Why IG Units Fail in Winter (Causes, Prevention, and Best Manufacturing Practices)

Insulating Glass (IG) units are engineered to maintain energy efficiency, reduce noise, and provide long-term performance in both residential and commercial buildings. Yet, many building owners begin to notice fogging, condensation, or seal failure specifically during winter—the season when IGUs should perform their best.So why do IG units fail more often in cold weather? And how can manufacturers minimize winter-related failures?

This guide explains the core reasons and offers practical solutions from a production perspective.

1. Why IG Units Are More Vulnerable in Winter

1.1 Extreme Temperature Differences

Winter creates the largest temperature gradient of the year.

- Inside: +18°C to +25°C

- Outside: –10°C to –30°C

This sharp contrast increases pressure inside the IG unit. Weak secondary sealing or uneven butyl coating can cause sealant fatigue and eventually micro-leakage.

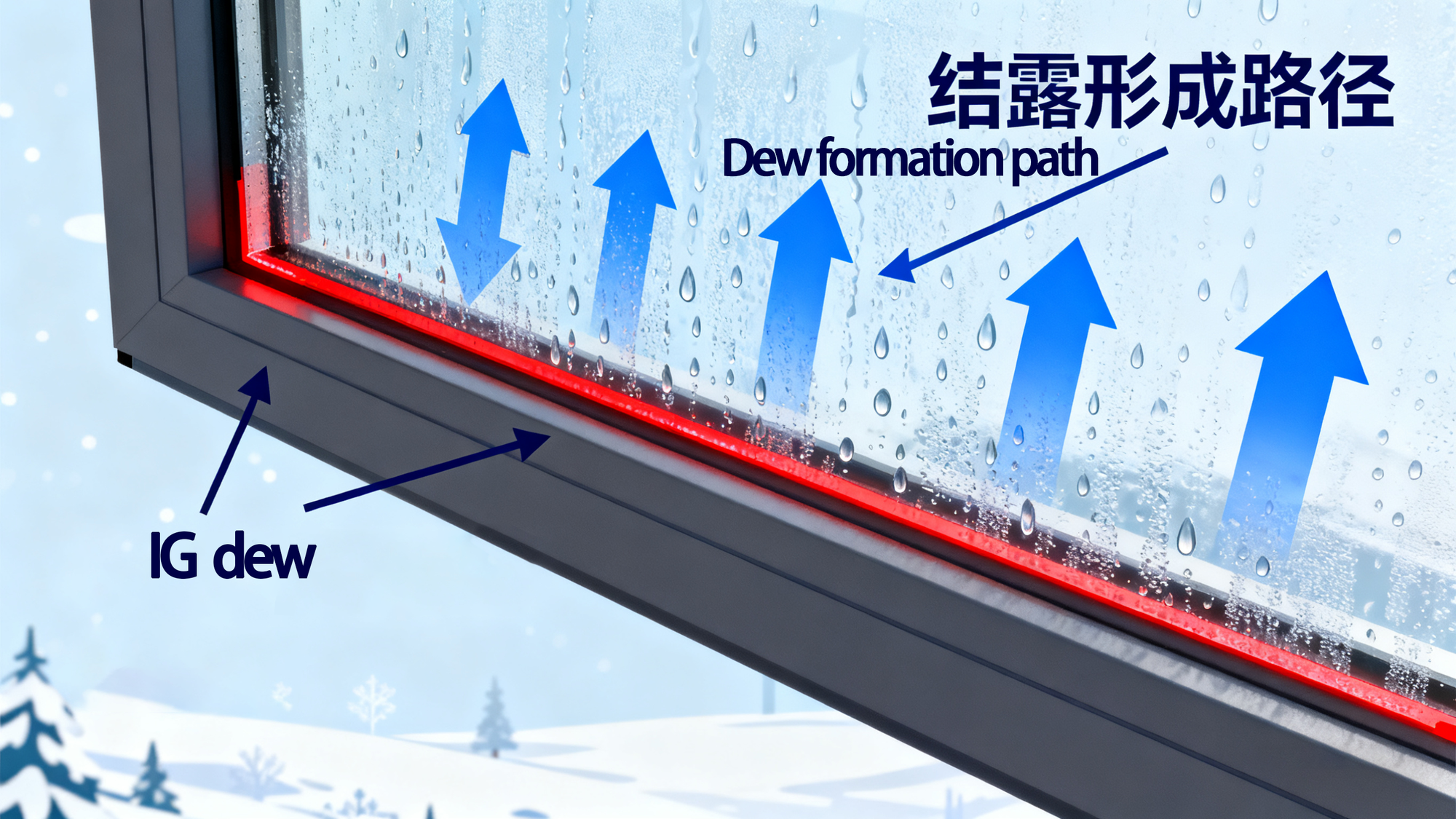

1.2 Moisture Ingress Accelerates in Cold Conditions

If the primary butyl seal is too thin or not continuous, cold air contracts and “pulls” moisture inward. This leads to:

- Fogging or mist between the panes

- Frost formation inside the IGU

- Silica gel desiccant saturation

1.3 Poor Spacer Adhesion at Low Temperatures

Aluminum, warm-edge spacers, and sealants contract at different rates.

If production does not ensure proper compression and butyl temperature control, low temperatures will cause:

- Gaps between spacer and glass

- Sudden pressure imbalance

- Seal separation

1.4 Expansion–Contraction Cycling

Winter days and nights create rapid thermal changes.

This repeated expansion and contraction stresses the IGU, making manufacturing defects more obvious.

2. Common Winter Failure Symptoms

2.1 Internal Condensation (Fog Between Glass)

This is the most common sign of seal failure, meaning moisture has entered the cavity.

2.2 “Milky” or Cloudy Insulating Glass

Desiccant inside the spacer becomes saturated and begins to break down, creating a permanent haze.

2.3 Edge Seal Cracks

Often caused by:

- Poor secondary sealant curing

- Insufficient butyl thickness

- Excessive winter temperature differences

2.4 Argon Gas Leakage

Argon escapes faster in winter due to pressure and viscosity changes.

This reduces the IGU’s thermal performance noticeably.

3. Manufacturing Errors That Lead to Winter Failures

3.1 Inaccurate Butyl Coating

If the butyl seal is not uniform, leaks occur naturally in cold months.

Common process mistakes include:

- Butyl temperature too low

- Uneven coating pressure

- Poor spacer alignment

Recommended solution:

Use an Automatic Insulating Glass Butyl Extruder Machine for consistent coating.

👉 Internal link: /insulating-glass-butyl-coating-machine/

3.2 Poor Washing and Drying Quality

Cold weather amplifies the effect of microscopic dust or moisture inside the IGU.If the washing machine has:

- low air-knife pressure

- weak heating

- insufficient demineralized water filtration

—it will lead to moisture residue that freezes and expands in winter.Recommended solution:

Upgrade to a Vertical Glass Washing & Drying Machine.

👉 Internal link: /vertical-glass-washing-machine/

3.3 Improper Sealant Curing

Sealants require specific temperature, humidity, and curing times.

If factory conditions do not meet these requirements, winter failures are almost guaranteed.Typical reasons:

- Secondary sealant mixed poorly

- Low workshop temperature

- Unstable mixing ratio in the sealing robot

Recommended solution:

Use a Fully Automatic IG Sealing Robot to ensure stable ratios.

👉 Internal link: /automatic-ig-sealing-robot/

3.4 Weak Gas Filling Control

Argon filling accuracy directly affects winter performance.

Low gas concentration = faster fogging in winter.Recommended solution:

Install an Automatic Argon Gas Filling Machine with online detection.

👉 Internal link: /argon-gas-filling-machine/

4. How to Prevent IG Unit Failure in Winter

4.1 Maintain Minimum Butyl Thickness

Industry standard: 0.3–0.5 mm continuous butyl line

Automated butyl machines ensure consistency year-round.

4.2 Keep Production Line Temperature Stable

Winter workshop temperature should not be below 18°C

Especially crucial for:

- butyl application

- sealant mixing

- gas filling

- glass washing/drying

4.3 Improve Spacer Preparation

Warm-edge spacers require careful handling:

- Maintain storage temperature

- Avoid bending cracks

- Ensure clean and static-free bonding surface

4.4 Use Automated and High-Precision Equipment

Automation reduces human errors that become bigger problems in winter:

- automatic washing

- automatic spacer bending

- automatic sealing

- automatic gas filling

- automatic butyl coating

LJ Glass Machinery production lines are designed to reduce winter failure rates by optimizing every stage.

👉 Internal link: /automatic-insulating-glass-production-line/

5. Conclusion

Winter exposes weaknesses in IGU production — but most winter failures are preventable with proper equipment, stable workshop conditions, and strict process control.Manufacturers who invest in automation and quality control experience:

- Fewer returns and warranty issues

- Higher customer satisfaction

- Longer IGU lifespan

- Stronger brand reputation

If you want to upgrade your IGU production line to reduce winter failure rates, LJ Glass Machinery provides complete automated solutions for high-performance insulating glass.