Laminated Glass Series - Application of Laminated Glass.

The previous issue of LIJIANG Glass gave a more detailed explanation of common interlayer film materials and production processes for laminated glass, and briefly understood the application of laminated glass in different fields. In this issue of LIJIANG Glass, we will continue to explore the key points and differences in the application of these laminated glasses in different scenarios to have a more comprehensive understanding of the diversity of their applications.

1. The PVB laminated glass

PVB laminated glass has good safety protection, durable weather resistance, good sound insulation, and heat insulation effects, and can meet the designer's pursuit of beauty and creativity, making it gradually become a popular choice in automotive glass, architectural glass, photovoltaic glass, and other fields.

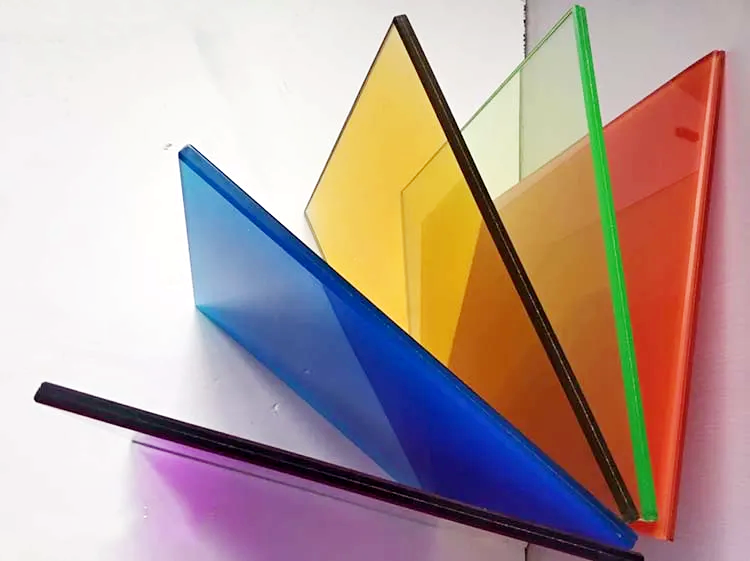

Figure 1 The PVB Laminated Glass

1.1 The automotive field

Car front windshields and side windows usually use PVB laminated glass. Windshields generally use tempered glass with a thickness of 2mm or 3mm as the substrate of laminated glass to enhance the strength and impact resistance of the glass and block the entry of ultraviolet rays. , while maintaining the bonding of the fragments when the glass breaks, improving passenger safety.

Figure 2 The car front windshields of laminated glass 1

Figure 3 The car front windshields of laminated glass 2

1.2 The construction field

At present, PVB laminated glass is widely used in the construction field. The primary purpose of the application is to provide higher safety, especially suitable for schools, hospitals, and other public places that require high safety protection.

In architectural design, PVB laminated glass provides more flexibility and creative space and can be processed into different shapes, sizes, and colors as needed to achieve personalized design effects.

Figure 4 The PVB laminated glass dome 1

In small glass products such as doors and windows, 2mm to 3mm thick glass substrates are usually used, while in large glass products such as daylight ceilings and awnings, 5mm to 10mm thick glass substrates may be required.

Figure 5 The PVB laminated glass dome 2

1.3 The photovoltaic field

PVB laminated glass plays a key role in the packaging of photovoltaic cell modules. It protects against damage to the battery from environmental factors such as UV rays, wind, rain, ice snow, etc. Moreover, PVB laminated glass has excellent insulation and high-temperature resistance properties, ensuring the safe operation of the battery. Its good light transmittance and weather resistance ensure that the battery maintains high photoelectric conversion efficiency during long-term use. With multiple properties, the application of PVB laminated glass helps improve the efficiency and stability of photovoltaic cells.

Figure 6 The photovoltaic cells application of PVB laminated glass

In addition, PVB laminated glass can also be used in aerospace, military, industry, and other fields, and is also used in banks, jewelry stores, museum display cabinets, and other places.

Figure 7 The aerospace application of PVB laminated glass

Figure 8 The museum display cabinets application of PVB laminated glass

Figure 9 The jewelry stores display cabinets application of PVB laminated glass

2. The SGP laminated glass

SGP laminated glass vs PVB laminated glass

Although SGP laminated glass is also used in the construction field and some places, in comparison, its field is not as extensive as PVB laminated glass. The main reasons are as follows:

1. Cost factors: The production cost of SGP laminated glass is relatively high, resulting in its price in the market being higher than that of PVB laminated glass.

2. Awareness: As a new building material, SGP laminated glass has relatively low awareness in the market. Many architects and developers have insufficient knowledge of its performance and benefits.

3. Application scope limitation: SGP laminated glass has better performance than PVB laminated glass in all aspects, so it is usually not used in general construction projects. It is mainly used in some high-end buildings with higher performance requirements such as safety and weather resistance. project.

4. Technology maturity: The production technology of PVB laminated glass is relatively mature, and there are a large number of manufacturers and product options on the market. The production technology of SGP laminated glass is relatively new. Currently, only a few manufacturers can produce it, and there may be certain differences in product specifications and quality.

SGP laminated glass is usually used in curtain walls, doors, windows, skylights, ceilings, stairs, railings of high-rise buildings and places or parts with high safety performance requirements such as shops, banks, showcases, partitions and underwater projects that require impact resistance.

2.1 The Applied to glass curtain wall

Figure 10 The architectural glass curtain wall appliaction of SGP laminated glass

SGP laminated glass for glass curtain wall vs Ordinary SGP laminated glass

Compared with ordinary SGP laminated glass, SGP laminated glass used for glass curtain walls has the following differences:

- More stringent production process

Including more precise cutting and edge polishing to ensure the overall beauty and safety of the glass curtain wall.

- Thinner glass substrate

To better adapt to the structural and design requirements of high-rise buildings.

- More layers

To improve the overall strength and safety of SGP laminated glass, while improving the thermal and sound insulation effects.

- Special intermediate material

High-strength sealant such as polyurethane ensures higher bonding strength and durability. The laminated film layer also requires a more automated laminated glass production line for thermal processing.

Figure 11 The SGP laminated glass adhesive

2. Apply to underwater engineering

Figure 12 The undersea tunnel application of SGP laminated glass

Under this circumstance, more attention needs to be paid to the water resistance, drug resistance, corrosion resistance, and transparency of SGP laminated glass. The following methods are usually used to improve these properties.

- Using the vacuum injection method, the SGP sealant sealing is injected into the laminated glass to ensure that the SGP sealant sealing is evenly distributed and fully penetrates the interlayer.

- After surface treatment, such as applying a special coating or coating, it can effectively prevent moisture penetration and chemical corrosion, ensuring the long-term use of the glass.

- Use high-quality, corrosion-resistant glass substrates, such as ultra-white (low-iron) glass, etc.

Figure 13 The undersea tunnel application of SGP laminated glass

3. Used in doors, windows, skylights, and ceilings of high-rise buildings

This requires SGP laminated glass to have higher light transmittance and thermal insulation properties to provide better indoor light and thermal comfort.

Figure 14 The high-rise building's ceilings application of SGP laminated glass

- Considering the glass substrate, float glass or high-transmittance tempered glass will be used.

- Considering the thickness of the interlayer, appropriately control the thickness of the interlayer to reduce the refraction and scattering of light.

- From the perspective of sandwich materials, add insulation materials, such as vacuum layers or insulation gas, to reduce heat transfer.

3. The EVA laminated glass

Compared with PVB laminated glass and SGP laminated glass, EVA laminated glass is prone to aging. Especially in outdoor environments, it is easily affected by ultraviolet rays and moisture and causes yellowing and aging. However, EVA laminated glass is still widely used in the construction industry, mainly because of its other excellent properties and characteristics, such as strong impact resistance, good sound insulation, good heat insulation, etc.

Figure 15 The wide construction industry application of EVA laminated glass

In the construction field, to make up for the shortcomings of easy aging of EVA laminated glass, high-performance substrates, anti-UV coatings, and multi-layer structures are usually used to enhance durability and service life.

Figure 16 The interior partition application of EVA laminated glass

In addition to the construction field, due to the characteristics of strong fluidity and high viscosity of EVA interlayer film, it is often made into decorative laminated glass and is widely used in various scenes, such as indoor partitions, decorative curtain walls, art installations (such as glass paintings, etc.), furniture (Such as glass coffee tables, glass tableware, etc.), both decorative and practical.

Figure 17 The glass paintings application of EVA laminated glass

Figure 18 The glass tea table application of EVA laminated glass

The applications and characteristics of different laminated glass are introduced here. Do you have a new knowledge and understanding of laminated glass? If you have any questions or want to know more about other knowledge about glass processing industry, please leave a message in the comment area.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.