How to Avoid Buying Low-Quality Glass Equipment (Complete 2025 Guide)

Choosing the right glass processing equipment is one of the most important decisions for any glass factory, IG unit manufacturer or glass deep-processing plant. Whether you are looking for glass cutting machines, insulating glass production lines, glass washing machines, or glass sealing robots, the quality of the machinery directly affects production stability, yield rate, delivery time, and long-term profitability.However, the global market is full of suppliers with drastically different standards—some reliable, some risky, and some selling low-quality machines that will cost you far more than you expect.

This guide explains how to identify high-quality glass equipment, avoid costly mistakes, and ensure you purchase machinery that lasts 10–15+ years.

1. Check Whether the Manufacturer Is the Real Producer (Not a Trading Company)

One of the most common industry pitfalls is buying from a “manufacturer” that actually outsources production.

Real manufacturers have:

- A physical factory with CNC centers, welding lines, assembly lines

- In-house engineers

- Quality inspection systems

- Long-term spare parts supply capability

Before buying, always request:

- Factory photos or live video calls

- Machine assembly details

- On-site testing videos

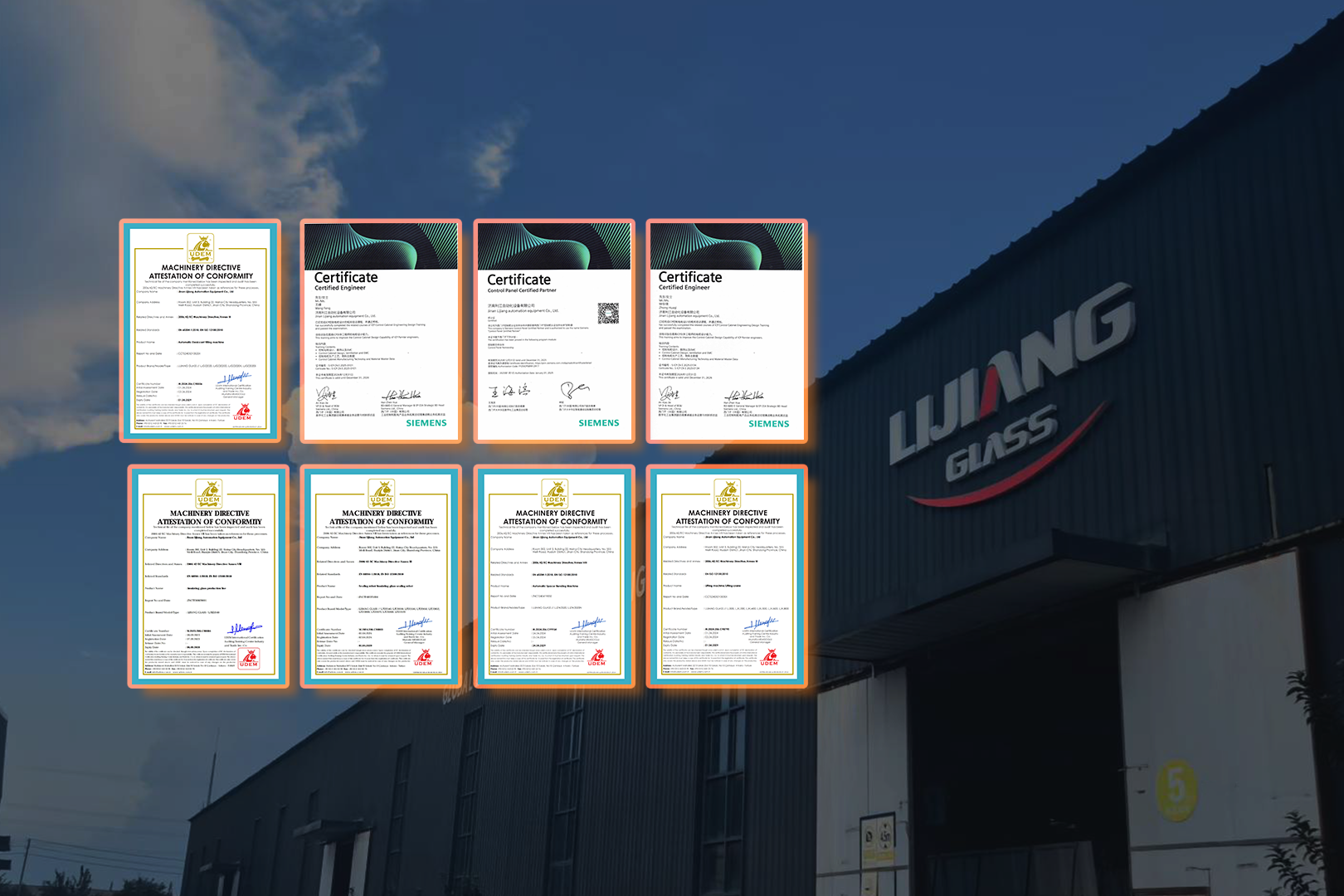

- Company registration & certifications

Suggested internal link:

- Glass Cutting Machine: https://www.ljglassmachinery.com/glass-cutting-machine

- Insulating Glass Production Line: https://www.ljglassmachinery.com/insulating-glass-production-line

2. Inspect the Core Components — These Determine Real Quality

Low-cost machines often cut corners using cheaper parts.

Key components you should check include:

Glass Cutting Machines

- Servo motors: Use Yaskawa / Schneider / Delta

- Linear guides: HIWIN / THK

- Cutting head: High-precision floating system

- Table structure: Anti-deformation steel frame

Insulating Glass Line

- Washing section: Stainless steel SUS304

- Air knives: Aluminum alloy, high-pressure

- Conveying rollers: High-quality rubber

- PLC brand: Siemens / Panasonic

Glass Sealing Robots

- Sealing pump brand

- Glue control accuracy

- Automatic height detection

- Repeatable sealing accuracy

High-quality components guarantee long service life and stable production.

Low-quality machines may work fine initially but break down frequently after 6–12 months.Suggested internal link:

- Glass Sealing Robot: https://www.ljglassmachinery.com/glass-sealing-robot

3. Ask for Real Customer Cases and Factory References

Reliable manufacturers can easily provide:

- Real user videos from glass factories

- Contact information of customers (if allowed)

- Feedback from IG line operators or maintenance teams

- Installations in the Middle East, Europe, South America, Asia, etc.

If a supplier cannot show any real factory cases, that's a red flag.

4. Evaluate the Machine Performance, Not Just the Price

A low price is tempting, but low efficiency and high failure rate will cost you much more.

Compare:

- Speed

- Precision

- Energy consumption

- Worker requirement

- Maintenance frequency

- Operating stability

Sometimes a “cheap machine” becomes the most expensive option after:

- Frequent shutdowns

- High repair cost

- Glue waste

- Glass breakage

- Lost orders due to delays

Always choose cost-performance, not lowest price.

5. Check Spare Parts Availability and Service Capability

A good supplier must provide:

- Spare parts lists

- At least 10 years parts availability

- Fast international delivery

- Remote service & training

- On-site installation support

Poor after-sales service = long downtime = big financial loss.

A serious manufacturer has engineers with 10–20 years experience and a complete service system.

6. Investigate the Software & Control System

Today’s glass equipment relies heavily on automation.

High-quality suppliers use:

- Siemens PLC

- Schneider electrical components

- Professional glass cutting optimization software

- User-friendly HMI touch screen

- Multi-language interface

Low-quality equipment may use unstable control boards that often fail and are difficult to repair.

7. Look for Safety Systems and Production Standards

Good machines integrate safety systems such as:

- Emergency stop buttons

- Overload protection

- Water-proof electrical cabinet

- Enclosed washing section

- Safety grating or light curtain (on IG lines)

These not only protect workers but also ensure long-term machine stability.

8. Compare the Structure and Craftsmanship

Ask for detailed machine photos and check:

- Steel frame thickness

- Welding quality

- Paint finish (powder coating preferred)

- Cable management

- Assembly precision

High-quality machinery always has clean structures and consistent finishing.

9. Read the Warranty Terms Carefully

You should receive:

- Minimum 1-year full warranty

- Free training

- Lifetime technical support

- Clear maintenance guidance

- Free software updates

Avoid suppliers who refuse to provide a written warranty.

10. Visit the Factory (If Possible)

This is the most reliable way to avoid buying low-quality machines.

During a visit, observe:

- Production line scale

- Stock machines

- Employee professionalism

- Quality inspection procedures

- Assembly details

If you cannot visit, ask for a real-time video call to check the machines and production workshop.

Conclusion: Choosing High-Quality Glass Equipment Protects Your Investment

A wrong purchase can cost you years of repair, downtime, and production losses.

But a well-selected machine increases:

- Productivity

- Output quality

- Customer satisfaction

- Long-term profits

- Factory competitiveness

Use the above checklist to evaluate any equipment supplier before purchasing.If you need glass cutting machines, insulating glass lines, glass washing machines, or sealing robots, Lijiang Glass Machinery (LJ Glass Machinery) provides reliable solutions built for long-term industrial production.

- Glass Cutting Machine: https://www.ljglassmachinery.com/glass-cutting-machine

- Insulating Glass Production Line: https://www.ljglassmachinery.com/insulating-glass-production-line

- Glass Sealing Robot: https://www.ljglassmachinery.com/glass-sealing-robot