Insulated Glass Sealing Machine Buying Guide

The LIJIANG Glass Buying Guide are here for you -- there are our go-to recommendations for ultimate question: What kinds of automatic insulated glass sealant sealing robot machine should you buy? There is a collection of buying guides by category.

When producing the insulated glass, what kind of sealant should be used for the second seal?

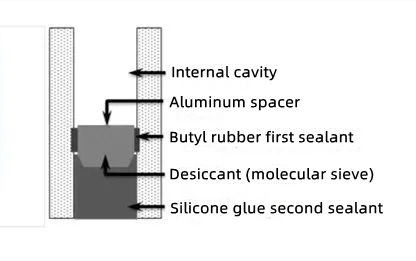

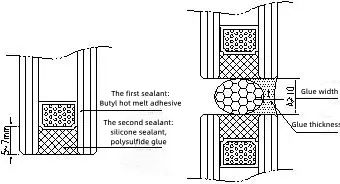

Insulating glass is a product that evenly separates two or more pieces of glass at a certain distance, and the periphery is bonded and sealed, so that a dry gas space is formed between the glass layers. According to the thickness of the gas layer required by the design, a spacer frame containing a desiccant is embedded between the two pieces of glass, and then two seals are performed on the periphery of the glass...

Know More

What are the double seals of insulating glass? What is the role of each?

The insulated glass first sealant uses butyl extruder coating, which has an extremely low water vapor transmission rate; the insulated glass second sealant mainly includes polysulfide sealant and silicone sealant. Insulating glass is always faced with external water vapor penetration and temperature changes during its service life, so it is required that the sealant must first be able to prevent external water vapor from entering the air layer of the insulating glass...

Know More

When the ambient temperature of silicone sealant is low in winter, the viscosity increases, and the sealant is not applied smoothly.

Insulating glass using silicone sealant is composed of chemical raw materials such as silicone rubber, silicone oil, and calcium carbonate. Taking winter in the northern hemisphere as an example, when the temperature drops in the winter in the northern hemisphere, silicone rubber, and silicone oil become thicker, less fluid, and more viscous. This thickening and sticky situation is normal and does not affect product quality.

Know More

The usage guide of insulating glass silicone structural sealant

The guide to the use of silicone structural sealant, including several common key issues during use, what are the reasons for the failure of the bond between silicone sealant and insulating glass, problems of sealant cracking, surface blistering, and wrinkle bulging. The two-component mixture contains bubbles and other problems, and the optimal processing environment for silicone sealant used in insulating glass processing is summarized.

Know More

What are the working principles of the two-component sealant machine for insulating glass?

The insulating glass two-component sealant sealing machine is a key equipment used in the production of insulating glass. It can mix two different sealant sealing materials and evenly apply them on the edge of the glass to achieve sealing of the glass sheet. Its working principle includes sealant sealing supply, mixing and deployment, sealant application, curing, and sealing, which can improve production efficiency and product quality stability.

Know More

Why we recommend you choose LIJIANG Glass TPS Automatic Sealing Robot Line?

To free you from the inefficient production of manually sealed insulating glass units, LIJIANG Glass has brought a new solution. With the TPS fully automatic sealer, we can upgrade the LIJIANG Glass insulating glass production line with spacer bending, filling, and coating from an entry-level configuration to a fully automatic production line. The main advantage of the new TPSS automatic sealing robot is the reliable gear pump precision sealant dispensing technology, which ensures extremely high sealant dispensing accuracy. This flow-controlled sealant dispensing function can accurately measure the sealant depth and spacer width of the sealant and then apply the required amount of sealant.

Know More