LJTB03 Automaitc Insulating Glass Butyl Extruder Coating Machine

LIJIANG Glass LJTB03 insulating glass butyl extruder coating machine is used for spreading aluminum spacer frames evenly with hot melt butyl extruder sealant, could use large electrical control panel which makes the operation more easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0 m/min to 47 m/min, which has the fastest speed in China. This type of machine is very popular with energy-saving. Its squeezing system adopts pneumatic and hydraulic supercharging system, which makes the squeezing pressure more stable. The dispensing cylinder uses vertical rotary support system and it makes the refill of butyl easier. It can prolong the life of squeezing system and set the heating time in 24 hours with electricity and air pressure.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LJTB03 Automatic Insulating Glass Butyl Extruder Coating Machine

Product Description

Structure and composition of automatic insulating glass butyl extruder coating machine

1. Transmission device:

It is composed of transmission motor, transmission, transmission gear train, conveyor belt, etc.

2. Heating system:

Composed of heating elements, thermocouples, etc.

3. Butyl extrusion device:

It consists of an oil cylinder, a glue extrusion piston, a glue cylinder, a glue head seat, a glue extrusion head, etc.

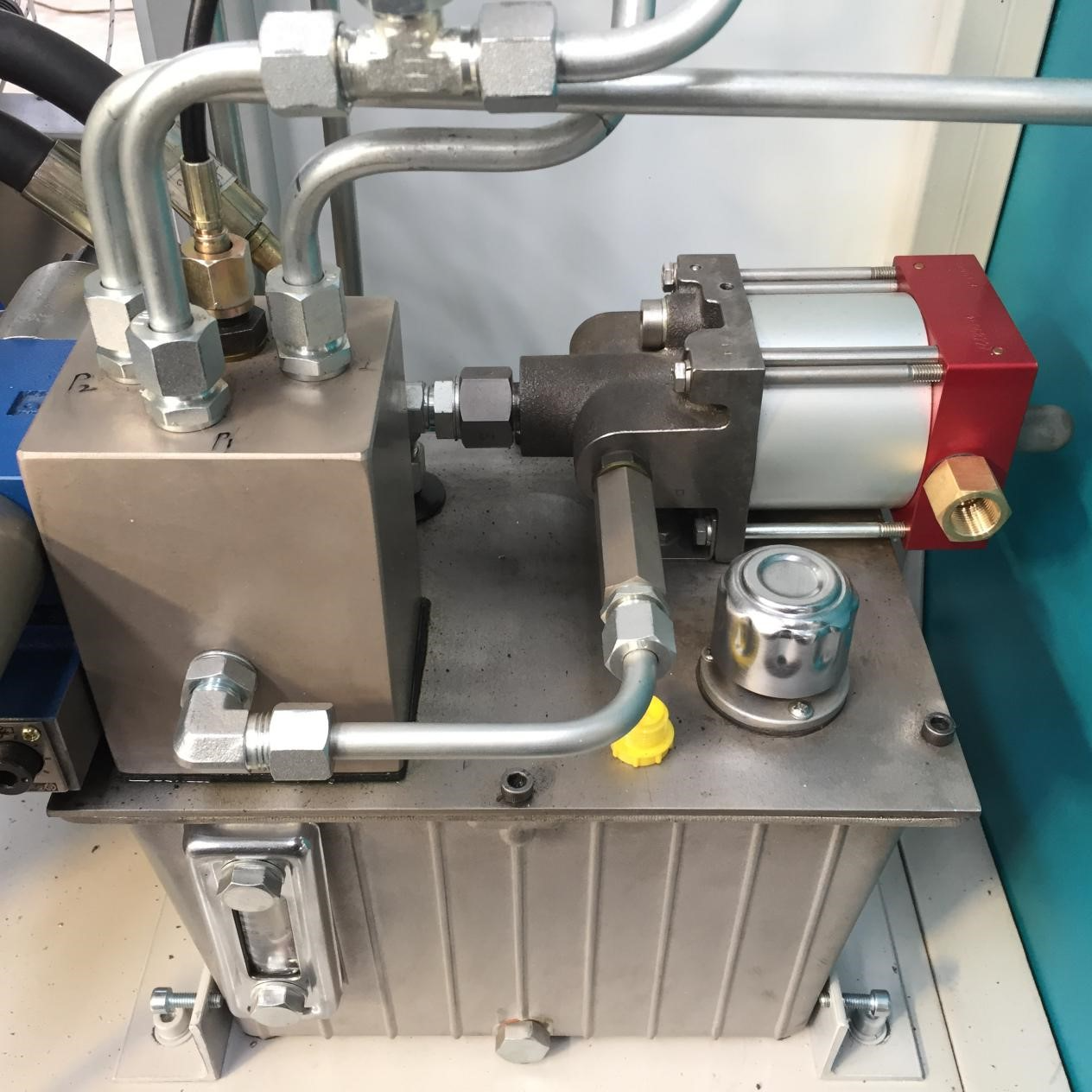

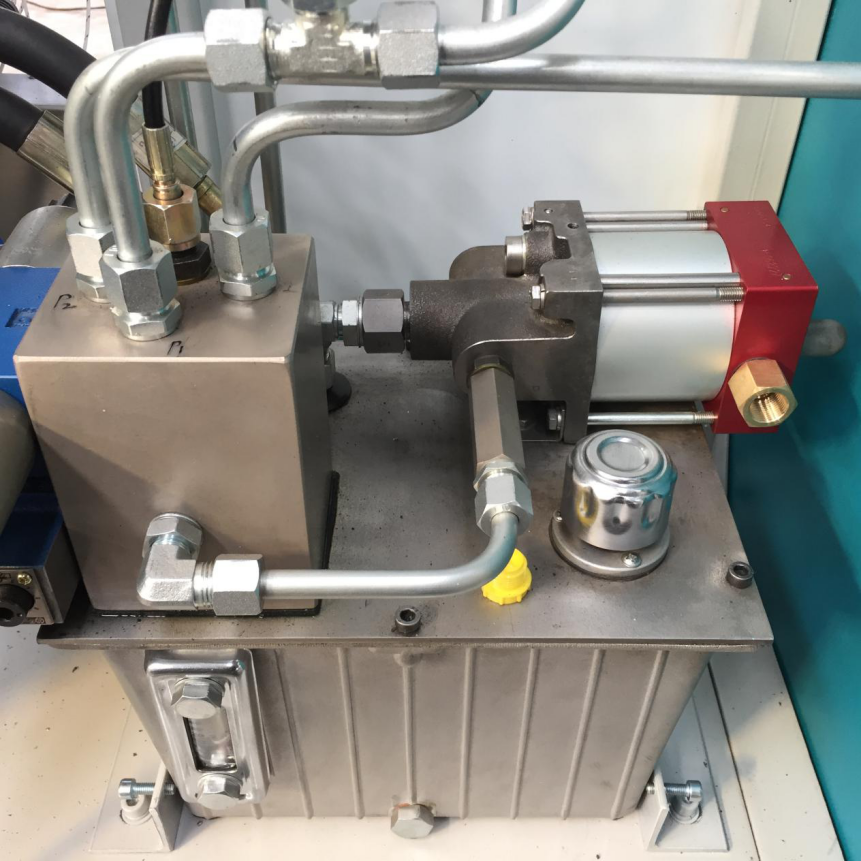

4. Hydraulic system:

It consists of oil pump, motor, oil tank, pressure gauge, electromagnetic reversing valve, pressure control valve, oil filter and corresponding pipelines.

5. Pneumatic system:

It consists of air source processing components, solenoid valves, throttle valves, pressure regulating valves, cylinders, joints and pipelines.

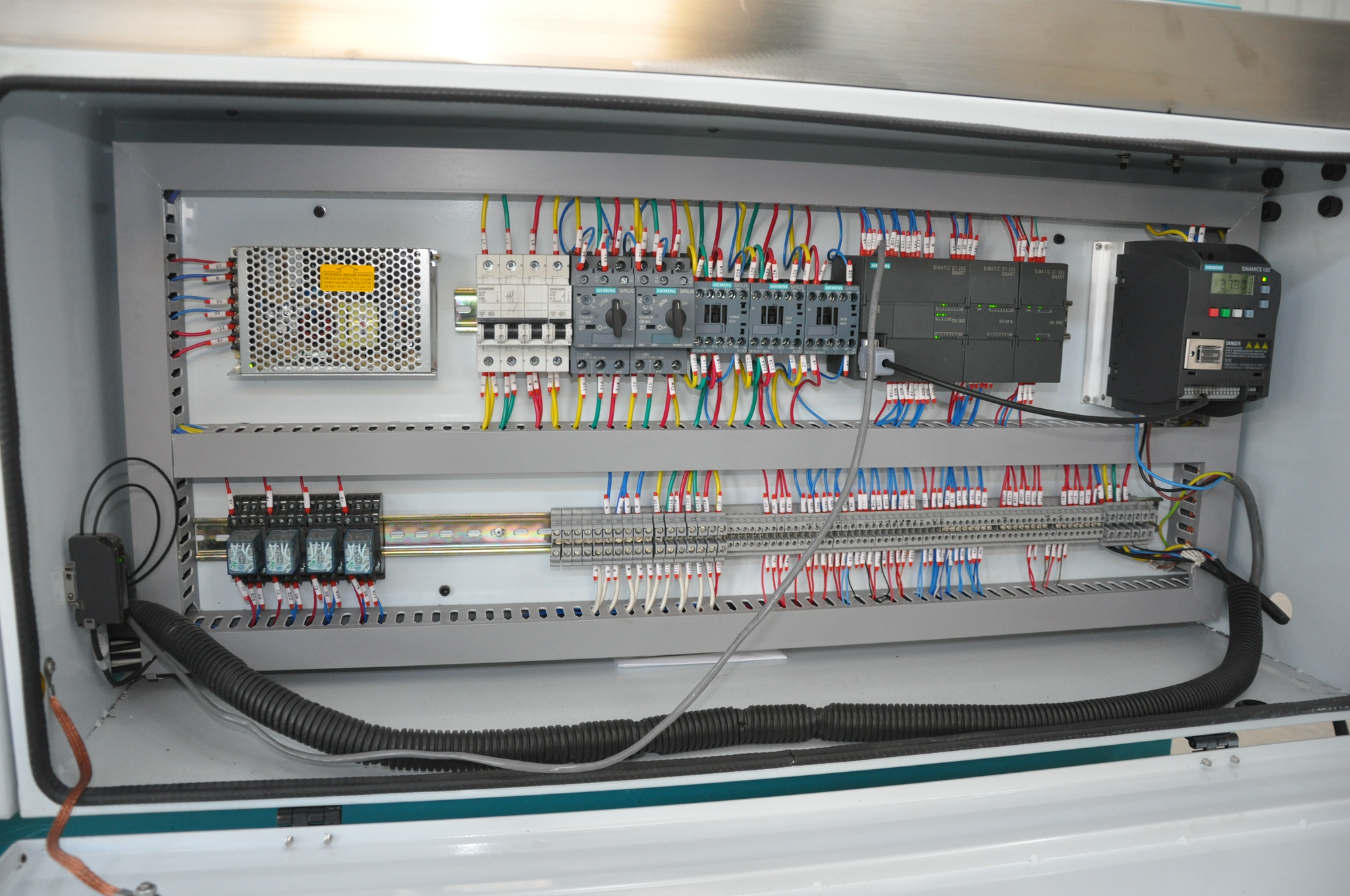

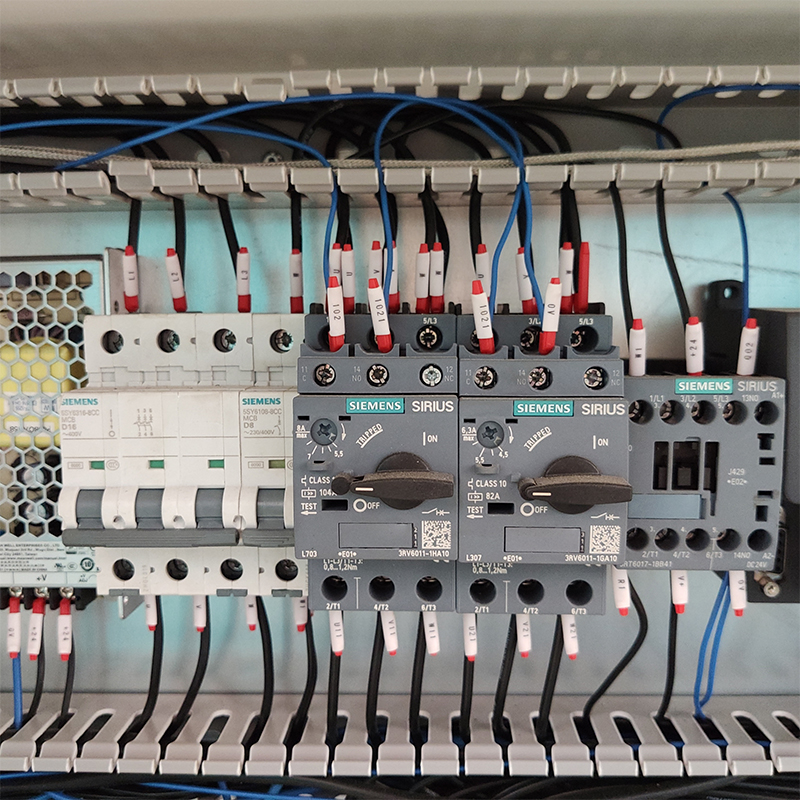

6. Electronic control system:

It consists of electrical detection components, thermal relays, time relays, control panels and operating switches.

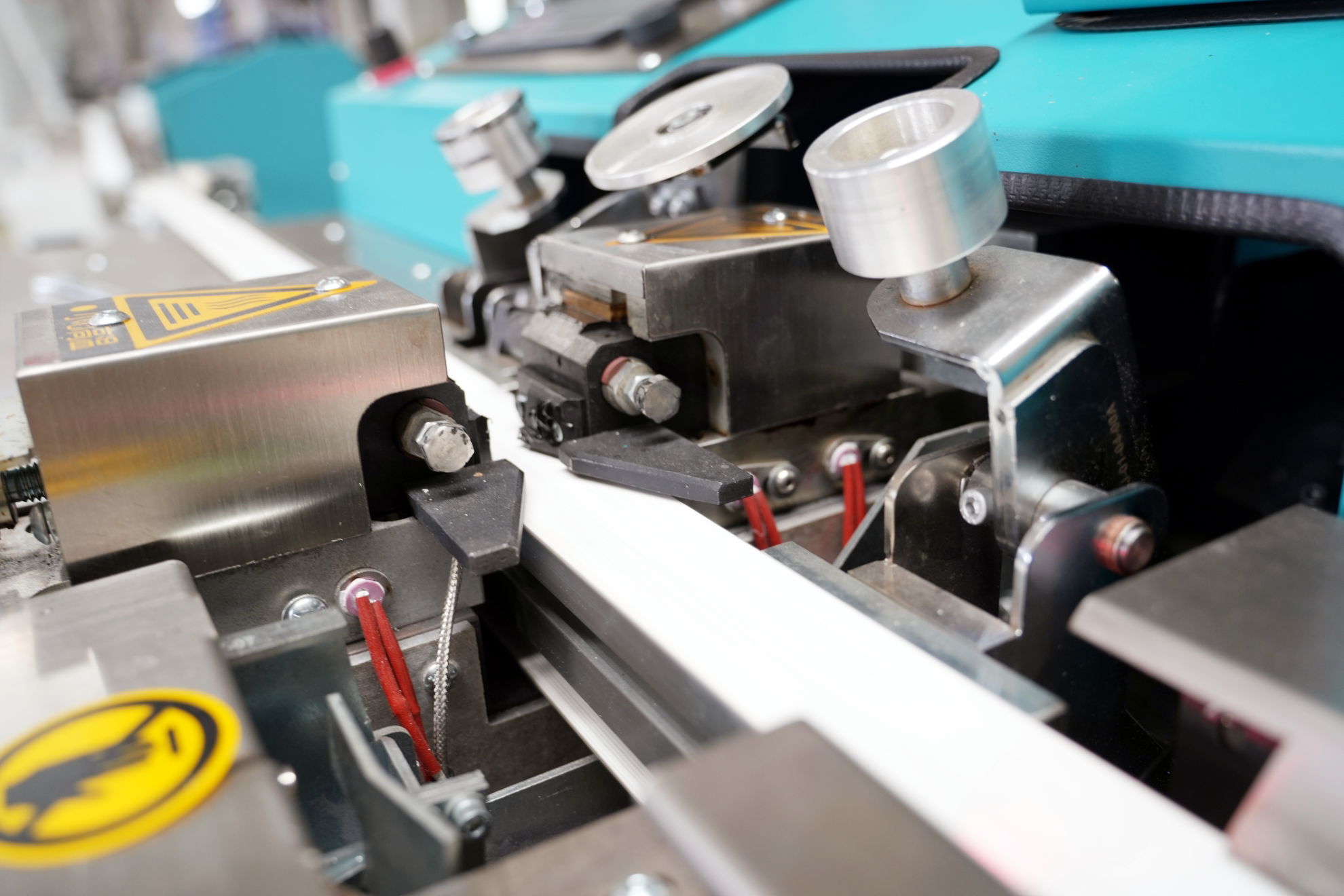

Figure 1 The automatic structure could adjust the glue nozzle

Figure 1 The automatic structure could adjust the glue nozzle

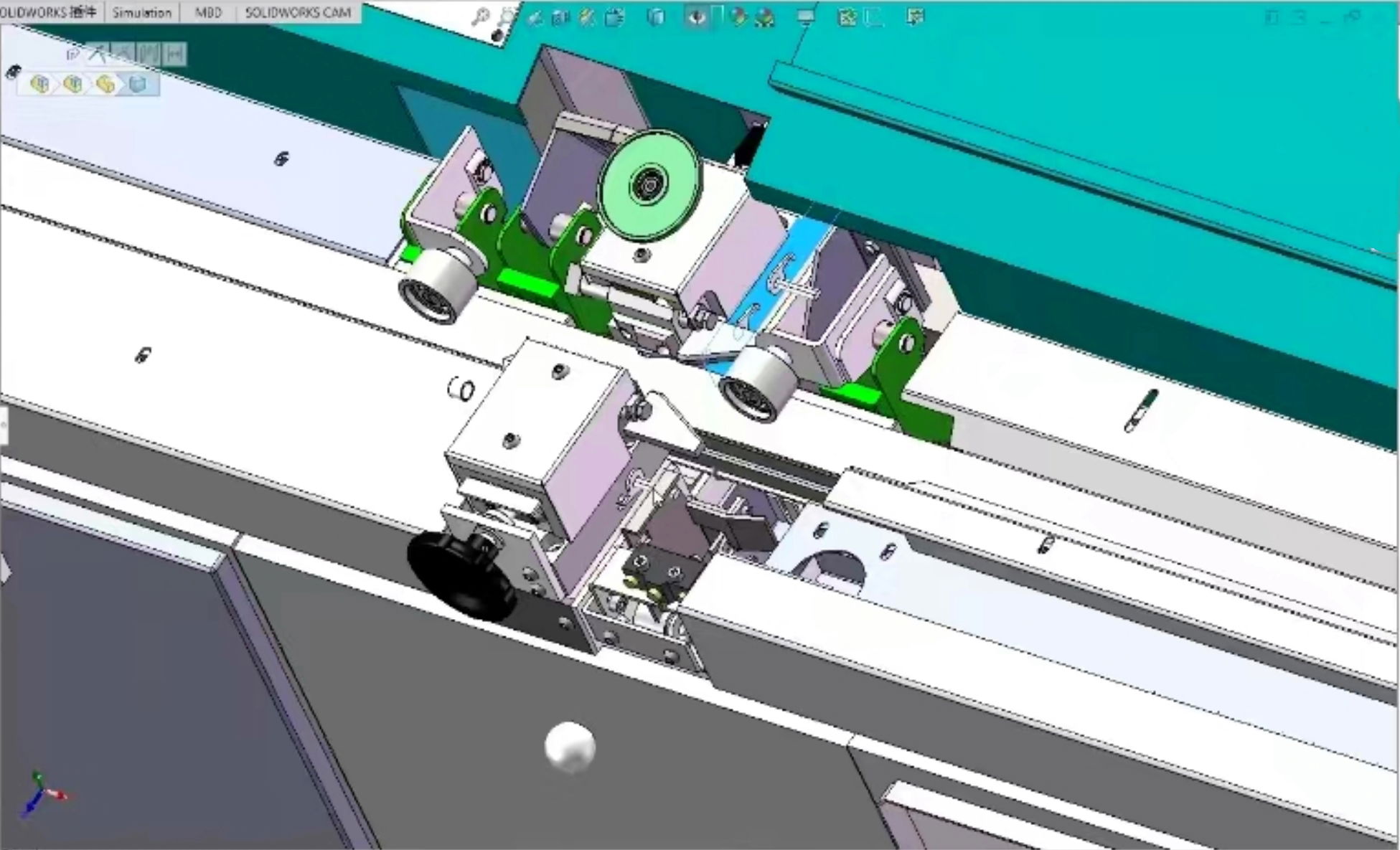

Figure 2 The automatic pressing and lifting structure for aluminum spacer strips sealing

Figure 2 The automatic pressing and lifting structure for aluminum spacer strips sealing

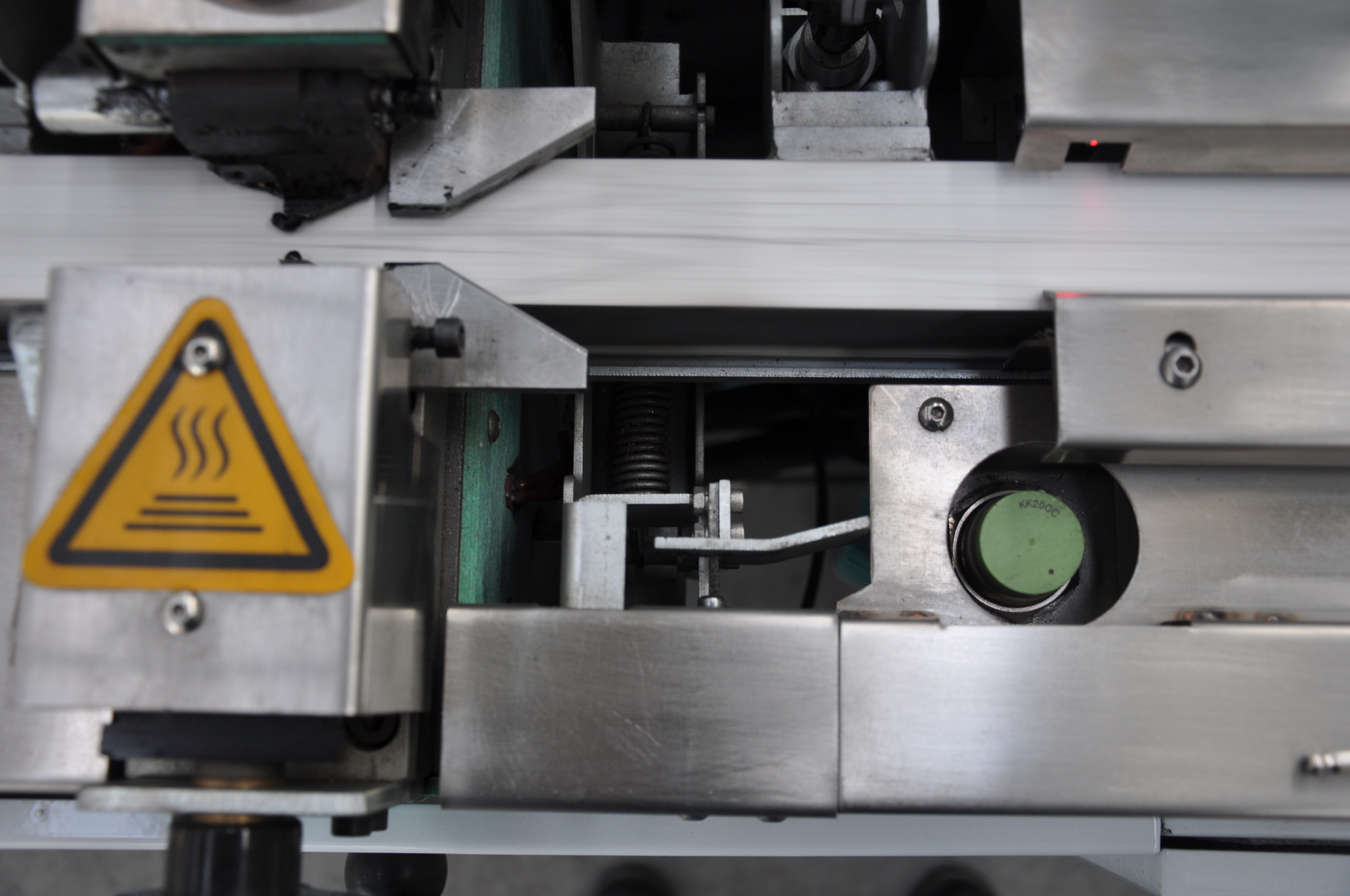

Figure 3 The oil cylinder, bottom plate, glue outlet hole, and structural beam can all be adjusted to meet different sealing thicknesses.

Figure 3 The oil cylinder, bottom plate, glue outlet hole, and structural beam can all be adjusted to meet different sealing thicknesses.

Advantages & Benefits

Advantages & Benefits

- Controlled by PLC System.

- Digital Display system can show you the quantity of the glue automatically.

- Butyl spreading is well-proportioned and the linearity is good.

- Temperature and pressure can adjust automatically. Also time of pre-heating can be set, then the machine can be turned on and off automatically.

- Adopting the imported hydraulic and pneumatic supercharging system makes sure of the stability and continuity of the butyl extruder coating.

- The butyl extruder coating jar warning system will make alarm when glue material is used up.

- Advanced device guarantees and best spreading effect on the arc aluminium frame.

The Butyl Head

The Germany Siemens PLC System

The Stainless Steel Work Surface

Could produce the special sharps

The hydraulic system

Equipment Inspection and Installation

1. After the equipment is transported to the user's site, unpack it and check for transportation damage, loose connections, falling wiring, etc. If there is no damage, it can be installed.

2. The equipment should be installed on a concrete foundation, and the equipment should be leveled. When leveling, the plumb line of the oil tank and the rubber tank should be used as the benchmark, so that the angle error between the center line of the oil tank and the rubber tank and the plumb line is not greater than 0.1°..

3. The equipment uses a 380V three-phase four-wire power supply with a rated load of 7.5Kw. The manufacturer must ground the equipment reliably. The grounding wire must be yellow and green two-color twisted wire. The cross-sectional area of the grounding wire must not be less than 2.5mm2. After grounding, the machine The ground resistance between the main body and the main ground point should be less than 4Ω.

4. The equipment uses clean and dry air with an air source pressure of 0.6MPa and dewatered air.

5. Check whether rainwater and impurities is leaking into the oil tank of the hydraulic station. (To ensure transportation safety, the hydraulic oil in the tank has been drained after the equipment is tested and before leaving the factory.) When refueling, unscrew the upper cover of the breathable cover and add anti-wear hydraulic oil according to the oil mark instructions. Use 46# anti-wear hydraulic oil in summer; use 32# anti-wear oil in winter. Other liquid media are not allowed to be used as the working oil of the power unit.

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.