Discussion on simple edge grinding characteristics and selection methods for glass processing.

1. The introduction

Glass edge grinding is based on the fact that the glass has sharp edges after cutting, accompanied by a large number of micro-cracks that are invisible to the naked eye. For further production and processing, the edges need to be ground to eliminate sharp edges and micro-cracks to ensure subsequent processing. Safety and yield, while meeting product usage requirements. From the perspective of deep processing, a lot of glass processed needs to be tempered. The tempered glass processing technology requires edge grinding of the glass to avoid micro-cracks on the edge of the glass from expanding and spreading during the heating process and causing explosions, ensuring the tempered yield rate. From the perspective of relevant standards, according to the industry standard requirements of "Tempered Glass for Building Doors, Windows and Curtain Walls": the edge processing of tempered broken glass for building doors, windows and curtain walls can be chamfered and finely ground on three sides; tempered glass for glass curtain walls and lighting ceilings should be processed for three-sided fine grinding and three-sided polishing, the chamfer width should not be less than 1mm. Therefore, the glass edge grinding is not only a production process requirement, but also a product use requirement.

2. The principle of simple glass edge grinding

Simple edge grinding is mainly to chamfer the glass. Its purpose is to grind and eliminate the sharp edges, small cracks, and micro-cracks left during cutting, create conditions for subsequent processing, improve the yield rate of the post-process, and prevent the installation and use of the glass. Slanderous. Simple edge grinding is also called rough grinding or chamfering. It usually uses a grinding wheel, abrasive belt, or diamond wheel to grind the edge of the glass edge through high-speed rotation. Water is used as a heat dissipation medium to prevent edge explosion and eliminate sharp edges and micro cracks. Purpose, its grinding principle is relatively simple. Simple edging is easy to operate. With the help of different simple edging equipment and grinding methods, glass edging of different shapes can be achieved, which solves the problem of special-shaped glass edging that cannot be handled by linear edging machines. To a large extent, it is an alternative and supplement to linear edge grinding, simple edge grinding usually focuses on grinding glass with a thickness of 6mm and below.

3. More types of simple edge grinding

3.1 Usually glass is mainly used in doors, windows, curtain walls, automobiles, furniture, and other industries.

Depending on the use, glass has different edge grinding requirements. There are three types of specific edge grinding methods:

(1) Use a double-edge machines for edge grinding.

The linear edge grinding machines usually have 9 or more grinding heads with edging and polishing functions, which can perform fine edge grinding and polishing at the same time. This edging method is mainly used for architectural glass such as "Tempered Glass for Building Doors, Windows and Curtain Walls". The industry standard requires that tempered glass for glass curtain walls and lighting ceilings should be finely ground and polished on three sides. Usually, one or more sides of the glass that need to be installed are exposed. Outside, those with a certain degree of ornamental value, such as railings, handrails, door glass, glass for shopping mall counters, etc., require better edge grinding quality and are generally finely ground and polished with a linear edge grinder.

Figure 1 The double straight-edge machines

(2) Use a special-shaped edge grinding machine and beveling machine for edge grinding.

Furniture glass, such as tabletops, counters, and indoor-specific decorative glass, usually requires good edge grinding quality and special edge grinding treatments such as rounded edges, rounded straight edges, and beveled edges.

Figure 2 The special-shaped edge grinding machine

(3) Use a simple edge grinding machine for simple edge grinding.

Some glass installations, such as building doors and windows, have their edges hidden and not exposed and can be simply edged if the process requirements are met. These glasses account for more than 60% of the processing volume of conventional glass processing enterprises.

There are many ways of simple edge grinding, and the equipment complexity is different. Commonly used ones include a four-sided grinding sequence edge grinding machine, a diamond wheel simple edge grinding machine, and an angle grinder. The grinding characteristics are mainly chamfering processing, except for such as In addition to the high price of the large vertical abrasive belt edge grinding machines provided by LiSEC, most simple edge grinding machines have lower grinding material costs and faster grinding speeds. If the technical requirements are not high, you can choose manual simple glass edge grinding machines.

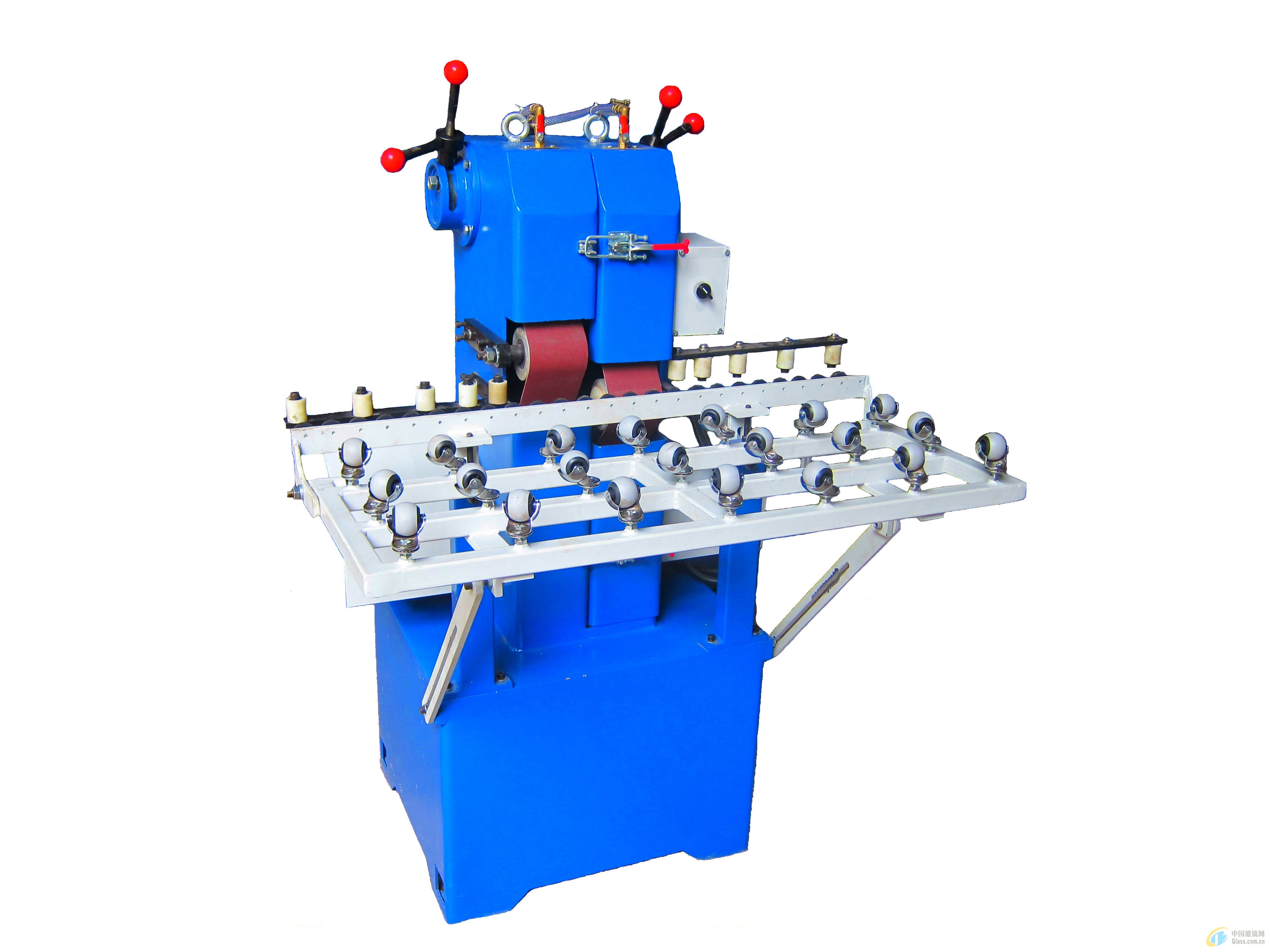

Figure 3 The simple edge grinding machine

3.2 Simple edge grinding machine types

There are many types of simple edge grinding machines, and different equipment can be selected according to different requirements. Currently, the following three types are commonly used on the market:

(1) Abrasive belt edge grinding machine.

It is divided into large abrasive belt edge grinding machine and simple abrasive belt edge grinding machine. Large-scale abrasive belt edge grinding machines have a large amount of glass grinding and can meet the chamfer edge grinding requirements of more than 1 mm. The equipment investment is relatively large. For example, LiSEC's abrasive belt edge grinding machine costs hundreds of thousands or even millions of yuan. This kind of edge grinding machine also comes with a film washing machine, which has high edge grinding efficiency, the best edge grinding quality, less edge explosion, and damage, and provides better protection for the subsequent tempering process; simple abrasive belt grinding The edge machine uses two motors to drive two abrasive belts to chamfer and grind the glass. Since it is necessary to manually hold the glass against the middle of the two abrasive belts for edging, it can grind a variety of special-shaped glasses. Its structure is simple and the price is cheap, but this edging method consumes a lot of human energy. When chamfering, is done by manually pushing the glass to move on the abrasive belt. Because the taut abrasive belt has a certain elasticity, it is greatly affected by the force. Affected by the tightening force, the chamfer width varies, making it difficult to control the chamfer width; at the same time, the glass has many cracked edges, which is not conducive to tempering production.

Figure 4 The abrasive belt edge grinding machine

(2) Four-edge grinding machine.

This kind of four-edge grinding machine is a new type of edge grinding machine that has grown rapidly in recent years. It can chamfer and grind the bottom edge, but chamfer grinding is relatively mature. Using a diamond wheel as the edge grinding material, the price of this kind of edge grinding machine is also relatively high, generally around 300,000 to 600,000 USD. Its characteristic is that it can chamfer glass of different sizes with high speed and high efficiency. It is extremely beneficial to enterprises with a lot of thin sheets. It can be loaded mechanically or manually, which is relatively labor-saving. Four-edge grinding mainly relies on the proximity switch to control the grinding wheel to grind the glass. The stability is difficult to control. The starting and tail parts of the grinding are frequently adjusted and difficult to control. It is easy to cause the grinding to fail or the glass to be damaged from the corners, but it saves personnel. , can grind rectangular glass of various specifications that can be changed at will, which is the basis for its wide use.

Figure 5 The four-edge grinding machine

(3) Diamond wheel simple edge grinding machine.

There are two types of diamond wheel simple edge grinding machines: single wheel and double wheel. Some also come with a film removal wheel, which can remove the film from coated glass while grinding the edges. The price of this equipment varies according to different configurations, usually around 5,000 to 40,000 USD. There is little difference in operation between the diamond wheel simple edge grinding machine and the simple belt grinder. A person is required to hold the glass for edge grinding. It can grind a variety of special-shaped glass edges and can grind glass of various sizes and specifications. Due to the high hardness of the diamond wheel, chamfering and edge grinding can be performed as long as the glass is held manually to ensure the position of the grinding wheel, without having to press the glass hard. The chamfer width is about 1mm, and the diamond wheel grinding has less edge explosion, which ensures the chamfering and grinding quality of the glass and can meet the further processing requirements of the glass. For glass processing enterprises, a simple edge grinding machine equipped with a double diamond wheel machine is relatively reasonable and effective and plays a good supplementary and auxiliary role in edge grinding. The diamond wheel edging machine occupies a small area. There is no need to adjust the edging machine according to the size and thickness of the glass. The glass can be replaced at any time for edging. In addition to edging batch orders, it can also quickly complete the edging of loose pieces and needs. It is more advantageous to grind the patch edges.

Figure 6 The diamond wheel simple edge grinding machine

(4) Hand-held simple grinder.

This type of hand-held edge grinding machine mainly uses a grinding wheel fixed on a manual angle grinder for edge grinding. It is mainly used for edge grinding of gaps, holes, and some special circumstances. The edging effect is not good, and the appearance after polishing is uneven, the edges are rough, and may be accompanied by new micro-cracks. However, because it can grind any glass edge, this edging method has its irreplaceable aspects.

Figure 7 The hand-held glass edge grinding machine

4. Characteristics and shortcomings of simple edge grinding

4.1 Features of simple edge grinding

Simple edge grinding has the following 7 characteristics:

(1) In terms of the current development trend of tempered, laminated and insulating glass based on thin plates account for a larger proportion in the glass processing industry, and simple edge grinding meets the product structure requirements of glass companies;

(2) Most simple edge grinding techniques do not require high requirements. Nowadays, many small and medium-sized enterprises commonly use four-edge grinding machines and diamond wheel simple edge grinding machines. Even new trainees can get started quickly, unlike linear edge grinding machines that require a lot of grinding experience. Only with experience in edge and grinding wheel adjustment can the operation be stable. In this way, the simple edge grinding machine can quickly produce efficiency, and the company does not have to go through troubles to find or retain an experienced edge grinding operator;

(3) Loose pieces and patches are the most troublesome problems that plague the delivery time of glass processing enterprises. Especially in the edge grinding process, if there are many loose pieces and patches, the traditional edge grinding method will be very slow, inefficient, and cause the wokers are unwilling to work hard, and they will delay if they can, which is not only affects production efficiency, but also affects production progress and delivery time. The simple edge grinding machine can complete the production of loose orders and patches the first time.

Especially the simple edge grinding machine with a diamond wheel can produce loose orders and patches in real-time, which solves a major problem in production management. Of course, under the premise of having a budget, between the two processes of glass cutting and edge grinding, glass processing manufacturers adopt a glass sheet cage storage system, which can effectively rectify and correct the phenomenon of loose orders and patches during the glass processing process.

(4) The simple edge grinding machine can grind special-shaped glass of various shapes, which makes up for the shortcomings of the linear edge grinding machine that cannot grind special-shaped glass. It complements the linear edge grinding machine and not only improves the grinding efficiency and quality, and also promotes higher overall edge grinding efficiency;

(5) Glass of different specifications can be edged without adjusting the length and width of the edger, and the grinding efficiency is high;

(6) The simple edging machine fills the glass into the column with moisture, and the edging does not change the shape of the glass, ensuring that the size of the glass does not change due to edging;

(7) Low grinding cost. The abrasive cost of the simple edge grinding machine is not high, the electricity consumption is small, and the equipment maintenance cost is low, which is helpful for enterprises to save costs.

4.2 Disadvantages of simple edge grinding

Simple edge grinding machines have their advantages and disadvantages. The disadvantages are mainly reflected in the following three aspects:

(1) The main feature of the simple edge grinding machine is corner chamfering. It does not have the functions of bottom edge grinding and polishing, so it has its edge grinding limitations. Glass that requires fine grinding and polishing cannot be processed, and thicker glass cannot be processed. Good for grinding. Generally, glass 6mm and below can be subjected to simple edge grinding, while glass above 8mm is not recommended for simple edge grinding. Because the thickness of the glass is thicker, the heating time required for tempering after rough edge grinding will be longer, which can easily cause glass deformation. At the same time, it is difficult for operators to control the heating time for some simple edge-grinded glasses, which also causes increased damage; the thicker the glass, the lower the glass will be. The unground area of the edge is also larger, slightlyThere are also more crack defects, which also increases the chance of glass breakage;

(2) Some parts, such as simple abrasive belt edge grinders and hand-held simple grinders, have more broken edges and poor aesthetics;

(3) Simple edge grinding requires an appropriate increase in heating time during tempering, which improves the edge grinding efficiency but also results in an increase in tempering power consumption and frequent glass deformation.

5. The conclusion

Edging is an important link in glass processing enterprises. Edging is more cumbersome and usually requires more equipment. Enterprises need to carry out different edging operations according to different customer needs and product usage, and they need to use appropriate equipment combinations. To meet the edge grinding needs. Simple edging equipment is undoubtedly the best complement and supplement to the traditional linear edging machine. It can not only perform batch order edging but also quickly grind special-shaped glass and scattered pieces, thereby improving the production efficiency of the enterprise. and on-time order delivery rate, providing enterprises with more edge grinding options and convenience.

Choosing the appropriate simple edging machine according to the characteristics of the enterprise and using the simple edging method rationally can make the simple edging method play a role in promoting the production of the enterprise, thereby improving the enterprise's production efficiency, customer satisfaction, and economic benefits, and providing a better environment for the enterprise.

For more information about LIJIANG Glass insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.