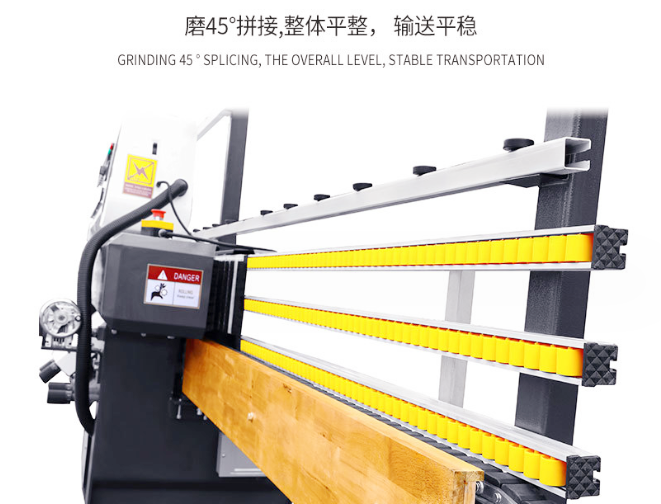

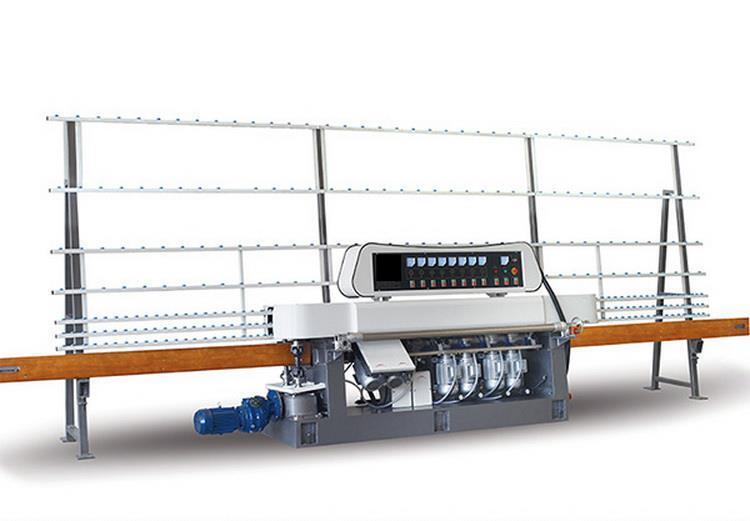

Automatic 45° Glass Grinding Machine (Optional Swing Head)

LIJIANG Glass Automatic 45° glass edge grinding machine is suitable for grinding the inclined plane and straight edge of metal belts of different sizes and thicknesses. It is equipped with grinding wheels and spare equipment. It has the characteristics of rough grinding, fine grinding and polishing at one time. It has long service life, regular forming and high efficiency.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LIJIANG Glass Auotmaitc Glass Edge Grinding and Polishing Machine (Optional Swing Head)

General Description

Auotmaitc Glass Edge Grinding and Polishing Machine 1

Auotmaitc Glass Edge Grinding and Polishing Machine 1

- Suitable for different size and thickness flat glass grinding.

- Rough grinding, fine grinding, arris, polishing can be finish on the same one time.

- Processing speed adjusted by CVT with large coverage adjustment and stable speed change. During processing the glass, both feed-in speed and grinding qty can be adjusted.

- Adjust front rail to match different glass thickness.

- The machine is equipped with automatic clamping system and pressure stabilizing system.

- Easy operation, high precision and efficiency, it’s widely used in flat glass processing.

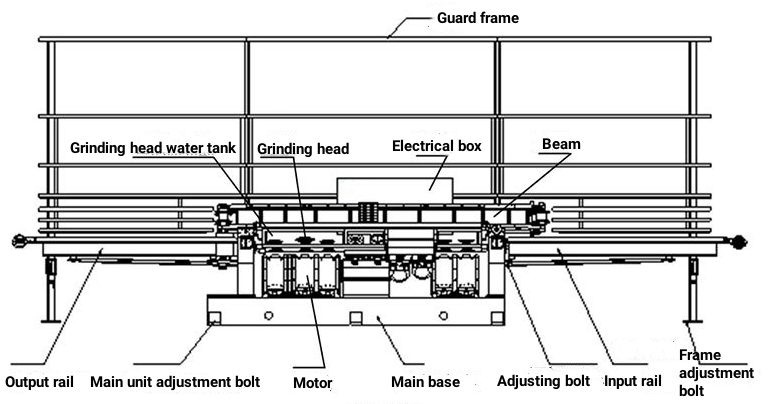

Equipment Main Structure

| Item. | Spec. |

| Grinding head quantity | 9 sets |

| Feed rate | 0.7~7 m/min |

| Minimum processing size | 60*60 mm |

| Processed glass thickness | 3~25 mm |

| Chamfer grinding amount | 1~2 mm |

| Bottom edge grinding amount | 1~3 mm |

| Power supply | 380V / 50Hz / 3P |

| Total power | 19.75 Kw |

| Weight (gross weight) | 3000 Kgs |

| Dimensions | 6800*1000*2500 mm |

| The finished product rate of edge grinding machine can reach 98% (The except for human operation and glass original film factors) | |

| The edge of the glass has uniform brightness, no cracked edges, no falling corners, etc. (The sealed sample provided by the precision ground and polished glass and equipment manufacturer shall prevail) | |

Equipment Configuration

| Item. | Spec. |

| Main machine frame | Annealing steel, no deformation |

| Grinding motor | Chinese brand: Hunan Jinlong |

| Continuously variable transmission | Chinese brand: Foshan Xingguang |

| Worm reducer | Chinese brand: Foshan Zhujiang |

| Pressure pads | Chinese brand: Shunde Zhenhong |

| Conveying chain | Chinese brand: Hangzhou Donghua |

| Gear | Chinese brand: Foshan Zhongmin |

| Bearing | HRE |

| AC contractor | Chint |

| Thermal relay | Chint |

| Transformer | Chint |

| Breaker | Chint |

| Ammeter, Voltmeter | Chint |

| Buttom, indeicator light | Shanghai Ergong |

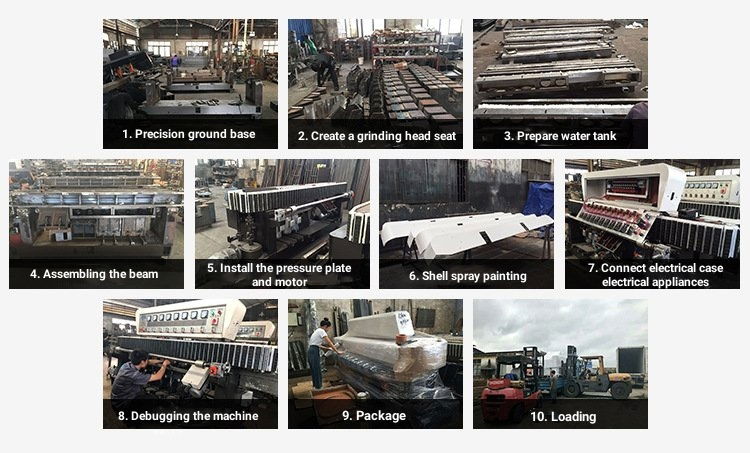

Production Process

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

Mechanical maintenance and upkeep

2. Check, adjust, and correct the grinding wheel every day. The circulating water pipe should be kept unimpeded at all times, and the water should be changed frequently to avoid the water pipe being blocked by the dirt in the water tank.

3. When changing the water, please unplug the power plug first, then take out the water tank, dump the wastewater, and clean the scale in the water tank and on the filter.

4. The chains, gears, screw sliders, etc. of the glass edging machine should be filled with lubricating grease regularly.

5. When suspending use, the surrounding environment of the glass edge grinder should be kept dry, and the equipment shell should be wiped frequently with a rag to prevent it from rusting.

6. Timely check whether the gaps between the various moving parts of the equipment have become larger, which will help maintain the accuracy of the workpiece.

7. When using a glass edger to process small-format glass, be sure to pay attention to whether the splint is flat to ensure that the small glass is clamped smoothly.

8. The continuously variable transmission and the turbo box should be filled with oil regularly to prevent the internal transmission parts from wearing out. Note: The residual oil must be drained before adding engine oil.

6 Main types and characteristics of glass edge grinding machines?

1. Single-arm special-shaped edge grinding machine (referred to as special-shaped machine or single-arm machine)

The biggest features of the special-shaped machine are its wide range of uses and low price. The special-shaped machine can grind straight edges, round edges, duckbill edges, and bevel edges; it can grind round workpieces, as well as oval and special-shaped workpieces. Install a template on the independent suction cup and use a special-shaped machine to grind some irregularly shaped workpieces. The structure of the special-shaped machine is simple and the manufacturing cost is relatively low, so the price is relatively cheap. Generally, domestic machines can be purchased for about 20,000 yuan.

2. Linear edge grinding machine

The linear edge grinding machine has three characteristics: first, it has a relatively single purpose and can only grind all kinds of straight edges; second, it can grind continuously and has high production efficiency; third, it can grind larger-sized flat glass. The linear edge grinding machine is the one with the most varieties and specifications among all types of edge grinding machines. According to the different straight edges that can be ground, it can be divided into the following three types:

(1) Linear edge grinding machine (referred to as straight edge machine)

The straight-edge machine can only grind the flat bottom edge and two corners of the glass. According to the number of grinding heads, there are several models including three, five, eight, nine, ten, thirteen, and fourteen grinding heads. Generally speaking, the more grinding heads, the higher the grinding accuracy and production efficiency, and correspondingly the higher the price of the machine. Computer-controlled straight-edge machines (generally with ten or more grinding heads) are more expensive. In recent years, a dual-purpose straight-edge machine that can grind both flat bottom edges and 45° bottom edges has appeared on the domestic market, and its usage is relatively large. There are also edge grinding machines that can grind one or two sets of bottom edges at an angle to each other, called multi-stage edge grinding machines. This type of machine has more grinding heads and is generally computer-controlled, so the price of the equipment is relatively high.

(2) Straight line circle (referred to as circle edge machine)

The round edge machine can grind the round edges, duckbill edges, etc. of glass, and is often used in the processing of furniture and glass. There are also several models of rounding machines with three, five, six, seven, eight, and nine grinding heads.

(3) Straight line beveling machine (beveling machine for short)

Beveling machines are generally used to grind glass bevels of 3~20°. Now, some beveling machines can also grind 45° bevels. Beveling machines are divided according to the number of grinding heads, and there are also models with seven, eight, nine, ten, eleven, and fourteen grinding heads. In recent years, a beveling machine that can grind various wavy patterns on the beveled edge of glass has appeared, called a wave beveling machine.

3. Profile edge grinding machine (referred to as profile machine profiling machine)

The prototyping machine uses templates to accurately position and can accurately grind the straight edges, round edges, duckbill edges, bevel edges, etc. of round or special-shaped glass. The glass ground by this edge grinding machine has an accurate shape, uniform size, and higher production efficiency. high. The use of a template edge grinder requires the production of special templates. When there are many production varieties, not only the cost of making templates is high but also management and replacement of templates are troublesome. Therefore, this type of machine is suitable for production with few varieties but large production batches. Large glass processing. There are also several types of profiling machines, including single-head, double-head, four-head, and six-head models.

4. Internal circle edge grinding machine (referred to as internal circle machine)

The characteristics of the internal circular machine are simple structure and low price, but its use is relatively single. It is mainly suitable for processing the periphery of circles (it can be a perfect circle, an ellipse, or a special-shaped circle). Nowadays, the internal circular machines produced by some domestic factories have longer swing arms, which increases the swing range of the grinding head. This type of machine can not only grind the inner circle but also grind the outer circle. It is also called an internal and external circle edge grinding machine.

5. Linear bilateral edge grinding machine (referred to as bilateral grinding machine)

The characteristic of the double-edge grinding machine is that it can grind two opposite sides of the glass at the same time. It has good processing accuracy and high production efficiency. It is suitable for large-scale glass edge grinding production. Double-edge grinding machines are divided into two types according to their performance: double-straight-edge grinding machines and double-round-edge grinding machines. Among them, double-straight-edge grinding machines are more commonly used. Bilateral grinding machines can be divided into small, medium, and large sizes according to the different widths of glass grinding. Those with a maximum grinding width of less than two meters are called medium and small double-sided grinders. The grinding heads are equipped with four, six, eight, twelve grinding heads, etc. Those with a maximum grinding width of two meters or more are called large double-sided grinding machines. The grinding heads are equipped with sixteen, twenty, twenty-two grinding heads, etc. Large-scale double-sided grinding machines are generally computer-controlled have a high degree of automation and are suitable for grinding large-sized flat glass. However, this equipment is relatively expensive.

6. Other edge grinding machines and special edge grinding machines

In addition to the edge grinding machines introduced above, there are also some edge grinding machines with simple structures and single uses, such as chamfering machines, small disc machines, polishing machines, etc. In addition, some special edge grinding machines are specialized in processing certain products.