Several issues in the glass washing process in the production of insulating glass.

In recent years, with the continuous development of building energy-saving work, the use of insulating glass has doubled year by year, and the production of insulating glass has gradually developed from early manual production to the current semi-automatic or fully automated production. The production capacity, technical level, and quality have made great progress. The quality of insulating glass mainly depends on the quality of raw materials and the quality control of each link in the production process. LIJIANG Glass only a few noteworthy issues in the glass washing and drying process will be discussed.

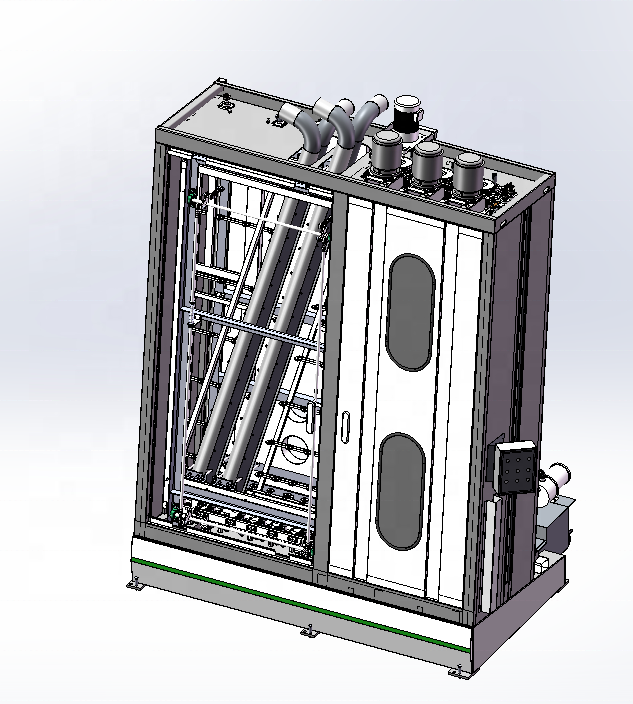

Figure 1 LIJIANG Glass vertical glass washing and drying machine

1. Pre-spray that is easy to be ignored

Regardless of whether horizontal or vertical cleaning is used, the pre-spray device is a significant and easily overlooked place. Most of the pre-spraying devices set up by domestic washing machine manufacturers use the method of drilling hollows on the stainless steel pipes. The spraying pressure and the amount of spraying water in this method are not enough.

The function of pre-spraying is mainly used to remove the floating dust and dirt on the glass surface. If the water spray pressure and amount of water cannot be reached, the glass surface cannot be cleaned effectively, thereby making the glass surface dirty. When the glass enters the washing machine, it will pollute the roller brush and the water tank.

2. Regular roller brush maintenance

The key part of glass cleaning is the roller brush part of the washing machine, which is very important for the regular maintenance of the roller brush. Floating dust, oil stains on the glass surface, and paper glue on the glass backing paper are easily attached to the bristles of the roller brush, and some of them will be hidden in the roots of the bristles. If it cannot be cleaned in time, it will contaminate the glass's surface.

Especially for the washing machine that cleans offline Low-E glass, pay more attention to the regular maintenance of the roller brush. A high-pressure water gun can be used for flushing during maintenance. In addition, after long-term use of some vertical cleaning machines, the lower part of the roller brush wears faster than the upper part and needs to be trimmed.

Figure 2 The roller brush of LIJIANG Glass vertical glass washing machine

3. Re-understand cleaning water

The quality of cleaning water is directly related to the result of cleaning, but this has not been paid enough attention by insulating glass manufacturers. At present, some insulating glass manufacturers use tap water, well water, or ordinary clean water to clean the glass, which does not meet the requirements. Because tap water, especially well water, contains a large amount of calcium, magnesium, and chloride ions when these ions adhere to the glass surface, they will affect the bonding quality of the butyl extruder coating, secondary sealant, and the glass surface, thereby affecting the sealing life of the insulating glass. , Easily lead to seal failure. Ordinary water purification only filters out the particulate impurities in the water, but cannot remove the ions.

The cleaning water for insulating glass should be deionized water with a conductivity of less than 20 gs/cm after being treated by a water treatment device with a deionization function. If it is processing offline toughened Low-E insulating glass, the requirements for cleaning water are more stringent. The water in the water tank of the washing machine should be changed frequently to keep it clean. When changing the water, clean up the sediment in the water tank to prevent the water supply pump of the water tank from bringing these sediments to the roller brush.

It is strictly forbidden to use detergent for the cleaning water of insulating glass. In addition, from the perspective of saving, the recycling technology of cleaning water for insulating glass is worthy of promotion.

4. Noteworthy wind knife design and maintenance

After washing the glass, there are many domestic glass washing machines whose air knives cannot completely blow off the water on the glass surface, especially when the speed of the washing machine is faster. This is mainly the design, manufacture, installation, and adjustment of the wind knife of the glass washing machine. The structure of the air knife of the washing machine, the angle between the air knife and the glass, and the wind force of the air knife are the key factors. In addition, the filter of the air inlet of the fan should be cleaned in time. Once the dust enters the fan, it will be difficult to clean it completely. Blowing the glass surface with water through the air knife will cause watermarks on the glass surface.

Figure 3 The wind knife of LIJIANG vertical glass washing machine

In the production process of insulating glass, the cleaning effect of the glass should be checked frequently. The recommended simple method is to use the Hatch method, which can directly see the cleanliness of the glass surface.

Video 1 LIJIANG Glass vertical insulating glass washing machine

For solar control film insulating glass and Low-E insulating glass, the cleaning of the glass surface is more important, because this kind of glass will clearly show watermarks and stains than ordinary white glass and affect the appearance of the insulating glass.

For more information about LIJIANG Glass insulating glass processing equipment and insulating glass processing accessories, please click here to learn more