More Glass Deep-process Blogs

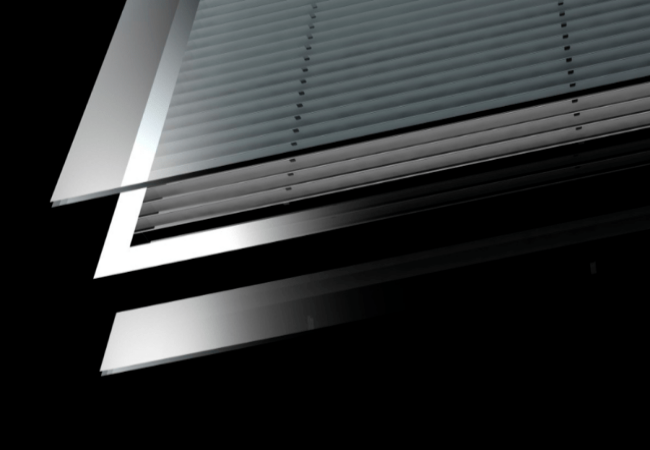

LIJIANG Glass has previously introduced how to use and what automation equipment is needed to realize the processing and production of insulating louver glass. Based on the "industry data statistics work" carried out continuously by the Aluminum Door, Window, and Curtain Wall Branch of China Construction Metal Structure Association for many years, and the "five elements" of enterprise evaluation, LIJIANG Glass brings you the preferred brand recommendation information for related supporting materials and service companies.

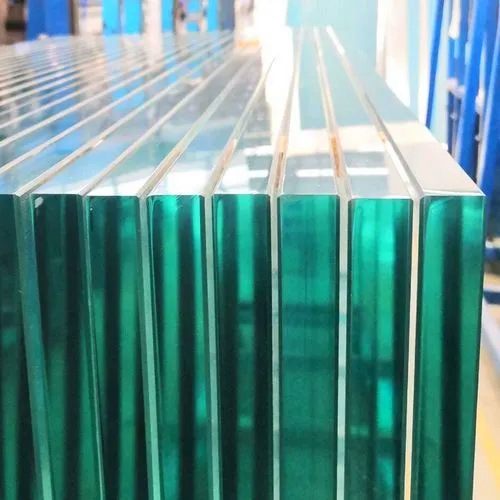

READ MOREFor plastic glass, after the inner and outer layers of the glass are damaged, whether there will be more secondary hazards depends on the function of the glass interlayer film. At the same time, safety glass and ultra-clear glass have become the first choice for super high-rise buildings and commercial landmarks, and the "film" between glass and glass has become the key. So, how to choose the thickness of the laminated glass PVB film? Next, LIJIANG Glass will share with you the relevant guidelines for the glass deep processing process...

READ MOREThe automatic glass edging machine, which is also called the glass edge polishing machine and glass edge grinding machine, is the indispensable equipment in the glass deep processing. To improve the quality of glass production and prolong the service life of the machine, it is particularly important to use the equipment correctly and maintain the machine.

READ MOREAre you thinking about including insulating glass merchandise to your manufacturing mix? Or are you questioning of reconfiguring your present day tools to supply new and higher offerings to your customers? Growth and growth are natural and necessary for all businesses. But how do you do it in the proper way to faucet into the insulating glass manufacturing niche?

READ MOREWith the improvement of people's living standards, the demand for glass curtain walls building is increasing, which drives the development of the entire glass deep-processing industry. As a part of the glass industry, the insulating glass industry has also experienced rapid development, which has also intensified the degree of competition in the entire glass industry. To increase the market share, it is necessary to reduce the sales price or improve the performance of the product. This requires enterprises to continuously increase R&D investment and improve product performance, on the one hand, thereby enhancing core competitiveness; on the other hand, it also requires strengthening cost control in the production process and improving product yield...

READ MORE