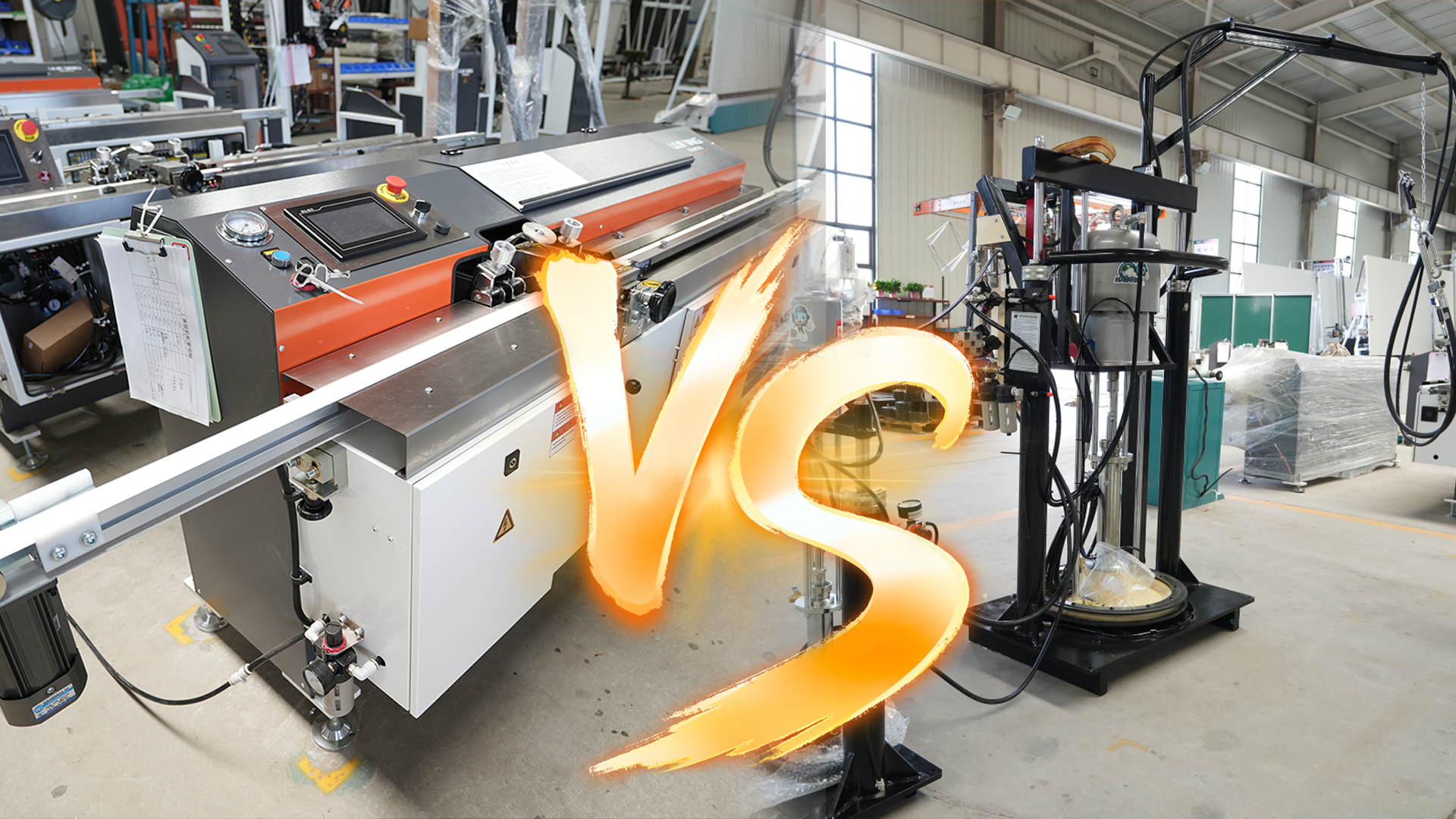

Butyl Extruder vs Two-Component Sealant Machine: Which One Do You Really Need?

In the insulating glass (IG) production line, sealant quality directly decides the insulation performance, lifetime stability, and long-term durability of IG units. Two essential sealing technologies dominate modern production: Butyl Extruders and Two-Component Sealant Machines. Although both apply sealants, their working principles, application positions, and performance outcomes are very different. This article compares them in detail to help glass processors choose the most suitable sealing solution.

1. What Is a Butyl Extruder?

A Butyl Extruder (IG butyl coating machine) heats and extrudes polyisobutylene (PIB) onto the aluminum spacer.PIB is the first sealing layer of insulating glass—responsible for moisture resistance and gas retention.

Key Functions

Applies continuous hot-melt PIB on both sides of the spacer

Ensures airtight sealing for high-performance IG

Prevents water vapor penetration

Maintains argon gas retention over the long term

Typical Features

High-temperature heating (≈180–200°C)

Precision extrusion nozzles

Servo-controlled feeding

Automatic centering for uniform thickness

In short, A Butyl Extruder ensures the IG spacer has a perfect primary seal.

2. What Is a Two-Component Sealant Machine?

A Two-Component Sealant Machine mixes and applies 2K silicone or polysulfide sealants as the secondary structural seal of IG units.

Key Functions

Proportioning A/B sealant materials accurately

High-strength structural sealing

Long-term UV, weather, and temperature resistance

Ensures the mechanical stability of IG units

Typical Features

Automatic A/B ratio monitoring

High-pressure mixing system

Stable bead application

Suitable for large, façade-grade, and high-performance IG

In short, A 2K Sealant Machine strengthens the structure and ensures long-term durability.

3. Where They Are Used in the IG Unit?Process Machine Purpose Step 1: Butyl Extruder Primary moisture barrier on spacer Step 2: Assembly + Pressing Form IG unit Step 3: Two-Component Sealant Machine Secondary structural sealing around the perimeter

The machines complement each other—they are not substitutes.

4. Performance Comparison4.1 Purpose & Function

Butyl Extruder: Air-tightness + Moisture barrier

2K Sealant Machine: Strength + Long-term structural stability

4.2 Sealant Material

Butyl: Hot-melt PIB

2K Sealant: Polysulfide / Silicone

4.3 Operating Temperature

Butyl: High temperature

2K Sealant: Room temperature mixing

4.4 Effect on IG Quality

Butyl → Gas retention is important for energy efficiency

2K → Essential for wind-load performance of façade IG

5. Which Machine Should You Choose? Choose a Butyl Extruder if you need:

Standard IG production line

High-speed spacer coating

Stable PIB thickness

Excellent moisture barrier performance

Choose a Two-Component Sealant Machine if you:

Produce façade, curtain wall, architectural IG

Need high structural strength

Work with silicone or polysulfide

Manufacture jumbo-size glass

For complete IG production:

You must have both, because each performs a different seal.

6. Recommended Machines from LJ Glass Machinery

✔ LJTB01 Butyl Extruder

Suitable for all IG spacer types, stable extrusion, fast heating, and high coating uniformity.Internal link:https://www.ljglassmachinery.com/insulating-glass-butyl-extruder/

✔ LJQH Two-Component Sealant Extruder

Accurate A/B ratio control, automatic mixing, ideal for large architectural IG.Internal link:https://www.ljglassmachinery.com/two-component-sealant-machine/

7. Conclusion: Use Both for Best IG Performance

A Butyl Extruder and a Two-Component Sealant Machine are not competing technologies—they complete the sealing system of insulating glass.

Primary Seal (PIB): Airtightness, moisture barrier

Secondary Seal (2K): Strength, weather resistance, structure

To ensure high-quality IG units that meet international standards (EN1279 / IGCC), both technologies are essential.