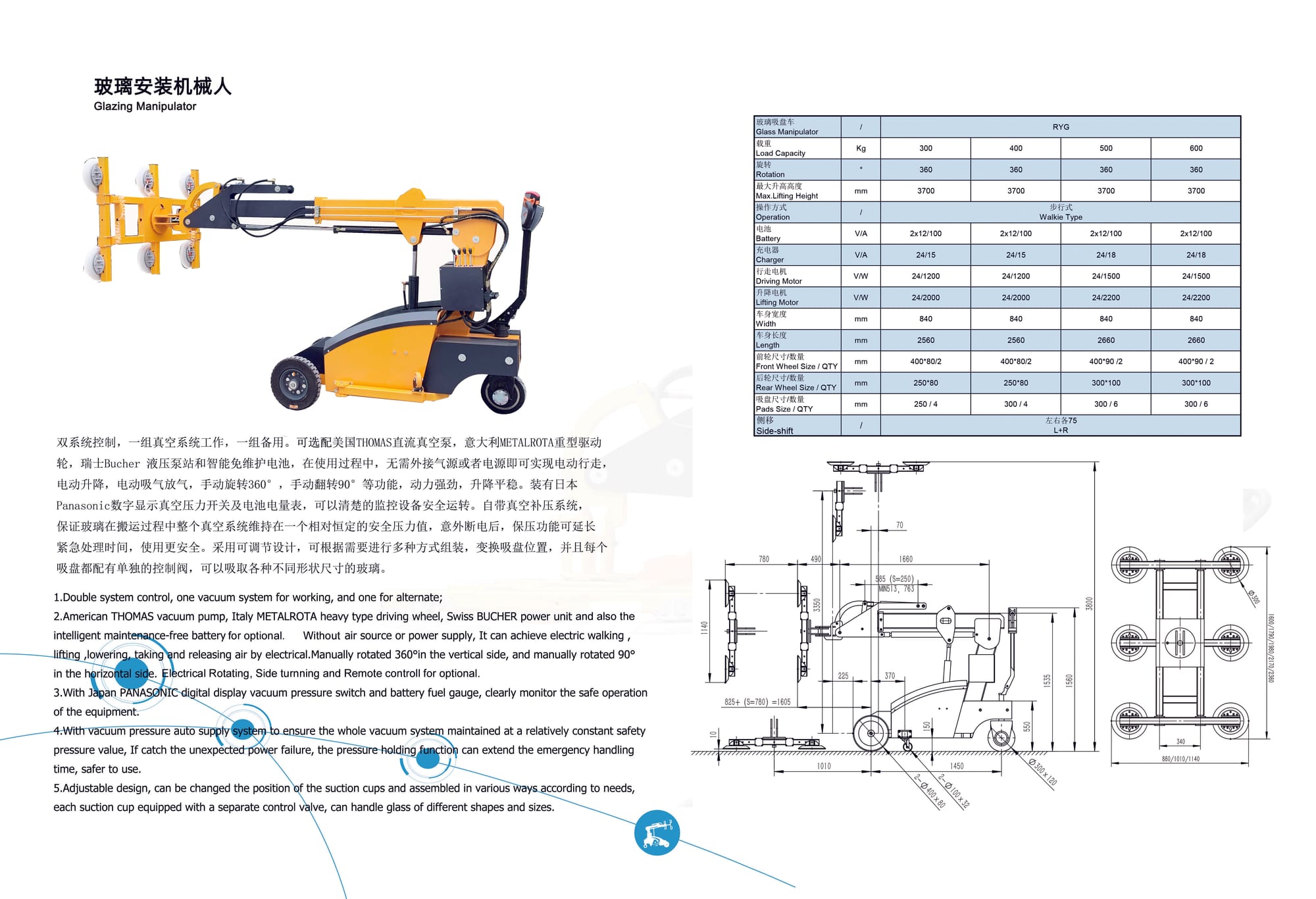

Glazing Manipulator

Dual system control, one set of vacuum systems is working, and the other set is standby. Optional American THOMAS DC vacuum pump, Italian METALROTA heavy-duty drive wheel, Swiss Bucher hydraulic pump station and intelligent maintenance-free battery are available. During use, no external air source or power source is required to realize electric walking, electric lifting, electric air suction and deflation, manual rotation of 360°, manual flip 90° and other functions. It has strong power and smooth lifting and lowering. Equipped with a Japanese Panasonic digital display vacuum pressure switch and battery meter, the safe operation of the equipment can be clearly monitored. It comes with a vacuum pressure replenishment system to ensure that the entire vacuum system maintains a relatively constant safety pressure value during the transportation of the glass. After an unexpected power outage, the pressure maintenance function can extend the emergency processing time and is safer to use. It adopts an adjustable design and can be assembled in a variety of ways according to needs, and the position of the suction cup can be changed. Each suction cup is equipped with a separate control valve, which can absorb glass of various shapes and sizes.

- Vendor: LIJIANG Glass

- Shipping:

Learn More