Automatic Insulating Glass Production Line for Factory Upgrade (LJBZ3060)

This automatic insulating glass production line is designed for glass factories producing double glazing and energy-saving windows. It helps manufacturers improve production efficiency, reduce labor costs, and ensure stable sealing quality for Low-E and insulating glass units. With easy operation and reliable performance, it is suitable for both factory upgrade and new production line setup.

- Shipping:

Learn More

TECHNICAL DESCRIPTION

Automatic Vertical Insulating Glass Processing Line LJBZ3060

Main components:

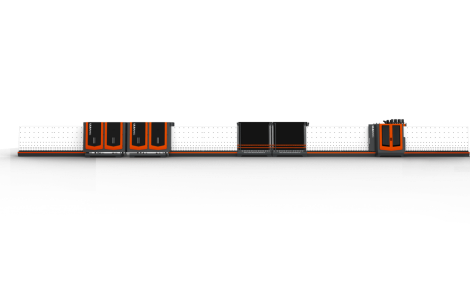

The line has 7 sections:

01 Loading section;

02 Washing and drying section;

03 Discharge section;

04 Inspection and spacer frame installation section;

05 Transfer section;

06 Pressing (& argon gas filling) section;

07 Unloading section.

PERFORMANCE:

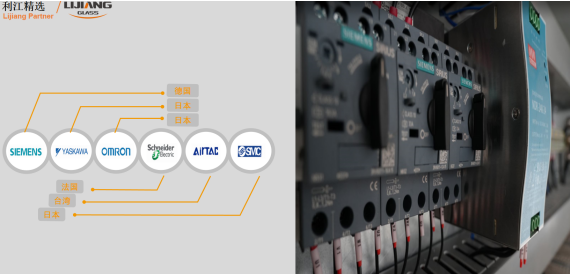

Germany Siemens PLC control system, touch screen interface

Automatic identification of coated glass and Low-E glass

3 pairs of soft brushes can wash online and offline Low-E glass

The washing machine adopts SS material and waterproof material

Air heating system

Air Fan automatically starts and stop device

Noise reduction system

Online display of washing speed

Intelligent intermittent work, saving energy

Adjustable screws inside the pressing panel keep the pressing panel straight

Automatic gas filling online(Option)

Connection mode of the aviation plug, easy for installation

01 Loading section

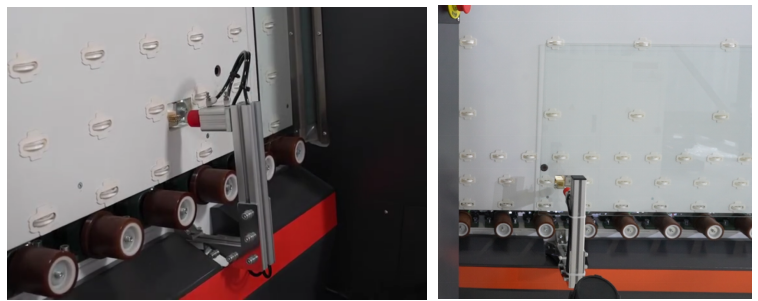

Low-e glass film detection

Adopt low-E glass point-contact type detection, when the low-E glass film surface is put reversed, it will automatically alarm, in order to not scratch the low-E film, with a high recognition rate.

Effectively solve the problem of high-transparent low-e glass film recognition.

Glass conveyor

The conveyor bearing blocks are fixed on an 8mm milled flat steel plate. The height of the bearing blocks can be adjusted to convey small pieces of glass smoothly. Increasing the load-bearing capacity of the glass.

02 Washing and drying machine

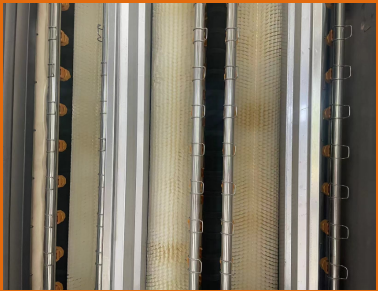

Washing section

1.304 stainless steel washing box, 3 pairs of soft washing brushes (for low-e glass)

1.304 stainless steel washing box, 3 pairs of soft washing brushes (for low-e glass)

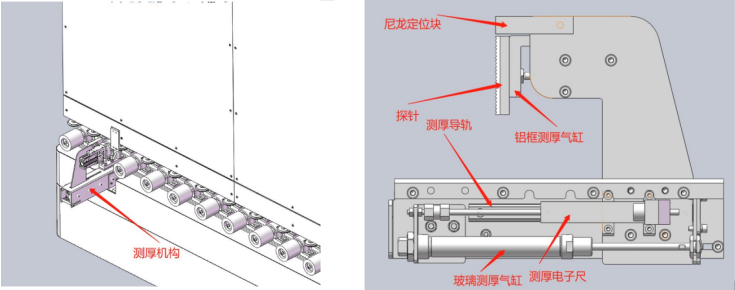

2. Automatic glass thickness measurement, when the glass size is over 8mm

3. Three independent washing sections, washing three times with separate water

4. Water tank automatic temperature control, water replenishing system

5. With the washing speed display, accurately displaythe washing speed (8-10m)

6. Using thrust bearings inside the washing machine

7. Silencing cotton reduces noise

Drying section

The opening and closing distance of the air knife can be automatically adjusted according to different glass thicknesses.

The adjusted structure adopts a mechanical structure with high stability.

It can continuously wash different thickness glasses automatically, which is good for making laminated insulating glass.

03 Discharge section

Rollers conveyor

Air -floating conveyor (optional function)

Air -floating conveyor (optional function)

04 Inspection and spacer frame installation section

Adopting an advanced screw adjustment structure design, the aluminum frame has high positioning accuracy.

The aluminum alloy guide rail is light and flat, automatically adjusted up and down according to the height of the glass.

Adopts a hollow design, and the maintenance door is designed to clean the stubborn stains on the back of the glass (Automatic lifting check backplane is an option).

05 Discharge section (Thickness measuring device for gas filling)

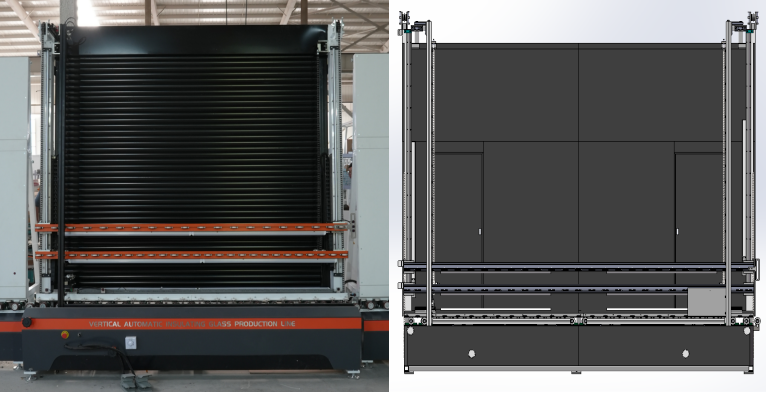

06 Pressing and argon gas filling section

Pressing machine

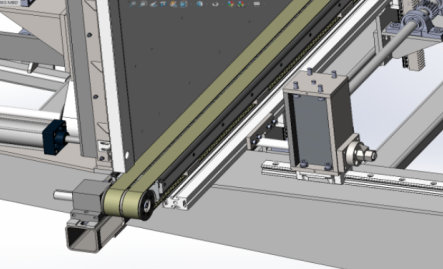

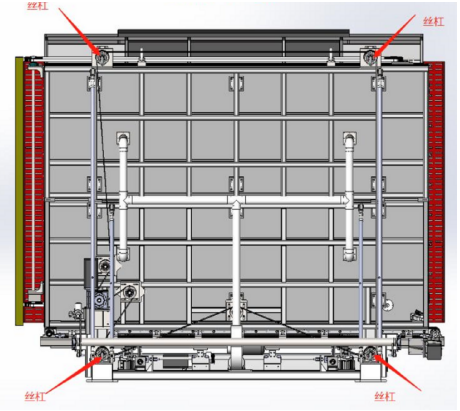

14. Using a servo motor synchronous belt to ensure ultra-high pressing precision and fast pressing speed. Can make large and thick glass.

15. Lead screw pressing (servo motor synchronous belt)

16. Pressing board with an adjustable structure to guarantee long-lasting service life

17. Automatically pressing glass according to different thick glass and the width of the aluminum spacer.

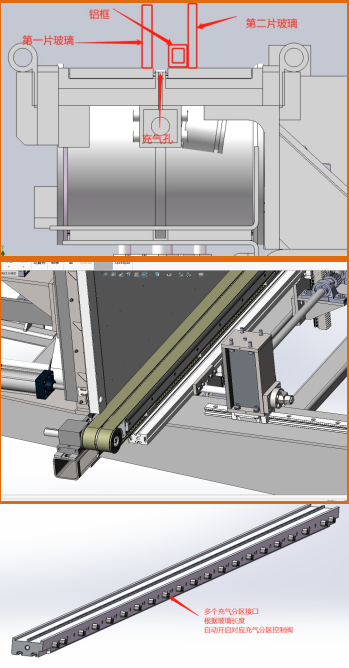

Gas filling online (Option)

18. Gas filling way: Gas filling holes are automatically positioned according to different glass sizes, ensuring the argon gas hole is always between the middle of the first glass and the spacer frame. Fora wide spacer of the residential window and doors, and triple glass, our advantages are obvious.

18. Gas filling way: Gas filling holes are automatically positioned according to different glass sizes, ensuring the argon gas hole is always between the middle of the first glass and the spacer frame. Fora wide spacer of the residential window and doors, and triple glass, our advantages are obvious.

There is a partition control of the argon gas filling beam. When using different sizes of glass, it will automatically detect the length of the glass and turn on the corresponding length of the argon gas hole, saving gas.

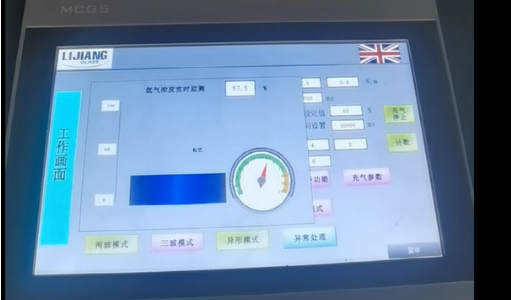

19. Display Function: The touch screen will display the whole argon gas filling process, and you will know very clearly how much argon gas is already filled inside

20. The filling concentration can be set according to the customer’s requirements. There are three modes: time mode, automatic calculation of volume mode, and automatic detection of argon content mode.

21. Filling will stop automatically when it is up to your requirements. Gas concentrations are more than 90%.

22. Argon gas filling time: 3-5 seconds (1*1m) insulating glass thickness: 12-60mm;12-80mm&12-100mm(Custom Optional)

23. Direct display of the inflation process /up than 90% /Air-fill the full automatic stop.

It is beneficial to add new functions (TPS, 4 SG, super spacer bar, etc.)

24. German Siemens control system, stable performance, strong scalability.

07 Unloading section (tilting table is optional)

Technical data

Max glass size | 3000mm*6000mm |

Min. glass size | 280mm*450mm |

Glass thickness | 3-30mm are option |

Insulating glass thickness | 80mm |

Glass washing speed | 2-10m/min |

Glass conveyor speed | 45m/min |

Washing brushes | 3 pairs of soft brushes with 0.12mm hair |

Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

Air supply | Flow: 0.8m/min |

Air pressure | ≥0.8MPa |

Electrical parameters

NAME | ORIGIN | BRAND |

Servo motor | Germany | SIEMENS |

PLC | Germany | SIEMENS |

Low-voltage electrical appliance | Germany | SIEMENS |

Frequency converter | Germany | SIEMENS/Tianchuan |

Transfer motor | Taiwan | LINHAI |

Brush motor | Taiwan | LINHAI |

Water pump | China | LINGXIAO |

Guide | Taiwan | HIWIN |

Pneumatic Components | Taiwan | AIRTAC |

Electric gauge | China | MIRAN |

Photoelectric switch | Korea | Autonics |

Micro Switch | Taiwan | TEND |

Button and indicator light | France | SCHNEIDER |

Touch screen | Taiwan | WEINVIEW |

Intermediate relay | Japan | OMRON |