Analysis of factors affecting the appearance flatness of curtain wall insulating glass.

1. The preface

The flatness of the glass appearance has a great influence on the overall appearance of the curtain wall. A glass curtain wall with good flatness gives people a high-end and solemn feeling, just like a person wearing crisp and decent high-end clothes. A glass curtain wall with poor flatness makes it look like a person wearing a dress with many wrinkles.

LIJIANG Glass was communicated and discussed with glass manufacturers, design companies, and curtain wall construction companies, and reviewed relevant information and literature. It is not only the glass itself that affects the smoothness of the appearance of glass, but also factors such as design, installation, ambient light, and shadow. The following analysis may provide some references.

2. The influence of the flatness of the glass itself

The flatness of the glass itself is mainly determined by the quality of float glass production and tempered glass processing. The flatness of untempered float glass is better than that of tempered glass, while the flatness of tempered glass depends on the tempering equipment and process.

The international standard for flat glass was annouced ted that glass appearance quality requirements are divided into ordinary grade flat glass and high-quality processing grade flat glass. The curvature of ordinary-grade flat glass should not be greater than 0.2%, and the curvature of high-quality processing grade The curvature of flat glass should not be greater than 0.1%, and high-quality processing-grade flat glass should be preferred for curtain wall glass.

At present, the curtain wall glass we use is roughly divided into insulating tempered glass and insulating laminated semi-tempered glass. Glass will deform after being tempered. The control of deformation depends on the tempering glass equipment and process. Advanced tempering glass equipment uses a double-chamber heating furnace and a specially designed blowing port to reduce the deformation of the glass by extending the heating time to balance the glass temperature and uniform blowing cooling. Semi-tempered glass generally needs to be made into laminated glass, mainly from the perspective of safety glass use. Whether it contributes to the flatness of the glass will not be considered in this article.

For tempered glass produced on the same production line, the thicker the glass, the smaller the impact of tempering processing on flatness, and the flatter the glass. When the thickness is greater than 15mm, it is difficult to distinguish whether it is tempered or not based on the appearance of flatness alone.

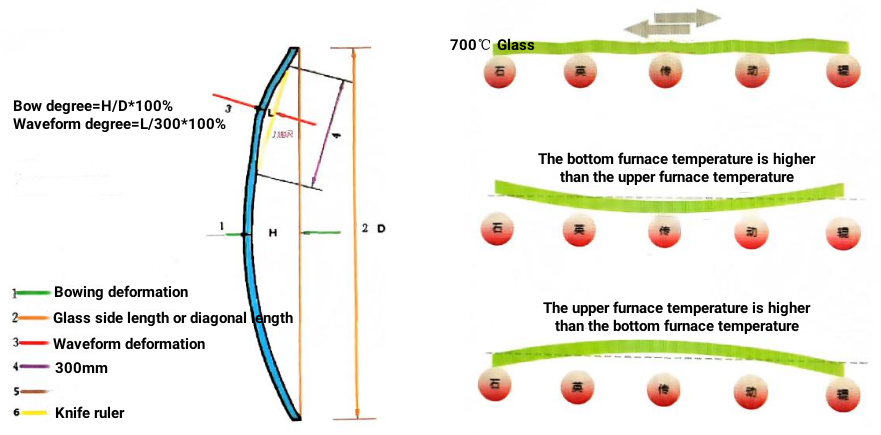

The industry standard of tempered glass divides the flatness into two types: wave deformation and bow deformation. Tempered wave deformation will produce wavy or even folding line deformation, which will seriously affect the smoothness of the appearance of the curtain wall; and the two short sides at the front and rear along the direction of tempering into the furnace, because it is easier to absorb heat, there will be a warpage deformation of about 150mm wide. The tempered bow will produce a "thin waist" or "bucket waist" deformation similar to that caused by temperature/pressure differences.

3. The impact of seasonal temperature differences on the flatness of insulating glass

The inside of the insulating glass is sealed gas. In summer, when the temperature of the gas increases, it expands and squeezes the outer convexity of the glass. In winter, when the temperature of the gas cools and shrinks, it absorbs the inner concavity of the glass. In addition, the temperature or air pressure of the place of use and manufacture also affects the concavity and convexity. This is the so-called insulating "convex and concave belly" phenomenon of glass, how much positive and negative pressure is generated by the expansion or contraction of gas?

According to the isovolumetric change process of the ideal gas equation of state, it can be known that:

P0/T0=P/T

In the formula:

P0, P---Air pressure (Pa) in the insulating glass cavity in winter and summer;

T0, T---The gas temperature (K) in the insulating glass cavity in winter and summer.

The pressure difference between winter and summer is:

△P=(△T/T0) P0

It can be seen that when the temperature difference between winter and summer is 27.3°C, △P is about 10% of P0, that is, one-tenth of the atmosphere or 10kPa. This additional pressure is enough to cause convex and concave deformation of the glass, and the degree of deformation is equivalent to forming two insulated pieces. It is related to factors such as the thickness of the glass, the geometry and size of the glass, and the elasticity of the sealant on the edge of the insulating glass.

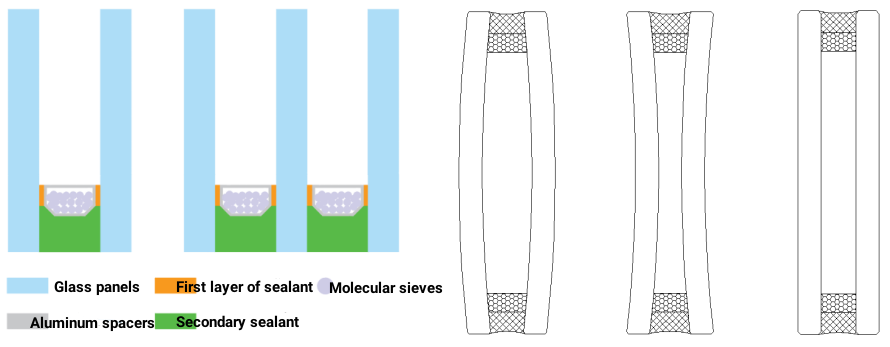

To solve this problem, the thickness of the insulating outer glass can be increased, that is, a non-equal thickness insulating glass structure can be used, because the visual sense of flatness is mainly determined by the outer glass, and the thinner inner glass has greater deformation, soothing without the pressure effect, the deformation of the outer glass will be weakened and the appearance flatness will be improved.

In addition, insulating glass is composed of two or more pieces of glass that are spaced and sealed. Each glass surface will produce reflected light. If the glass surfaces are not completely parallel and the reflected light does not completely overlap, ghost deformation will occur.

4. The influence of glass frame and installation

For hidden frame glass curtain walls, the process of making curtain wall panels with frames in the factory is very important to control the flatness. When the frame is attached horizontally, the middle part of the glass will be deformed due to gravity falling. The structural adhesive will form permanent deformation after curing, so measures should be taken to maintain the frame. The flat state of the glass during the process.

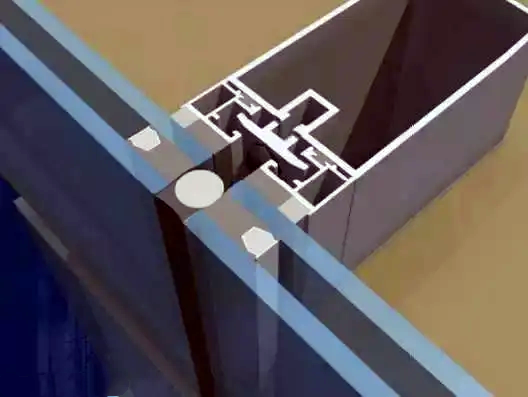

For exposed frame and semi-hidden frame glass curtain walls, the glass is generally fixed on the inner keel with aluminum alloy pressing plates or pressing blocks through machine screws. When the pressing plates and pressing blocks are arranged in a segmented spacing type if there is an installation gap between the inner side of the glass and the keel, or the pressure plate does not adopt a fixed distance type. When the pressure plate is fixed, an installation load will be applied to the glass here, causing the glass to deform at the fixed part of the pressure plate.

Whether the pressure used to fix the glass beading is uniform has a great impact on the smoothness of the appearance. Using a torque wrench to tighten the beading screws is an effective method to reduce the deformation of the glass edge.

Regardless of the form of the curtain wall, the process of installing glass will cause bending or distortion of the glass. The thicker the glass, the stronger the stiffness and the smaller the deformation caused by the same external force.

5. The influence of ambient light and shadow

The flatness of glass can be divided into objective flatness and visual flatness. The three factors discussed above all belong to the category of objective flatness. There is no flat large-area mirror surface in the real world. The very flat surfaces we see are either non-mirror material surfaces, such as metal plates, ceramic tiles, walls, and other diffuse reflective material surfaces, or they are mirror surfaces that reflect shadowless background light. Although the objective flatness of the mirror may not be good, the visual flatness may be very good.

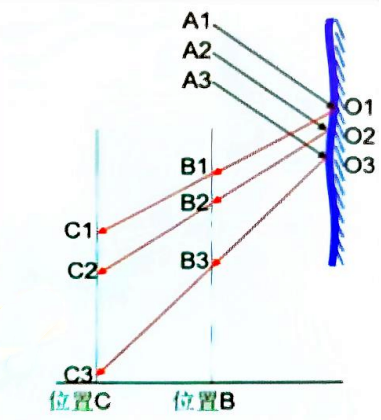

What affects the appearance of flatness of curtain wall glass is visual flatness. Environmental light and shadow are the most important factors affecting visual flatness. This is because regardless of the objective flatness, when there is no imaging target, it is impossible to see whether the glass is deformed, such as In observing the glass against a uniform sky background, no glass deformation can be seen at all, and the visual flatness is very good. The glass is deformed but looks very flat.

When observed in a light and shadow environment with surrounding buildings as reference objects, the image reflected by the glass will amplify the deformation of the glass. The objective flatness will not change but the visual flatness will become worse. This part of the area belongs to the light sensitivity of the building. district. When the imaging target is linear objects such as eaves, straight pipes, and linear outline buildings, it can be seen that the glass is deformed. When the position of the glass and the imaging target remain unchanged, the farther the observation distance is, the more obvious the observed image deformation will be.

6. Summary

- To summarize the above analysis results, to improve the flatness of curtain wall glass, we should first improve the objective flatness of the glass. The simplest and most effective way is to increase the thickness of the glass.

- Choose high-quality processing-grade flat glass and strictly control the deformation rate.

- Increase the thickness of the outer glass sheet at a cost-controllable cost, alleviate the deformation rate, and reduce the deformation of the outer glass sheet due to changes in the internal air pressure of the insulating glass.

- Effectively control the extrusion of glass by stressed components and improve the flatness of glass keel installation. Fixed-distance pressing blocks are used at the hidden frame position to avoid direct extrusion of the glass by the pressing blocks; full-length pressing plates and reasonably designed exposed frame keels are used at the exposed frame position. The structure prevents local deformation.

- The thicker the glass, the smaller the temperature difference deformation. The improvement in objective flatness will naturally benefit the visual flatness. Especially when the surrounding building image environment is complex, at least the thickness of the main facade glass or light-sensitive area glass should be increased. Engineering practice has confirmed the effectiveness of this method.

- When controlling the imaging environment, we should focus on the imaging environment around the glass curtain wall from the main entrance and exit viewing angles. The facade model should simulate the main viewing angles, consider the impact of the imaging environment on the glass surface, evaluate the impact of the imaging environment (especially the linear environment) on the viewing angle, and control the glass surface.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.