Influence of many complex factors on the sealing performance of insulating glass.

With the development of the economy, the advancement of technology, and the improvement of people's living standards, the insulating glass originally used for high-end buildings, as an effective glass energy-saving structure, has been popularized in ordinary people's residences. However, in the popular use of insulating glass in the past ten years, there are still voices in all aspects that the quality of insulating glass is worrying, ranging from air leakage and water ingress to outer pieces falling off.

Insulating glass is a glass composite structure, that is composed of 2 or more pieces of glass, which are evenly spaced for effective support and are bonded and sealed around the periphery to form a glass product with a dry gas space between the glass layers(quoted from the industry standard "Insulating Glass"). We know that the structure of insulating glass makes it significantly improved in terms of sound insulation, heat insulation, heat transfer coefficient reduction, and energy-saving effect compared with single-piece glass. Therefore, the original monolithic use is presented as a insulated structure when conditions permit. Due to the different purposes of use, the combination of multiple types of functional glass can form tempered insulating glass, coated insulating glass, Low-E coating insulating glass, laminated insulating glass, silkscreen insulating glass, fireproof insulating glass and more. So many types of use, such a wide range of use, put forward higher requirements for the quality of insulating glass, and also make everyone pay more attention to the sealing performance of insulating glass. For insulating glass, the primary premise for the performance or function of insulating glass is to ensure the sealing of the product, and the guarantee of sealing depends on good raw materials, standardized processing technology, and strict quality management. Among them, the spacer, desiccant, and sealant (or composite material) form the edge sealing system of the insulating glass for the glass. In this system, the desiccant is filled in the spacer, the butyl extruder is hot-coated on the spacer, the spacer has adhered to the glass through the butyl extruder, the outer sealant and the butyl extruder is bounded, and the gap around the glass is filled so that one of the edge systems is the barrier of whether the insulating glass is sealed or not.

As a professional manufacturer of insulating glass processing equipment, LIJIANG Glass is also willing to extract one of the various raw materials for making insulating glass for in-depth analysis, to call on insulating glass manufacturers to strengthen their quality awareness, pay attention to the selection of raw materials, and protect the interests of users.

In the insulating glass industry or the glass processing industry, it is often discussed:

- Is the performance of the sealant in the edge system good or bad?

- What is the water adsorption capacity of the desiccant or molecular sieve?

- How much should the filling amount of the desiccant be, etc.,

several discussions have been launched on this.

But just as we call the combination of raw materials at the edge of a system, the tightness not only depends on each independent factor but also needs to consider the composite factors after the combination, that is, both independent factors and composite factors cannot be ignored. If one has to rank the contribution of raw materials to the sealing performance of insulating glass, it is undoubtedly the butyl extruder coated that bears the brunt. Because the water vapor transmission rate of butyl extruder is the lowest between silicone structural adhesives and polysulfide extruders (see Table 1). The core butyl extruder is coated on the spacer by the hot-melt method. If the cleanliness and quality of the spacer cannot be guaranteed, it will directly affect the sealing performance of the final insulating glass product, that is, the service life of insulating glass units.

Table 1 The comparison of physical properties of commonly used insulating glass sealants

| Sealing form | Water vapor penetration rate /mg*m-2*d-1 | Gas retention | UV resistance | Heat resistance | Application equipment and method | Application range |

| Hot melt butyl sealant | 0.65 | Excellent | Good | Good | Equipment application or automatic | Insulated use |

| Polysulfide sealant | 40~65 | Poor | Good | Good | Apply or automatic | Insulated second seal |

| Silicone sealant | 200 | Poor | Excellent | Good | Pump application | Curtain wall insulated second seal |

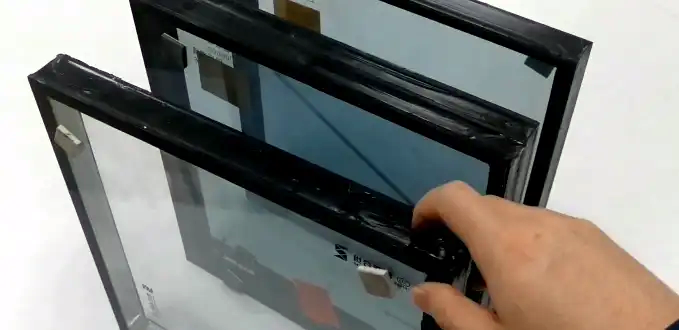

The author discusses the composite factor of the adhesion between the spacer and the butyl extruder as an entry point. From Figure 1 and Figure 2, the bonding situation of the butyl extruder can be seen.

Figure 1 Butyl extruder and aluminum frame are bonded normally

Figure 2 Butyl extruder and aluminum frame are completely peeled off

Figure 1 The spacer strips bar is an aluminum strips bar, with a smooth surface, no oil stains, and good adhesion with butyl extruder. What is seen in Figure 2 is the severe peeling of the butyl extruder coating from the spacer.

First of all, the peeling is localized, because we can still see the adhesion of butyl extruder on the spacer at the upper and lower positions of the peeling, but the degree of adhesion is not very good. This degree of peeling should be more serious. Because this is a fully peeled state, no coated marks remain on the spacers.

Secondly, if there is peeling between the spacer and the butyl extruder, there is every reason to believe that there will also be poor adhesion between the spacer and the second sealant.

We can analyze the poor adhesion of butyl extruder from the following points:

(1) Oxidation of spacers strips.

Due to the production process or improper storage conditions, the spacer strips are oxidized, as shown in Figure 3.

Treatment method: If it is the cause of the spacer itself, the incoming inspection of raw materials should be strengthened. In addition to verifying the appearance, the on-machine test can be directly carried out. For the storage conditions of the spacer, pay attention to whether there is any leakage of rain or water. It should be placed separately from the chemicals, and should not be placed directly on the ground, and ventilation should be ensured. In the rainy season, avoid being soaked in rainwater. When using, it is found that there is oxidation and blackening, and batches should be exchanged in time.

Figure 3 The surface oxidation of spacer strips

(2) The quality of the spacer bars is qualified.

The quality of the spacer bars is qualified, but due to the poor placement environment or use environment, the spacer bars are stained with oil and dirt.

Treatment method: When the spacer is not oxidized, the oil stains attached to the surface are easier to clean up. This lies in the quality requirements of the manufacturer. If we require that the surface of the spacer be decontaminated before coating the butyl rubber, defects can be effectively prevented. The easiest way is to use cotton gauze with alcohol to wipe it.

(3) Butyl extruder coating equipment

Butyl extruder coating equipment often uses talcum powder, so even if the spacer strips are of acceptable quality, they are decontaminated before coating, but due to the Excessive talc powder will inevitably contaminate the spacer and affect the bonding between the spacer and the butyl extruder, as shown in Figure 4.

Figure 4 The working site of butyl extruder coating machine

Treatment method: Clean the equipment in time every shift, especially the talc and other pollutants on the conveyor belt; or use the LIJIANG Glass LJTB01 Insulating Glass Butyl Extruder Coating Equipment, the equipment is driven by a non-stick synchronous belt, no need to apply talcum powder, The sealed effect coating is thick and not easy to wear.

Video 1 The processing of LIJIANG Glass Butyl Extruder Coating Equipment

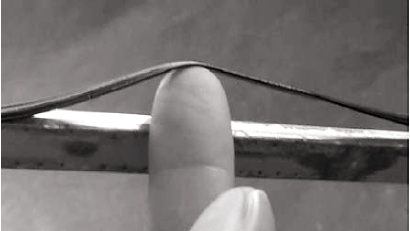

(4) Spacer bar deformation

Twisting and uneven surface due to process problems of spacer bars. Such unevenness affects the width of the spacer on a microscopic level, and in the process of applying the butyl extruder, there is no substantial bonding between the butyl extruder and the spacer in some places.

Treatment method: Such problems, can be picked out by testing in the frame-making process. When the situation is serious, it will affect the normal operation of the butyl extruder coating equipment.

Because of its low water vapor transmission rate, butyl extruder has become the guarantee of the sealing performance of insulating glass products. But "if the skin does not exist, the hair will be attached", if the butyl extruder does not have a spacer that can be well bonded to it, then ensuring the tightness is useless.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.