High Speed Glass Washing Machine

Learn More

3060 Washing machine consists of the in-feed, pre-wash, washing& drying, out-feed section. To achieve good washing performance and quick air drying, it adopts 3 pairs of brushes and 3 pairs of air knives with 1pc air blower. It fits for tempered glass, solar glass, laminated glass, Low-e glass, or any other flat glass processing.

Technical parameter

Parameter | ||||

Max. Width | 3000mm | |||

Min. Size | 450×450mm | |||

Glass thickness | 3~28mm | |||

Working table height | 900mm±30mm | |||

Blower power | 35Kw | |||

Total power | 51kw | |||

Weight | 5000kg | |||

Low-e brush: 2pcs,dia 0.15mm, | Hard brush: 4pcs, dia 0.25mm | |||

Water heater | 1pc of 6kw | |||

Air heater | 1pc of 6KW | |||

Brush roller dia | 160mm | |||

Rubber roller dia | 80mm | |||

Processing Speed | 3~15m/min | |||

Speed suggestion as follows | ||||

4mm~6mm thickness, speed suggested to 12-15m/min | ||||

8mm~10mm thickness, speed suggested to 8-10m/min | ||||

10mm~12mm thickness, speed suggested to 6-8m/min | ||||

15mm~19mm thickness, speed suggested to 4-5m/min | ||||

20mm or more, speed suggested to 3m/min | ||||

Configuration | ||||

Item | Spec | |||

Main machine frame | Aluminum alloy + steel, no deformation. | |||

High-pressure pump | China's famous brand: Jinlong | |||

Frequency converter for conveying | China's famous brand: Delta | |||

Brush motor | China's famous brand: Jinxing | |||

Bearing | China's famous brand: HRE | |||

Electrical Appliance | Siemens | |||

Rubber roller | NBR Perduran(sour liquid forbiddion), stainless steel shaft | |||

Water tank, sink, side covers, all parts touch water | Stainless steel 304 | |||

PLC | Siemens | |||

Characteristics

Horizontal structure, simple operation. The machine frame adopts heavy-thickness metal + aluminum alloy to avoid being out of shape when working for a long time. |

Witha stainless steel water sink and high-pressure pre-spraying (high-pressure pump) in loading ( in-feed), the rubber roller can pre-wash automatically to clean out the glass powder or scraps. |

Brush: The top and bottom brushes are transmitted by 1 motor, respectively. |

Water tank (with heater): 1 water tank is separated into 3 sections, 1 section for pre-wash, and the others for deep washing. |

Blower: Low noise and vibration. |

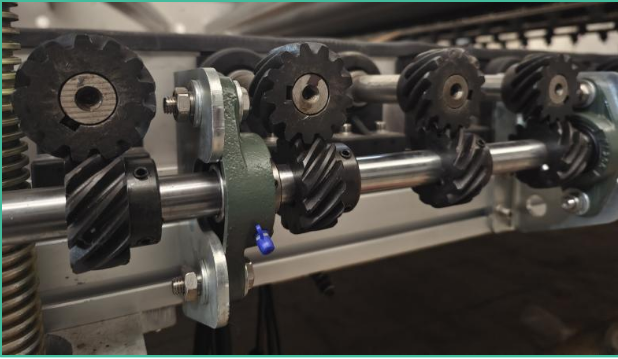

Conveying adopts a frequent converter, digital display, and convenient operation, which is good to connect with double edging line, hollow glass line, safety glass line, etc. Table rollers are adapted to superior rubber and are transmitted by a gear wheel, which ensures stable working. |

Side covers, tanks, and any other water-touched material adopt stainless steel 304. |

The washing and Drying section can be lifted to Max. 400MM by adjustment on the electrical board with 4 legs(corners), increasing through motors and the encoder. |

3 pairs of air knives adopt an advanced technique device, large power, and quick air drying. |

Spare parts list

item | Name of goods | qty |

1 | Chain | 2pcs |

2 | Bearing | 10pcs |

3 | Brackets of bearing | 5pcs |

4 | Contractor and thermal relay | 2pcs |

5 | Gear | 6pcs |

6 | Installation instruction | 1pc |

7 | Tool box | 1pc |

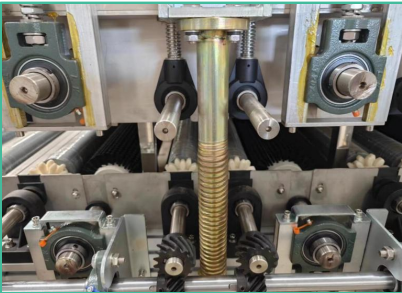

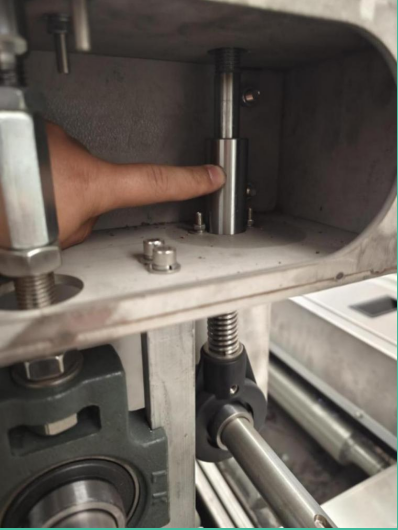

Electrical lifting structure

Ball screw(dia 40mm) + gear wheel + worm, no wheel-pin. Max lifting 400mm for machine maintenance.

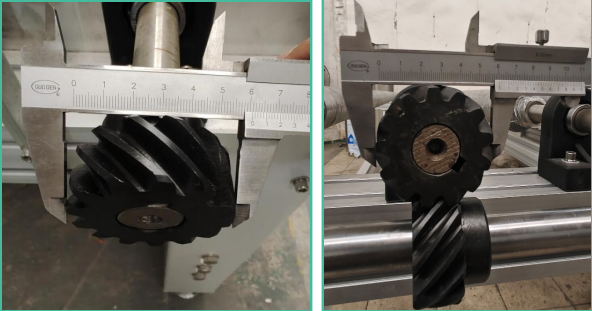

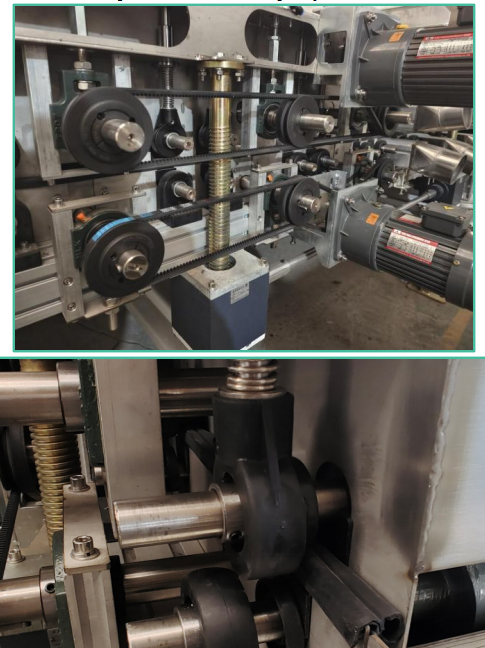

Transmission gear

The transmission gear is made of high-quality 45 # steel quenched material, which is durable with low transmission noise, low load, stable work efficiency, and long service life.

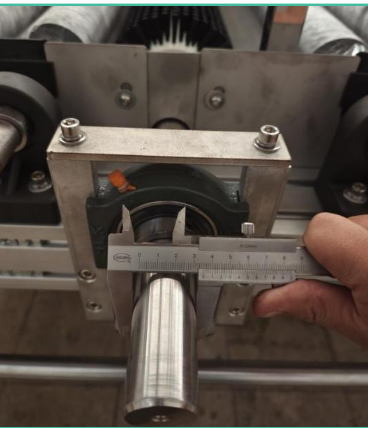

Brush shaft head

The brush adopts a 35 diameter large shaft head, ensuring the stability and durability of the brush during the glass cleaning process.

Waterproof system

3 sections waterproof system with a silicon ring and a block board to avoid water from dropping into the bearing.

Transmission structure

The XPA belt-driven brush ensures the smoothness and durability of the brush during high-speed rotation. The gear motor ensures sufficient torque of the brush when cleaning thick glass, and will not cause the motor to jam due to insufficient torque caused by low speed under variable frequency conditions.

Patent design

Independently researched and developed a fixed sliding sleeve for the rubber roller in the cleaning room. This design allows the rubber roller to slide smoothly up and down when pressing the glass into the cleaning room, without getting stuck and damaging the glass due to swinging left and right. Greatly improves the qualification rate of glass during cleaning. This design solves the instability, practicality, and common problems of easily damaging glass that many domestic manufacturers process on cleaning room shelves.

2 sections of pre-wash

Pre-wash the glass powder on the glass surface.

Snap-in spraying nozzle for prewash

Quick release, convenient maintenance.

3-section water tank

Quick coupler

Easy to take out the water tank for cleaning with the quick coupler by disconnecting the 4pcs pumps.

No-glass sensor

No-glass sensor

The blower will stop when no glass comes, and restart when glass comes again. Sleeping mode can be adjusted to 5 min, 10 min, etc.

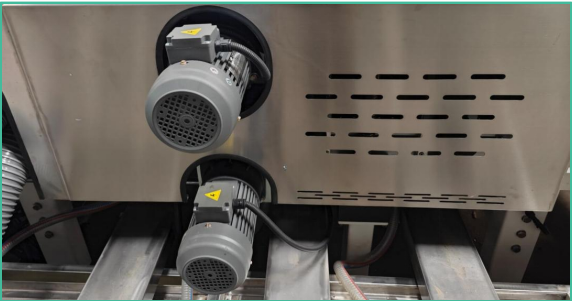

Brush motor

Brush motor

A separate motor to transmit the upper brush and down brush.

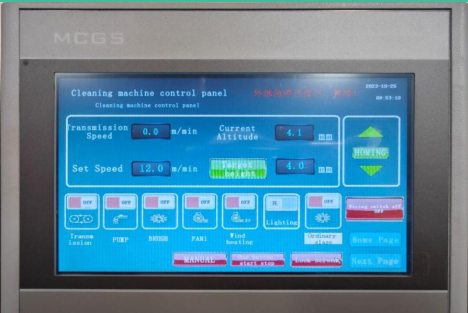

Touch screen

Touch screen

With an internet connection to match the double edger, the user can adjust the washing indication in the double edger system.

Blower with filter cotton