Analysis and research on the air knife layout and air knife cross-section of glass washing machine

After the glass substrate is washed by a washing machine, the surface and cross-section need to be dried. Commonly used drying methods include sponge roller squeeze drying and strong cold and hot air blow drying. Extrusion drying using a sponge roller has a poor drying effect on the cross-section of the substrate. At the same time, the sponge roller needs to be replaced regularly, otherwise it is easy to contaminate the glass again. Air knife drying uses high-pressure air to blow away the moisture attached to the glass surface during the glass washing process to ensure that the washed glass is clean, dry, and free of impurities and watermarks. Therefore, the quality of the air knife function directly affects washing. Use strong wind to dry. During the entire drying process, the front section, side section, and the upper and lower surfaces of the glass are the easiest to dry. The rear section of the glass is the most difficult to dry because water has been blown into the rear section.

The principle of air knife water cutting is to use high-speed knife-shaped airflow to make the moisture and particles on the glass surface roll away from the glass surface along the direction of the airflow. After the high-pressure and strong wind enters the air knife, it is blown out through the 1~2mm air nozzle gap, thereby forming a high-speed air flow sheet. This sheet air curtain forms a thin high-strength, large-flow impact air curtain. The air curtain strength is uniform and at the same time, This sheet will also channel several times the ambient air around it. The glass drying process with a high-pressure air knife can be divided into the following stages.

1) Water layer removal stage.

This stage mainly uses pairs of air knives to blow away the thick water layer formed on the glass surface. Most of the water on the glass surface is blown to the rear of the glass and flows away from the sides and rear of the glass.

2) Water film removal stage.

When a large amount of water layer on the upper and lower surfaces of the glass is blown away, a thin layer of water film will be left on the upper and lower surfaces of the glass. This process uses pairs of air knives to remove the water film on the glass surface. The water film is dried and evaporated.

3) Except for the tail section stage

there is no water layer and water film on the front glass surface at this stage, and there are only water traces on the tail section of the substrate. The water traces on this section are mainly caused by the water layer and water film on the large surface repeatedly flowing into the tail section. In this stage, pairs of air knives are mainly used to dry the tail section of the substrate.

1. Types and characteristics of wind knives

When designing the air knife, the blade extends as far as possible along the square of the wind blowing, so that the air will be sprayed out in a straight line as a whole, and the airflow will be easier to control. This design will also improve the airflow in the air knife. Entrainment of the inner wall of the cavity allows the air knife to provide stable, continuous, and large amounts of air based on the Coanda effect and air entrainment. The lengthened blade utilizes the Coanda effect to guide air to attach to the surface of the blade. In this way, the integrity of the wind continues to the downstream airflow and creates surrounding air entrainment, ultimately improving wind utilization. Generally, the air knife in the water removal layer stage and water removal film stage mainly removes water rapidly, which requires high wind speed and pressure of the air knife. The cross-section of the air knife at this stage should adopt a curved shape, which can reduce the generation of eddy currents. At the same time, in theory, to make the wind The knife effect is better. The cross-section should be gradually reduced from the air inlet end to the end. This can not only increase the longitudinal speed but also increase the wind speed at the end. However, this will increase the difficulty and cost of manufacturing. In actual manufacturing, equal-section air knives are often used. Except for the tail section stage, because there are no watermarks on the large surface of the glass at this time, and there are only watermarks on the tail section, the wind speed and pressure requirements of the air knife are not high. Instead, a large flow of air is needed for drying. The air knife at this stage In consideration of manufacturing difficulty, rectangular air knives can be considered. According to the structure, air knives can be divided into straight air knives, oblique air knives, and combined air knives. Straight air knives and inclined air knives have higher requirements on wind pressure and wind speed and adopt curved and pointed air knife cross-sections. The wind knife does not have high requirements on wind pressure and wind speed. It often adopts a rectangular structure and is equipped with a wind guide plate.

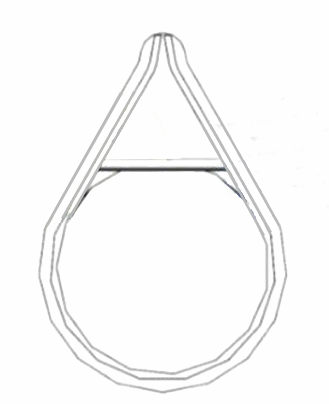

Figure 1 Straight and inclined air knife sections

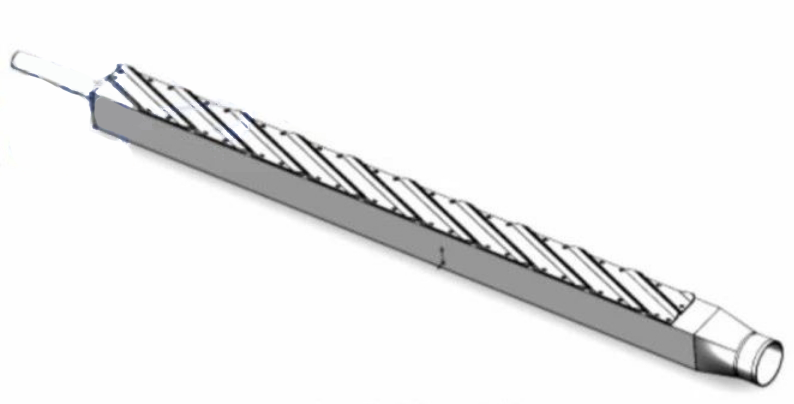

Figure 2 Structure of LIJIANG Glass air knife

1.1 Straight air knife

A straight air knife means that the center line of the air knife is parallel to the center line of the roller, and the airflow of the air knife starts cutting water parallel to the front section of the glass and ends at the rear section of the glass. The straight-air knife is mainly used to remove most of the water layer on the glass surface, and can also be used to isolate between cleaning units.

1.2 Inclined air knife

The oblique air knife means that the center line of the air knife is at a certain angle with the center line of the roller. The air knife divides the transmission roller into two parts. The airflow starts cutting water from one corner of the glass and ends at the other corner of the glass. The inclined air knife is mainly used to remove water on the surface and section of the glass. The general placement of the inclined air knife, the better the drying effect on the cross-section. However, a larger angle will not only increase the length of the equipment but also produce greater lateral force on the glass substrate, making the glass easy to deflect. Figure 1 shows the commonly used straight and inclined air knife sections.

1.3 LIJIANG Glass air knife

The combined air knife is square. The air knife incision is at a certain angle with the center line of the target, and multiple parallel cuts are used. The combined air knife is placed parallel to the roller surface and is often used in the last set of hot air drying air knives to dry the moisture in the rear section of the glass. As shown in Figure 2, the structure of the LIJIANG Glass Air Knife.

2. The layout of the wind knife

General industrial air knife water removal parameters correspond to different outlet wind speeds and air knife gaps according to different water removal modes. Please refer to Table 1 for details.

Table 1 Industrial air knife water removal parameters

| Model | Wind speed/(m*s-1) | Knife edge gap/mm |

| Remove water quickly | 70~120 | 1~1.5 |

| Remove water in generally | 1~1.5 | 1~1.5 |

| Water-based coating drying | 5 | 5 |

| Steam sterilization | 0.3 | 0.3 |

| Air drying by hot wind | 2~5 | 2~5 |

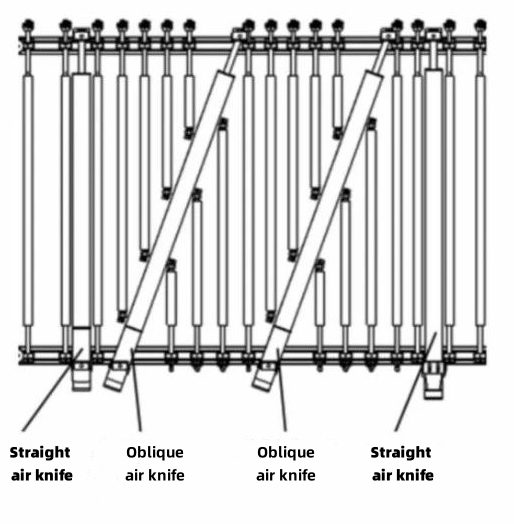

According to the analysis of the water removal stage of the air knife and the parameters of industrial air knife water removal, it can be seen that when removing water from the glass, the glass must first be quickly dewatered, and the high-pressure and high-speed air curtain formed by the high-pressure air knife is used to quickly blow it away There is a large amount of water layer on the glass, so the first set of air knives uses straight air knives. The gap between the blades of the straight air knives is 1~1.5mm. The distance between the air knife tip and the upper and lower surfaces of the glass is 3~5mm. The front inclination angle of the knife edge is 15 °~30°, the strong wind curtain of the straight-air knife can be effectively used to quickly drive the water layer on the glass to the rear section of the glass.

Secondly, an inclined air knife needs to be installed behind the straight air knife. The inclined air knife can quickly remove watermarks on the glass surface and cross sections. It also has a good removal effect on the rear section especially, which can reduce the pressure on the combined air knife behind. The inclined air knife can The number is determined by the speed of glass transmission. The time between the blades of the inclined air knifeThe gap is 1~1.5mm, the distance between the air knife tip and the upper and lower surfaces of the glass is 3~5mm, the front inclination angle of the knife edge is about 5~10°, and the angle of the oblique air knife is 15°~25, which can effectively use the incline The water cutting effect of the air knife realizes progressive water removal along the diagonal line. The oblique air knife can not only remove water from the glass surface but also has a good water removal effect from the glass cross-section.

Finally, a combination of air knives should be arranged behind the inclined air knife. The combined air knife is often used with electric heating to dry with hot air. The air knife is mainly used to remove a small amount of water stains remaining on the rear section of the glass. The gap between the combined air knife edges is 1.5~2mm. , the distance between the air knife tip and the upper and lower surfaces of the glass is usually 5~6mm, which can effectively dry the tail section. Figure 3 shows the layout of the air knife.

Figure 3 The layout of the air knife

3. Simulation of wind knife

From the previous analysis, it can be seen that the rapid water removal stage is the key to glass drying. This stage can not only quickly peel off the water layer and water film on the glass, but also reduce the pressure for the rear section of the air knife to remove water. Therefore, rapid water removal can The advantages and disadvantages of the cross-sectional shapes of straight air knives and inclined air knives in the water stageDirectly affects the blow-drying effect.

This article uses the FloXpress module in Solidworks to perform fluid simulation to verify the wind speed at the air knife outlet compare it with the theoretically calculated wind speed, and finally obtain the cross-sectional drainage effect of the air knife.

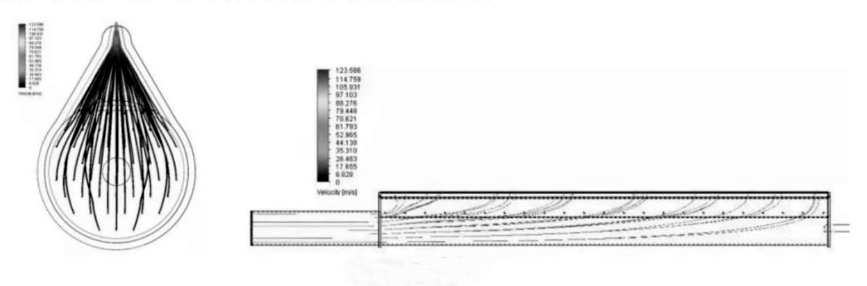

Figure 4 Air velocity field of wind knife

It is known that the effective length of the air knife blade is 1450mm, and the blade gap is 1.3mm. According to the actual use of the fan, the air inlet flow of a single air knife is 815m/h3, then the theoretical wind speed is V-Q/A-815/3600/1.45x0.0013=120 m/s. The same air knife parameters and flow rate are added to the FloXpress module, and the air velocity field of the air knife is obtained through simulation, as shown in Figure 4. It can be seen from the FloXpress simulation that the airflow speed of the air knife is maximum at the knife nozzle, and the maximum wind speed is 123.586 m/s, which is consistent with the theoretical calculation results, indicating that this air knife section has a better effect on wind diversion, and this speed value meets the requirement for rapid water removal. speed requirements. Therefore, this air knife section has a good effect on the water layer and water film on the glass surface and the tail section. At the same time, combined with the hot air drying effect of the combined air knife on the tail section, it can achieve rapid drying of the glass surface and section.

4. The experimental tests

To further verify the accuracy of the simulation results, experiments were conducted to test the drying effect of the cleaning machine. During the test, the maximum speed of 18m/min was used for testing. Figure 5 shows the equipment test site, and Figure 6 shows the air knife drying effect. It can be seen from the test results that using this kind of air knife arrangement structure has a better drying effect on the surface and cross-section of the glass, and can achieve rapid drying.

Figure 5 Equipment test site 1

Figure 5 Equipment test site 2

Figure 6 Air knife drying effect

5. The conclusion

With the development of the glass industry and national policy support, automatic glass washing and drying machines, as one of the important process equipment in the glass processing production line, are developing towards high cleanliness and high dryness. This article analyzes the process of glass water removal from the theory of glass water removal conducts the cross-section design and air knife layout of the air knife according to the water removal process and water removal mode, and simulates the important air knife cross-sections through FloXpress to theoretically verify. The effect of the air knife in rapidly removing water was demonstrated, and it was concluded that the air knife using this cross-section and layout has a better drying effect on the glass surface and cross-section.

For more information about LIJIANG Glass insulating glass processing equipment and insulating glass processing accessories, please click here to learn more