Insulating glass triple energy-saving boosts the development of passive house doors and windows.

The origin of the passive house

The concept of a passive house originated from a discussion in May 1988, proposed by Prof. Bo Adamson of Lund University in Sweden and Dr. Wolfgang Feist of Institutfür Wohnen und Umwelt in Germany. After that, after in-depth research and funding from the Hesse state government in Germany, the concept of the passive house was gradually established. The first passive houses were built in Darmstadt, Germany in 1990. Founded in Darmstadt in 1996 (Passivhaus-Institut), it promotes and regulates passive house standards. Since then, more and more passive houses have been built. Passive house energy efficiency indicators based on German climatic conditions include annual heating (cooling) demand per unit area ≤ 15kWh/(m2a); total primary energy demand (including heating, cooling, ventilation, lighting, hot water, auxiliary energy, and household appliances) ≤ 120kWh/(m2a); the heat transfer coefficient of external doors and windows Uw≤0.8W/(m2·K); the air tightness of the building satisfies n50<0.6/h, that is, under the condition of indoor and outdoor pressure difference of 50 Pa, hourly The number of air changes shall not exceed 0.6 times.

In the 1870s, architects and scientists began to study zero-energy-consumption houses. It is very hard to reduce energy consumption to zero. Although it is feasible from a theoretical point of view, due to the extremely high cost and complex process, So far, it has only stayed at the level of scientific research projects. Low-energy buildings (heating energy demand<70 kWh/m²a) are rapidly gaining popularity due to their superior cost performance. If the passive house is combined with more solar power generation equipment, then a "zero energy" house will be achieved, because no one wants to live in a house without a refrigerator and a TV.

As of 2010, more than 13,000 passive energy-saving houses have been put into use in Germany alone (37,000 in the world in 2012), including single-family houses, apartments, schools, office buildings, swimming pools, etc. Especially multi-story buildings can better reflect their advantages. For example, the "Lodenareal" project in Innsbruck, which can accommodate 354 residents, is the largest passive building in the world.

Figure 1 The "Lodenareal" project in Innsbruck 1

The basic principle of Passive House is energy efficiency. Outstanding thermal insulation walls, innovative door and window technology, efficient building ventilation, and electrical energy saving are the basis for solving energy efficiency.

2. Requirements for the physical properties of doors and windows in passive houses

Some countries, such as developed countries such as the United States, or developing countries such as Brazil, have vast territories, span multiple latitudes, and have complex and diverse climates. The demand for heating, cooling, and total primary energy consumption needs to be based on different regional climate characteristics and building types. The indicators are adjusted accordingly. In severe cold and cold regions, the heating energy consumption of passive houses in winter should be 1/10-1/4 of ordinary energy-saving buildings, which can eliminate the dependence on traditional fossil fuels; in areas with hot summer and cold winter, passive houses do not have centralized heating indoors in winter. The temperature can reach above 20℃, and the air-conditioning load in summer is only 1/3 of that of ordinary buildings, which minimizes the use time of air-conditioning.The requirements for the external windows of passive houses are to have good lighting, heat insulation, and thermal insulation properties. The Uw value of the whole window can be calculated by the following formula:

Among them:

Uw—the heat transfer coefficient of the whole window, W/(m2·K);

Ag - the area of the insulating glass, m2;

Ug—the heat transfer coefficient of the center of the insulating glass, W/(m2·K);

If—the heat transfer coefficient of the profile, W/(m2·K);

Af — the area of the profile, m2;

Lg — the perimeter of the edge of the insulating glass, m;

Ψg —Linear heat transfer coefficient at the edge of the insulating glass, W/(m·K).

It can be seen from the above formula that the heat transfer coefficient U value of the window frame profile, the heat transfer coefficient U value of the center of the insulating glass, and the linear heat transfer coefficient Ψ value of the glass edge are the three main factors to reduce the U value of the whole window. Reasonable selection is an important way for doors and windows to meet the requirements of energy-saving indicators.

3. The triple energy-saving insulating glass system

The heat is lost in three ways: radiation, convection, and conduction. The triple energy saving of insulating glass is aimed at systematic energy saving: the use of Low-E glass can reduce radiation heat transfer, the inert gas filling can reduce convection heat transfer and flexible warm edge heat insulation strips are used, which can weaken heat conduction.

3.1 Triple energy-saving technical measures for insulating glass

(1) Reasonable selection of Low-E glass. According to the climatic characteristics of different regions, different varieties of Low-E glass are selected.

(2) Optimize the air spacer of insulating glass and fill it with inert gas.

(3) Adopt flexible warm edge sealing technology. The high-quality flexible warm edge has a very low Ψ value of the linear heat removal coefficient of the insulating glass edge. Flexible sealing technology accommodates the breath of the glass, maximizing inert gas retention. The high-quality flexible warm edge also reduces the Ψ value of the linear heat transfer coefficient at the edge of the insulating glass, making the surface temperature difference between doors and windows smaller and reducing cold radiation.

(4) The use of glass with different thicknesses is beneficial to improve the sound insulation performance of the exterior windows.

3.2 Calculation of the whole window of triple energy-saving insulating glass system

According to European standards, choose the triple energy-saving insulating glass system to calculate the whole window configuration that meets the requirements of the passive house (see Table 1).

| Specification | Configuration | Center U value of insulating glass |

| Triple glass double insulating glass | 5Low-E+12.7Ar+4+16Ar+5Low-E (Flexible warm edge insulating glass) | 0.58 |

According to a formula 2-1, the profile accounts for 25% of the entire window area, the high-quality flexible warm edge ψ=0.02, the glass perimeter is 4.5m, the Uw of the whole window = 0.8, calculate the heat transfer coefficient of the window frame profile:

0.8=0.25×Uf+0.75×0.58+0.02×4.5/(0.75+0.25)

Uf=1.1 W/(m2·K).

According to the calculation results, as long as the heat transfer coefficient of the profile can reach Uf≤1.1W/(m2·K), the requirement of the heat transfer coefficient U≤0.8W/(m2·K) of the whole window of the passive house can be met. Therefore, doors and windows with different profiles (plastic windows/fiberglass windows/solid wood windows/aluminum-clad wood windows) can be selected according to design requirements and budget.

3.3 Calculation of heat transfer coefficient of external windows of different standards

Calculating the heat transfer coefficient of external windows, the calculation parameters of European standards, American Window and Door Evaluation Committee standards, and my country's industry standards are different, so the calculation results are also different. See Table 2 and Table 3.

Table 2

| Standard system type calculation boundary condition parameters | ISO (EN) standard system: ISO15099 | US NFRC standard system: NFRC100 /NFRC200 | Chinese standard system: JGJ/T151 | |

| Winter | Indoor air temperature(℃) | 20 | 21 | 20 |

| Outdoor air temperature(℃) | 0 | -18 | 20 | |

| Indoor convection heat transfer coefficient W/(m2·K) | 3.6 | ASHRAE /NFRC | 3.6 | |

| Outdoor convection heat transfer coefficient W/(m2·K) | 20 | 26 | 16 | |

| Outdoor convection heat transfer coefficient of door and window frames W/(m2·K) | / | / | 8 | |

| Outdoor convection heat transfer coefficient at the edge of the glass near the frame (within 63.5mm) W/(m2·K) | / | / | 12 | |

| Solar radiation illuminance W/(m2·K) | 300 | 0 | 300 | |

Summer | Indoor air temperature(℃) | 25 | 24 | 25 |

| Outdoor air temperature(℃) | 30 | 32 | 30 | |

| Indoor convection heat transfer coefficient W/(m2·K) | 2.5 | ASHRAE /NFRC | 2.5 | |

| Outdoor convection heat transfer coefficient W/(m2·K) | 0 | 15 | 16 | |

| Solar radiation illuminance W/(m2·K) | 500 | 783 | 500 | |

Table 3

| Glass configuration | China JGJ/T151 | US NFRC100 | European EN673 | |

| Summer daytime | winter night | |||

| 5Low-E+9Ar+5 | 1.75 | 1.91 | 1.81 | 1.9 |

| 5Low-E+12Ar+5 | 1.67 | 1.70 | 1.68 | 1.7 |

| 5Low-E+16Ar+5 | 1.71 | 1.53 | 1.73 | 1.5 |

It can be seen from Table 3 that due to the different calculation standards used, the calculation results of the heat transfer coefficient of the glass differ by about 0.2W/(m2·K), which will have a corresponding impact on the heat transfer coefficient of the entire window.

4. The characteristics of passive houses are introduced

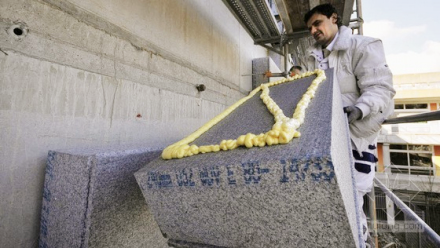

The insulation layer of the outer protective structure is particularly thick. As shown in Figure 2 below:

The yellow part is the insulation layer, the left side is the thickness of the insulation layer of the general house, and the right side is the thickness of the insulation layer of the passive house.

Figure 3 Clay brick sample with an interior cavity filled with insulation material

Figure 4 The construction site where extra-thick foam insulation board is pasted on the exterior wall

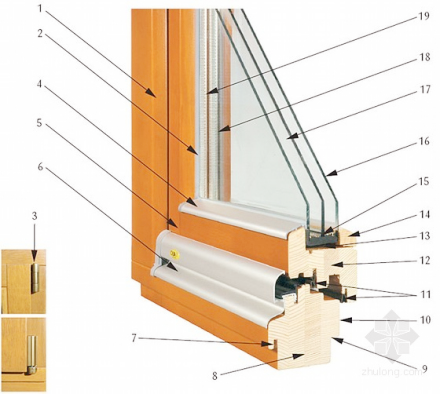

Figure 5 Three-dimensional cutaway diagram of passive house wall and window structure

Super energy-saving window

A "passive house" is required not only to reduce heat loss but also to increase insulation and comfort. Indoor side glass can exceed 17°C even in cold frosty weather.

Indicators of passive house windows:

A. Uw value≤0.8W/(m²K)

B. Ug-1.6 W/(m²K)·g< 0, the g value is generally around 0.5.

This condition is satisfied,It shows that the solar thermal energy obtained by passive windows in winter is greater than the energy lost due to conduction.

Figure 6 Three-layer glass insulation window three-dimensional cutaway diagram

Passive houses have extremely high requirements for the performance of windows. At present, there are very few window companies in China that can produce such windows. But the good news is that in 2012, some domestic window companies began to contact the “Passivhaus-Institut” mentioned above to discuss and cooperate on a series of issues such as energy saving of building exterior windows. And has developed a product that meets the passive house window standard - Senying PASSIVE120. The window frame adopts a super thermal insulation composite frame, and the glass adopts a three-glass two-chamber structure (double Low-E glass, double warm edge, argon filling), which makes it have super thermal insulation performance. It can meet the thermal insulation requirements of a "Passive House".

Some parts of the building envelope, under the action of indoor and outdoor temperature differences, form areas with relatively dense heat flow and low inner surface temperature. These parts become bridges with more heat transfer, so they are called thermal bridges and sometimes cold bridges.The so-called thermal bridge effect, that is, the physical effect of heat conduction, because there are concrete ring beams and structural columns at the floors and corners, and concrete materials have better thermal conductivity than masonry materials (the thermal conductivity of concrete materials is the thermal conductivity of ordinary bricks). At the same time, due to poor indoor ventilation, the large temperature difference between indoors and outdoors in late autumn and early winter, frequent contact between hot and cold air, uneven heat conduction of wall insulation layer, resulting in thermal bridge effect, resulting in condensation and mildew on the inner wall of the house even dripping.The thermal bridge-free building structure of Passive House can avoid the above phenomenon.

Good seal

There are strict requirements for gas loss during positive and negative pressure detection. Because the sealing is not good, convection of cold and hot gas will occur, resulting in heat loss.

Ventilation system

Active ventilation (counter-flow air/air heat exchange) provides high-quality air while at least 75% of the waste heat from the exhaust air is used to heat the incoming fresh air without mixing the exhaust and fresh air. Because the passive house is very well sealed, the air exchange can be optimized and strictly controlled at 0.4/h (air exchange rate per hour).

The outdoor fresh cold air first enters the core control components of the indoor energy recovery ventilation system through the green pipeline lines. The exhaust gas containing a certain amount of heat in the room is also collected into the core control components of the indoor energy recovery ventilation system through the yellow pipeline lines. An energy recovery ventilation system that retains most of the heat in the exhaust air and heats the fresh air entering the room. The preheated fresh air is sent to each room through the blue pipeline. The exhaust gas after heat recovery is discharged to the outside through pipeline lines.

Indoor energy recovery ventilation system, solar hot water system + boiler hot water system + floor heating system + radiator heating + domestic hot water - hot water exchange and storage hybrid system, schematic diagram.

5. Summary and reflection

It is recommended in the international standard "Passive Low-Energy Building": use three layers of Low-E glass, fill inert gas (argon or krypton) between the glass, the heat transfer coefficient of insulating glass Ug≤0.8W/(m2·K), and the glass space The strips are made of non-metallic spacers with good weather resistance, and the solar heat gain coefficient SHGC of the insulating glass is greater than or equal to 0.5. The window frame is usually a multi-cavity wood frame or plastic frame, filled with high-efficiency thermal insulation core material, and the heat transfer coefficient value of the whole window reaches 0.8-1.0W/(m2·K).

The triple energy-saving insulating glass will have a variety of choices according to different U values, so the types of profiles selected will be wider and the cost will be lower. It lays a good foundation for the large-scale promotion of passive houses.

The promotion of passive houses will benefit future generations. The triple energy-saving insulating glass system provides economical and reasonable products for energy-saving doors and windows of passive houses and low-energy buildings in the world.

For more information about insulating glass processing equipment and glass processing machinery, please click here to learn more.