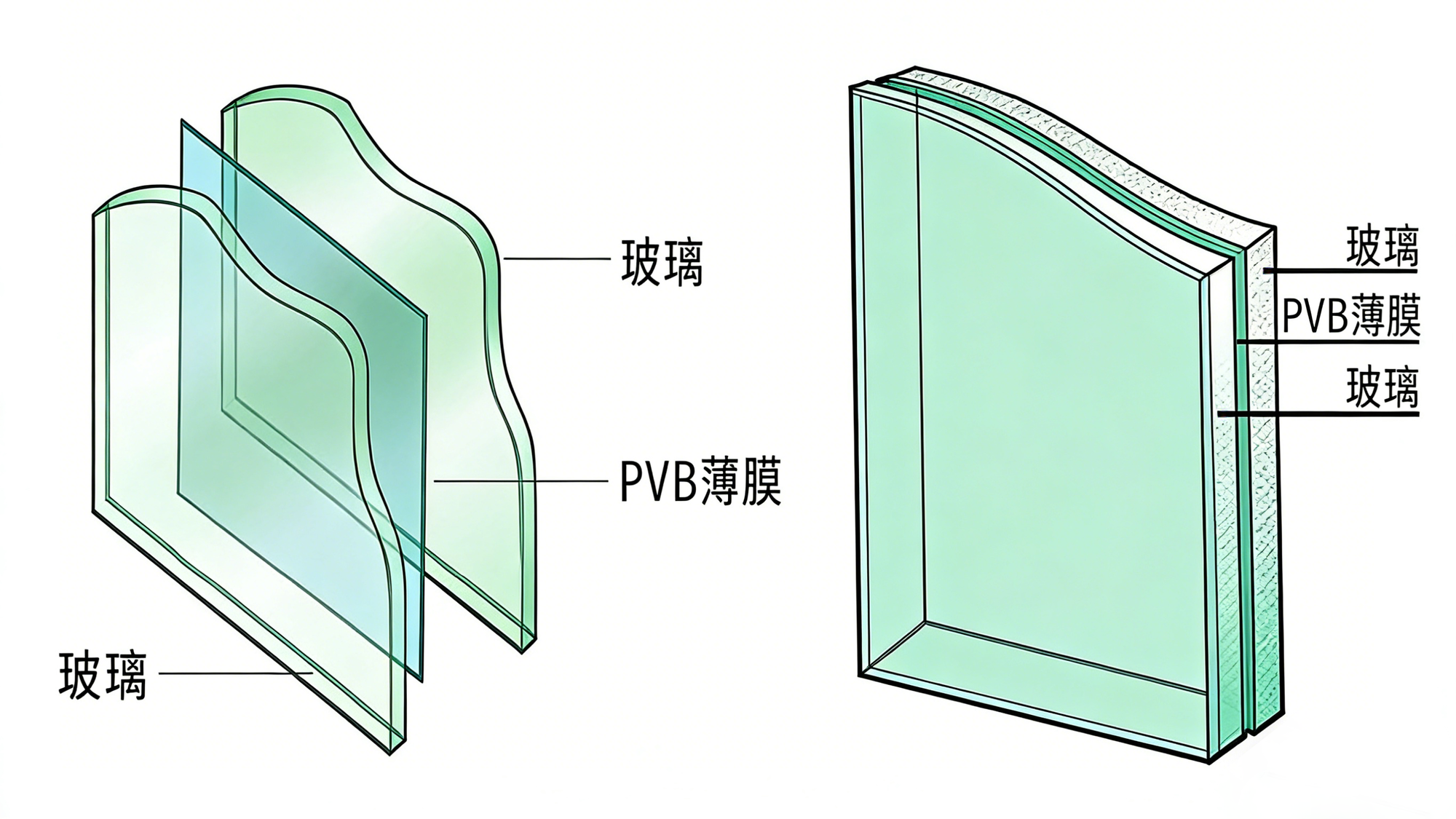

What Is PVB Interlayer Laminated Glass?

PVB interlayer laminated glass is a type of safety glass made by bonding two or more pieces of glass together with a Polyvinyl Butyral (PVB) interlayer under heat and pressure. This structure significantly improves safety, sound insulation, UV resistance, and impact performance.

Today, PVB laminated glass is widely used in architectural glass, automotive glass, curtain walls, skylights, railings, and high-security applications.

What Is PVB Interlayer?

PVB (Polyvinyl Butyral) is a high-performance thermoplastic film placed between glass layers. During the lamination process, the glass and PVB film are pre-pressed and then processed in an autoclave under high temperature and high pressure. The PVB interlayer bonds tightly to the glass, forming a strong composite structure.

Key Properties of PVB Interlayer:

Excellent adhesion to glass

High impact resistance

Strong penetration resistance

Sound insulation performance

99% UV blocking capability

Enhanced safety after breakage

When laminated glass breaks, the fragments remain attached to the PVB film instead of scattering, reducing injury risk.

Structure of PVB Laminated Glass

Standard PVB laminated glass structure:

Glass + PVB Interlayer + Glass

More advanced configurations can include:

- Multi-layer laminated glass

- Tempered laminated glass

- Low-E laminated glass

- Colored or decorative PVB laminated glass

The thickness of the PVB interlayer usually ranges from 0.38mm to 1.52mm or more, depending on safety and performance requirements.

Advantages of PVB Interlayer Laminated Glass.

1. Enhanced Safety

PVB laminated glass is classified as safety glass. Even when broken, it holds together and prevents dangerous shards from flying.

2. Sound Insulation

The PVB interlayer effectively absorbs sound waves, making it ideal for buildings near highways, airports, and urban centers.

3. UV Protection

PVB blocks up to 99% of harmful UV radiation, protecting interior furniture and materials from fading.

4. Security Protection

Due to its strong bonding and impact resistance, PVB laminated glass is commonly used in banks, jewelry stores, and high-security areas.

5. Aesthetic Flexibility

Colored PVB interlayers allow decorative designs and customized architectural solutions.

How Is PVB Laminated Glass Manufactured?

The production of PVB laminated glass typically includes:

- Glass cutting and edge processing

- Glass washing and drying

- PVB film laying and alignment

- Pre-pressing (laminating machine)

- Autoclave processing

- Inspection and packaging

Modern glass factories use automatic laminated glass production lines to ensure high efficiency and stable quality.

Professional laminated glass machines include:

- Glass washing and drying machine

- PVB laminating machine

- Pre-press machine

- Autoclave system

- Automatic glass loading/unloading system

Choosing high-quality glass processing machines ensures better bonding strength and production efficiency.

PVB Laminated Glass vs. EVA Laminated Glass

Although both are laminated glass types, PVB laminated glass is more widely used in the architectural and automotive industries due to:

- Stronger adhesion

- Better long-term durability

- Higher optical clarity

- International safety certifications

EVA laminated glass is often used for decorative or indoor applications.

Applications of PVB Interlayer Laminated Glass

PVB laminated glass is commonly used in:

- Curtain wall glass

- Skylights and glass roofs

- Balcony railings

- Glass floors

- Bullet-resistant glass

- Automotive windshields

- Hurricane-resistant windows

With increasing global demand for safety glass, PVB laminated glass production lines have become essential equipment for modern glass factories.

Why Invest in a Laminated Glass Production Line?

If your factory plans to expand into safety glass manufacturing, investing in a laminated glass production line can:

- Increase product value

- Expand market competitiveness

- Meet international building standards

- Improve ROI for glass factories

A well-designed laminated glass production solution ensures stable output, lower labor costs, and high automation.

Conclusion

PVB interlayer laminated glass is a high-performance safety glass solution that offers strength, safety, UV protection, and sound insulation. As global construction standards continue to rise, the demand for laminated glass processing machines and automated production lines is steadily increasing.

For glass manufacturers looking to upgrade their production capabilities, investing in advanced laminated glass machinery is a smart and profitable decision.