LJGZ2020 Automatic Insulating Glass Desiccant Filling Machine

LIJIANG Glass LJGZ2020 Insulating Glass Desiccant Filling Machine could automatically achieve actions of drilling holes automatically in the insulating glass spacing frames, filling desiccant and sealant. The control system of Desiccant filling machine adopts Germany Siemens, so the speed of filling is quick and stable operation ensure the valid closure property of sealant. Desiccant filling machine improves quality of insulating glass, it’s a necessary equipment in the process of insulating glasses...

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LJGZ2020 Automatic Desiccant Molecular Sieve Filling Machine

Details Display

Main Technical Parameter

| Item. | Spec. |

|---|---|

| Filling aluminum frame’s maximum size | 2000mm*2000mm |

| Filling aluminum frame’s minimal size | 150mm*300mm |

| Article aluminum specifications | 5.5mm-24mm |

| Air source | ≥0.65MPa |

| Power supply and power consumption | AC220V 50Hz 1Kw |

| Molecular sieve diameter needed | 0.5mm-0.9mm |

| Dimension | 1300mm*1100mm*3650mm |

| Total power | AC220/380V 50Hz 2.5Kw |

| Dimension | 10500mm*2200mm*2600mm |

| Name | Brand |

|---|---|

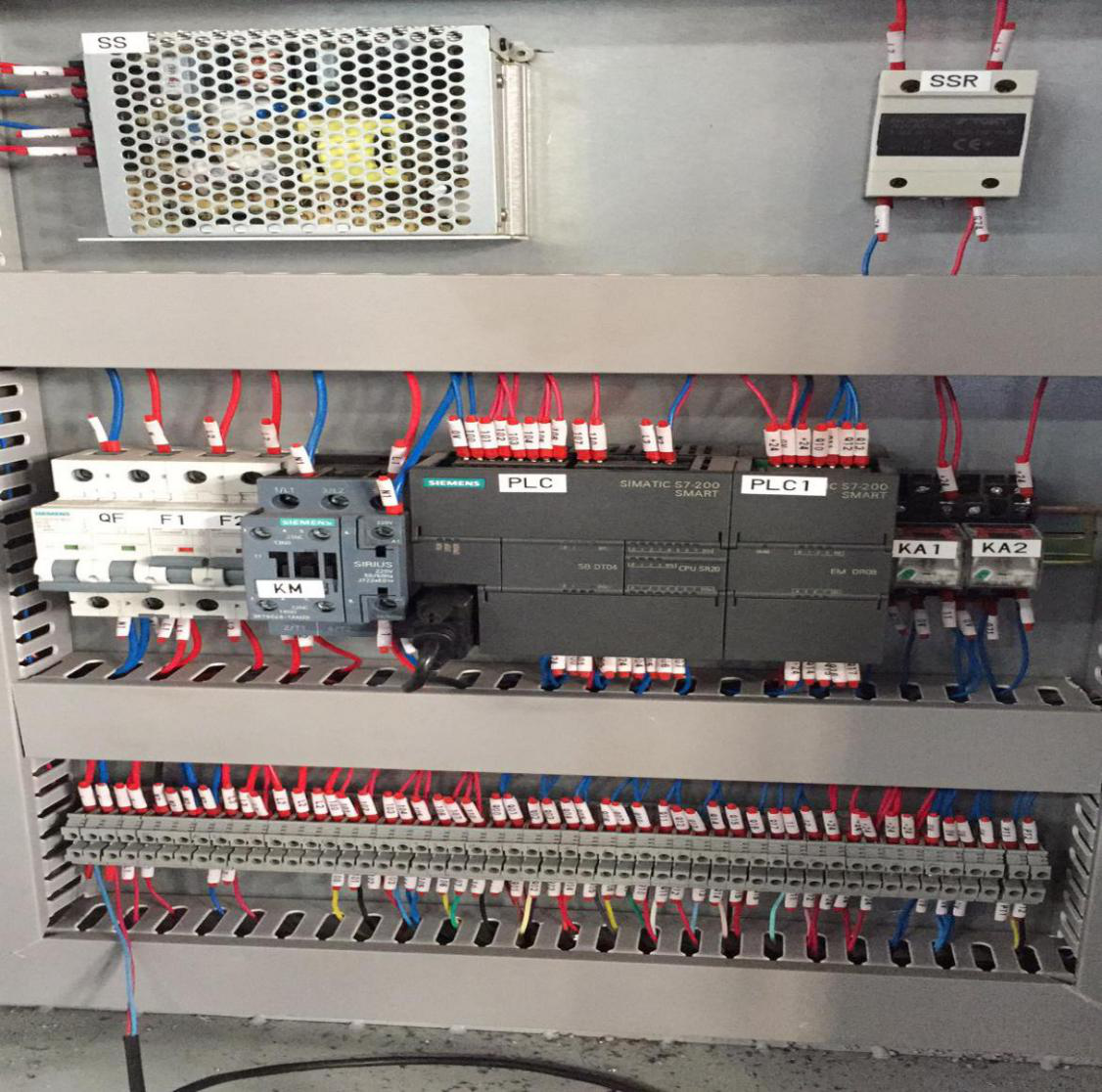

| PLC system | German SIEMENS |

| Low voltage electrical apparatus | German SIEMENS |

| Sensor | Korea AUTONICS |

| Guide | Taiwan TBI |

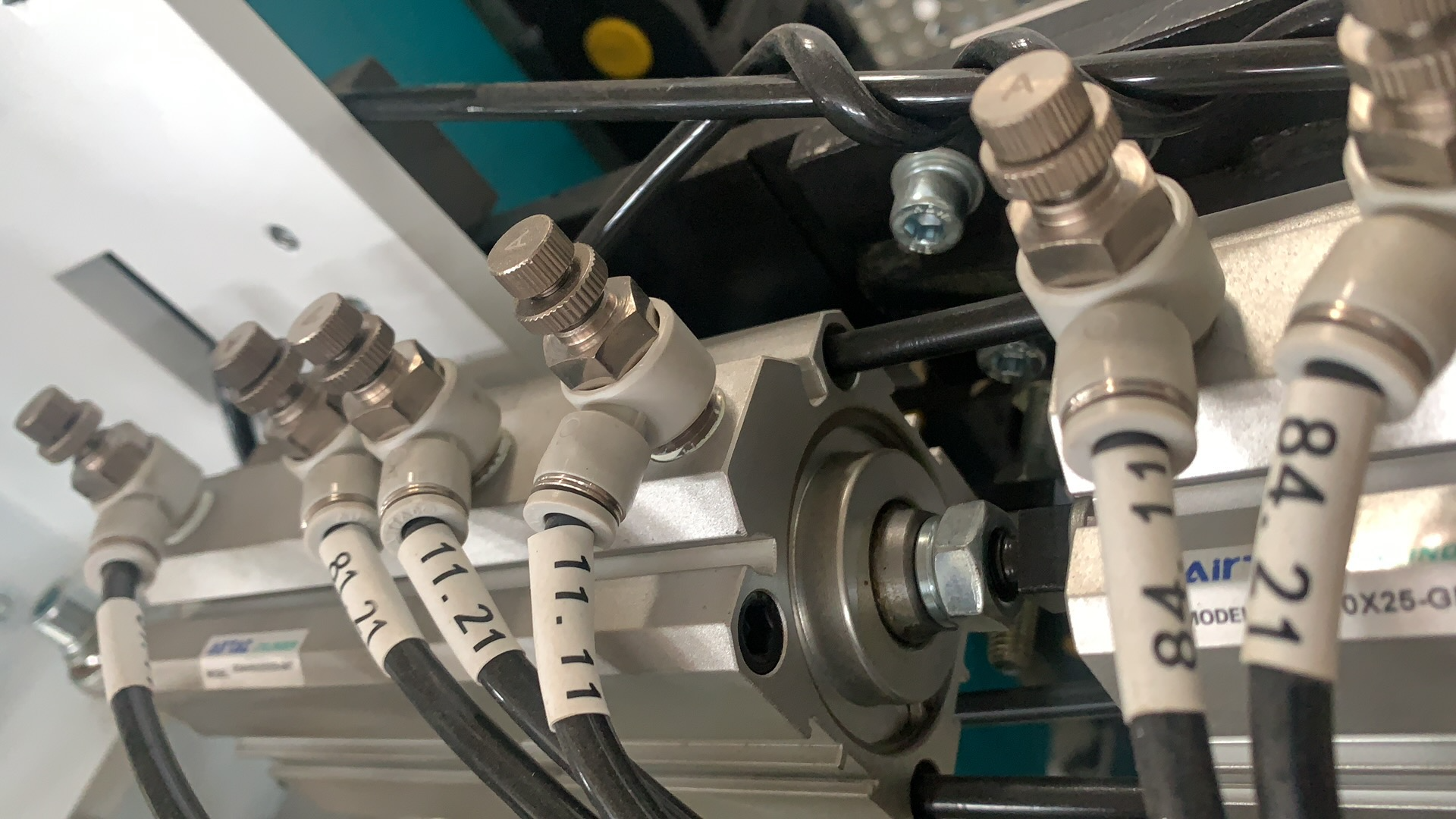

| Triplet | Taiwan AIRTAC |

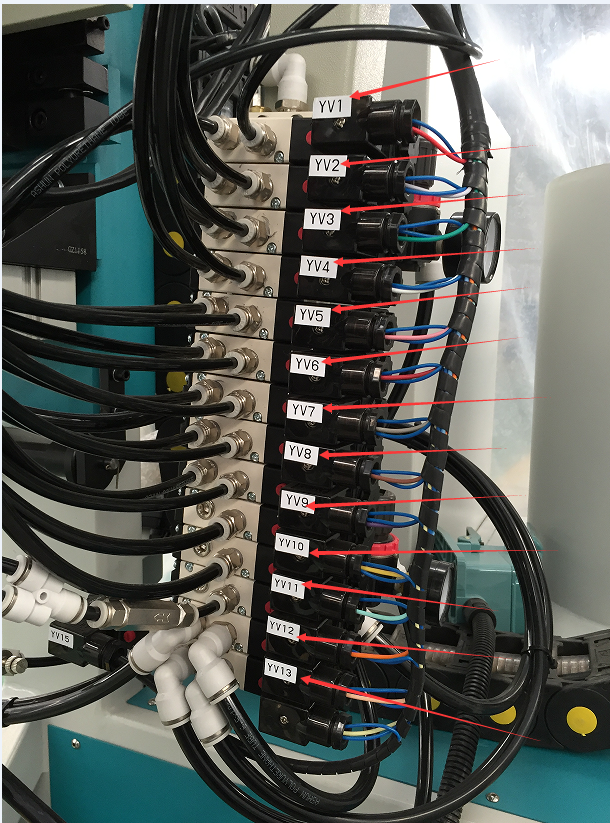

| Solenoid valve | Taiwan AIRTAC |

| Gas driller | Taiwan BOA |

| Switch power | Taiwan TEND |

Advantages & Features

Main Feature

- The filling height of can be adjusted according to the size of spacer frame

- Filling time can be adjusted

- Desiccant auto loading and replenish

- Auto drilling, filling and sealing function

- Germany Siemens PLC control system

- Touching screen interface, simple and visible

- Adding glue way is safe and easy

- Machine can fill the arc frame.(optional function)

- Could filling Molecular sieve diameter 0.5-0.9mm, 1.0mm-1.5mm(optional function)

The Unique ID Code Number

The Touching Screen Interface

The Materials Bucket

The Electrical Component

Video 1 Jinan LIJIANG LJGZ2020 Insulating Glass Desiccant filling machine

The processing flow of molecular sieve filling

1. Molecular sieve filling machine aluminum bar positioning and compression

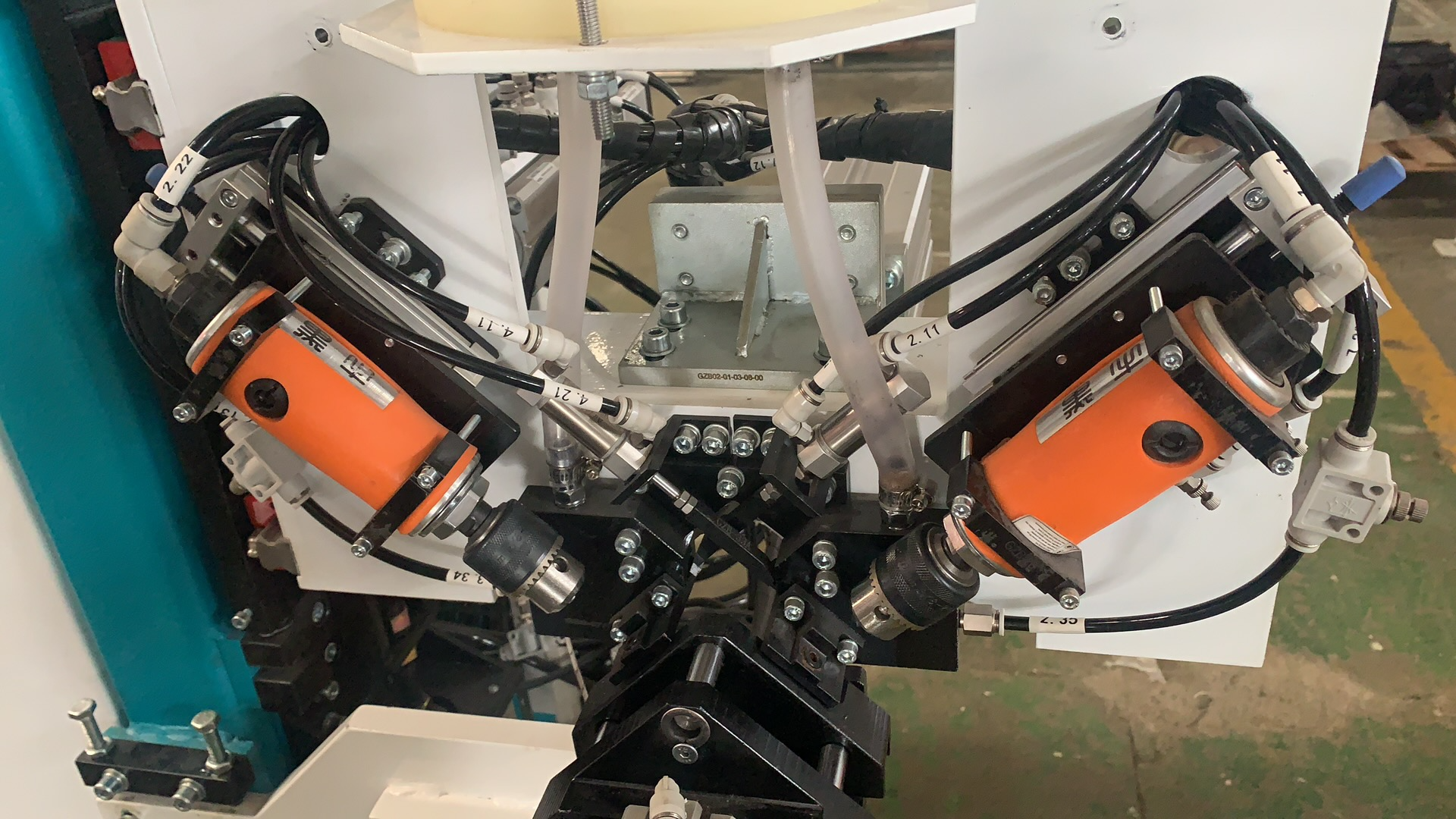

The aluminum bar positioning and pressing device consist of a pressing and positioning component, a square tube bracket, and a rear panel; the pressing and positioning component consists of a transverse pressing device and a longitudinal pressing device and is connected to the hollow glass molecular sieve filling device through the square tube bracket and the rear panel. Installed on the machine.

When the foot switch is turned on, the transverse compression cylinder works to push the transverse compression block and push the aluminum bar to the transverse positioning plate. After reaching the designated molecular sieve filling position, the transverse positioning is completed; the longitudinal compression cylinder pushes the V-shaped compression block to the horizontal positioning plate. The aluminum strip is pressed longitudinally, and the longitudinal pressing is stopped after the aluminum strip spacer is pushed to the position of the pressing block.

2. Molecular sieve filling machine aluminum strip drilling

The aluminum strip drilling device consists of a fixed connecting block, a connecting plate, a guide mechanism, a pneumatic drilling device, and a pneumatic drilling device positioning mechanism.

The PLC receives signals to control the solenoid valve to turn on and off the air in the cylinder. The cylinder pushes the screw movement to drive the drilling device forward and backward. At the same time, the pneumatic motor drives the drill bit to rotate, and the two drill bits feed to complete the drilling work.

3. Molecular sieve filling machine desiccant filling

The feeding device of the molecular sieve filling machine consists of a material box, a material box cover, a vacuum pump, a sensor, a cover plate, a feeder, a feeding pipe, a heater, etc.

The molecular sieve filling machine uses dual-control discharging to fill the molecular sieve. There is a connected blowing hole at the discharging port. During filling, the PLC controls the solenoid valve to blow air into the two discharging ports to speed up the filling speed of the molecular sieve.

At the same time, a sensor is installed in the upper, middle, and lower parts of the molecular sieve material box. The sensor detects the amount of molecular sieve in the material box, and uses a vacuum pump to evacuate the material box to generate negative pressure inside the charging box to realize the automatic replenishment function.

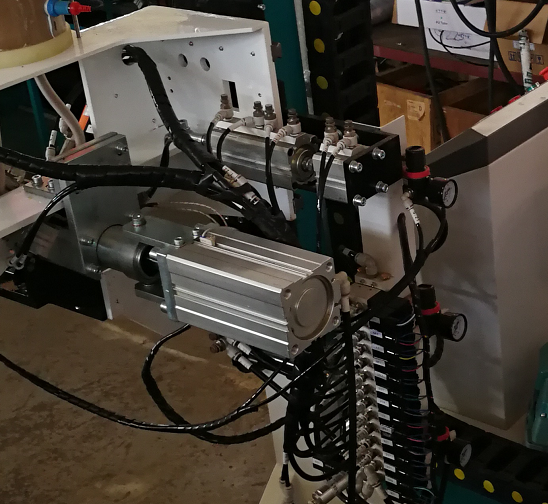

4. Molecular sieve filling machine butyl extruder sealing

The butyl extruder sealing device consists of a hot mold, a hot mold bracket, a baffle, a connecting lever, a rubber bucket, a tie rod, a cylinder, a cylinder bracket, a resistance wire, and a thermocouple sensor.

The resistance wire and thermocouple sensor are heated in the hot mold and PLC is used to control the butyl extruder blocking temperature; the glue-pushing device uses a cylinder to push glue, and PLC is used to control the butyl extruder pushing pressure, which is conducive to controlling the size of the glue pushing pressure and avoids The butyl extruder pushing pressure is too high or too low.

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

How to adjust the filling volume of molecular sieve?

Can it be filled with large particle molecular sieves? What diameter range does the large particle that can be filled refer to? What diameter range do small particles refer to?

How long does it take to fill a 1-meter-long and wide 12A aluminum strip to fill the 4 sides?

How about the start-up operation process of automatic molecular sieve filling machine?

Check whether there is no debris in the filling barrel of the molecular sieve filling machine, the parameters meet the processing requirements, and the emergency stop switch is normal, then turn on the air source and power supply; open the compressed air main valve (the pressure is set to 6Bar), and press Control On to open Control the power supply, and the control power prompts to confirm and cancel the alarm; the operator holds the aluminum bar frame spacer frame, puts the aluminum bar frame on the receiving hook of the filling machine, steps on the switch pedal, the aluminum bar frame is tightened and fixed in position, and then in the aluminum bar frame Drill holes on both sides and fill with molecular sieve.

Precautions

1. It is strictly prohibited to approach the screening area during the production process;

2. Push the butyl glue to seal, and the butyl glue should be heated to about 60°C (about 15 minutes);

3. Adjust the filling mode according to the size of the aluminum frame;

4. Working operator should wear protective eyewear when operating to prevent molecular sieves from falling into their eyes.