Glass Loading Five-axis Transverse Manipulator Lifter

LIJIANG Glass Loading Five-axis Transverse Manipulator Lifter has a single-section type, single-arm operation and five-axis AC servo motor drive. It is suitable for various glass deep processing scenarios. It adopts a 5-axis drive and control integrated control system, which has accurate positioning, fast running speed, long life and low faults, ensuring operation. It improves the safety of personnel, reduces the manual effort to carry glass, and is connected to the ERP system to accurately control the production volume of glass.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LIJIANG Glass Loading Five-axis Transverse Manipulator Lifter

The arm of LIJIANG Glass Loading Five-axis Transverse Manipulator Lifter has a single-section type, single-arm operation, and a five-axis AC servo motor drive. It is suitable for various glass deep processing scenarios. It adopts a 5-axis drive and control integrated control system, with accurate positioning, fast operation speed, and long life and failure rate; optional Equipped with automatic fault detection and alarm recording functions to ensure the safety of operators and reduce manual effort to carry glass; reserved contacts can be connected to peripheral auxiliary equipment such as conveyor belts and receiving tables, and can optionally be connected to the ERP system for precise control Glass production volume.

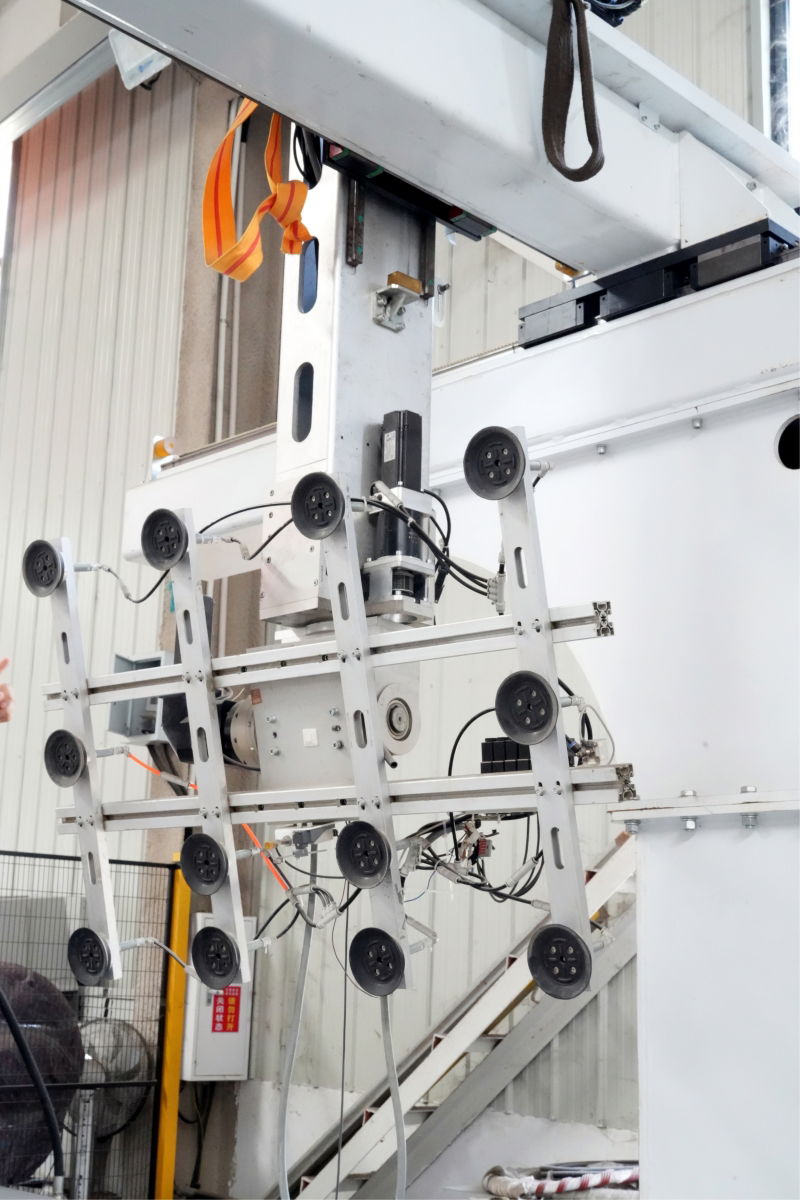

Figure 1 The LIJIANG Glass Loading Five-axis Transverse Manipulator Lifter

Figure 1 The LIJIANG Glass Loading Five-axis Transverse Manipulator Lifter

Figure 2 The LIJIANG Glass Loading Five-axis Transverse Manipulator Lifter

Figure 2 The LIJIANG Glass Loading Five-axis Transverse Manipulator Lifter

Benefits and Advantages

- The robotic arm adopts a high-strength cast iron molded structure and is matched with precision linear slide rails to ensure low noise and long service life.

- It is driven by horizontal AC servo motor to realize multi-point parking function and high positioning accuracy.

- The motion unit adopts imported linear guide;

- It adopts five-axis manipulator PLC operating system, touch screen + handle control, and the operation screen is clear and easy to understand;

- The vacuum system uses high-quality vacuum suction cups, with high negative pressure and sufficient suction power, and the glass is firmly adsorbed and does not fall off;

- The machine is equipped with automatic alarm for material shortage, under-voltage protection, power-off protection and other functions, and has a high safety factor;

- It is suitable for removing glass sheets from the top and bottom of insulating glass production lines, vertical glass washing and drying machines, automatic glass edge grinding machines and other equipment.

Figure 3 The LIJIANG Glass Loading Five-axis Transverse Manipulator Lifter

Figure 3 The LIJIANG Glass Loading Five-axis Transverse Manipulator Lifter

Figure 4 The LIJIANG Glass Loading Five-axis Transverse Manipulator Lifter

Figure 4 The LIJIANG Glass Loading Five-axis Transverse Manipulator Lifter

Figure 5 The LIJIANG Glass Loading Five-axis Transverse Manipulator Lifter

Figure 5 The LIJIANG Glass Loading Five-axis Transverse Manipulator Lifter

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

After-sales Maintenance Methods of Glass Loading Five-axis Transverse Manipulator Lifter

The harmonic reducer is a high-precision part, which has its own extreme stress and excessive push and pull. Unreasonable collisions will damage the internal structure of the harmonic reducer, resulting in reduced accuracy or abnormal noise of the reducer. In severe cases, the flex spline of the reducer will break and the reducer will be scrapped.

Every six months when the equipment is used, disassemble the distribution box and check whether the screws are loose and the related cables are worn. Tighten the loose screws and apply engine oil to the joint cables for maintenance.

Every six months when the equipment is used, remove the track protective cover and check the tightness of the belt. The belt will slowly lengthen during long-term operation. Tighten the belt and deal with the residue of belt wear.