What are the double seals of insulating glass? What is the role of each?

What are the double seals of insulating glass? What is the role of each?

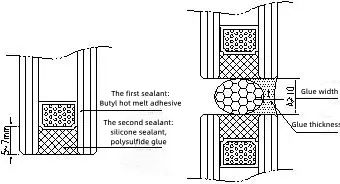

The insulated glass first sealant uses butyl extruder coating, which has an extremely low water vapor transmission rate; the insulated glass second sealant mainly includes polysulfide sealant and silicone sealant.

The role of double-channel sealing of insulating glass

The sealing and structural stability of the insulating glass system is realized by the insulating glass sealant. Insulating glass is always faced with external water vapor penetration and temperature changes during its service life, so it is required that the sealant must first be able to prevent external water vapor from entering the air layer of the insulating glass.

After the insulating glass is installed, it is often affected by external forces such as temperature difference, air pressure, and wind load from the outside world, so the sealant is required to ensure the structural stability of the system. It is equally important to ensure the sealing of the air layer of the insulating glass and to maintain the structural stability of the insulating glass system. Sealing depends on the integrity of the structure, and the structure ensures the stability of the seal. the

The insulating glass system must be sealed in two ways. The first sealant is used to prevent the invasion of water vapor, and the second sealant is used to maintain the stability of the structure. If the insulating glass system only adopts single-channel sealing, the insulating glass sealant should not only play a sealing role but also play a structural role, but any kind of glue cannot have excellent sealing and structural properties at the same time. Therefore, the result of single-channel sealing can only greatly reduce the sealing life of the insulating glass.