The slider + gear + reducer structure of Low-E glass film removal machine head

Figure 1 The slider + gear + reducer structure of Low-E glass film removal machine head

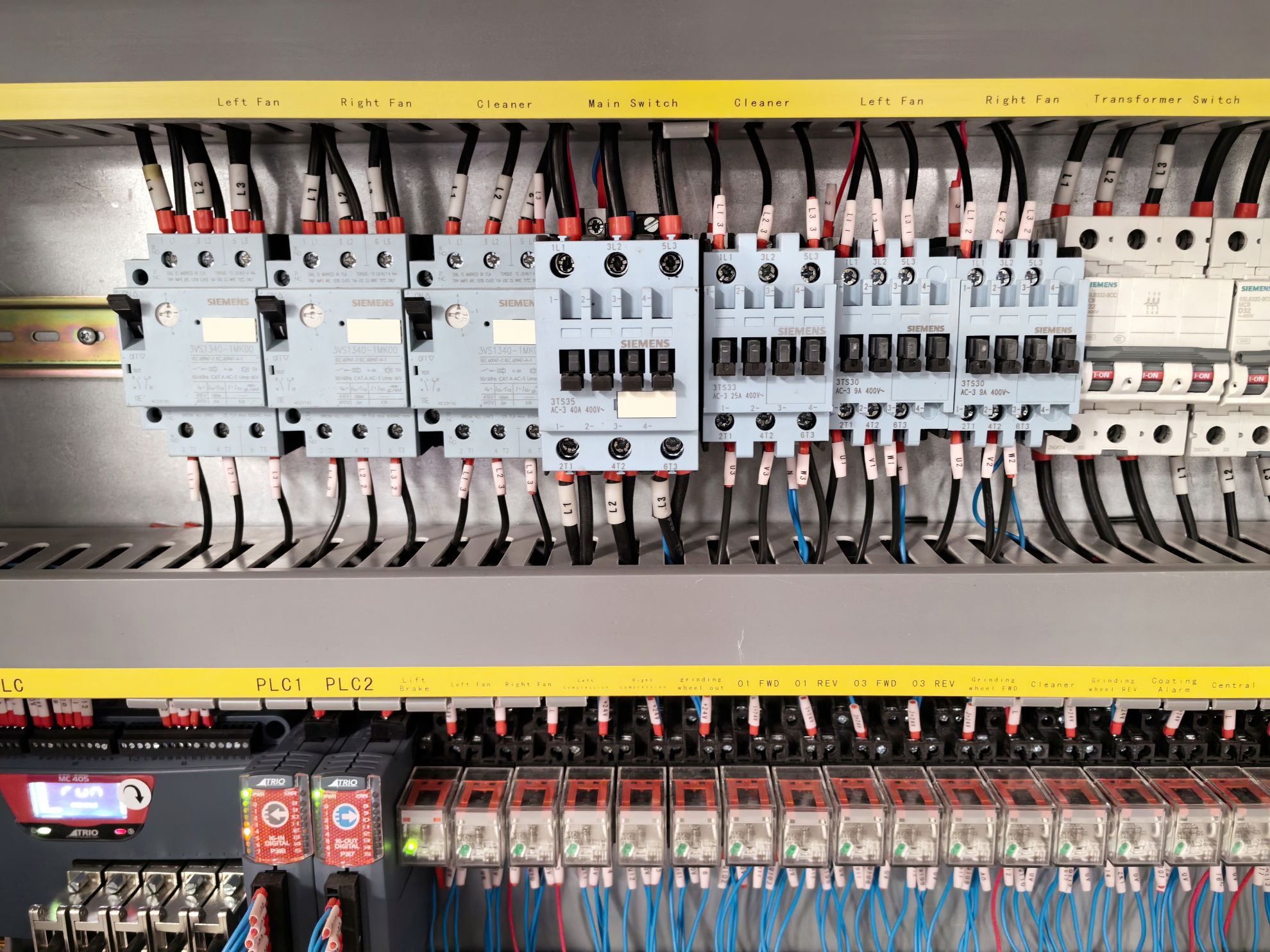

Figure 3 The electrical components in the distribution case are clearly marked

Figure 3 The electrical components in the distribution case are clearly marked

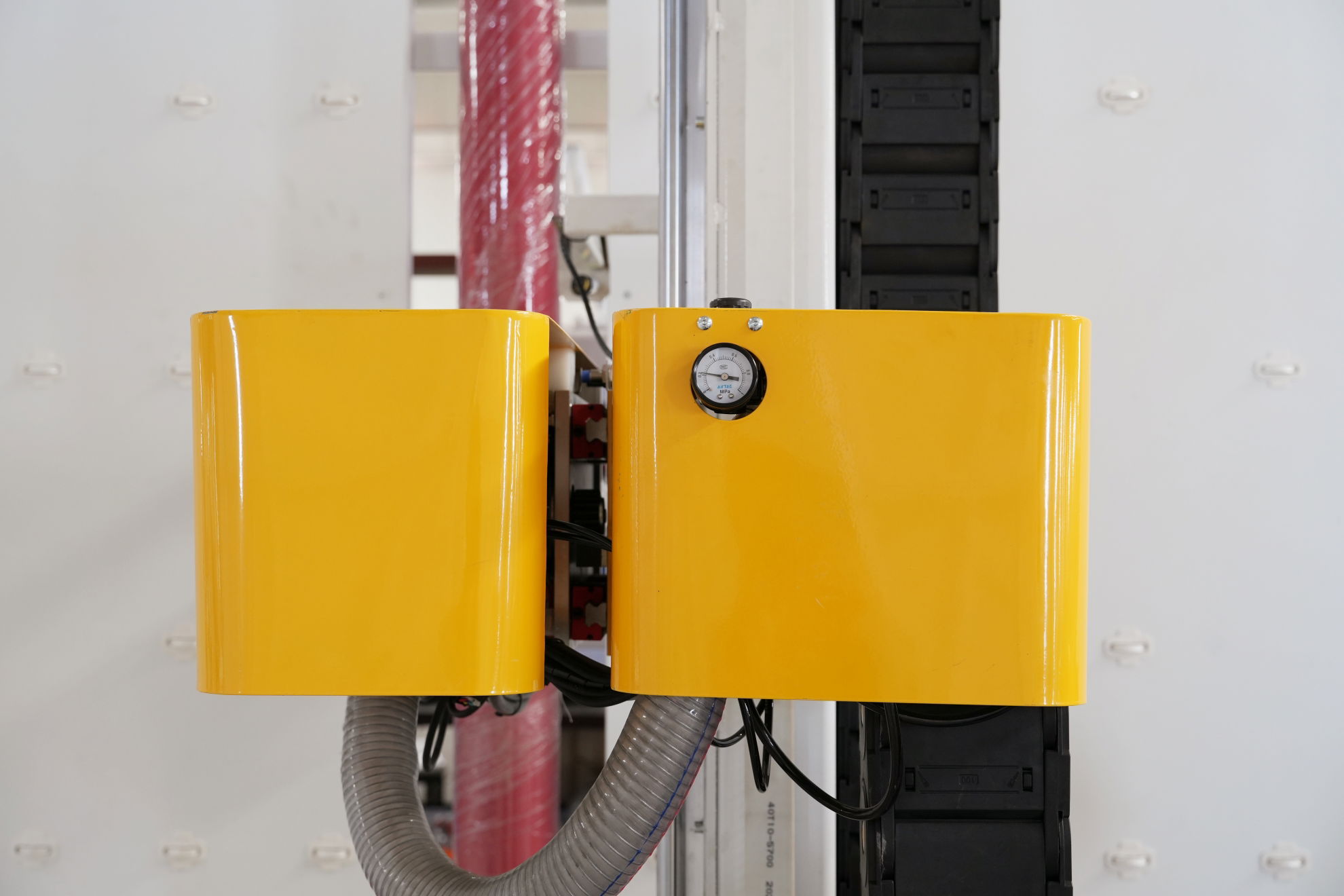

Figure 4 The slider + gear + reducer structure of Low-E glass film removal machine head 2

Figure 4 The slider + gear + reducer structure of Low-E glass film removal machine head 2

Figure 5 The Low-E glass film photoelectric sensor 1

Figure 5 The Low-E glass film photoelectric sensor 1

Figure 6 The Low-E glass film photoelectric sensor 2

Figure 6 The Low-E glass film photoelectric sensor 2

Main Technical Parameter

| Item. | Spec. |

| Max. glass processing size | 2000mm*3000mm |

| Min. glass processing size | 400mm*280mm |

| Glass thickness | 3-15mm |

| Diameter of grinding wheel | 200mm |

| Conveyor height | 500mm |

| Edge deleting width | 10-50mm |

| Transmission speed | 29m/min |

| Edge deleting speed | 2-29m/min |

| Abrasive wheel width | 10/12/15mm |

| Grinding wheel speed | 0~3000r/min |

| Total air consumption | 100L/ min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50Hz 3.35Kw |

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

What is the maximum and minimum size of your equipment for film removal? What is the required range of glass thickness?

What direction can the Low-E Glass Film Removal Machine be divided into?

How many sections is the Low-E Glass Film Removing Machine divided into? What is the size of each segment?

What are the advantages and disadvantages of the Low-E Glass Film Remover Machine?

The disadvantage is that it increases the length of the entire production line and occupies a large area. However, compared with the high manual wages and the uncertainty of manual operation, it would be a good choice to choose automated equipment.

In addition, compared with automatic film removal, manual film removal has poor film removal effect and slow speed. Compared with Low-E Glass, other glass has to remove the film before tempering, because the heating time of white glass and Low-E Glass is different during tempering, which will cause glass deformation.

Why we should use the Vertical Low-E Glass Film Delecting Machine first to removal the Low-E Film?

Since offline Low-E glass contains materials that are easily oxidized by air, it cannot be used as a single piece. Before the insulating glass is synthesized, the surrounding film layer needs to be removed to avoid contact between the film layer and the sealant. After the insulating glass is synthesized, The protection of two layers and one layer of sealant can effectively isolate sulfide in the air and ensure that the film layer is not oxidized. Another is that the adhesion between the offline film layer and the glass is not very good, so it needs to be removed.

The existing Low-E glass film removal methods include manual film removal with a hand-held film remover and automatic film removal with an all-in-one glass cutting and film removal machine or an all-in-one glass edge grinding and film removal machine; manual film removal is prone to residue and removal. The problem of inconsistent film depth and uneven edges; using automatic film removal, the existing automatic film removal mechanism is prone to uneven film removal edges due to the vibration of the cutting machine or edge grinder, and has problems with inconvenient adjustment.

Seven factors for choosing the Vertical Low-E Coated Glass Film Removal Machine?

The following seven factors are mainly considered when choosing a Low-E coated glass film removal machine:

1. The film removal length range that the Low-E coated glass film removal machine can remove.

The film removal length range of the vertical Low-E coated glass film removal machine must be able to meet the requirements of the large and small size length ranges of coated glass. For a small amount of particularly long coated glass, a manual film removal machine can be used to remove the film.

2. Film removal width of Low-E coated glass film removal machine

The film removal width of the film removal machine must adopt a computer-controlled width adjustment function. If the film removal wheel is too wide, the contact area is too large and the pressure per unit area is too small, which will affect the film removal effect.

3. Film removal efficiency

The working efficiency of the film removal machine is very important. The working efficiency of the film removal machine not only affects the production capacity of the company but also high-efficiency equipment can also reduce the production cost of the product.

4. Film removal shape

In addition to square glass, the film removal machine will be more practical if it can remove other shapes of special-shaped glass.

5. There must be a certain amount of "elasticity" between the film removal wheel and the glass.

Since the film removal wheel wears and wears continuously, it is very important to choose a film removal machine with an "elastic" structure between the film removal wheel and the glass to be removed, and the film removal head should be convenient and simple to adjust.

6. It must have a dust collection function

The dust collection function can prevent dust from falling into the moving parts of the equipment and causing grinding damage to the movable parts of the mechanical equipment. What is more important is to prevent people from suffering from occupational diseases such as silicosis.

7. Security

Whether the equipment has safety protection is one of the very important indicators when considering purchasing equipment.