Application of laser technology in gas content detection of gas-filled insulating glass.

To keep up with the market's demand for high-performance insulating glass products, companies have been making unremitting efforts in quality control, especially when it comes to the gas retention of gas-filled insulating glass. New non-destructive testing methods make it possible to test the gas content of any complex insulating glass configuration to ensure that the gas-filled insulating glass delivered to the end customer meets the order requirements. Today, the market has increasingly higher performance requirements for glass products, and the growing demand has made manufacturers pay no slack in product quality.

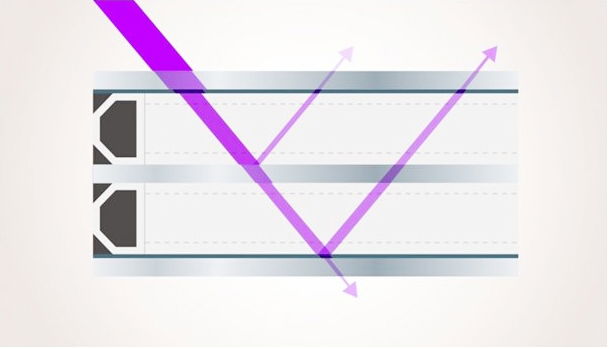

Figure 1 The new non-destructive testing methods of insulating glass argon-gas filling

Today's glass products contain a variety of elements to enhance their performance. One of the main performances is energy saving, whether it is in hot or cold building engineering applications. Energy-saving properties can be achieved in many ways, such as coating, multiple sheets of glass and adding a medium in between. The medium can be air, vacuum, or a specific gas - usually argon or krypton.

A common method to enhance the thermal insulation performance of insulating glass is to fill the spacer layer with argon or krypton gas. This operation can be performed through the plate pressing section of the automatic insulating glass production line, or it can also be completed by semi-automatic manual operation. The challenge of this operation is how to determine the correct gas content and how to ensure that the initial concentration of gas-filled insulating glass reaches the standard. Gas may escape through improper application of the sealant of the insulating glass, which requires gas content testing before packaging and shipping to customers. The product liability of insulating glass products and door and window companies usually extends for several years after delivery. Therefore, they are looking for ways to increase the safety of gas filling.

Even though there is no clear standard in all areas, the industry and manufacturing companies have accumulated best practices to manufacture high-quality inflatable insulating glass products. The fact that small molecule gases are relatively easy to leak is the real challenge. Therefore, in order to ensure that the gas content can reach the highest level after the filling operation is completed, glass processing enterprises basically set it to 95% or higher during filling.

The actual argon content can be measured by destructive or non-destructive testing methods. Destructive testing methods all require a syringe to penetrate the sealant of the insulating glass into the cavity layer to take gas, and then automatically calculate the gas sample. These methods are usually cheap and highly accurate robust technologies, but they require the destruction of the insulating glass structure. In actual operation, this means that the measured insulating glass product cannot be repackaged and delivered to the customer, and the insulating glass product cannot be repeatedly measured.

Figure 2 The plasma emission spectrometry test method

Non-destructive testing methods can detect gas content without destroying the insulating glass structure. The most commonly used non-destructive testing method is plasma emission spectroscopy, that is, the testing instrument uses high-voltage electric spark discharge to penetrate the surface of the glass to be tested so that the argon gas in the spacer layer is ionized. The instrument collects the light beam after the gas is ionized, and the argon content is automatically calculated. This testing method is fast and accurate. It is widely used in the field of ordinary double-pane insulating glass. You only need to lightly touch the non-coated side to take a random point for measurement. Non-destructive testing methods can also repeatedly test the same piece of inflatable insulating glass product according to the quality system or customer requirements. However, the technical limitation of plasma emission spectroscopy is that it can only measure the double-pane insulating glass products with single-sided coating.

Currently, there have been new advances in the field of measurement technology, which have solved the problems encountered by the above detection methods when applying the gas content of gas-filled insulating glass. The latest tunable semiconductor laser technology can penetrate the coating and laminated to perform non-destructive detection of gas-filled insulating glass products. This innovative technology can detect the gas content of complex gas-filled insulating glass products, such as energy-saving three-glass two-chamber gas-filled insulating glass. Laser technology improves the quality assurance of these high-performance products and matches them with product expectations. Because this laser technology measures the oxygen content in the spacer layer by non-destructive methods, it can detect the content of any types gas-filled.

Figure 3 The tunable semiconductor laser technology

This innovative technology uses a tunable laser beam to shoot into the insulating glass and uses the reflection, intensity, and harmonic changes of the measurement signal to determine the oxygen content in the spacer layer. Then, the oxygen content is converted into a percentage of inert gas , the most commonly used inert gases are argon and krypton. For a insulating glass production line with efficient quality control, it can read the gas content information in each piece of inflated insulating glass.

The laser gas analysis system meets this requirement and can be integrated and installed on the existing insulating glass production line and connected to the production control software or system. In today's production management and operation, quality control plays an unprecedented role. It can not only eliminate the appearance of defective products but also provide technical support when sales complaints occur.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.