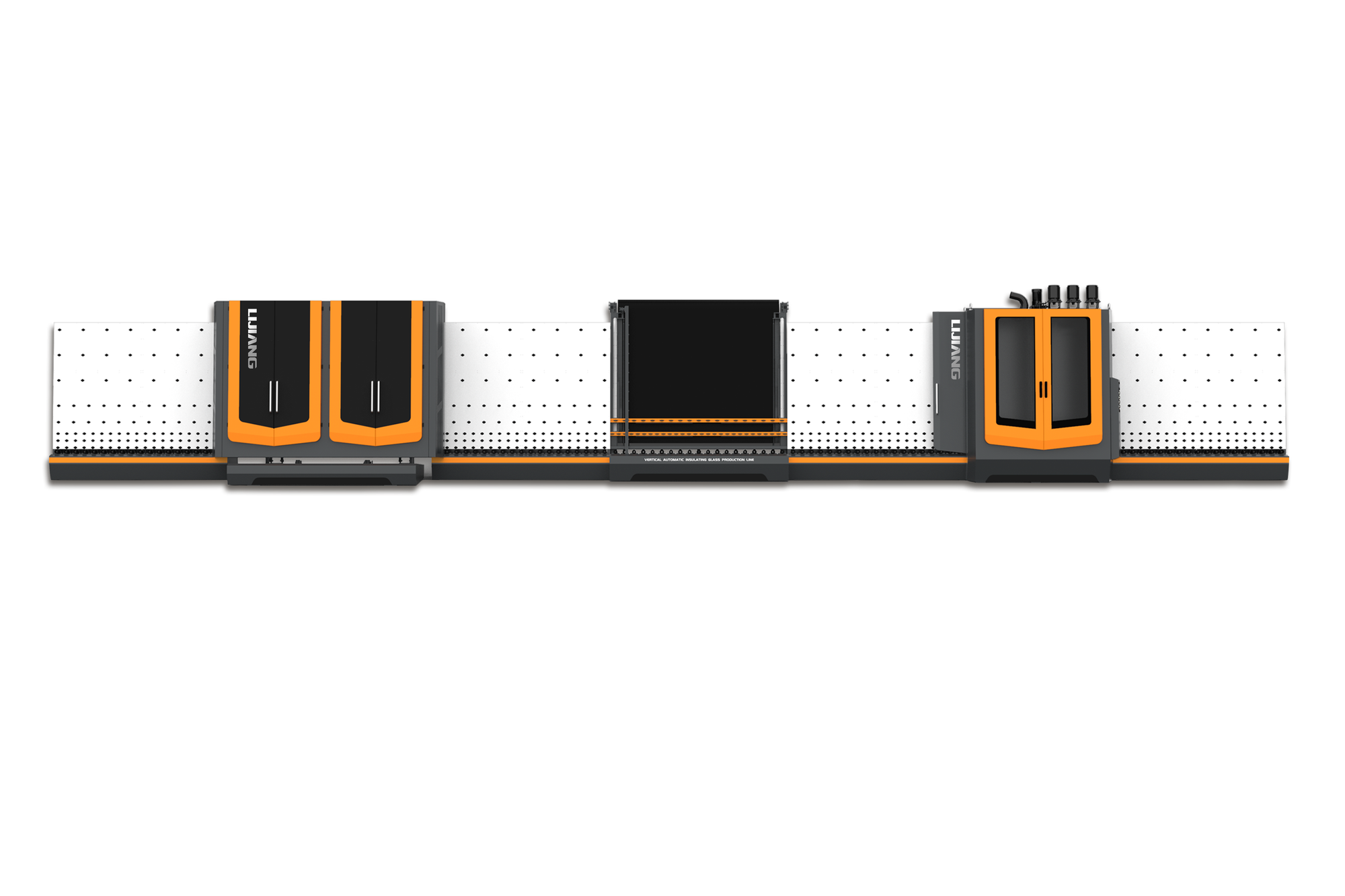

LJBZ2535 Vertical Automatic Insulating Glass 2.5m Double Channel Inflated Production Line

LIJIANG Glass LJBZ2535 Vertical Automatic Insulating Glass 2.5m Double Channel Inflated Production Line adopts the automatic gas filling, which could set the gas value and display the processing of filling online with high gas concentration, and also adopts the option function, which could automatically accurate positioning for 3 or 4 side step insulating glass. The equipment will be your first pick applicable to produce triple insulating glass and shaped insulating glass.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LJBZ2535 Automatic Vertical Insulating Glass Production Line

Details Display

The whole insulating glass production line usually includes 7 parts:

(from right to left)

- The Loading section (with Low-E glass checking)

- The washing and drying section (can wash Low-E glass)

- The conveyor section

- The checking and assembly section

- The conveyor measures, and the sensor section

- The press part with gas filling

- The unloading section.

LJBZ2025 Automatic Vertical Insulating Glass Production Line

LJBZ2025 Automatic Vertical Insulating Glass Production Line

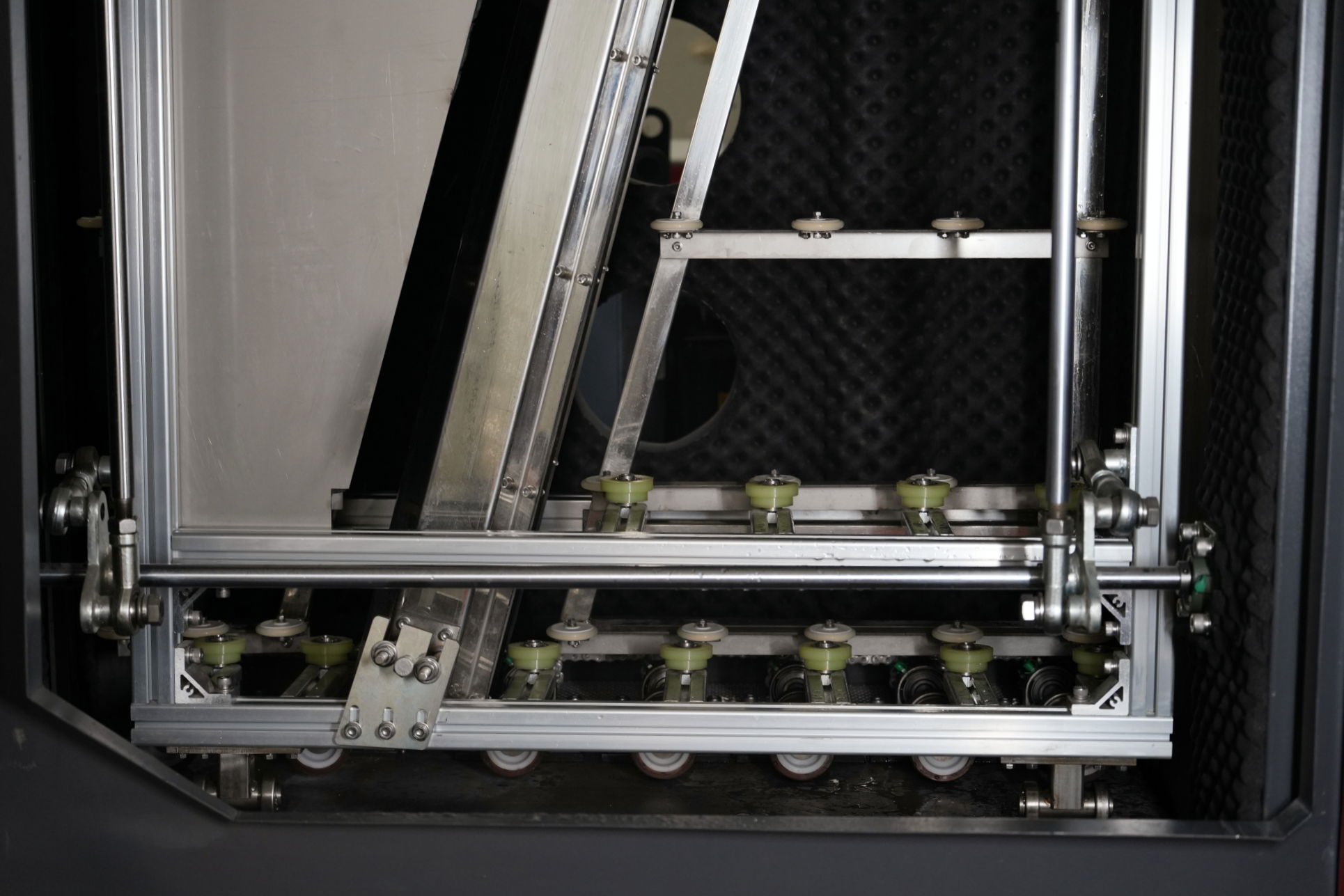

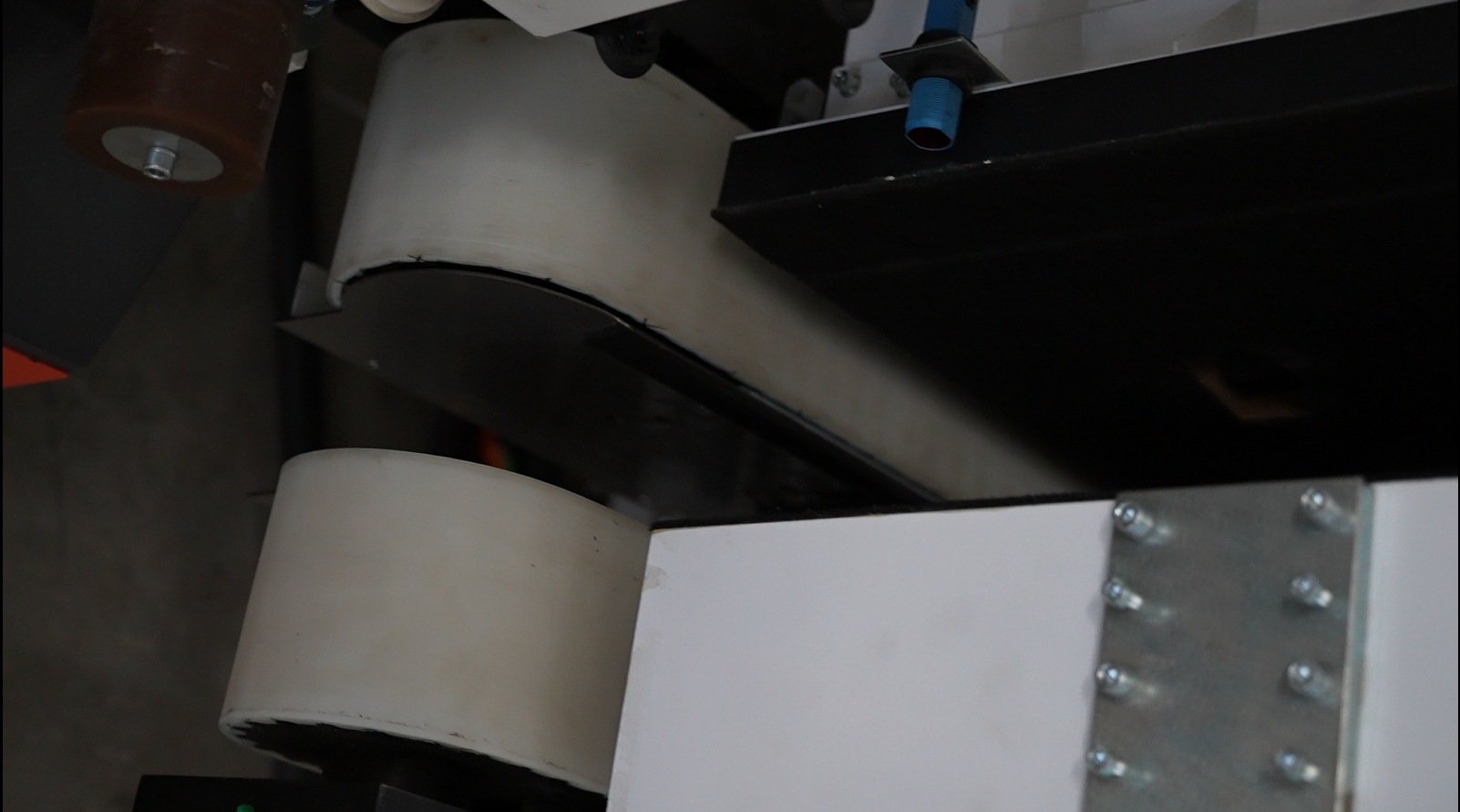

The second part: the washing and drying section.

Figure 1 The three pairs of soft brushes in this glass washing section

Figure 1 The three pairs of soft brushes in this glass washing section

Figure 2 The transfer wheel from this glass washing section

The axle and bearing of brushes are made of all stainless steel, which can keep the machine washing stable and usable for a long time. The whole drying machine uses a sound-insulation design, which could reduce noise pollution effectively. Figure 3 Adopt all stainless steel of the whole glass washing section

Figure 3 Adopt all stainless steel of the whole glass washing section

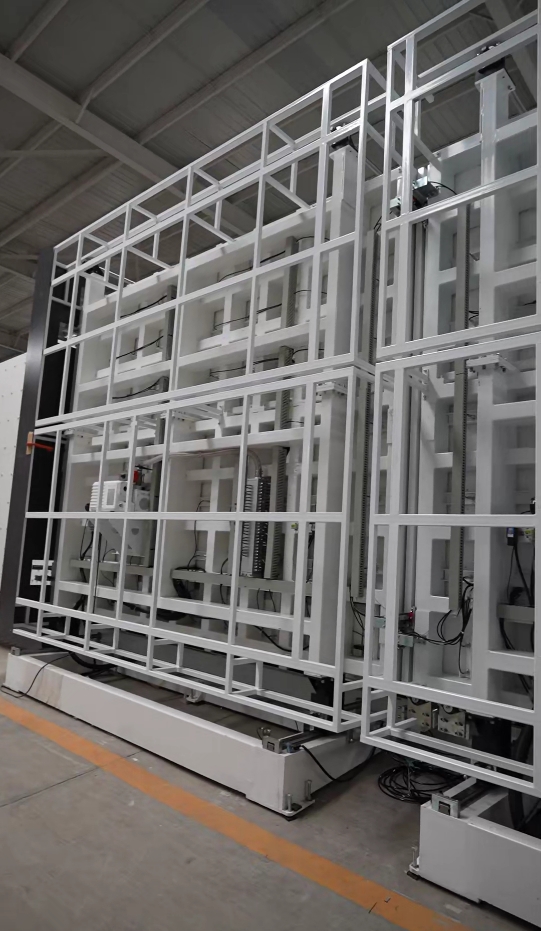

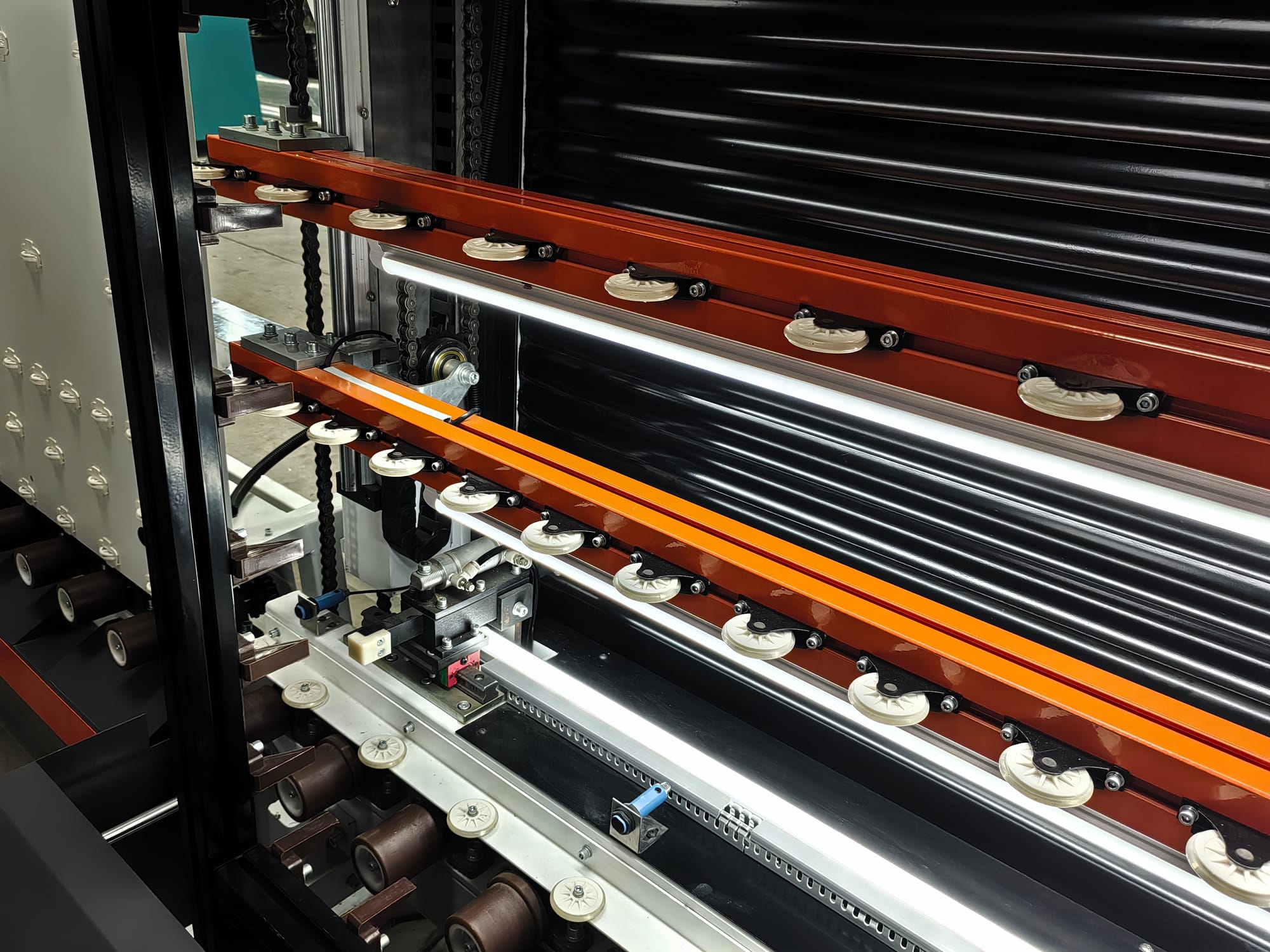

The 6th part: the pressing and gas filling section.

Figure 4 More reinforcement of structural beams on argon-gas filling section

Figure 4 More reinforcement of structural beams on argon-gas filling section

Figure 5 The synchronous belt lifting glass of argon-gas filling section

Figure 5 The synchronous belt lifting glass of argon-gas filling section Figure 6 The matrix-type plate pressing section, freely adjustable

Figure 6 The matrix-type plate pressing section, freely adjustable

Figure 7 The inflatable and plate pressure effect

Figure 7 The inflatable and plate pressure effect

Benefits & Advantages

- Adopt the Siemens control system, keep a stable performance PLC control system, and a touch screen interface

- Automatically adjust the depth of sealant with a digital display

- Using a servo to control the system, the modular function, and the superposition function

- Applicable to produce stepped IG, triple IG, and shaped IG

- Two pieces of IGU can be made and filled with argon gas at the same time (Optional)

- Min & Max glass sizes can be optional European design concept, simple and smart operation; the world-famous brand of core components, ensure stable operation and long service life; It is designed for processing high quality glass, such as reflective glass, Low-E glass, reflective glass and tempered glass; Large glass processing size, various models and customization available; Large production capacity, output 1,000pcs in working days; It can be used for two-layer, three-layer, pad and glass with irregular shape; Automatic air gas filling during the glass paper assembly process.

The coating inspection

Figure 8 The automatic Low-E glass coating inspection

Figure 8 The automatic Low-E glass coating inspection

The pressing case uses the high-precision servo motor.

Figure 9 The Siemens high-precision servo motor

Figure 9 The Siemens high-precision servo motor

Air floating technology - Optional

Figure 10 The air-floating technology

Figure 10 The air-floating technology

The first one to use adjustable points to ensure that the platen will never deform.

Figure 11 The intelligent control panel

Figure 11 The intelligent control panel

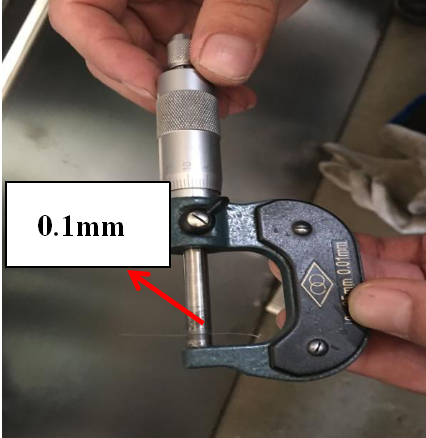

It uses six soft (Low-E Glass) brushes with a 0.1mm diameter only.

The whole washing machine uses 304 stainless steel materials

Main Technical Parameter

Item. | Spec. |

Max. glass size: | 2500*3500mm |

Min .glass size | 450*280mm |

Glass thickness | 3-15mmp |

Insulating glass thickness | 60mm |

Glass washing speed | 2-10m/min |

Glass conveyor speed | 45m/min |

Washing brushes | 3 pairs |

Water supply | Water consumption:0.5t/h conductivity:≤50μs/cm |

Air supply | Flow: 0.8m³/min |

Air pressure | ≥0.8MPa |

Dimension | 23850*3500*3700mm |

Name | Brand |

Servo motor | Germany Simens |

Servo driver | Germany Simens |

Servo motor | Germany Simens |

Servo motor | Germany Simens |

PLC | Germany Simens |

Low-voltage component | Germany Simens |

Frequency converter | Germany Simens |

Switching power supply | Taiwan MW |

Optoelectronic switch | Korea Autonics |

Pneumatic component | Taiwan Airtac |

Pneumatic component | Taiwan Airtac |

Touch screen | Taiwan Wenview |

Travel switch | Taiwan (TEND) |

Relay | Japan Omron |

Button and indicator light | French Schneider |

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine; meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via phone or email.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness of the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine has any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problems.

3.2. Free after-sales service life for the machine. Please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, Skype, and email.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before leaving the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set of glass deep-processing machines. We could send the glass deep-processing machine to your country's port directly. Please tell us your port name. There will be the best shipping freight and machine prices for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special-ordered machines, it would be 15 to 30 days, depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves as much space as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL, which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling out the form with your name, email, detailed address, product, and requirements. We will shortly contact you with the full information, including the most suitable delivery method (fast, secure, discreet) and freight.

How is the drying section of the insulating glass production line driven? What are the advantages?

What method is used for Low-E Glass coating detection in the feeding section?

How many pieces of glass can be parked at the same time in the third section?

How to adjust the glue depth for the upper frame section of the aluminum frame?

Section 5 needs to measure the thickness of glass and aluminum frame, what is its main function?

What is the structure of the inflatable beam and the conveyor belt in the pressure section of the inflatable plate?

The inflatable beam and the conveyor belt in the pressure section of the LIJIANG Glass inflatable plate adopt an integrated synchronous belt structure. This method has better sealing performance, and the insulating glass is not easy to leak during the process of inflating and assembling; other manufacturers use a separate structure for the transmission wheel and the inflating beam. In this way, the bottom is prone to air leakage during the inflating and closing process.