Automatic Glass Cutting Machine vs Manual Cutting: Which One Truly Improves Your Production Efficiency?

In today’s competitive glass processing industry, factories are under increasing pressure to deliver higher accuracy, greater efficiency, and more stable output. Whether producing architectural glass, automotive glass, household glass, or industrial glass components, the cutting process directly influences downstream performance and the overall cost of production.For many factories, the biggest question during the upgrading process is:

Should we choose an Automatic Glass Cutting Machine or continue with Manual Cutting?To help you make the right decision, this article provides a comprehensive comparison of both cutting methods, covering precision, efficiency, cost, labor requirements, production risks, long-term value, and typical application scenarios.

1. Cutting Precision: Stability vs Experience

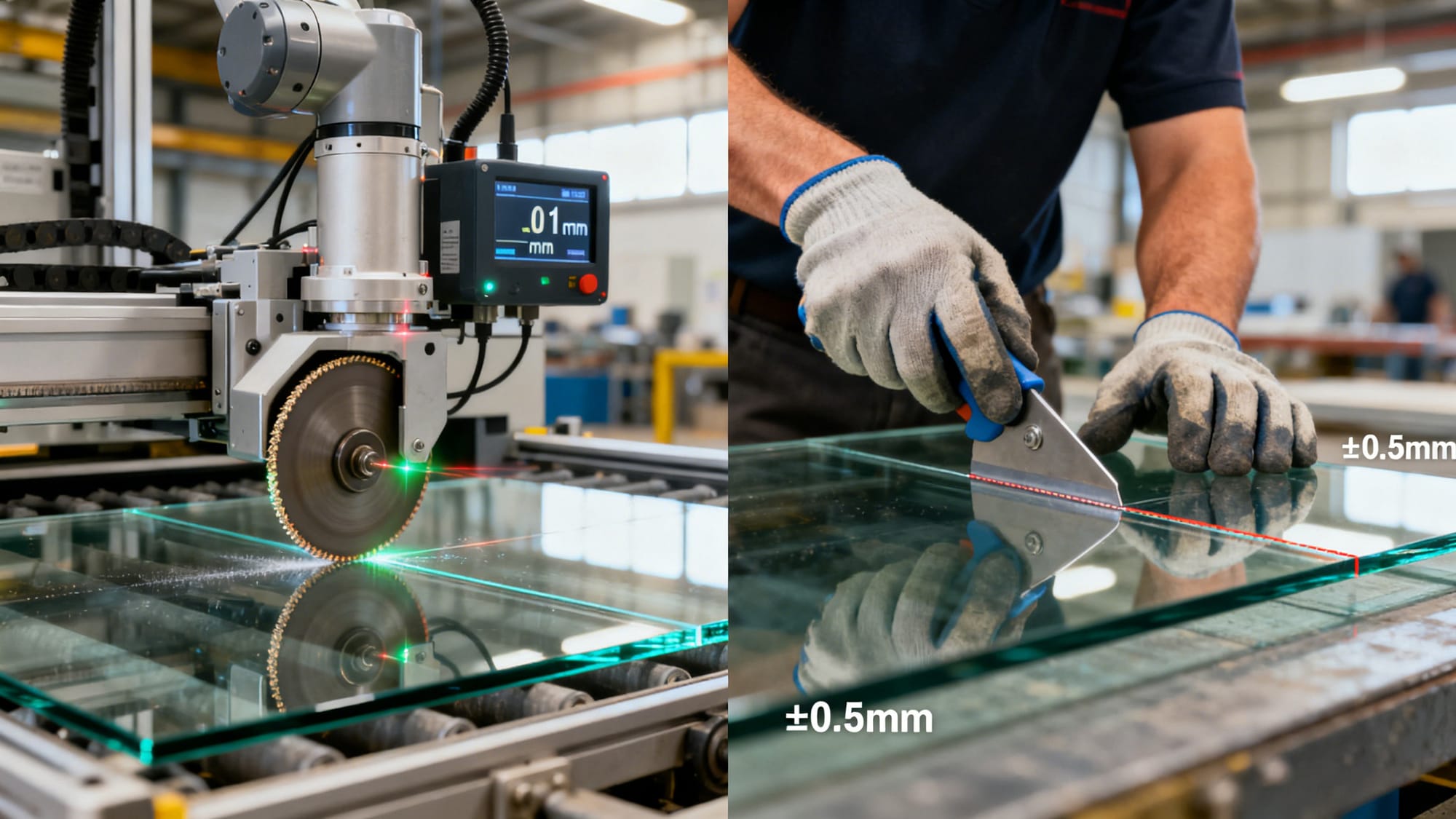

Automatic Glass Cutting Machine

Modern automatic glass cutting machines use CNC control systems, servo motors, and high-precision positioning technology. They perform scoring and cutting with a repeatable accuracy that manual workers cannot consistently achieve.Key advantages include:

- Accuracy typically within ±0.2–0.5 mm.

- Stable performance during continuous production.

- Automatic pressure control for uniform scoring depth.

- Efficient optimization layout to reduce edge errors.

For industries requiring strict tolerance—such as coated glass, laminated glass, household appliances, and high-end construction—the difference in accuracy is especially significant.

Manual Cutting

Manual cutting depends heavily on the operator’s skills and experience. Even skilled workers struggle to maintain consistent precision during long shifts or complex shapes.Limitations include:

- Difficulty maintaining straight lines on large plates.

- Uneven pressure resulting in breakage or deviations.

- High scrap rate for coated or Low-E glass.

- Almost impossible to achieve large batch consistency.

Conclusion:

If your factory requires high-precision and stable output, a CNC Automatic Glass Cutting Machine is far superior.

2. Production Efficiency: Speed, Output, and Continuity

Automatic Cutting Machine

Automation provides a significant leap in productivity. Machines can perform scoring, breaking, labeling, and even loading/unloading automatically.Typical advantages:

- Cutting speed can reach 120–180 m/min depending on the model.

- Fully automatic layout saves time and improves scheduling efficiency.

- Continuous, stable operation — ideal for high daily output.

- Suitable for 24/7 production in industrial lines.

For factories processing dozens of glass sheets per hour, an automatic system ensures predictable output and avoids bottlenecks.

Manual Cutting

Manual cutting is slow and requires rest intervals. Each sheet must be moved, aligned, measured, and scored by hand.Challenges:

- Slower processing speed, especially with large panels.

- High dependency on manpower availability.

- Frequent inconsistencies delay downstream operations.

- Not suitable for large-scale production environments.

Conclusion:

For medium to large factories, only automatic machines can meet modern productivity requirements.

3. Labor Costs and Workforce Requirements

Automatic Cutting Machine

Automation significantly reduces the need for skilled operators. One or two staff members can monitor the entire operation.Benefits:

- Lower labor costs.

- Less reliance on training or specialized technicians.

- Reduced human error and fatigue.

- Improved safety with enclosed cutting zones.

Manual Cutting

Manual cutting requires multiple workers:

- At least one skilled cutter.

- One or two helpers for positioning and moving glass.

- Higher staff turnover due to physical load and safety concerns.

Long-term issues:

- Difficulty hiring experienced workers.

- Frequent retraining.

- Risks of workplace injuries.

Conclusion:

With global labor costs rising, automatic machines provide long-term savings and reduce dependence on skilled manpower.

4. Waste Rate, Material Utilization, and Loss Control

Automatic Glass Cutting Machine

- Intelligent optimization software increases material utilization.

- Cleaner break lines reduce scrap.

- Uniform scoring prevents micro-cracks and defects.

- Better for expensive coated or Low-E glass, which has strict quality requirements.

Most factories report 3–8% improvement in yield after adopting automation.

Manual Cutting

- Material loss is high due to human error.

- Uneven pressure often causes crack propagation.

- Difficult to optimize nesting manually.

- Long-term scrap cost is significantly higher.

Conclusion:

Automation is more cost-effective, especially for high-value glass.

5. Safety: Operational and Environmental Protection

Automatic Cutting

- Enclosed structures minimize operator exposure.

- Automatic glass loading reduces risk of cuts and handling injuries.

- Dust control systems improve workshop safety.

- Suitable for strict safety and environmental regulations.

Manual Cutting

- High risk of glass cuts and injuries.

- Heavy lifting leads to musculoskeletal strain.

- Difficult to comply with advanced safety standards.

Conclusion:

Automatic systems create a safer and more professional production environment.

6. Investment and Return: Long-Term Value vs Short-Term Savings

Automatic Cutting Machine

While the upfront investment is higher, the return on investment is rapid because of:

- Lower labor costs.

- Less scrap.

- Faster delivery times.

- Higher product consistency.

- Increased competitiveness.

Most factories see ROI within 6–18 months.

Manual Cutting

Though investment is small, long-term losses include:

- High labor expenses.

- High waste rate.

- Lower production capacity.

- Difficulty handling large orders.

Conclusion:

Automatic cutting is not an expense — it is an upgrade that strengthens the entire supply chain.

7. Application Scenarios: Which Method Fits Your Factory?

Choose Automatic Glass Cutting Machine if you are:

- A medium or large glass processing factory.

- Producing high-precision or coated Low-E glass.

- Running continuous production lines.

- Targeting international markets with strict quality requirements.

- Planning to automate your IGU line or tempered glass line.

Choose Manual Cutting if you are:

- A small workshop with low daily output.

- Only doing simple on-site cutting.

- Handling irregular or one-time custom shapes.

- Operating in a low-volume, low-budget environment.

Final Conclusion

In nearly every aspect—precision, speed, safety, waste reduction, labor savings, and long-term profitability—the Automatic Glass Cutting Machine outperforms manual cutting. For factories aiming to remain competitive in the fast-growing global market, upgrading to automation is not just a choice but a necessity.LIJIANG Glass offers complete solutions including CNC glass cutting machines, laminated glass cutting lines, automatic loading systems, and fully integrated production lines to help factories transition smoothly into intelligent manufacturing.