2026 Tempering Furnace Industry Update: Smarter, More Efficient Glass Tempering Solutions

As global demand for high-performance architectural and automotive glass continues to rise, tempering furnace technology is entering a new stage in 2026—defined by energy efficiency, intelligent control, and flexible production. Glass manufacturers are accelerating upgrades to meet stricter quality standards, lower energy costs, and increasing customization needs.

Intelligent Control Becomes Standard

In 2026, intelligent control systems are no longer optional. Modern tempering furnaces now integrate real-time temperature monitoring, adaptive heating algorithms, and automated quench control, enabling consistent tempering quality across different glass thicknesses and sizes. These systems reduce operator dependency while improving yield and stability.

Energy Efficiency and Cost Reduction

Rising energy prices continue to push factories toward high-efficiency tempering furnaces. Advanced insulation materials, optimized airflow design, and precise heating zones significantly reduce power consumption. Many glass processors report energy savings of 15–30% after upgrading to new-generation furnaces, helping achieve faster ROI.

Flexible Production for Diverse Glass Applications

The market in 2026 demands flexibility. Tempering furnaces are increasingly designed to handle:

Architectural glass

Low-E glass

Furniture and appliance glass

Automotive and safety glass

Quick recipe switching and intelligent parameter storage allow manufacturers to respond rapidly to small-batch and customized orders without sacrificing quality.

Automation and Smart Factory Integration

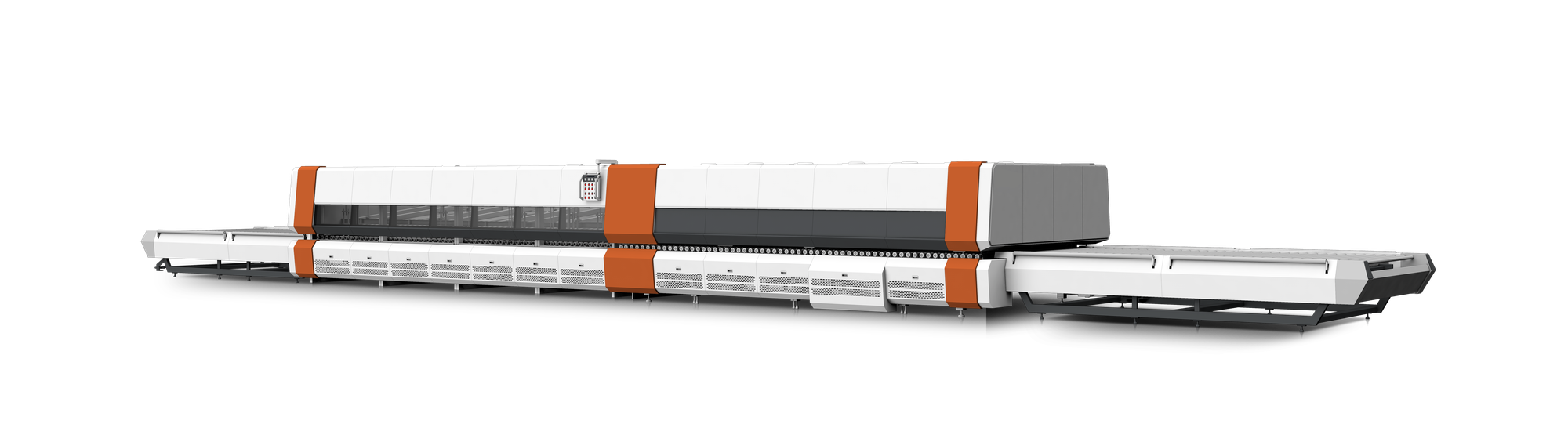

Tempering furnaces are now closely connected with automatic glass cutting, edging, washing, and handling systems, forming fully integrated glass processing lines. Through digital management platforms, factories can track production data, monitor furnace performance, and optimize maintenance schedules—supporting the transition toward smart glass factories.

Outlook for 2026 and Beyond

Looking ahead, the tempering furnace market will continue to evolve toward higher automation, lower emissions, and smarter production control. Manufacturers that invest in advanced tempering solutions will be better positioned to meet global quality standards while maintaining competitive production costs.

At LIJIANG Glass Machinery, we remain committed to providing reliable and intelligent tempering furnace solutions that help glass factories improve efficiency, quality, and long-term value in 2026 and beyond.