3 Minutes to Understand about the Insulated Glass Super Spacer: Must-read for new practitioners.

1. The Origin of the Insulating Glass Super Spacer Strips

The United States is a big energy-consuming country, of which building energy consumption accounts for more than 25%. In order to reduce energy consumption, the United States has carried out many energy-saving reforms. The focus of energy reform is the energy-saving performance of building envelopes. The total energy consumption of building envelopes Among them, the energy consumption of building doors and windows accounted for 49% of their energy consumption. It can be said that building doors and windows are the weakest part of the building’s thermal insulation performance, directly affecting buildings' energy-saving performance. Therefore, improving the thermal insulation performance of doors and windows is the main way to ensure building energy conservation. Energy-saving doors and windows have attracted more and more attention from people and society.

In the 1980s, American Aijie Insulating Glass Technology Co., Ltd. successfully developed the insulating glass super spacer. The spacer does not contain any metal materials and is made of 100% polyester elastic microporous structure material. It can be applied Intermediate system of insulating glass for doors, windows, and curtain walls. The spacer simultaneously solves the contradiction between the energy saving and durability of insulating glass and has caused a revolution in the insulating glass industry, greatly improving the energy-saving effect and service life of door and window glass. At present, super spacers have been widely used in developed countries such as Europe and the United States. With the increasing requirements for building energy saving in various countries worldwide, super spacers are bound to be widely adopted.

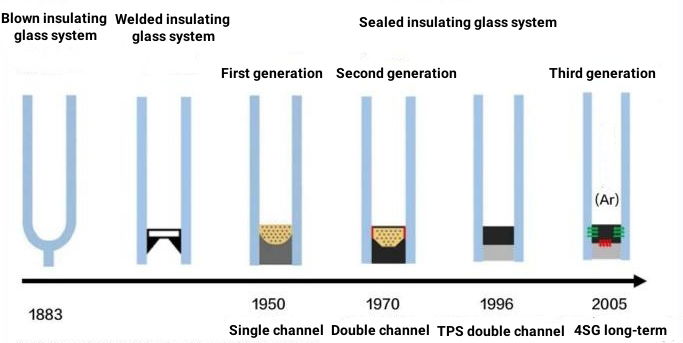

Figure 1 The Insulating Glass Super Spacer Strips 1

2. The Use of Insulating Glass Super Spacer Strips

In the production of insulating glass, the super aluminum spacer only replaces the normal aluminum spacer of ordinary insulating glass. The super spacer contains 40% molecular sieve, and both sides of the spacer have been coated with acrylic structural adhesive, so the process of installing molecular sieve and butyl sealant is omitted in the production process, and molecular sieve and butyl sealant are also omitted.

Material costs and labor costs. The upper equipment is divided into manual equipment and automatic equipment. The manual equipment is simple and easy to operate, which can meet the supporting requirements of the domestic insulating glass production line, and the price is low, the automatic equipment is expensive, and the production efficiency is high. After the spacer is installed, the second piece of glass can be placed, which can be pressed by hand or machine, without hot pressing. Then polysulfide sealant, hot melt butyl sealant, polyurethane can be applied (for door and window glass), or silicone structural sealant (for hidden frame curtain wall glass).

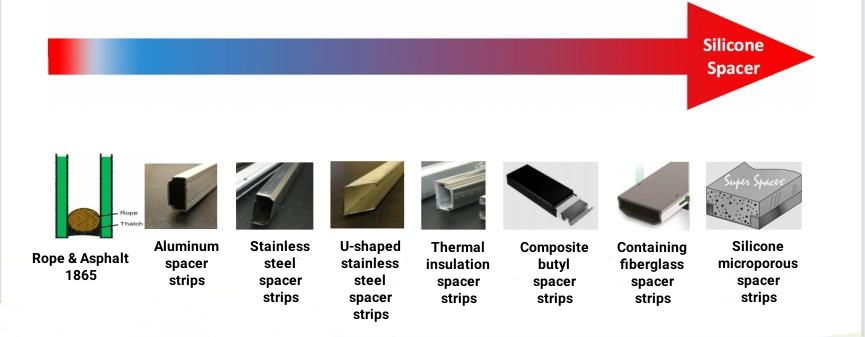

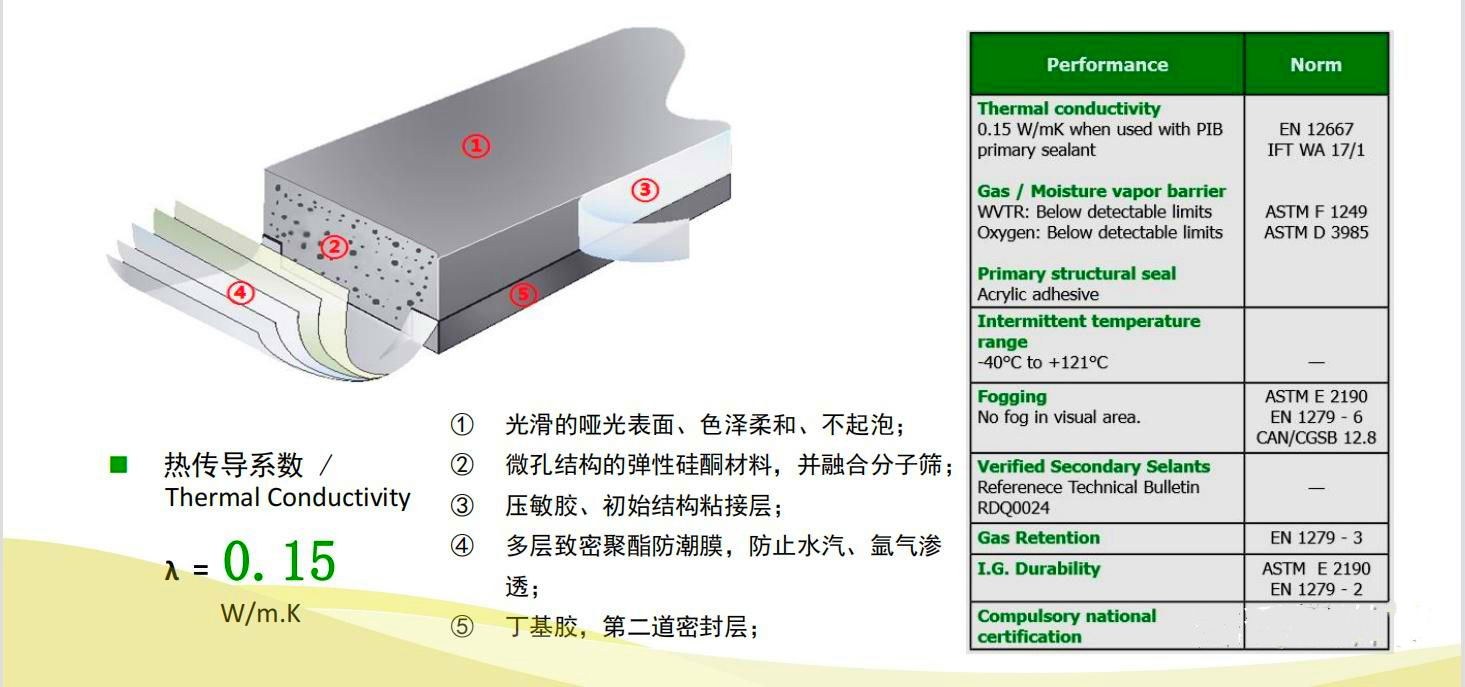

Figure 2 The Insulating Glass Super Spacer Strips 2

Figure 3 The development history of insulating glass super spacer strips

Figure 4 More material composition of insulated glass spacer strips

3. The performance of the Insulating Glass Super Spacer Strips

3.1. Energy-saving

Insulating glass super spacer does not contain any metal materials, it is a thermosetting, elastic, microporous structure, and has the characteristics of strong respiration. The thermal conductivity of super spacers is only 0.168W/m² ·K, which is 1/950 of aluminum spacers and 1/85 of stainless steel spacers, which is almost nonexistent. The ratio of insulating glass made with super spacers to channel aluminum insulating glass can reduce the K value by 0.6-0.8W/m²·K, which has an excellent energy-saving effect, and the K value of the entire window can be reduced by 0.2-0.4W/m²·K.

Figure 5 The energy-saving performance of the insulating glass super spacer strips

3.2 Memory

The super spacer is a thermosetting, elastic, microporous structure with a 100% elastic memory function, which can reduce the stress of insulating glass and reduce the explosion of insulating glass during transportation and installation. At the same time, due to the influence of external factors such as temperature difference, wind load, pressure, etc., it is always in the expansion and contraction of the "pump" movement, forming stress at the edge seal of the glass. When the glass is deflected inward, stress is formed at the chamfered contact point between the inside of the glass and the upper end of the spacer, the glue at the upper end is squeezed inward, and the glue at the lower end, especially the structural glue, stretches outward; when the glass is deflected outward, Stress is formed at the chamfered contact between the inner side of the glass and the lower end of the spacer. The sealant at the upper end, especially the sealing butyl seanlant, stretches outwards to shorten the water vapor channel, and the glue at the lower end, especially the structural glue, squeezes outward and inward. This "pump" movement of insulating glass is inevitable for any structure of insulating glass. But in terms of the degree of performance the consequences, it is different. For trough aluminum spacers, when the insulating glass expands and contracts, because the aluminum metal has rigidity, it cannot absorb or buffer the stress generated by the movement of the glass. Therefore, the stress on the contact surface between the inner side of the glass and the aluminum spacer is very large.

On the contrary, the super spacer has elasticity. When the insulating glass expands and contracts, it will be consistent with the direction of the glass movement, so that the edge cloth stress is minimized, thereby minimizing the possibility of insulating glass bursting, and improving the sealing life of insulating glass. The rigidity of the aluminum spacer not only shortens the sealing life of the insulating glass of this kind of structure but also increases the possibility of the explosion of the insulating glass. This is most prominent in areas with large temperature differences, especially in cold winter areas.

3.3 Durability

All products of Super Spacer have passed the most stringent accelerated aging test in the insulating glass industry. The P1 test life of each hollow glass that passes a week is considered by industry experts to be equivalent to one year of actual use. Insulating glass made of standard super spacers and hot melt butyl glue has passed the P1 test for at least 60 weeks, and the special super spacers performed even better, with a passing test time of up to 125 weeks. At the same time, the insulating glass made of super spacers has a wide operating temperature range, ranging from -51°C to 127°C. In developed countries, the shelf life of insulating glass made with other spacer seal structures is only 5-15 years, while the shelf life of insulating glass made with super spacers is 20-30 years.

3.4 Anti-condensation and Noise Reduction

The heat conduction value of the super spacer is only 0.168 W/m²·K, which is 1/950 of the aluminum spacer. The ratio of the hollow glass and the channel aluminum hollow glass produced by it, the edge temperature can be increased by 9.23℃, which greatly improves the resistance to condensation; The sound volume can be increased by 18%, and the noise reduction ability can be increased by 7-10 decibels.

3.5 Convenience

Using super spacers to make insulating glass, it is easy to operate, easy to learn, and feasible, and greatly improves production efficiency. At the same time, because the super spacer is an elastic material, it is not limited by the shape of the glass in the production, and different special-shaped insulating glass can be produced, and the operation is the same as that of ordinary insulating glass, without the need to increase the production process, which is very convenient. At the same time, there are a variety of colors to choose from, complete specifications, and the width can be selected at will from 2.5 mm to 25 mm.

For more information about LIJIANG Glass insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.