Summary and cost analysis of factors affecting energy-saving characteristics of energy-saving glass, insulating glass, and various types of glass.

Insulated glass has outstanding thermal insulation performance and is an important material for improving the energy-saving level of doors and windows. In recent years, it has been extremely widely used in buildings. However, with the continuous improvement of energy-saving standards, ordinary insulating glass can no longer fully meet the technical requirements of energy-saving design. For example, in the energy-saving design standards of hot summer and cold winter areas, The limit index for the heat transfer coefficient of exterior windows with a large window-to-wall ratio reaches 2.5 W/m2K. In areas with hot summers and warm winters, this index reaches 2.0 W/m2K under some conditions.

What is insulating glass? There are two situations I often encounter in life. One is that many people think that insulating glass is vacuum glass; others think that insulating glass is filled with nitrogen; let’s take a look at the definition of "GB11944 Insulating Glass": Insulating Glass (Sealed Insulating Glass Units) A product in which two or more pieces of glass are evenly spaced with effective support and bonded and sealed to form a dry gas space between the glass layers. From this definition we can see the composition of insulating glass:

- Two or more pieces of glass;

- Effective support and bonding in the middle;

- Dry gas in the spacer layer.

Type of glass

The types of glass that make up hollow glass include white glass, heat-absorbing glass, solar control coating, Low-E glass, etc., as well as deep-processed products produced from these glasses.

There will be slight changes in the optical and thermal properties of the glass after it is heat-bent and tempered, but it will not cause significant changes to the insulating system, so only the original glass sheets that have not been further processed are analyzed here. Different types of glass have very different energy-saving characteristics when used as a single piece. When combined into a insulating glass, the combination of various forms will also show different changing characteristics.

Heat-absorbing glass reduces the transmittance of solar heat and increases the absorption rate through body coloring. Since the airflow speed on the outdoor glass surface is greater than indoors, it can take away more heat from the glass itself, thereby reducing solar radiation. The extent to which heat enters the room.

Different color types and different depths of heat-absorbing glass will greatly change the SHGC value and visible light transmittance of the glass. However, the emissivity of heat-absorbing glass in various color series is the same as that of ordinary white glass, which is about 0.84. Therefore, under the same thickness, the heat transfer coefficient K value is the same when forming insulating glass.

Several representative 6mm thick heat-absorbing glasses from different manufacturers were selected. The insulating combination method is heat-absorbing glass + 12mm air + 6mm white glass. The calculation results show that the heat-absorbing glass can only control the heat transfer of solar radiation and cannot change the heat transfer due to solar radiation. Heat transfer is caused by temperature differences.

The influence of different types of heat-absorbing glass on the energy-saving characteristics of insulating glass types. The K value, SHGC value, and visible light transmittance of the glass type manufacturer are as follows:

- White Glass Ordinary 2.703W/m2K 0.701 0.786

- GrayPPG 2.704 W/m2K 0.454 0.395

- GreenPPG 2.704 W/m2K 0.404 0.598

- Brown Pilkington 2.704 W/m2K 0.511 0.482

- Turquoise Pilkington 2.704 W/m2K 0.509 0.673

Solar control-coated glass is a layer of metal or metal compound film coated on the surface of the glass. The film not only makes the glass appear rich in color, but its main function is to reduce the SHGC value of the glass and limit the direct entry of solar heat radiation.

Different types of coatings will cause great changes in the SHGC value and visible light transmittance of the glass, but they have no obvious reflection effect on far-infrared thermal radiation. Therefore, when the sunlight control-coated glass is used alone or in a insulated space, the K value is different from that of white glass.

Low-E glass is a coated glass with a high reflectance for far-infrared rays in the wavelength range of 4.5 to 25 microns.

In the environment around us, the heat transfer caused by temperature differences is mainly concentrated in the far-infrared band. White glass, heat-absorbing glass, and solar control-coated glass have a very small reflectivity of far-infrared thermal radiation and a high absorption rate. The heat will increase the temperature of the glass itself, which will cause the heat to be transferred to the lower temperature side again.

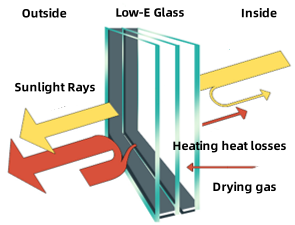

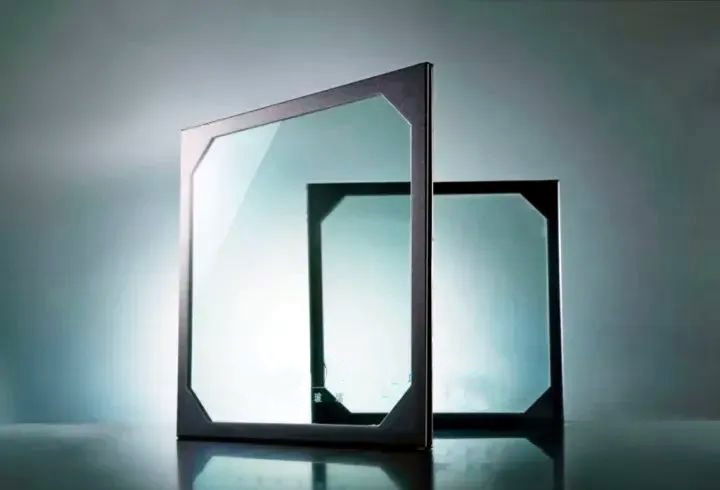

Figure 1 The Low-E Glass

On the contrary, Low-E glass can reflect more than 80% of the far-infrared heat radiation transmitted from the side with higher temperature, thereby avoiding secondary heat transfer due to the increase in its temperature, so Low-E glass has a great lower heat transfer coefficient.

Taking the online Low-E glass produced by Yaohua as an example, when Yaohua Low-E Glass is combined into a hollow glass, the heat transfer coefficient can reach 1.9 W/m2K, which is 30% lower than the K value of ordinary white insulating glass. Moreover, the SHGC value and visible light transmittance of Low-E insulating glass can be adjusted during production according to the needs of energy saving. When used in severe cold areas, Yaohua Low-E insulating glass with high visible light transmittance can be used. In hot areas, Yaohua Low-E insulating glass with high transmittance can be used. Yaohua Sun-E insulating glass with sunshade effect.

Comparison of energy-saving characteristics of different types of glass Glass types Single piece K value Hollow combination Hollow K value SHGC (%)

- Transparent glass 5.86 White glass +12+6 White glass 2.772

- Heat absorbing glass 5.86 blue glass + 12 + 6 white glass 2.743

- Heat reflective glass 5.46 Reflection +12+6 White glass 2.634

- Yaohua Low-E3.86 White Glass+12+6Low-E1.966

- Yaohua Sun-E3.76Sun-E+12+6 white glass 1.838

Comparison of K value of commonly used insulating glass | ||

| Glass Configuration | K value (Air) | K value (90% Argon-gas) |

| 5+12A+5 | 2.68 | 2.53 |

| 5+12A+5 | 2.66 | 2.54 |

| 5+12A+5+12A+5 | 1.77 | 1.64 |

| 5 Single Silver Low-E+12A+5 | 1.72 | 1.46 |

| 5 Double Silver Low-E+12A+5 | 1.66 | 1.39 |

| 5 Single Silver Low-E+15A+5 | 1.74 | 1.49 |

| 5 Double Silver Low-E+15A+5 | 1.68 | 1.42 |

| 5 Single Silver Low-E+12A+5+12A+5 | 1.28 | 1.09 |

| 5 Double Silver Low-E+12A+5+12A+5 | 1.25 | 1.05 |

| 5 Single Silver Low-E+12A+5 Single Silver Low-E+12A+5 | 0.97 | 0.77 |

| 6 Single Silver Low-E+12A+6 Single Silver Low-E+12A+5 | 0.92 | 0.71 |

| 6 Single Silver Low-E+15A+6 Single Silver Low-E+15A+6 | 0.86 | 0.69 |

Type of insulating glass spacer

The performance of the sealing material at the edge of the insulating glass has a certain impact on the K value of the insulating glass. Usually, most intervals use the aluminum strip method. Although it is light in weight and simple to process, its thermal conductivity is large, resulting in a reduction in the thermal resistance of the edge of the insulating glass.

When the outdoor temperature is particularly cold, frost may form on the edges of indoor glass. The warm edge sealing system represented by Swiggle strips has better thermal insulation performance, greatly reducing the heat transfer coefficient at the edge of the insulating glass, effectively reducing-edge frosting, and at the same time, it can seal the center of the white insulated glass the K value is reduced by more than 5%, and the central K value of the Low-E insulated glass is reduced by more than 9%.

Installation angle of insulating glass

Under normal circumstances, insulating glass is placed vertically, but the application range of insulating glass is becoming more and more extensive. If it is used in greenhouses or sloped roofs, its angle will change.

When the angle changes, the convection state of the internal gas will also change, which will inevitably affect the heat transfer effect of the gas, and ultimately lead to changes in the heat transfer coefficient of the insulating glass. Taking the commonly used 6+12+6 white glass air-filled combination as an example, the commonly used K value when placed vertically (90°) is 2.70W/m2K, and when placed horizontally (0°), the K value is 3.26 W/m2K.

Therefore, when the insulating glass is placed horizontally, the impact of the increased K value on the energy-saving effect of the building must be considered.

Changes in outdoor wind speed

When testing or calculating the heat transfer coefficient of a piece of insulating glass by domestic and foreign standards, the convection heat transfer on the indoor surface is generally set to a natural convection state, and the outdoor surface is set to a forced convection state with a wind speed of about 3~5m/s.

However, when it is installed on a high-rise building, the wind speed on the outer surface of the glass will increase as the height increases, which will enhance the heat transfer capacity of the outer surface of the glass and the heat transfer coefficient of the insulating glass will increase slightly. When the wind speed increases from 5m/s used in the test standard to 15m/s, the K value of the white glass hollow increases by 0.16 W/m2K, and the K value of the Low-E hollow increases by 0.1 W/m2K.

For high-rise building structures with a small window-to-wall ratio, the above changes in the K value will not have a big impact on the energy-saving effect. However, for high-rise buildings with pure curtain walls, to maintain a good thermal environment in the top-floor rooms, it is necessary to the impact of increased high-altitude wind speed on energy-saving effects should be considered.

Variations using different standards

The test or simulation calculation conditions for the heat transfer coefficient and SHGC value of insulating glass are slightly different in the standards of various countries.

The United States adopts NFRC100 and NFRC200, and the international ISO standard is ISO15099. Europe's prEN ISO 10077 and prEN 13363 standards mainly adopt the relevant regulations of ISO. My country's glass heat transfer coefficient test standard is GB8484, and an equivalent standard has been added to JGJ113-2003. According to the heat transfer coefficient calculation conditions of ISO10292, the optical thermal performance of glass can be tested or calculated according to GB/T2680.

Insulating glass characteristics and cost changes

The above factors that affect the K value and SHGC value of insulating glass will also affect the cost of insulating glass. The following table shows the impact of color, thickness, surface treatment method, and insulated layer on the cost of insulating glass.

| Name | Original Tempered Glass | Low-E Glass | Insulating Glass Thickness | White Low-E Insulated tempered glass finished product | |||||||

| White | Green | Blue | Single Silver | Double Silver | 9mm | 12mm | Single Silver X+9+X | Double Silver X+9+X | Single Silver X+12+X | Double Silver X+12+X | |

| 6mm | 103 | 119 | 153 | 45 | 75 | 38 | 45 | 186 | 216 | 193 | 223 |

| 8mm | 137 | 153 | 187 | 45 | 75 | 38 | 45 | 220 | 250 | 227 | 257 |

| 10mm | 162 | 178 | 212 | 45 | 75 | 38 | 45 | 245 | 275 | 252 | 282 |

| 12mm | 202 | 218 | 252 | 45 | 75 | 38 | 45 | 285 | 315 | 292 | 322 |

Partial conclusions:

① Green glass is 16 usd/m2 cheaper per side than white glass.

② Blue glass is 50 usd/m2 cheaper per side than white glass.

③ Glass thickness 8 is thicker than 6, and the height of insulating glass per side is 34 usd/m2.

④ Double silver glass is 30 usd/m2 higher per side than single silver glass.

⑤ For insulated layer structural adhesive brands, the price of imported brands is about 25 usd/m2 higher than that of domestic brands.

⑥ The insulated layer gas is generally filled with air (A). If it is argon (Ar), the processing fee needs to be increased by 10~20 usd/m2 based on the air layer.

⑦ Coated glass, common ones include solar control film glass and Low-E coating glass. Among the low-e film processing fees, the double silver processing fee increases by about 10~15 usd/m2 based on single silver. When it comes to special color film systems such as gold, the processing fee increases by about 15 usd/m2 based on regular colors.

⑧ For ultra-white glass, the price of raw glass is about 100~150 usd/ton higher than that of ordinary white glass.

Ordinary flat glass

Figure 2 The ordinary flat glass

1. 3--4mm centimeters of glass are also called centimeters or units in daily life. What we call 3 centimeters (pieces) of glass refers to glass with a thickness of 3mm. Glass of this size is mainly used for the surface of picture frames.

2. 5--6mm glass is mainly used for small-area light-transmitting shapes such as exterior wall windows and door leaves.

3. 7-9mm glass is mainly used in indoor screens and other large-area shapes that are protected by frames.

4. 9--10cm glass can be used for large-area indoor partitions, railings, and other decoration projects.

5. 11--12cm glass can be used for floor spring glass doors and some partitions with a large flow of people.

6. Glass of 15cm or above is generally less sold on the market and often requires ordering. It is mainly used for large-area floor spring glass doors and entire glass exterior walls.

Deep processed glass

To meet various needs in production and life, people carry out deep processing on ordinary flat glass. The main categories are:

1. Tempered glass.

It is a kind of prestressed glass that is reprocessed from ordinary flat glass. Compared with ordinary flat glass, tempered glass has two major characteristics:

(1) The strength of the former is several times that of the latter, the tensile strength is more than 3 times that of the latter, and the impact resistance is more than 5 times that of the latter.

(2) Tempered glass is not easily broken. Even if it is broken, it will break into particles without sharp angles, which greatly reduces the damage to the human body.

Figure 3 The Tempering Glass

2. Frosted glass.

It is also frosted on ordinary flat glass. Generally, the thickness is mostly below 9 centimeters, with the majority being 5 or 6 centimeters thick.

3. Sandblasted glass.

The performance is similar to frosted glass, the only difference is that it is changed from frosted to sandblasted.

Figure 4 The Sandblasted Glass

4. Patterned glass.

It is a kind of flat glass made by the rolling method. Its biggest feature is that it is light-transmitting and opaque, and it is often used in decoration areas such as bathrooms.

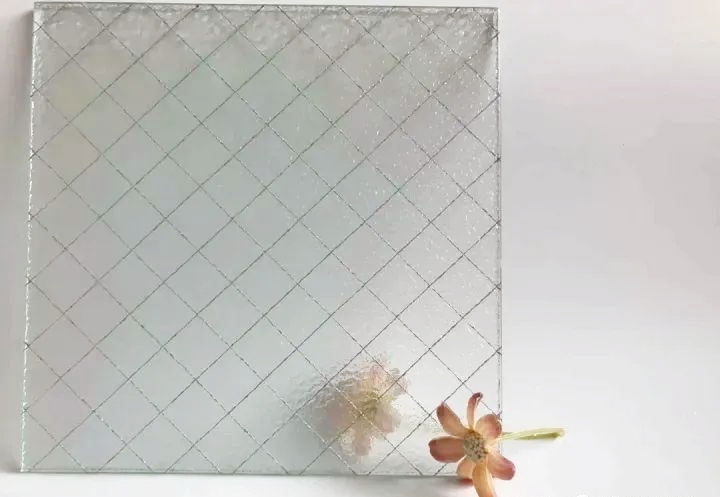

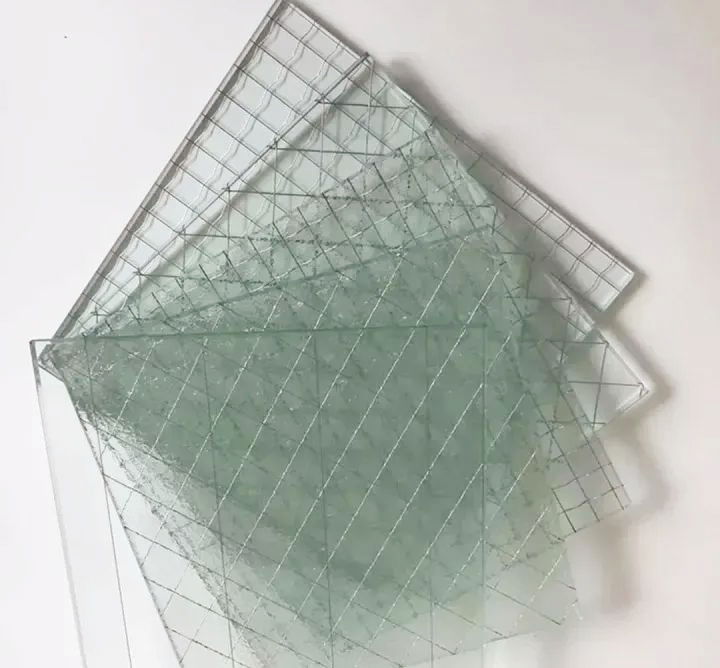

5. Wired glass.

It is a kind of impact-resistant flat glass made by using the rolling method to embed metal wire or metal mesh in the glass plate. When it is hit, it will only form radial cracks and will not cause injury when it falls. Therefore, it is mostly used in high-rise buildings and factories with strong vibration.

Figure 5 The Wired Glass

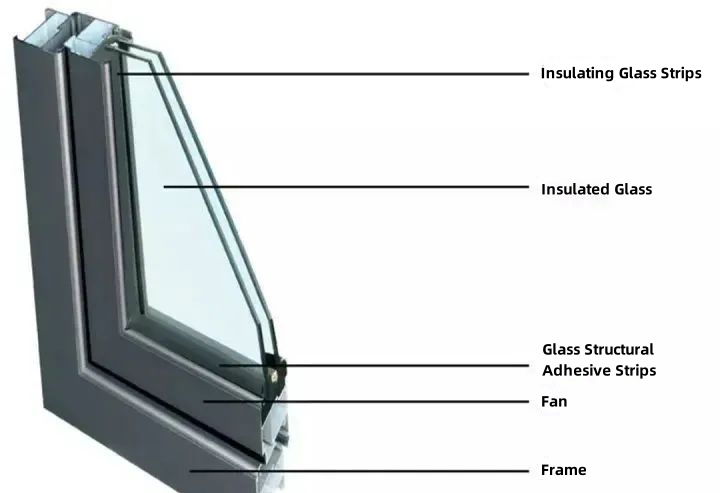

6. Insulated glass.

Sealing is often used to keep two pieces of glass at a certain distance. The gap is filled with dry air, and the surrounding area is sealed with sealing materials. It is mainly used in decoration projects with sound and heat insulation requirements.

Figure 6 The Insulated Glass

7. Laminated glass.

Laminated glass is generally composed of two pieces of ordinary flat glass (it can also be tempered glass or other special glass) and an organic adhesive layer between the glasses. When damaged, the fragments still adhere to the adhesive layer, preventing damage to the human body from splashing fragments. It is mostly used in decoration projects with safety requirements.

Figure 7 The Laminated Glass

8. Bulletproof glass.

It is a type of laminated glass, but the glass is mostly made of higher-strength tempered glass, and the number of interlayers is relatively large. It is mostly used in decoration projects with very high safety requirements such as banks or luxury homes.

Figure 8 The bulletproof glass

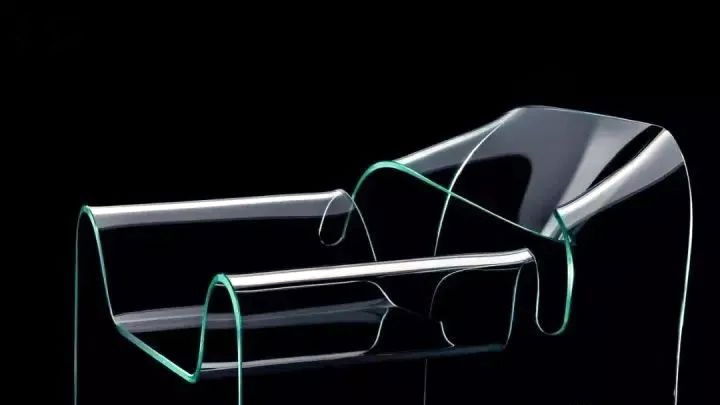

9. Hot-bent glass.

Curved glass is made by heating and softening high-quality flat glass in a mold, and then annealing it. The style is beautiful and the lines are smooth.

Figure 9 The Hot-bent Glass

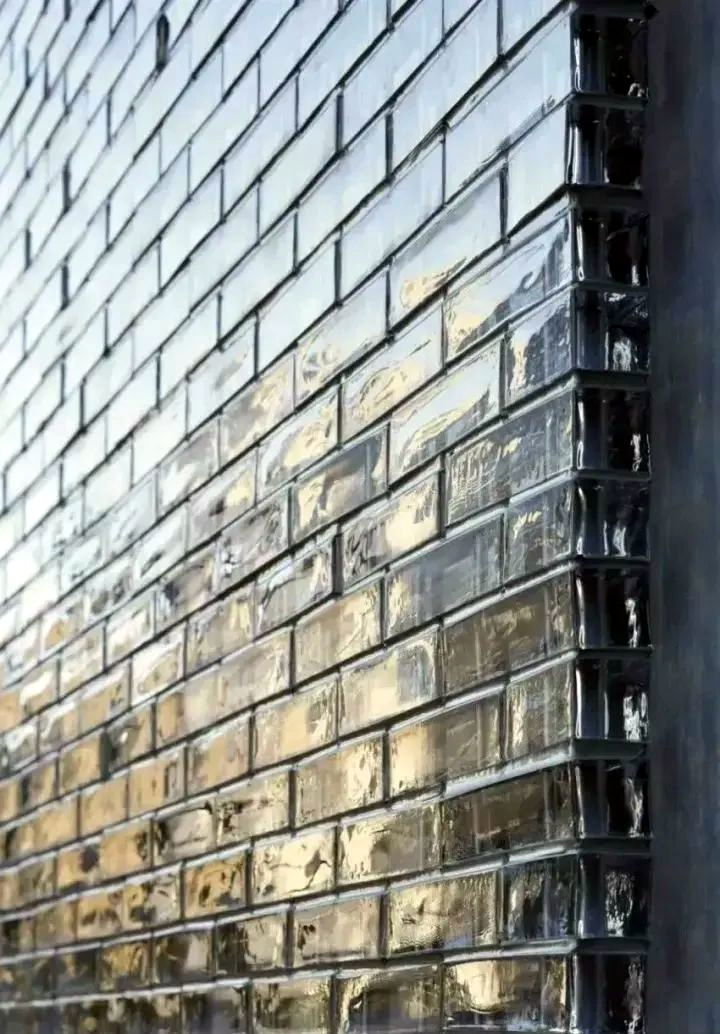

10. Glass bricks.

The manufacturing process of glass bricks is the same as that of flat glass, but the difference is the molding method. There is dry air in the middle. It is mostly used in decorative projects or light-transmitting shapes with thermal insulation requirements.

Figure 10 The glass bricks

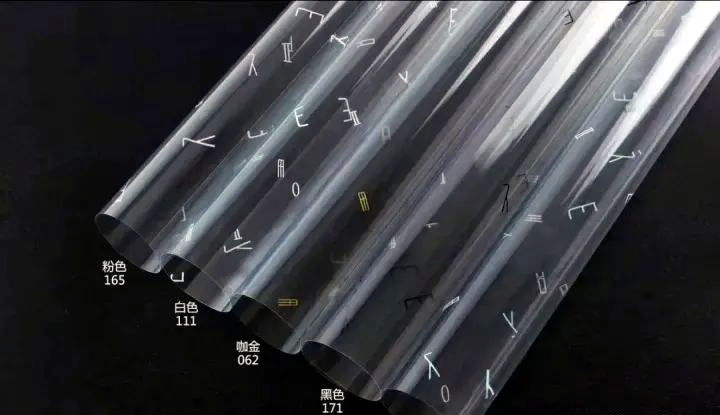

11. Cellophane.

Also called glass film, it comes in a variety of colors and designs. Depending on the properties of the paper film, it has different properties. Most of them function as heat insulation, anti-infrared rays, anti-ultraviolet rays, and explosion-proof.

Figure 11 The Glass Film

12. LED photoelectric glass.

Photoelectric glass is a new type of environmentally friendly and energy-saving product. It is a combination of LED and glass. It has the transparency of glass and the brightness of the LED. It is mainly used for indoor and outdoor decoration and advertising.

13. Dimmable glass.

When the power is on, the glass will be essentially transparent, and when the power is off, it will be white-frosted, and opaque. In the opaque state, it can be used as a rear projection screen.

Figure 12 The dimmable glass

New Types of Glass

Glass is an ancient building material. With the rapid improvement of modern science and technology and the rapid development of application technology, various types of glass with unique functions have come out one after another, and the glass family has prospered.

1. Unbreakable glass

A British aircraft manufacturing company has invented a type of unbreakable glass for use in aircraft. It is a multi-layered glass sandwiched with debris and bonded into a transparent plastic film. This polyurethane-based plastic film has a viscous, semi-liquid consistency. When someone tries to break it, the battered polyurethane film slowly clumps together and regains its unique integrity.

Figure 13 The unbreakable glass

2. Glass can be nailed

This kind of glass successfully developed by Japan's Mitsubishi Electronic Instruments Laboratory is made by mixing boric acid glass powder and carbonized fiber and heating it to 1,000 degrees Celsius. It is made of cemented carbide-reinforced glass. Its maximum fracture stress is more than twice that of ordinary glass. It has no brittle weaknesses. You don't have to worry about breaking when nailing or installing wood screws.

3. Non-reflective glass

The non-reflective glass developed by the German SCHOTT Glass Company has a light reflectivity of only within 1% (general glass is 8%), thus solving the headache of glass reflection and dazzling.

4. Anti-theft glass

This kind of glass developed by a Hungarian research institute has a multi-layer structure, with extremely thin metal wires embedded in the middle of each layer. If a thief breaks the glass, an alarm system connected to the metal wires will immediately send out an alarm signal.

Figure 14 The Anti-theft Glass

5. Soundproof glass

A Japanese company introduced technology from Germany to create a new type of sound-insulating glass. This kind of glass uses a soft resin up to 5 mm thick to bond two layers of glass together. It can absorb almost all noise and is especially suitable for use in recording studios and broadcast studios. Its price is equivalent to 5 times that of ordinary glass.

Figure 15 The Soundproof Glass

6. Air conditioning glass

This is made of double-layer glass, which can send heat into the glass interlayer and distribute it into the room through the pores, replacing the radiator. This not only saves energy, but is also convenient, soundproof, and dustproof, and can be converted to air conditioning in the summer.

7. Vacuum glass

Vacuum glass is a vacuum layer of 1/100 atmospheric pressure with a 0.2 mm interval between two pieces of glass with a thickness of 3 mm. There is a small metal cylinder support in the layer to prevent external atmospheric pressure from causing the two pieces of glass to stick together. This kind of vacuum glass is only 6.2 mm thick and can be installed directly on ordinary window frames. It has good thermal and sound insulation effects and is suitable for windows in residential houses and high-rise buildings.

Figure 16 The Vacuum Glass

8. Smart glass

The transparency of this glass developed in the United States can change with the change of viewing angle. It has a special polymer film whose astigmatism, thickness, area, and form can be freely selected by the manufacturer. It can provide certain protection and shielding effects.

Figure 17 The Smart Glass

9. Holographic glass

Holographic diffractive glass developed by a research team in Boston, USA, can concentrate light of certain colors into selected directions. Windows using this kind of glass can decompose natural light into spectral combinations of colors, and shoot the light to the ceiling, and then reflect it to all corners of the room. Even in rooms without windows, sunlight can be "obtained" from the reflective wall through ventilation ducts, and then Light is diffused onto the ceiling by perforations.

Figure 18 The Holographic Glass

10. Temperature glass

A British company has successfully developed a thermochromic tempering glass called cloud glue. It is a synthetic glass with plastic films on both sides and a polymer water-color solvent sandwiched in the middle. It is transparent in a low-temperature environment and absorbs the heat energy of sunlight. When the ambient temperature rises, it turns into an opaque white cloud color and blocks the heat energy of sunlight, thereby effectively regulating the indoor temperature.

11. Bioglass

The University of Florida has developed a new type of bioglass that combines bioactive energy with active tissue. This kind of bioglass is biologically adaptable and can be used in artificial bones and artificial gums.

12. Antenna glass

A Japanese company has successfully developed a TV antenna window glass with a very thin antenna embedded in the inner layer of the glass. Once installed, indoor TVs can present a clearer picture.

13. Tissue glass

German scientists have created an ultra-thin glass that can be used in optoelectronics, biosensors, computer displays, and other modern technology fields. It is only 0.003 mm thick.

Figure 19 The Tissue Glass

14. Information glass

Tokushima University in Japan has invented a glass that can record information. When it records information, it first uses an optical microscope to focus the laser on a certain point inside the glass. It completes one irradiation in 30 picoseconds, leaving a recording spot. When reading the information, it scans the spot with the laser. This kind of recording information can be carried out at room temperature, and its performance is already higher than that of the optical discs used by everyone.

15. Contamination of color-changing glass

The California Air Pollution Observation Laboratory has developed a pollution-colored glass that can detect pollution. This kind of glass can change color when polluted by polluting gases. For example, it turns green when polluted by acidic gases, turns yellow-gray when polluted by amine-containing gases, etc. It will have a wide range of uses when used to make pollution detection materials and marking materials.

16. CO2-emitting glass

The Osaka Industrial Technology Research Institute of the Japan Institute of Technology has developed a carbon dioxide-permeable glass film, which can be applied to the glass windows of homes to discharge indoor carbon dioxide gas to the outside. It transmits different amounts of carbon dioxide under different humidity. The greater the humidity, the higher the permeability.

17. Electrolytic atomized glass

Electrolytic atomized glass is scratch-resistant, comfortable and soft to the touch, and free of sweat stains and fingerprints. It changes the cold and stiff look of traditional glass. Its biggest feature is that after the electrolytic atomized glass is energized, it will automatically produce a surface atomization effect and instantly change the transparency. On the outside, it looks like a normal white wall. Japan's transparent public toilets are the result of applying electrolytic atomized glass.

Figure 20 The Electrolytic Atomized Glass

18. Foam glass

Bulgarian building materials experts have successfully developed a type of foam glass that has good biological stability, does not rot, has poor hygroscopicity, is easy to process, and is easy to bond with other building materials. This new type of foam glass is successfully manufactured based on liquid glass with various mineral components.

19. Self-cleaning glass

The University of Tokyo in Japan has invented titanium dioxide-coated glass that can prevent dirt and water points from accumulating on the surface. It can achieve automatic cleaning and shock-proof effects and can clean glass windows effortlessly.

For more information about insulating glass processing equipment and glass processing machinery, please click here to learn more.