Application Scenarios and Advantages of Laminated Glass Cutting Machines

Laminated glass is increasingly common in modern architecture, automotive manufacturing, and high-end home furnishings. To meet the demands of high precision and efficiency, laminated glass cutting machines have emerged as a core piece of equipment in glass processing plants and industrial production lines. This article will detail their application scenarios, technical advantages, and value to the industry.

I. Application Scenarios in the Construction Industry

Laminated glass is widely used in the construction industry for curtain walls, doors and windows, partitions, and building safety glass. Laminated glass cutting machines can efficiently and accurately cut laminated glass of varying thicknesses, meeting the following requirements:

Large Curtain Wall Glass: In the construction of high-rise building curtain walls, cutting accuracy and dimensional consistency directly impact installation efficiency and overall aesthetics.

Safety Glass: Public spaces such as schools, hospitals, and shopping malls have stringent safety glass requirements. Laminated glass's high strength and impact resistance are preferred, and precision cutting ensures safety after installation.

Low-E Glass Cutting: Some buildings use low-emissivity (Low-E) glass for energy-saving design. Professional cutting equipment can effectively remove edge coatings and prevent glass damage.

II. Applications in the Automotive and Transportation Industries

Laminated glass is often used in car windshields, side windows, and rear windows to ensure safety and comfort. Laminated glass cutting machines offer the following advantages in automotive glass production:

High-speed cutting: Ensures efficient operation of automotive production lines and shortens production cycles.

Precise edge trimming: Ensures a tight fit between the glass and the vehicle body, reducing air leakage and vibration noise.

Compatible with a variety of glass types: Easily cuts both standard laminated glass and high-end glass with heat insulation and UV protection.

III. Applications in the High-end Home Furnishings and Furniture Industries

In modern home design, laminated glass is used in a variety of applications, including partitions, tabletops, cabinet doors, and stair railings. Professional cutting equipment not only improves production efficiency but also maintains smooth and beautiful glass edges.

Customized design: Accommodates irregularly sized and shaped glass, increasing the flexibility of home design.

High-quality cutting results: Reduces burrs and breakage on glass edges, ensuring product aesthetics and safety.

Improves mass production efficiency: Helps home furnishing manufacturers achieve rapid, high-volume production while maintaining precision.

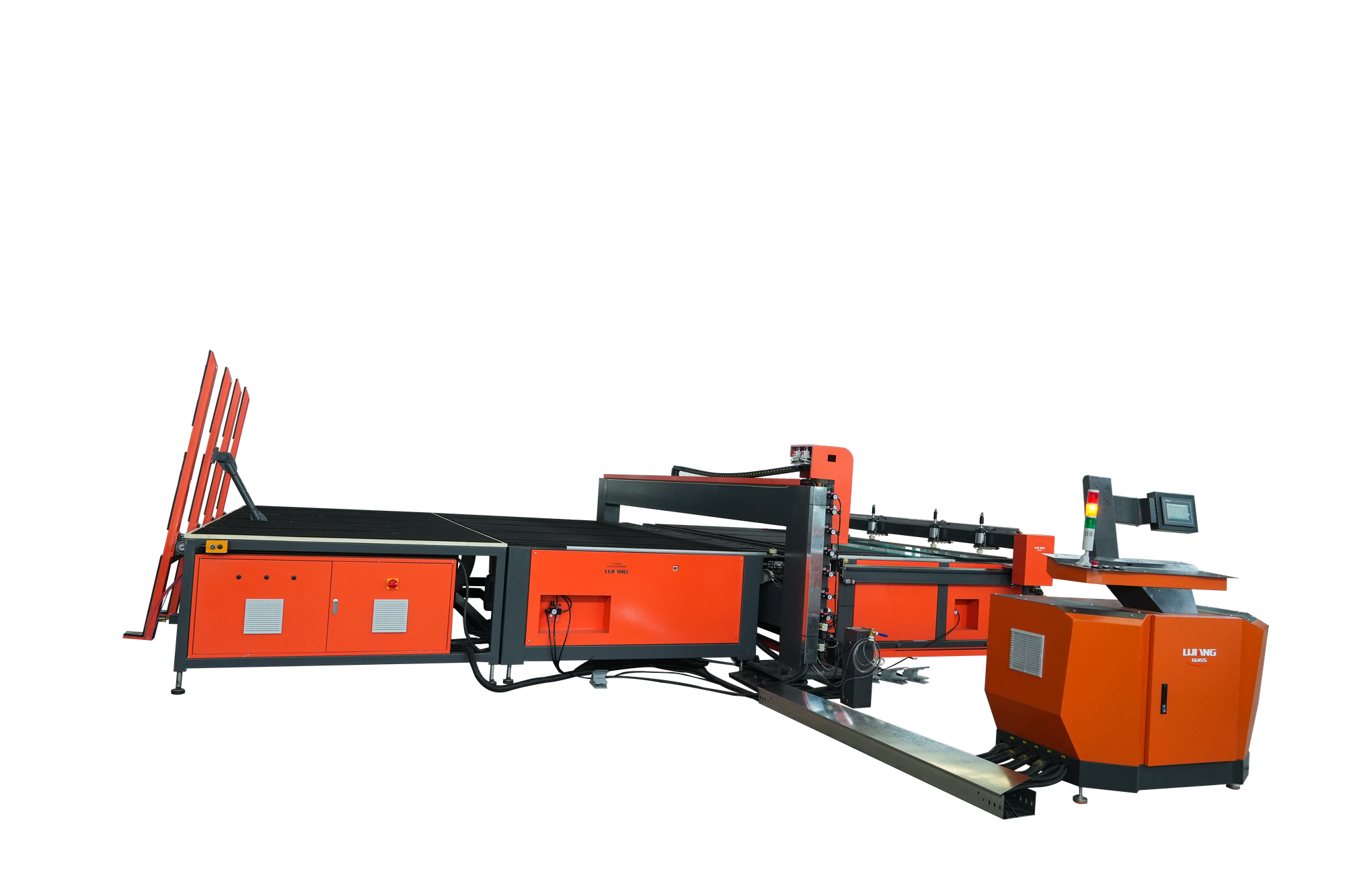

IV. Technical Advantages of Laminated Glass Cutting Machines

Automated and semi-automated operation: Reduces manual intervention and improves production safety.

High-precision cutting: Utilizing CNC technology, it achieves millimeter-level cutting accuracy.

Adapts to a wide range of glass thicknesses: From standard laminated glass to specialty Low-E or bulletproof glass, this cutting machine is capable of cutting them all.

Material savings: Precision cutting reduces glass waste and lowers production costs.

Easy maintenance and high stability: Designed for long-term use, the machine offers a low failure rate and is suitable for continuous production environments.

V. Summary

With the development of the construction, automotive, and home customization industries, the demand for laminated glass continues to grow. The Laminated Glass Cutting Machine not only improves production efficiency and cutting accuracy, but also provides manufacturers with reliable guarantees in terms of safety, aesthetics, and cost control. Whether it is large-scale production or small-batch customization, this equipment is an essential tool for modern glass processing factories.