For Beginner Guide 101: The application of insulating glass in building curtain wall.

Abstract: Insulating glass has good thermal and sound insulation properties, and has been widely used in the building curtain wall industry. LIJIANG Glass discusses the process and characteristics of insulating glass, as well as the lamination process, starting from the processing and technical requirements of insulating glass. various material requirements. Due to the many development advantages of insulating glass, it has been more and more widely used in modern building curtain walls.

Keywords: building curtain wall insulating glass; insulating coated glass; insulating tempered glass

1. The production process and characteristics of insulating glass

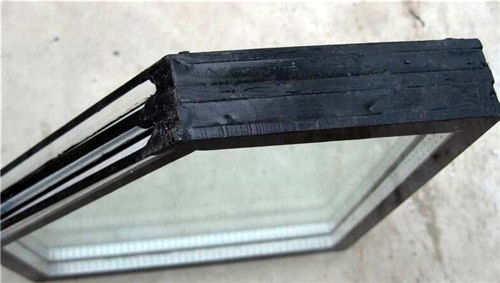

Insulating glass is composed of 2 or more glass plates, the glass plates are separated by an edge sealing system, and the middle is filled with gas. The glass plate can be ordinary flat glass, tempered glass, or Low-E glass, which can be selected according to the application and function of the insulating glass; the gas-filled between the glass plates must be dry, which can be air, argon, or other special gases, and use molecular sieves to keep the gas dry; there are many kinds of edge sealing systems, with great changes, from the initial aluminum spacer to today's various polymer materials and their combinations of spacers, spacers the strips are placed between the two layers of glass to separate the glass plates; the edges of the insulating glass are sealed with a sealant to bond the glass together and prevent the gas in the layer from escaping (see Figure 1).

Figure 1 The edges of the insulating glass are sealed 1

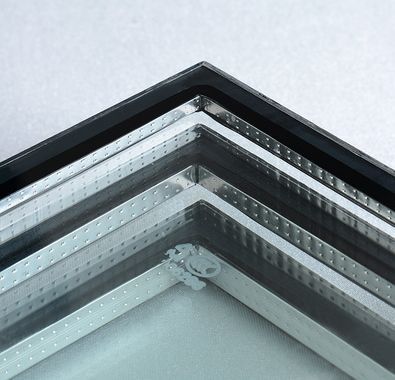

When sealing insulating glass, there are two types of aluminum alloy isolation frames for each specification (6 and 6A, 9 and 9A, 12 and 12A). Different types of 6A, 9A, and 12A (ie small models) are selected respectively, to ensure that the design size of the insulated layer of the insulating glass is 6mm, 9mm, and 12mm, and can also reduce the amount of sealant used. In addition, it should be noted that: according to the specification, the thickness of the insulated layer of the insulating glass for curtain walls should not be less than 9mm.

Compared with monolithic glass, insulating glass has an obvious thermal insulation effect, and its thermal insulation ability mainly comes from the sealed air layer. The study found that the thermal conductivity of air is 0.026 W/ (m·K) at 20 ℃, while the thermal conductivity of an ordinary transparent glass plate is 0.76 W/ (m·K), and the ratio is 1:29. In the air layer sealed by the insulating glass, the heat transfer mode is mainly heat conduction, and the convective heat transfer accounts for a small share, so its small thermal conductivity can greatly improve the thermal resistance of the insulating glass, and play a role of thermal insulation.

2. Technical requirements for insulating glass

The technical requirements for insulating glass are specified in relevant international industry standards:

2.1 Material:

2.1.1 Glass: Glass can be float glass, laminated glass, tempered glass, semi-tempered glass, coated glass, etc. Float glass shall comply with relevant international industry standards; laminated glass shall comply with relevant international industry standards; tempered and semi-tempered glass used in curtain walls shall comply with relevant international industry standards.

2.1.2 Sealant: insulating glass should be double-sealed: butyl hot-melt sealant should be used for the first seal; silicone structural sealant should be used for the second seal of insulating glass for the hidden frame, semi-hidden frame, and point-supported glass curtain wall, and the frame is exposed. The secondary sealing of insulating glass for curtain walls can use polysulfide insulating glass sealant or silicone structural sealant.

2.1.3 Spacer frame: The spacer aluminum frame of insulating glass can be of continuous bending type or gusset type, and hot-melt spacer strips shall not be used; when using metal spacer frames, decontamination or chemical treatment shall be performed.

2.1.4 Desiccant: The quality and performance of the desiccant filled in the insulating glass should meet the corresponding standards and the weight of the filling should be calculated and determined according to the size and requirements of the glass plate.

The allowable deviation of the length and width of insulating glass is as follows.

| Length | Allowable deviation |

| <1000 | +1.0,-2.0 |

| 1000~2000 | +1.0,-2.5 |

| >2000~2500 | +1.5,-3.0 |

| Nominal thickness (mm) | Allowable deviation (mm) |

| t<17 | ±1.0 |

| 17≤t<22 | ±1.5 |

| t>22 | ±2.0 |

Note: The nominal thickness of the insulating glass is the sum of the nominal thickness of two pieces of glass and the thickness of the spacer frame.

The difference between the two diagonals of the insulating glass: the difference between the diagonals of the square and rectangular insulating glass should not be greater than 0.2% of the average length of the diagonal.

2.1.5 The thickness of the adhesive layer of insulating glass:

The thickness of the single sealant layer is 10mm±2mm, the thickness of the double sealant outer sealant layer is 5mm~7mm, and the thickness of the adhesive strip sealant layer is 8mm±2mm. The thickness of the second sealant layer of the insulating glass of the hidden frame curtain wall shall be adopted according to the calculation result).

2.1.6 Appearance:

The insulating glass must not have stains, inclusions, and splashes of sealant that hinder perspective; measures should be taken during glass processing to eliminate the concave and convex phenomena that may occur on the glass surface.

2.1.7 Performance requirements:

The sealing, dew point, ultraviolet irradiation, climate cycle, and high temperature and high humidity performance of insulating glass should meet the requirements of relevant international industry standards; the insulating glass used for curtain wall should be tested for necessary dew point with dry ice.

2.2 Application Status of Insulating Glass - Insulating Coated Glass, Insulating Tempered Glass

At present, insulating glass has been widely used in the exterior walls of buildings, especially the glass curtain wall. Vision space and create a comfortable living and working environment; it can not only fully reflect the architect's imagination, show the modern style of the building, and meet the designer's concept but also make the building appear unique, bright, and with modern taste, To beautify and decorate the appearance of buildings. In recent years, with the progress of society and the improvement of people's living standards, the insulating glass curtain walls have been widely used at home and abroad...

To meet the needs of energy-saving and emission reduction, adapt to the development trend of modern buildings, and better utilize the advantages of insulating glass, it is necessary to use glass with better thermal insulation properties, so the insulating coated glass came into being.

Coated glass or Low-E glass is a thin film system composed of multiple layers of metals such as silver, copper, or tin or their compounds plated on the glass surface. The product has high transmittance to visible light and high reflectivity to infrared rays. It can make indoor heat not easily dissipated to the outside. In a building like the north, there is enough brightness and only a small part of the sunlight energy passing through the glass can be radiated through the glass so that the internal temperature of the building can be maintained at a high level, and the internal energy is greatly reduced.

The energy-saving properties of Low-E glass are reflected in its shielding properties against sunlight heat radiation—that is, thermal insulation. Due to the poor strength of the film layer, it is generally used as insulating glass, so that the coating surface is inside the insulating layer.

The glass design of modern building curtain walls pursuing large-area lighting has become a trend, which contradicts the energy-saving trend of architectural design. If transparent glass is used, too much sunlight and heat energy will enter the room in summer, and in winter, it cannot prevent the overflow of indoor heat energy. The cost of maintaining a suitable indoor temperature can only consume a large amount of energy consumption of air conditioning or heating. The most effective way to solve this contradiction is to use glass products that have been coated and insulating processed, so the application of insulating coated glass is more and more pursued by people.

To meet the needs of the safety of special parts of the building and enhance the strength and wind pressure resistance of the glass, it is necessary to use glass with better safety performance. The insulating tempered glass made of tempered glass can achieve this function.

Tempered glass is a glass that heats float glass to near the softening temperature and then conducts uniform and rapid cooling so that the glass surface obtains compressive stress; compared with ordinary glass of the same thickness, tempered glass has 3 ~ 5 times higher bending strengths and impact resistance. When tempered glass is loaded, its maximum tensile stress is not located on the glass surface like ordinary glass, the tempered glass does not break under the same load; in addition, tempered glass has relatively high heat resistance.

Impact resistance, compared with ordinary glass of the same thickness, the thermal shock resistance is 3 times higher, Tempered glass is widely used due to its high strength and good safety performance. The insulating glass made of tempered glass not only has the advantages of high strength and good safety performance of tempered glass but also has the advantages of strong heat insulation and sound insulation performance of ordinary insulating glass.

3. The conclusion

Because glass is fragile, and glass curtain walls are generally used in street-facing buildings, glass breakage is unavoidable, and glass breakage may cause harm to people. Although the production technology level of the glass industry has been continuously improved in recent years, there are more and more varieties, and the selection space for glass is becoming larger and larger, but how to choose glass reasonably so that the safety of the curtain wall can reach a better ideal state, It is necessary to have a more comprehensive understanding of the safety of curtain wall glass. How to choose insulating glass, beautiful design, and cost reduction still needs to be continuously explored and summarized by curtain wall designers.

For more information about insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.