How to Choose the Right Insulating Glass Production Line for Your Glass Factory

Choosing the right insulating glass (IG) production line is a critical decision for any glass factory. The right configuration can significantly improve production efficiency, product quality, and long-term profitability—while the wrong choice can lead to wasted investment and operational bottlenecks. This guide will help you understand how to select an insulating glass production line that truly fits your factory’s size, production goals, and market demands.

1. Understand Your Glass Factory’s Production Requirements

Before comparing machines or suppliers, the first step is to clearly define your factory’s actual needs. Key questions to consider:

- What is your daily or monthly IGU output target?

- What glass sizes and thickness ranges do you process most often?

- Do you focus on residential, commercial, or high-performance architectural glass?

- Is your factory planning to expand capacity in the next 2–3 years?

Small and medium-sized factories may benefit from a semi-automatic or compact automatic IG line, while large-scale manufacturers typically require a fully automatic insulating glass production line with high-speed washing, gas filling, and intelligent control systems.

2. Choose the Right Level of Automation

Insulating glass production lines generally fall into three categories:

Semi-Automatic IG Production Line

- Lower initial investment

- Suitable for small factories or startups

- Higher labor dependency

- Limited production speed

Fully Automatic Insulating Glass Production Line

- High efficiency and stable output

- Reduced labor cost

- Consistent product quality

- Ideal for medium to large glass factories

High-End Intelligent IG Line

- Servo-driven systems

- Automatic glass recognition and adjustment

- Online gas filling and quality monitoring

- Designed for high-volume and high-specification IGU production

Selecting the right automation level ensures you don’t overpay for unused capacity—or underinvest and restrict growth.

3. Focus on Core Equipment Configuration

A reliable insulating glass production line should include well-matched core components:

- Glass Washing and Drying Section

Ensures clean, residue-free glass surfaces for strong sealing performance. - Automatic Spacer Frame Assembly

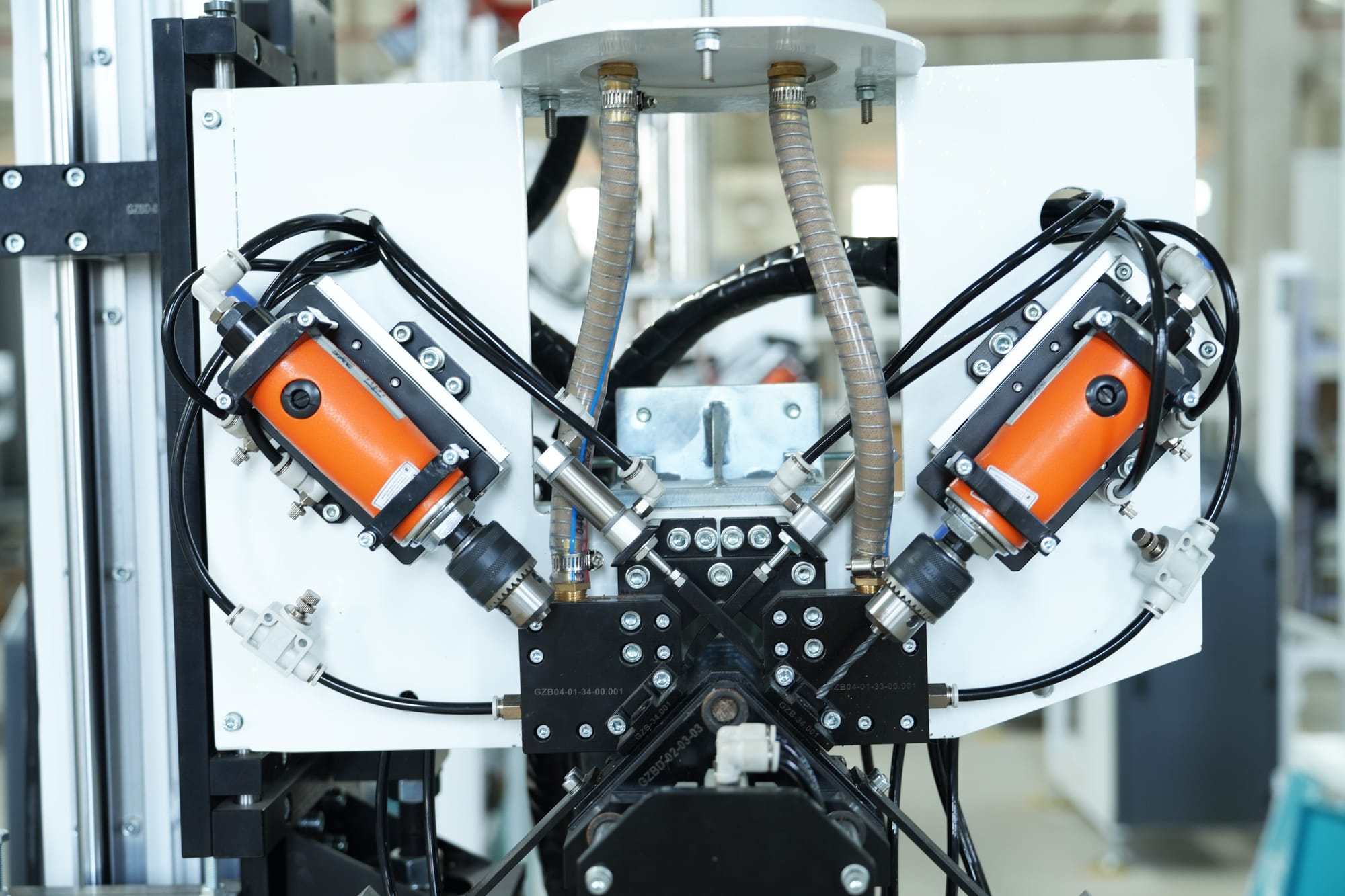

Accurate spacer positioning improves IGU sealing quality and lifespan. - Pressing & Gas Filling Unit

Stable pressing pressure and precise gas filling directly affect thermal performance. - Control System & Sensors

Intelligent systems reduce human error and improve production consistency.

Rather than chasing excessive features, focus on stable performance, easy maintenance, and long-term reliability.

4. Consider Factory Space and Layout Planning

Many buyers overlook factory layout until installation—leading to inefficient workflows or costly modifications. A professional supplier should help you:

- Optimize production flow

- Match line length to workshop size

- Plan glass infeed and outfeed directions

- Reserve space for future expansion

A well-designed layout can increase real production efficiency by more than 20% without upgrading equipment.

5. Evaluate Supplier Experience and Support

An insulating glass production line is a long-term investment, not a one-time purchase. When selecting a supplier, pay attention to:

- Years of experience in IG equipment manufacturing

- Global installation and service cases

- Availability of technical training

- Spare parts supply and after-sales response speed

Working with an experienced manufacturer reduces risks during installation, commissioning, and future operation.

6. Think Beyond Price: Calculate Real ROI

The cheapest machine is rarely the most cost-effective in the long run. A proper evaluation should include:

- Labor savings

- Energy consumption

- Maintenance costs

- Production efficiency

- Product quality consistency

A well-configured insulating glass production line should help you recover investment faster while improving overall factory competitiveness.

Conclusion: Make a Decision Based on Data, Not Guesswork

Choosing the right insulating glass production line means balancing capacity, automation level, factory layout, and long-term return on investment. With the right planning and professional support, your production line can become a core competitive advantage—not just a piece of equipment. If you are planning a new insulating glass production line or upgrading an existing one, a professional evaluation can save time, cost, and future risks.

Get Professional Support for Your Glass Factory

To help you make the right decision, we offer:

- Free Layout Drawing

- Free Production Line Proposal

- Free Glass Factory ROI Analysis

Contact us today to receive a customized insulating glass production line solution tailored to your factory’s real needs.Free Production Line ProposalFree Glass Factory ROI Analysis, Glass Washing and Drying Section