Why Your IG Unit Has Sealant Leakage (Causes + Solutions)

Insulated glass (IGU) sealant leakage is one of the most common and costly failures in IG production. Once the sealant spills, cracks, or separates, the insulation performance drops sharply, leading to fogging, air leakage, poor aesthetics, and customer complaints.This guide explains why IG units develop sealant leakage, how to diagnose each cause, and the most effective solutions to eliminate the problem in your factory.

1. Common Signs of Sealant Leakage in IG Units

You may notice one or more of the following:

- Sealant overflowing from the edges

- Gaps between sealant and aluminum spacer

- Uneven or messy sealing shape

- Air bubbles inside the sealant

- Corners not fully filled

- Sealant peeling off after a few days

- Sealant cracking during transportation or installation

These symptoms point to equipment, material, or process issues — all solvable once identified.

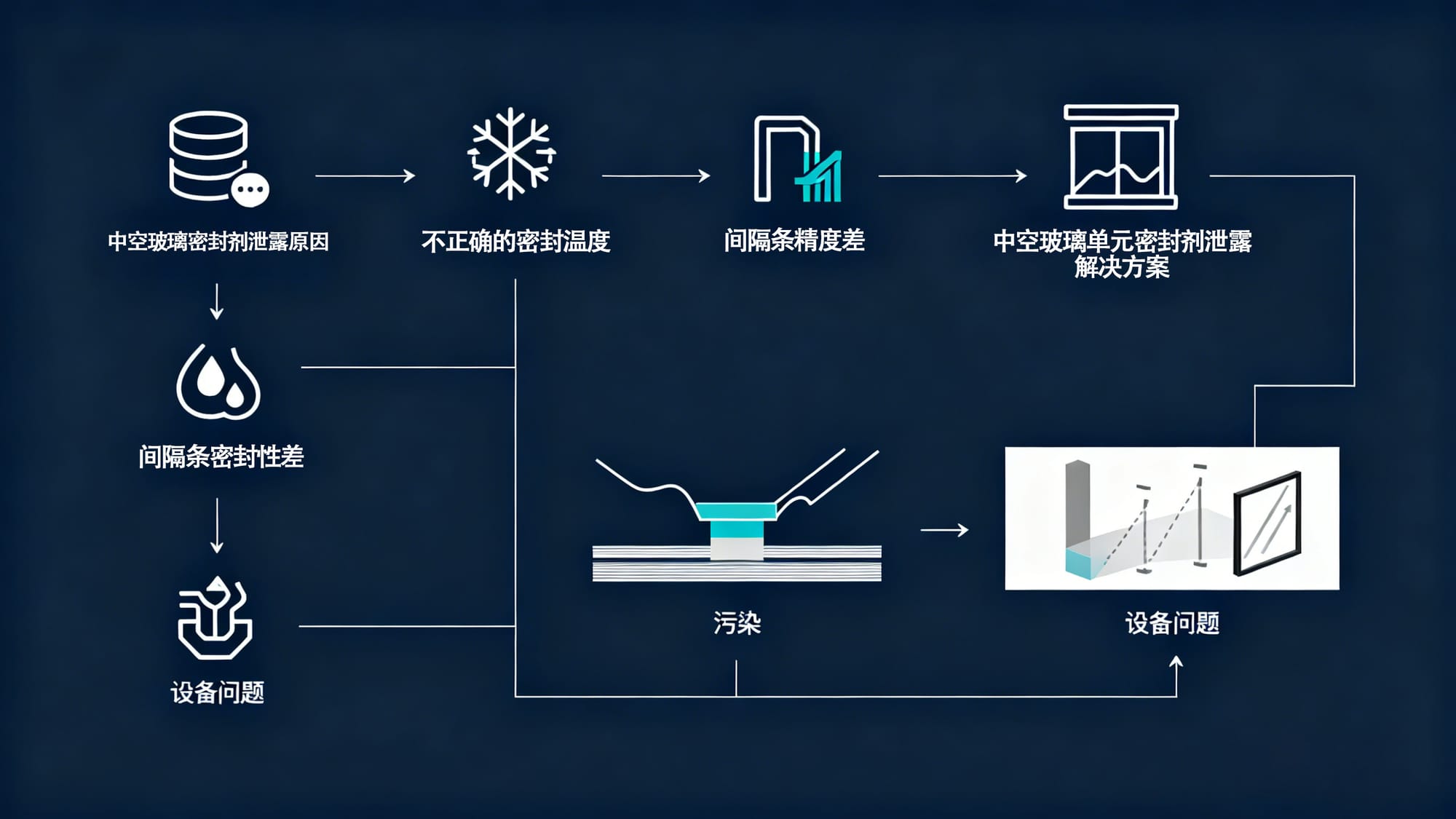

2. Major Causes of IG Sealant Leakage (Detailed Analysis)

2.1 Incorrect Viscosity or Temperature of Sealant

Symptoms

- Sealant too soft → flows and “leaks”

- Sealant too thick → cannot fill fully

Causes

- Butyl extruder temperature too low/high

- Two-component mixing ratio not correct

- Improper storage temperature

Solutions

- Keep butyl sealing temperature at ~180–200°C (depends on material)

- Maintain 2K mixing ratio at exact proportions (A:B = 10:1 or manufacturer requirement)

- Store sealant in dry, temperature-stable room (18–25°C)

2.2 Spacer Bending or Cutting Accuracy Problems

Symptoms

- Corners leaking

- Gap between spacer and glass

Causes

- Manual spacer bending errors

- Inconsistent 90° corner

- Incorrect length after cutting

Solutions

- Use automatic spacer bending machine for precise 90° corners

- Recalibrate cutting length

- Check spacer hardness before use

2.3 Uneven Glass Surface or Wrong Glass Size

Symptoms

- Sealant cannot fill the edge fully

- One side overflows, other side insufficient

Causes

- Glass size deviation ±1–2 mm

- Chips or defects on glass edge

- Uneven edge due to worn grinding wheel

Solutions

- Use an automatic cutting line with accurate servo control

- Recalibrate the glass cutting table

- Inspect and replace grinding wheels regularly

2.4 Contamination on Glass Surface (Very Common)

Symptoms

- Sealant cannot adhere

- Sealant peeling after days or weeks

Causes

- Oil stains from cutting fluid

- Dust on glass

- Dirty rollers in washing machine

Solutions

- Ensure washing machine brushes are clean

- Maintain water conductivity < 20 μS/cm

- Use oil-free air knives

- Keep glass away from dusty areas before sealing

2.5 Manual Sealing Errors

Symptoms

- Sealant line inconsistent

- Corners not filled

- Speed varies → sealant thickness uneven

Causes

- Operator skill issues

- Poor control of pressure & speed

- Fatigue during long production hours

Solutions

- Train operators regularly

- Set standard guideline: sealing speed 3–4 m/min

- Use robot sealing system to eliminate human error

2.6 Poor-Quality or Expired Sealant

Symptoms

- Sealant looks watery or separated

- No bonding strength

Causes

- Expired material

- Low-cost formulations with unstable components

Solutions

- Use certified brands (HB Fuller, Dow Corning, Kommerling, etc.)

- Rotate inventory FIFO (First In, First Out)

- Check batch numbers before use

2.7 Speed Mismatch Between Line Processes

Symptoms

- Sealant spills at corners

- Sealant squeezed due to timing mismatch

Causes

- Pressing section too fast or too slow

- Sealant not cured enough before pressing

- Manual transfer too slow

Solutions

- Match pressing machine speed to sealing speed

- Ensure sealant has initial shape before pressing

- Keep product flow consistent to avoid delays

3. Equipment-Related Reasons for Sealant Leakage

3.1 Butyl Extruder Problems

- Temperature sensors inaccurate

- Nozzle worn out

- Pressure fluctuations

Fix:

- Replace heating elements annually

- Clean nozzle every shift

- Calibrate PID temperature control

3.2 Two-Component Sealant Machine Problems

- A/B ratio wrong

- Mixer clogged

- Pump pressure unstable

Fix:

- Calibrate ratio daily

- Replace static mixing tube often

- Check pump seals

3.3 Manual Sealing vs Robot Sealing

Manual sealing:

- Uneven

- Depends on experience

- Higher scrap rate

- More leakage

Robot sealing:

- Perfect edge consistency

- Accurate corner filling

- Stable pressure

- Almost zero leakage rate

→ If your factory has repeated leakage issues, upgrading to an IG sealing robot is the most effective long-term solution.

4. Best Practices to Avoid IG Sealant Leakage Permanently

✔ Maintain stable temperature & humidity

Environment: 18–25°C, humidity < 60%.

✔ Use automatic equipment for critical steps

- Spacer bending

- Sealing

- Pressing

✔ Build a quality-control checklist

Before pressing, check:

- Spacer alignment

- Sealant thickness

- Corner filling

- Glass size

- Surface cleanliness

✔ Replace consumables on schedule

- Mixer tubes

- Brushes

- Filters

- Cutting wheels

✔ Keep detailed production logs

Track issues → helps find root causes faster.

Conclusion

Sealant leakage in IG units is avoidable once the root causes—equipment, materials, or processes—are identified. By implementing standardized procedures, upgrading key equipment, and maintaining consistent quality control, manufacturers can drastically reduce sealing defects and improve production efficiency.