LJZW2020A Automatic Insulating Glass Aluminum Spacer Bending Machine

LIJIANG Glass LJZW2020A Automatic Insulating Glass Aluminum Spacer Bending Machine adopts the PLC automatic control system, spacer bar loading, positioning, bending, and cutting are formed in one time; it can realize automatic blanking, automatic splicing, automatic cutting, and automatic avoidance of aluminum strip angle insertion; it can automatically connect aluminum strips continuously, and the joints can be intelligently judged Whether to continue the connection to prevent the generation of waste materials; it can fold quadrilateral spacers and special shapes such as circles, trapezoids, arches, and polygons.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LJZW2020A Automatic Insulating Glass Aluminum Spacer Bending Machine

Main Feature

- Germany Siemens PLC control system

- Japan Fuji CNC servo control system

- Four spacer size storage units

- Optional for different specification and size aluminum spacer

- Auto spacer connecting and cutting function

- Automatically avoid the connection while bending and cutting

- Continuous bending

- Bending stainless steel spacer, TECHNOFORM warm edge spacer, SWISS spacer and aluminum spacer

- Distinctive bending structure with more powerful function

- Pause&reset device, convenient for machine malfunction maintenance,protect the servo motor

- USB input function, read the excel sheet directly(Optional)

- Spacer printing function (Optional).

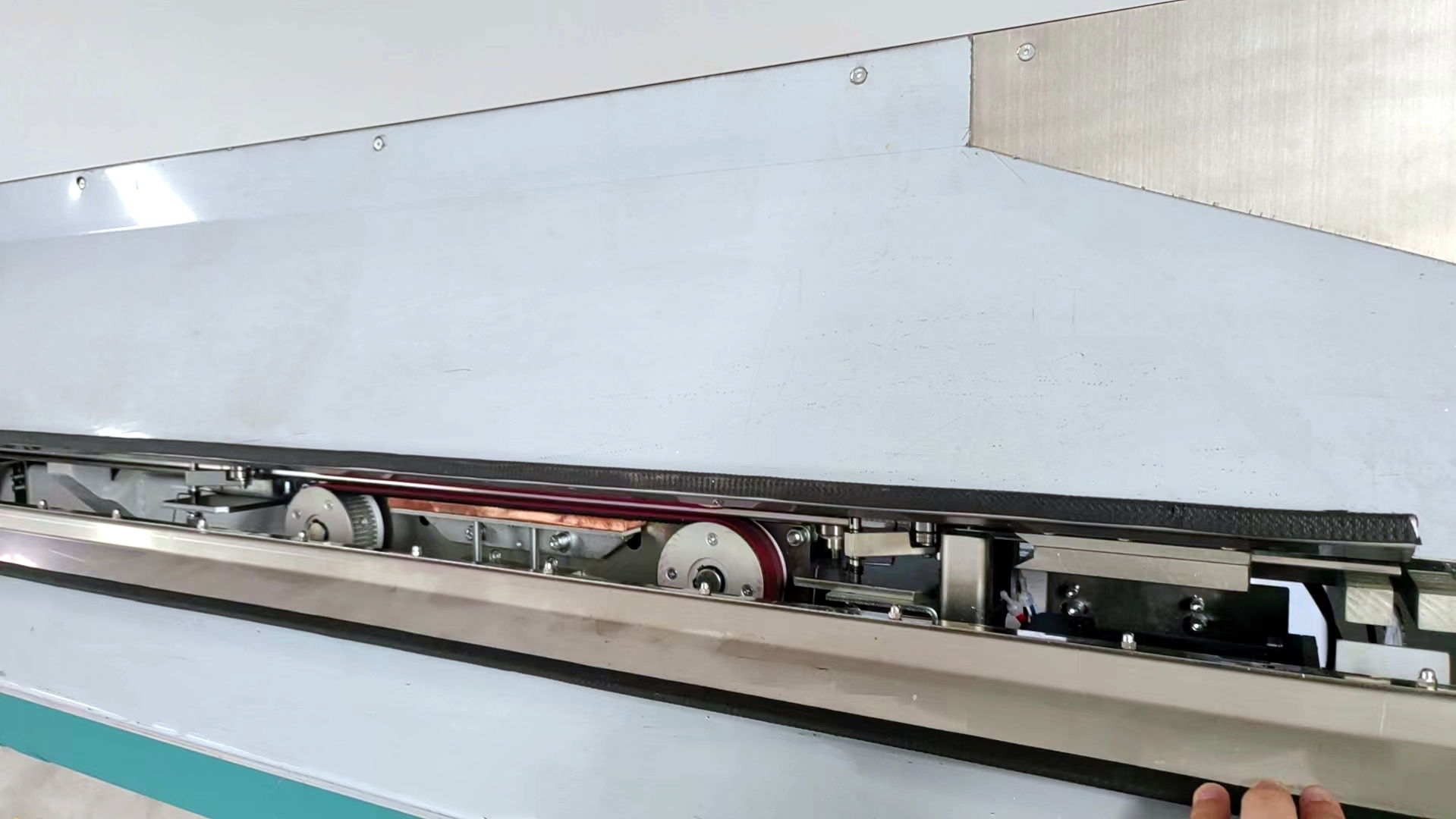

Figure 1 The bending structure of insulating glass aluminum spacer bending machine 1

Figure 1 The bending structure of insulating glass aluminum spacer bending machine 1

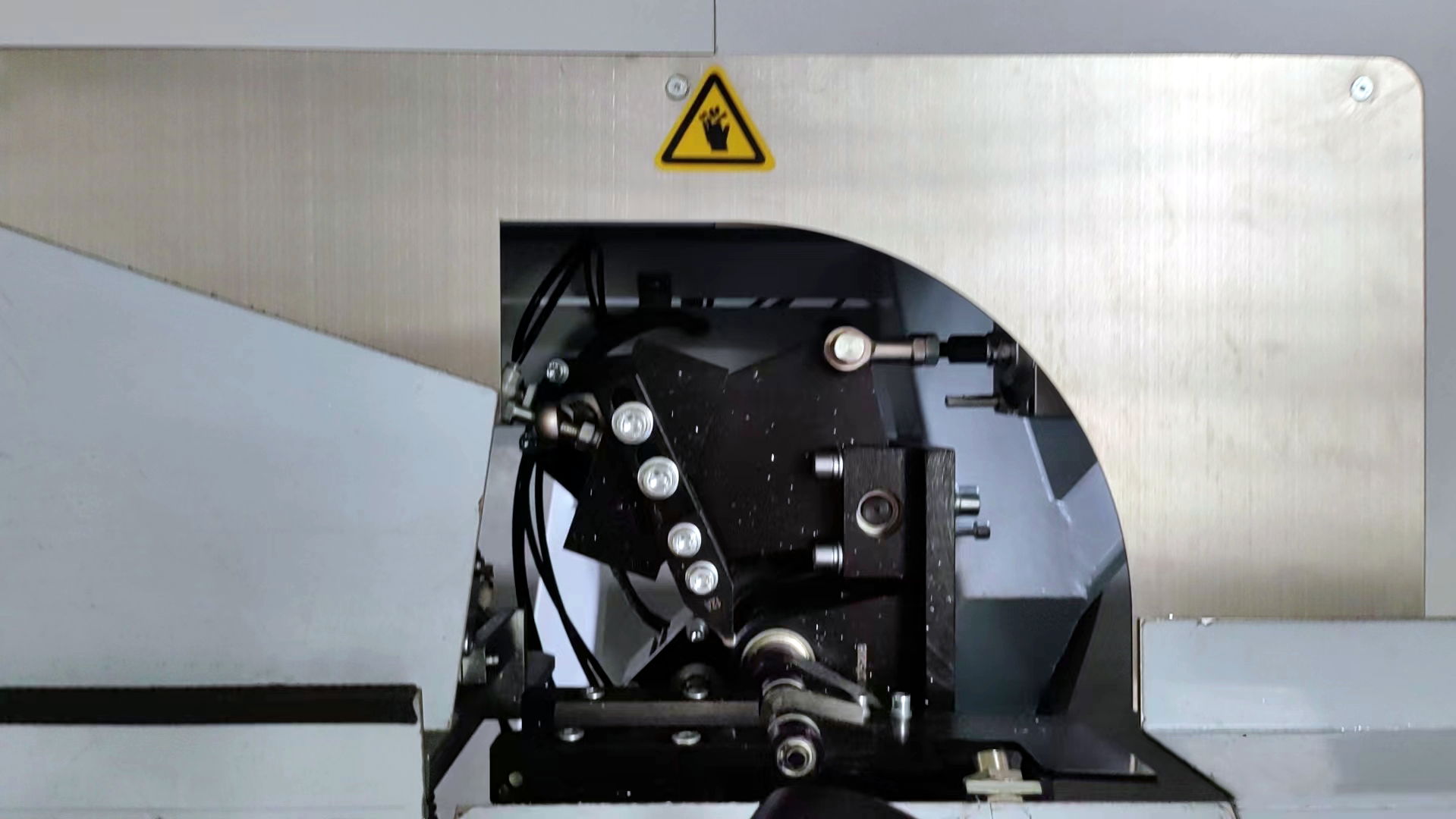

Figure 2 The bending structure of insulating glass aluminum spacer bending machine 2

Figure 2 The bending structure of insulating glass aluminum spacer bending machine 2

Figure 3 The touch srceen operation of insulating glass aluminum spacer bending machine

Figure 3 The touch srceen operation of insulating glass aluminum spacer bending machine

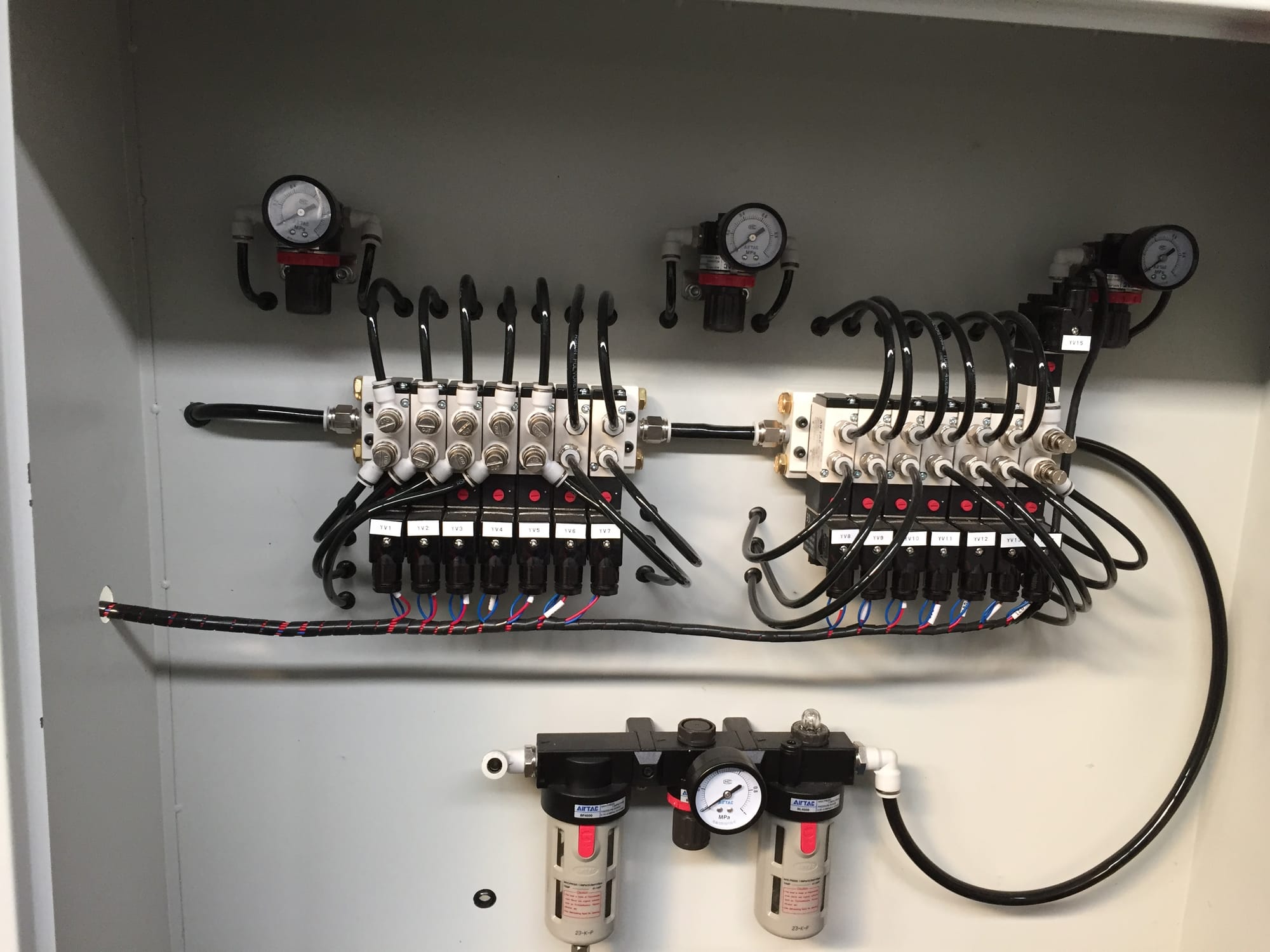

Figure 4 The pneumatic componment of insulating glass aluminum spacer bending machine

Figure 4 The pneumatic componment of insulating glass aluminum spacer bending machine

Operation Method

- Turn on the power, turn on the operating switch on the control console, start the oil pump button, and hear the oil pump rotating and making a sound.

- Adjust the bending stroke. When the bending stroke goes from top to bottom, there must be a gap to avoid causing certain wear and tear on the machine. Therefore, it is necessary to set the bending stroke for manual or electric micro-adjustment.

- Select the bend notch. Generally speaking, the thickness of the selected board is about 8 times the width of the notch. For example, if the board is 5cm, the notch needs to be about 40cm.

- Adjust the bending stopper. The stopper behind the bending machine also requires certain manual or electric fine-tuning.

- Depress the foot pedal switch to bend the aluminum bar. The foot pedal switch of the bending machine can be released and depressed at any time. Release it to stop working, and depress it to continue bending. ,

- When the bending machine stops working, turn off the operating switch on the operating table, turn off the power, and clean the bending machine workbench to make its surface clean and tidy.

- Pay attention to maintaining the bending machine at any time to increase the service life of the equipment.

Main Technical Parameter

| Item. | Spec. |

Max.bending size | 2000mm*2000mm |

Min.bending size | 250mm*200mm |

Aluminum spacer width | 5.5-24mm |

Dimensional error: | ≤±0.5mm |

Angle error | ≤±1º |

Processing speed | ≤26s |

Air supply | ≥0.65MPa |

Total power | AC220/380V 50Hz 2.5KW |

Dimension | 10500mm*2200mm*2600mm |